Method for producing nickel/ferrum from nickel laterite ores

A technology of laterite nickel ore and roasting products, which is applied in the field of metallization reduction roasting-combined fire-wet smelting to separate valuable metals, and the production of nickel/iron from laterite nickel ore, which can solve the problems of high production temperature, high smelting energy consumption, and difficult production Control and other issues, to achieve the effect of low reduction temperature, low comprehensive income, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

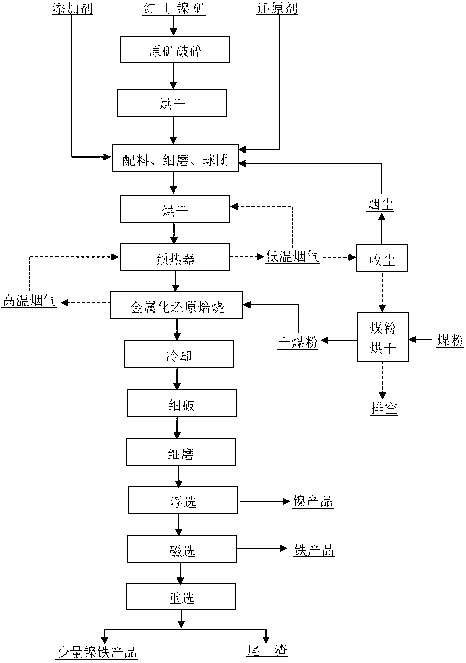

Image

Examples

Embodiment approach 1

[0027] Embodiment one: the steps of the method for producing nickel / iron from laterite nickel ore in this embodiment are:

[0028] (1) Firstly, the laterite nickel ore (the composition is iron 11wt%, nickel 2wt%, magnesium oxide 22.7wt%, cobalt 0.02wt%) is sequentially crushed, first dried and finely ground (to a particle size of 110-130μm), and then Blend with carbonaceous reducing agent and additives and mix evenly (first, mix carbonaceous reducing agent and laterite nickel ore evenly, the amount of carbonaceous reducing agent added is 8% of the mass of laterite nickel ore, then add additives and mix evenly, additive The addition amount is 5% of the mass of laterite nickel ore; the carbonaceous reducing agent refers to the mixture of bituminous coal, anthracite and coke with a carbon content of more than 70wt%; the additive is silicon dioxide), pressed, and Drying again at ℃ for 1 hour, preheating the material at 350℃ for 1.5 hours after drying again, and finally reducing an...

Embodiment approach 2

[0030] Embodiment two: the steps of the method for producing nickel / iron from laterite nickel ore in this embodiment are:

[0031] (1) Firstly, the lateritic nickel ore (the composition is iron 10wt%, nickel 1.5wt%, magnesium oxide 25.6wt%, cobalt 0.2wt%) is sequentially crushed, first dried and finely ground (to a particle size of 75-100 μm), Then mix with carbonaceous reducing agent and additives and mix evenly (firstly, carbonaceous reducing agent and laterite nickel ore are evenly mixed, the amount of carbonaceous reducing agent added is 10% of the quality of laterite nickel ore, then add additives and mix uniformly, The amount of additive added is 11% of the mass of laterite nickel ore; the carbonaceous reducing agent refers to a mixture of bituminous coal and anthracite with a carbon content above 70wt%; the additive is any proportion of silicon dioxide, calcium oxide and calcium fluoride Mixture), pressed, and dried again in the drying kiln at 150-200°C for 0.5h, the ma...

Embodiment approach 4

[0036] Embodiment four: the steps of the method for producing nickel / iron from laterite nickel ore in this embodiment are:

[0037] (1) Firstly, the laterite nickel ore (the composition is iron 50wt%, nickel 0.8wt%, magnesium oxide 3wt%, cobalt 0.02wt%) is sequentially crushed, first dried and finely ground (to a particle size of 100-150 μm), and then Mix with carbonaceous reducing agent and additives (first, mix carbonaceous reducing agent and laterite nickel ore evenly, the amount of carbonaceous reducing agent added is 10% of the mass of laterite nickel ore, then add additives and mix evenly, additive The amount added is 25% of the mass of lateritic nickel ore; the carbonaceous reducing agent refers to a mixture of bituminous coal and anthracite with a carbon content above 70wt% in any proportion; the additive is a mixture of silicon dioxide, calcium oxide and calcium fluoride in any proportion) , pressed, and dried again in the drying kiln at 220°C for 2 hours, the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com