High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

A technology of aluminum alloy materials and aluminum alloy plates, which is applied in the field of aluminum alloy plates and its manufacture, and aluminum alloy materials, and can solve problems such as decreased elongation, unstable mechanical properties of plates, and segregation of magnesium and silicon atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment A1-A8

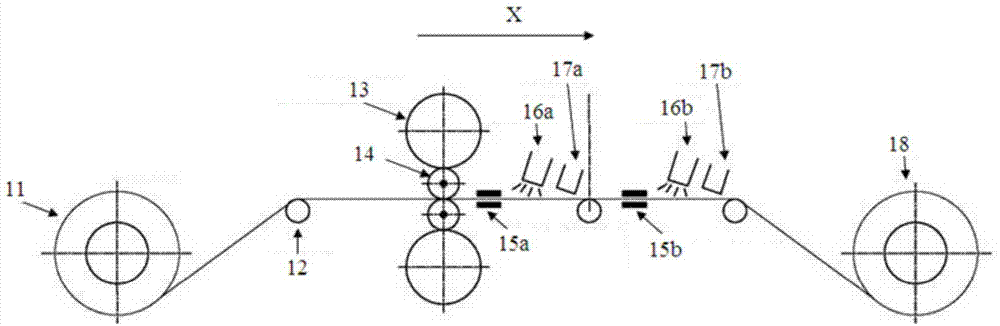

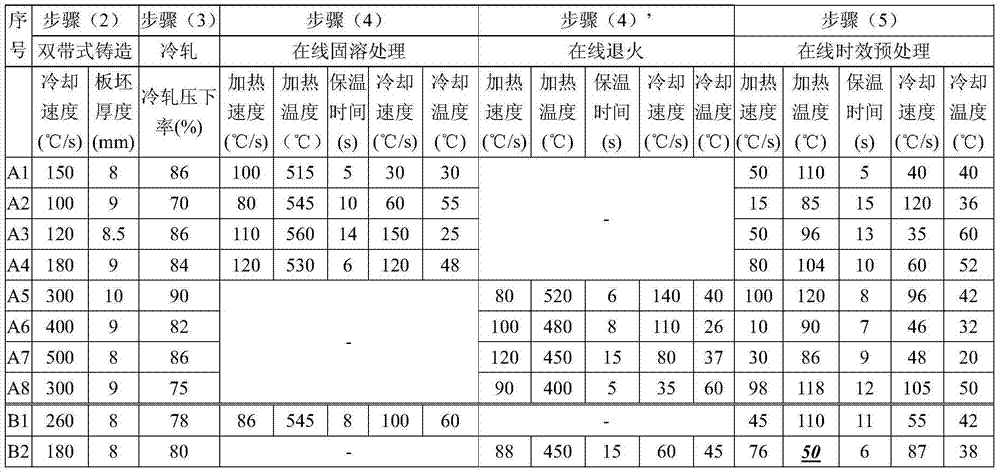

[0075] see figure 1 , manufacture the aluminum alloy plate in embodiment A1-A8 and comparative example B1-B2 according to the following steps:

[0076] 1) Smelting: add master alloy and refiner to molten aluminum water by conventional smelting method, and control the mass percentage ratio of each chemical element as shown in Table 1;

[0077] 2) Double-belt casting: cooling from the liquidus temperature (720°C) to the solidus temperature at a cooling rate of 100-500°C / s, and the thickness of the cast slab is 8-10mm;

[0078] 3) Cold rolling: the right turning roll 12 transports the slab to the work roll, and the slab is rolled by the work roll 14 of the rolling mill, and the cold rolling reduction rate is controlled to be 70-90%, so as to obtain a cold-rolled slab with a thickness of 1mm ;

[0079] 4) On-line solution treatment: heat the aluminum alloy plate to 500-560°C at a heating rate of 80-120°C / s through the first on-line induction heating device 15a, keep it warm for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com