Stackable ribbed bottle system

a bottle system and ribbed technology, applied in the field of containers, can solve the problems of increasing the likelihood that the contents of the bottles will leak out of the bottles, the stackable bottles do not include, and the stackable bottles are not ideal, so as to improve the collapsibility of the bottle, increase the top load capacity, and strengthen the bottl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

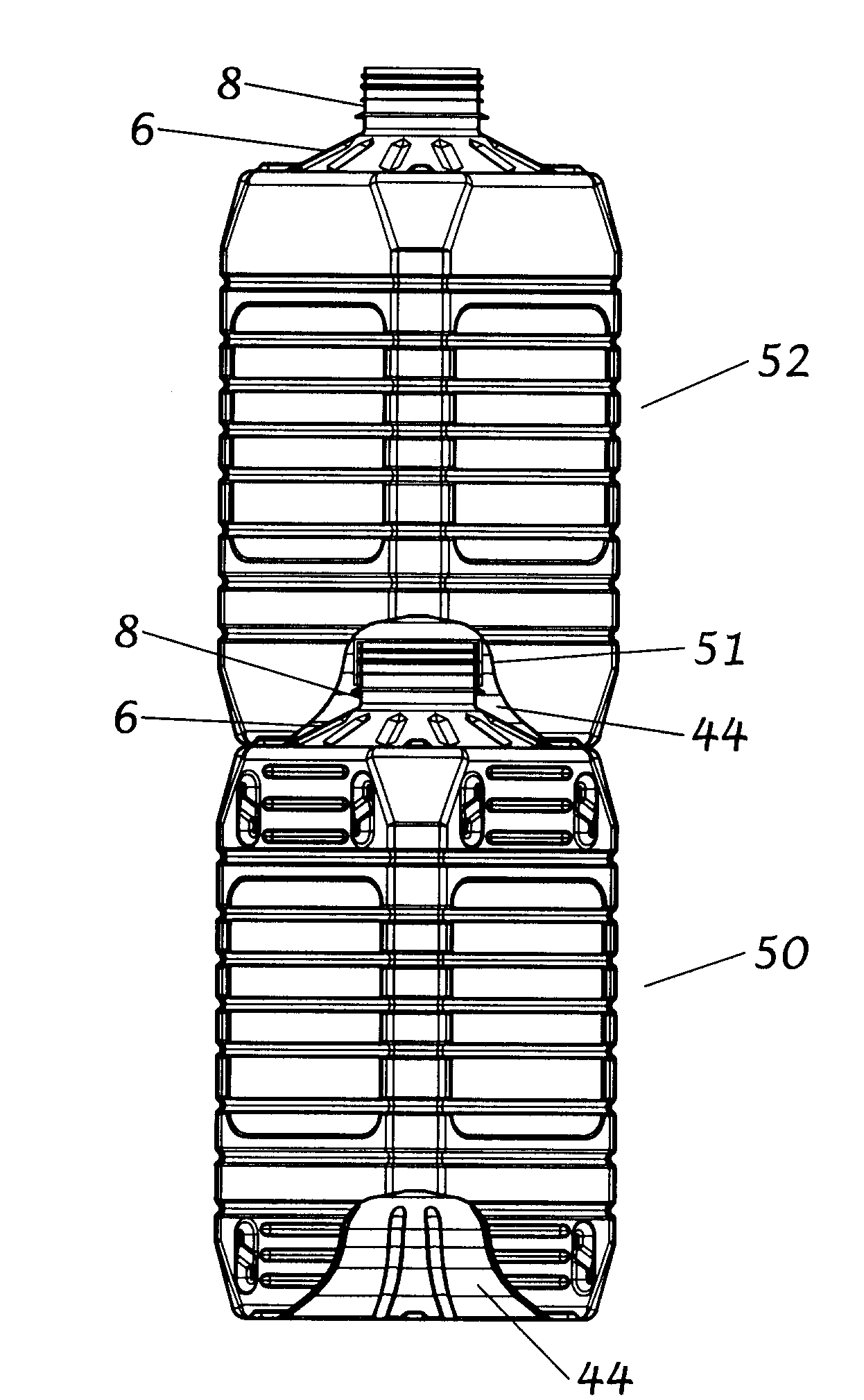

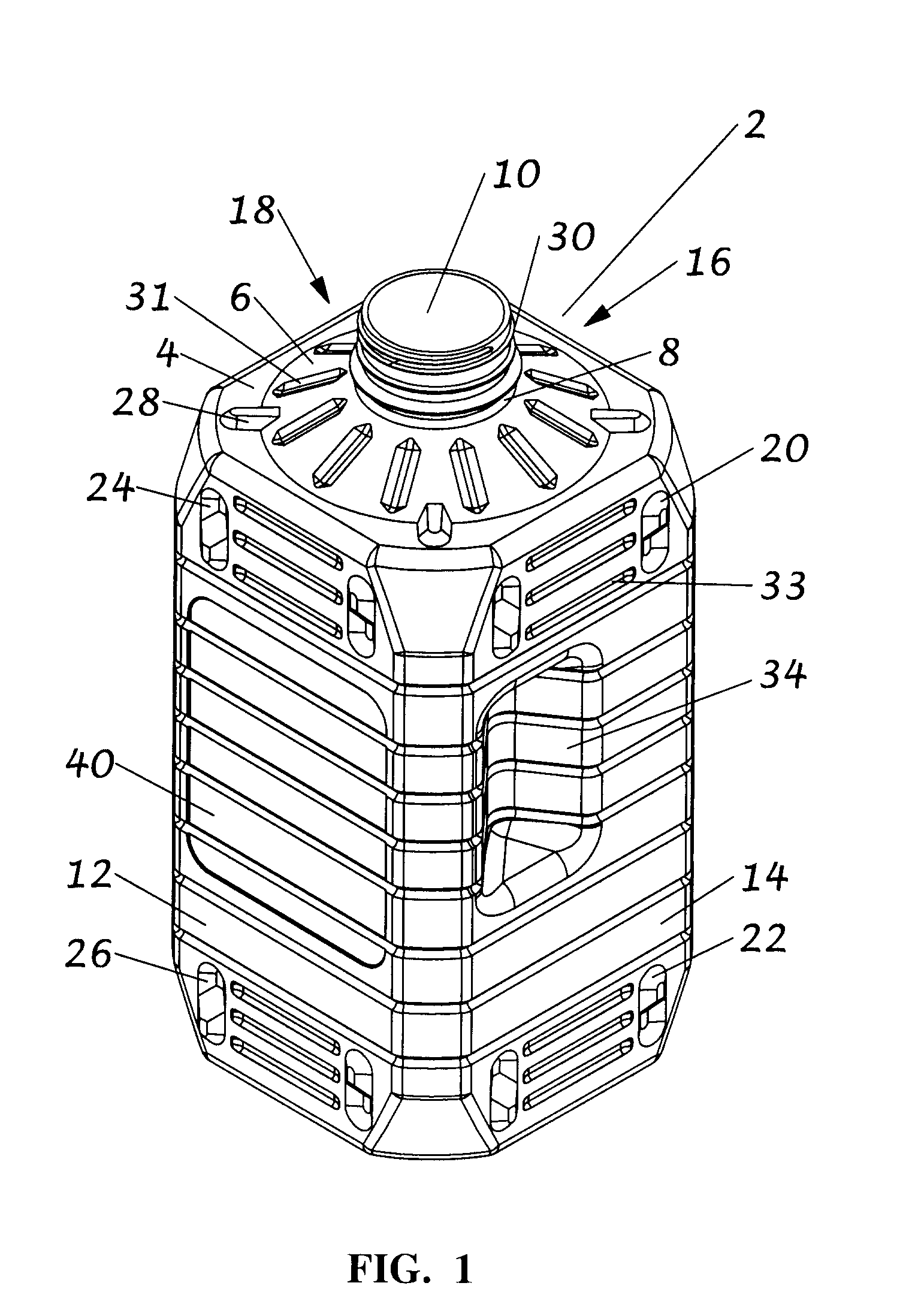

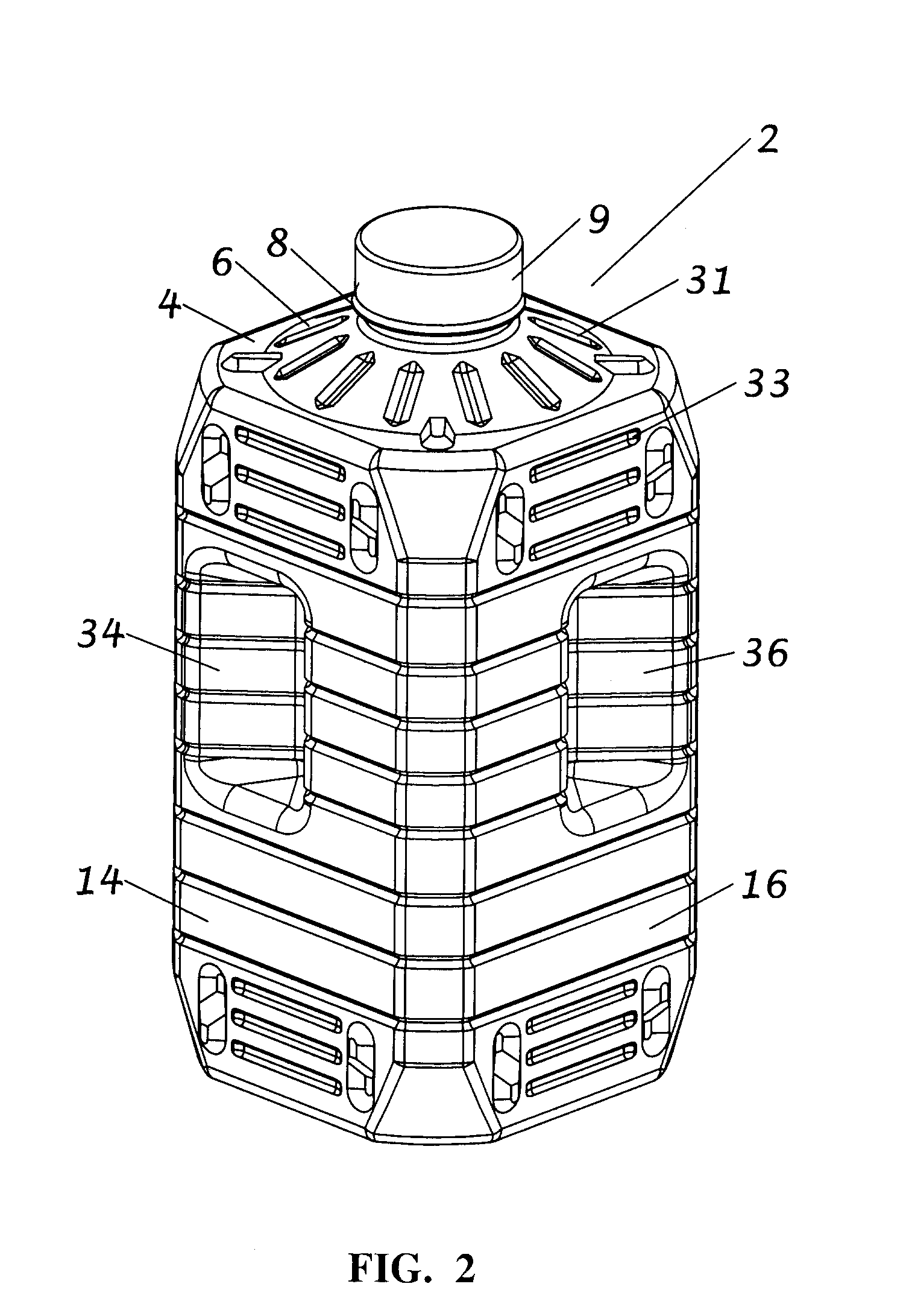

[0029]Referring first to FIGS. 1 to 3, a stackable bottle 2 according to the present invention comprises a storage compartment having an upper surface 4 with a conical ceiling 6, a centrally disposed neck 8 extending from the conical ceiling with an opening 10 therein, and a lower surface 42. The bottle has four side walls 12, 14, 16, 18, vertical interlocking means comprising side wall protrusions 20, 22 corresponding to side wall recesses 24, 26, and horizontal interlocking means comprising at least one upper surface protrusion 28 corresponding to at least one lower surface recess 46.

[0030]The side wall protrusions are of a size, relative to the size of the side wall recesses, which permits a releasable locational transition fit engagement of the protrusions into the recesses. Similarly, the upper surface protrusions are of a size, relative to the size of the lower surface recesses, which permits a releasable locational transition fit engagement of the protrusions into the recesse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com