Production method for zinc electroplated baked hardened steel plate for automobile outer plate

A baking hardening and production method technology, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of affecting the appearance of the car body, the difficulty of stable control of the surface quality, etc., and achieve the reduction of production costs, wide range of process parameters and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

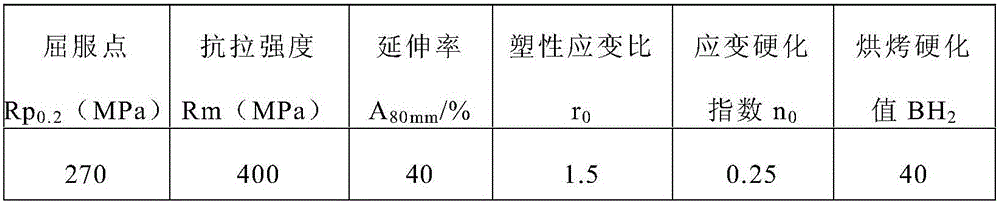

Embodiment 1

[0043] The selected hardened steel plate has the following components and mass percentages: C: 0.0016%, Si: 0.025%, Mn: 0.46%, P: 0.047%, S: 0.015%, Nb: 0.0006%, Als: 0.03%, N: 0.0025%, the balance is iron and unavoidable impurities.

[0044] This preparation method passes through successively:

[0045] 1) Smelting and casting into slabs;

[0046] 2) Heating the slab prepared in step 1) to 1220°C, and controlling the final rolling temperature to 910°C;

[0047] 3) Conventional water cooling to the coiling temperature and coiling, the coiling temperature is controlled at 680°C;

[0048] 4) Carry out cold rolling: control the total reduction ratio of cold rolling to 85%;

[0049] 5) Carry out continuous annealing: control the annealing soaking temperature to 800°C, and control the strip running speed to 180m / min. The purpose is to promote the initial nucleation and growth of γ-oriented textured grains, so as to obtain good deep drawing performance. Therefore, the temperature...

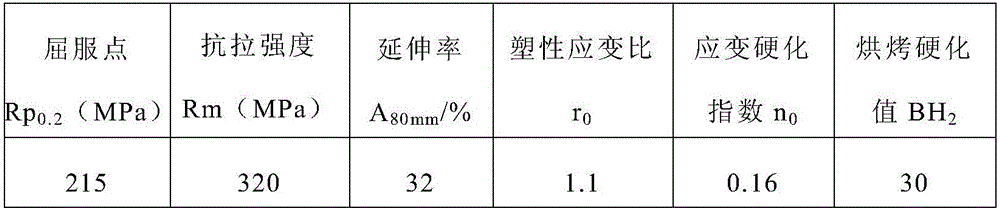

Embodiment 2

[0062] The selected hardened steel plate has the following components and mass percentages: C: 0.0035%, Si: 0.030%, Mn: 0.40%, P: 0.060%, S: 0.015%, Nb: 0.0012%, Als: 0.055%, N: 0.004%, the balance is iron and unavoidable impurities.

[0063] This preparation method passes through successively:

[0064] 1) Smelting and casting into slabs;

[0065] 2) Heating the slab prepared in step 1) to 1230°C, and controlling the final rolling temperature to 915°C;

[0066] 3) Conventional water cooling to the coiling temperature and coiling, the coiling temperature is controlled at 690°C;

[0067] 4) Carry out cold rolling: control the total reduction ratio of cold rolling to 80%;

[0068] 5) Carry out continuous annealing: control the annealing soaking temperature to 805°C, control the strip running speed to 190m / min, and rapidly cool to 405°C; then perform overaging treatment at a temperature of 385°C, and control the treatment time to 190s;

[0069] 6) Leveling: control the roughne...

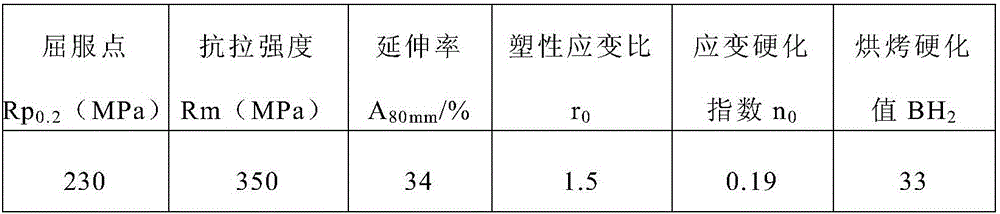

Embodiment 3

[0076] The selected hardened steel plate has the following components and mass percentages: C: 0.0016%, Si: 0.025%, Mn: 0.7%, P: 0.053%, S: 0.010%, Nb: 0.0009%, Als: 0.045%, N: 0.0030%, the balance is iron and unavoidable impurities.

[0077] This preparation method passes through successively:

[0078] 1) Smelting and casting into slabs;

[0079] 2) Heating the slab prepared in step 1) to 1240°C, and controlling the final rolling temperature to 920°C;

[0080] 3) Conventional water cooling to the coiling temperature and coiling, the coiling temperature is controlled at 700°C;

[0081] 4) Carry out cold rolling: control the total reduction rate of cold rolling to 78%;

[0082] 5) Carry out continuous annealing: control the annealing soaking temperature to 810°C, control the running speed of the strip steel to 200m / min, and rapidly cool to 400°C; then perform overaging treatment at a temperature of 380°C, and control the treatment time to 200s;

[0083] 6) Leveling: control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com