Preparation method of composite adhesive used for solar energy backboard

A technology for composite adhesives and solar backsheets, which is applied in the field of preparation of composite adhesives for solar backsheets, can solve the problems of difficult composites and high requirements for adhesives, and achieve improved adhesion and good UV resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

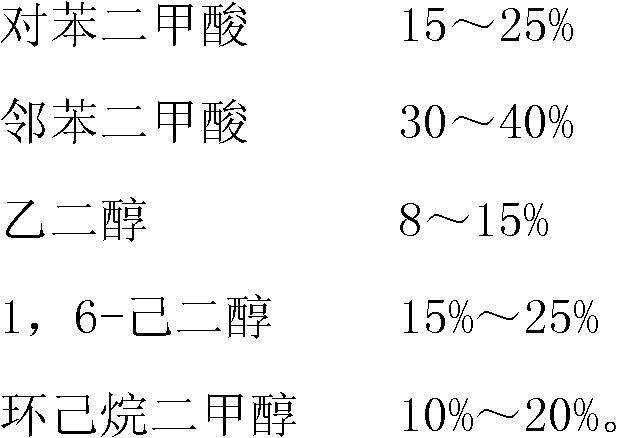

[0017] The embodiment of the present invention provides a method for preparing a composite adhesive, which can prepare a composite adhesive that is resistant to high heat, high humidity and ultraviolet light for composite solar battery back sheets. The method includes the following steps:

[0018] Prepare the main ingredient:

[0019] Esterification: put ethylene glycol and phthalic acid into the esterification reaction kettle and mix them, then fill the nitrogen gas protection, raise the temperature of the esterification reaction kettle to 220°C, and start the esterification reaction when the water comes out of the esterification reaction kettle, the esterification reaction If the water output of the kettle reaches the theoretical water output, the esterification reaction is completed;

[0020] Put terephthalic acid and 1,6-hexanediol, cyclohexanedimethanol into the esterification reactor after the above-mentioned esterification reaction is completed, the still temperature of...

Embodiment 2

[0033] This example provides a method for preparing a solar backsheet composite adhesive, which can prepare a three-layer composite structure of a solar backsheet that can meet the requirements of fluorine-containing materials such as PVDF / PET / EVA. The intensity attenuation is small, and the ultraviolet light resistance is good. The method includes the following steps:

[0034] Prepare the main ingredient:

[0035] Esterification: Put 8kg of ethylene glycol into the esterification reaction kettle, heat it up, then add 30kg of phthalic acid, and heat up after nitrogen replacement. Start; the end point of the esterification reaction is judged on the basis that the water output of the esterification reactor reaches the theoretical water output;

[0036] For the second feeding, 18kg of terephthalic acid, 15kg of 1,6-hexanediol, and 12kg of cyclohexanedimethanol are put into the esterification reaction kettle, and the water is discharged for the second time to carry out the esteri...

Embodiment 3

[0040]This example provides a method for preparing a solar backsheet composite adhesive, which can prepare a three-layer composite structure of a solar backsheet that can meet the requirements of fluorine-containing materials such as PVDF / PET / EVA. The intensity attenuation is small, and the ultraviolet light resistance is good. The method includes the following steps:

[0041] Prepare the main ingredient:

[0042] Esterification: Put 9kg of ethylene glycol into the esterification reaction kettle, heat up, then add 33kg of phthalic acid, heat up after nitrogen replacement, the temperature of the esterification reaction kettle reaches 220°C, and water begins to flow out, and the esterification reaction start; the end point of the esterification reaction is judged based on the theoretical water output;

[0043] For the second feeding, 15kg of terephthalic acid, 18kg of 1,6-hexanediol, and 10kg of cyclohexanedimethanol are put into the esterification reaction kettle, and the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com