Fast aging response type Al-Mg-Si-Cu-Zn series alloy and preparation method thereof

An al-mg-si-cu-zn, aging technology, applied in the field of aluminum alloy, can solve the problem of reducing the hardening ability of alloy baking paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

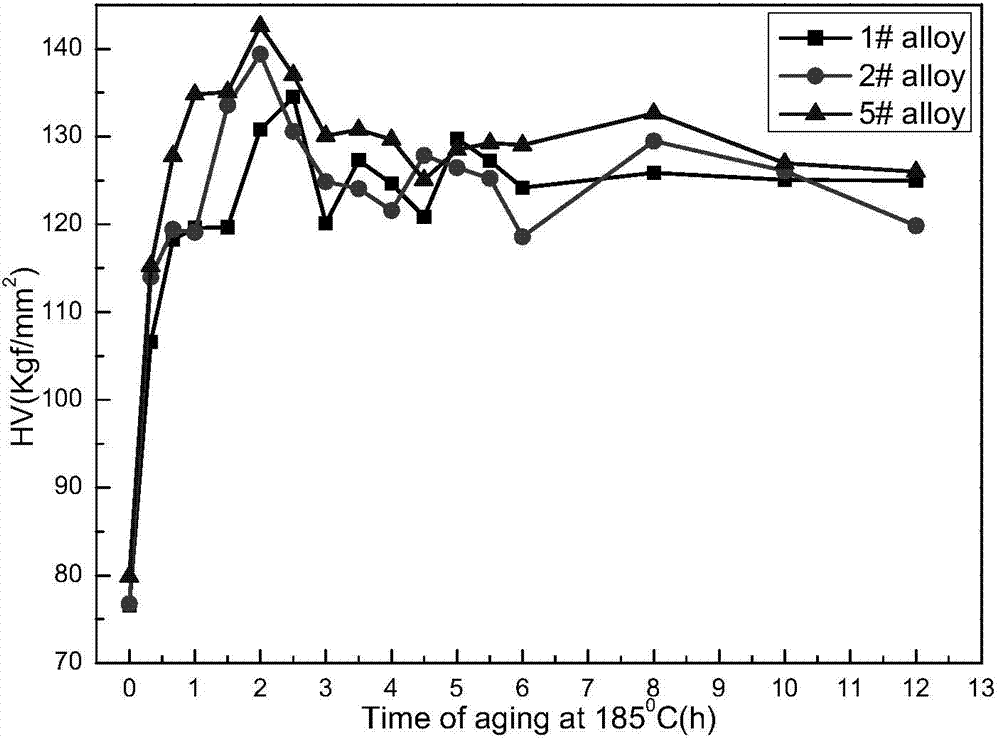

[0041] After the invention alloys 1#, 2# and 5# are smelted and cast, they are subjected to homogenization treatment. The treatment process is: start to heat up at a heating rate of 20-40°C / h, and keep warm for 2~ 5h, then continue to heat up at 20-40°C / h to 545-555°C for 14-20h, and then take out the sample when cooling down to 100°C with the furnace at a cooling rate of 20-40°C / h. Then directly cut the sample from the homogenized bulk material and place it in a salt bath furnace for 545-555°C / 1-6min solid solution treatment (i.e., carry out 1-6min in a salt bath furnace at 545-555°C solution treatment) and water quenching treatment, and then directly placed in an aging furnace at 185°C for artificial aging at different times to compare the aging precipitation behavior of various alloys (see figure 1 shown).

Embodiment 2

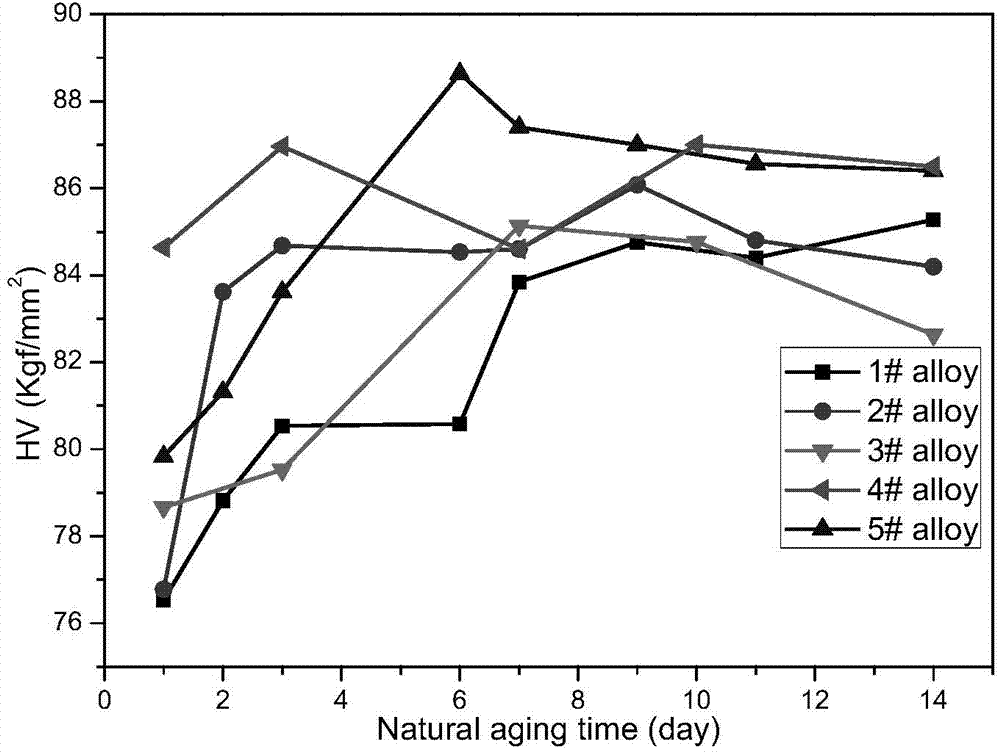

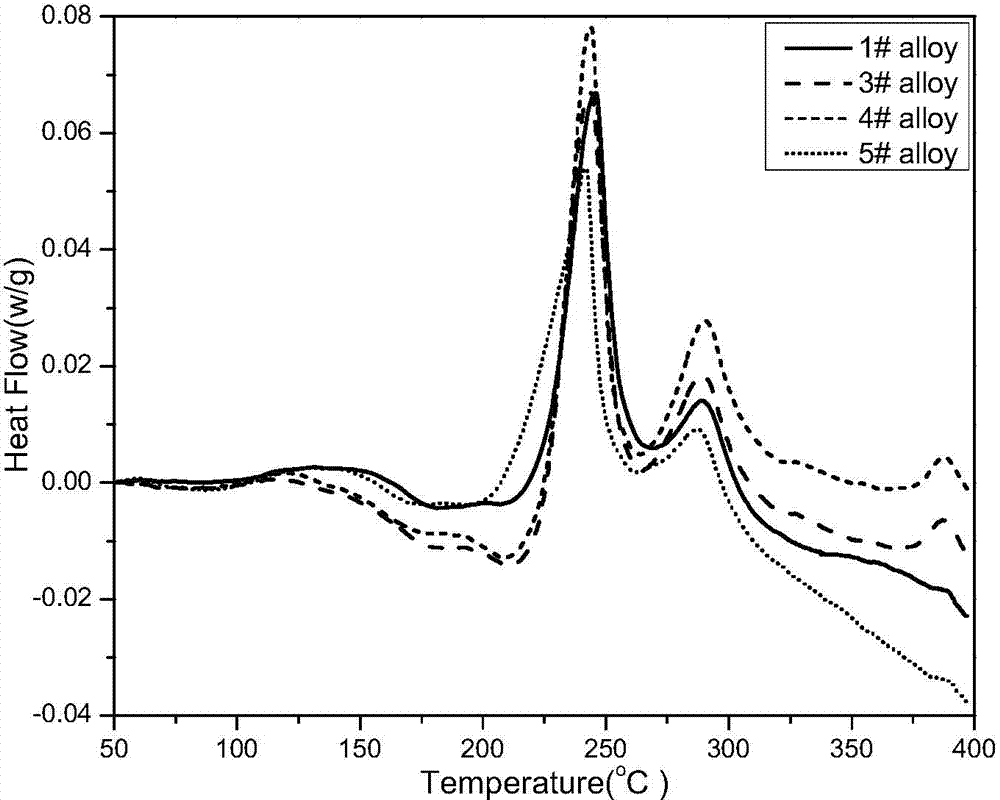

[0043] After the invention alloys 1#, 2#, 3#, 4# and 5# are smelted and cast, they are homogenized. The treatment process is: start to heat up at a heating rate of 20-40°C / h, and wait until the temperature reaches 470 Insulate at ~485°C for 2~5h, then continue to heat up at 20~40°C / h to 545~555°C for 14~20h, and then take out the sample when cooling down to 100°C with the furnace at a cooling rate of 20~40°C / h . Then cut the sample directly from the homogenized bulk material and place it in a salt bath furnace for 545~555℃ / 1-6min solid solution and water quenching treatment, and then directly perform natural aging at room temperature to measure the alloy Variation law of hardness with natural aging time (see figure 2 shown). In addition, DSC analysis was carried out on the 14-day natural aging sample. The specific implementation plan is: cut out a disc with a diameter of 3mm×1mm and a mass of about 15mg, and use a differential scanning calorimeter Q2000 (DSC) for differenti...

Embodiment 3

[0045] After the invention alloys 1#, 2#, 3#, 4# and 5# are smelted and cast, they are homogenized. The treatment process is: start to heat up at a heating rate of 20-40°C / h, and wait until the temperature reaches 470 Insulate at ~485°C for 2~5h, then continue to heat up at 20~40°C / h to 545~555°C for 14~20h, and then take out the sample when cooling down to 100°C with the furnace at a cooling rate of 20~40°C / h . Then directly cut the sample from the homogenized block material and place it in a salt bath furnace for 545~555℃ / 1-6min solid solution and water quenching treatment, and then carry out natural aging for 14 days at room temperature (T4 state), and finally carry out artificial aging treatment on the natural aging state samples at 185°C for different times, and measure the change law of hardness of the alloy (see Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com