Catalytic cracking method of hydrocarbon oil

A catalytic cracking, hydrocarbon oil technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of short adjustment time, increased dry gas and coke yield, etc., to reduce the generation of dry gas and coke, reduce excessive cracking , the effect of reducing the contact temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment adopts a medium-sized riser reactor, which is a cylindrical structure with a total height of 10 meters and a diameter of 25 centimeters. The height ratio of the lower and upper reaction zones is 1.8:7.5. is the pre-lift segment.

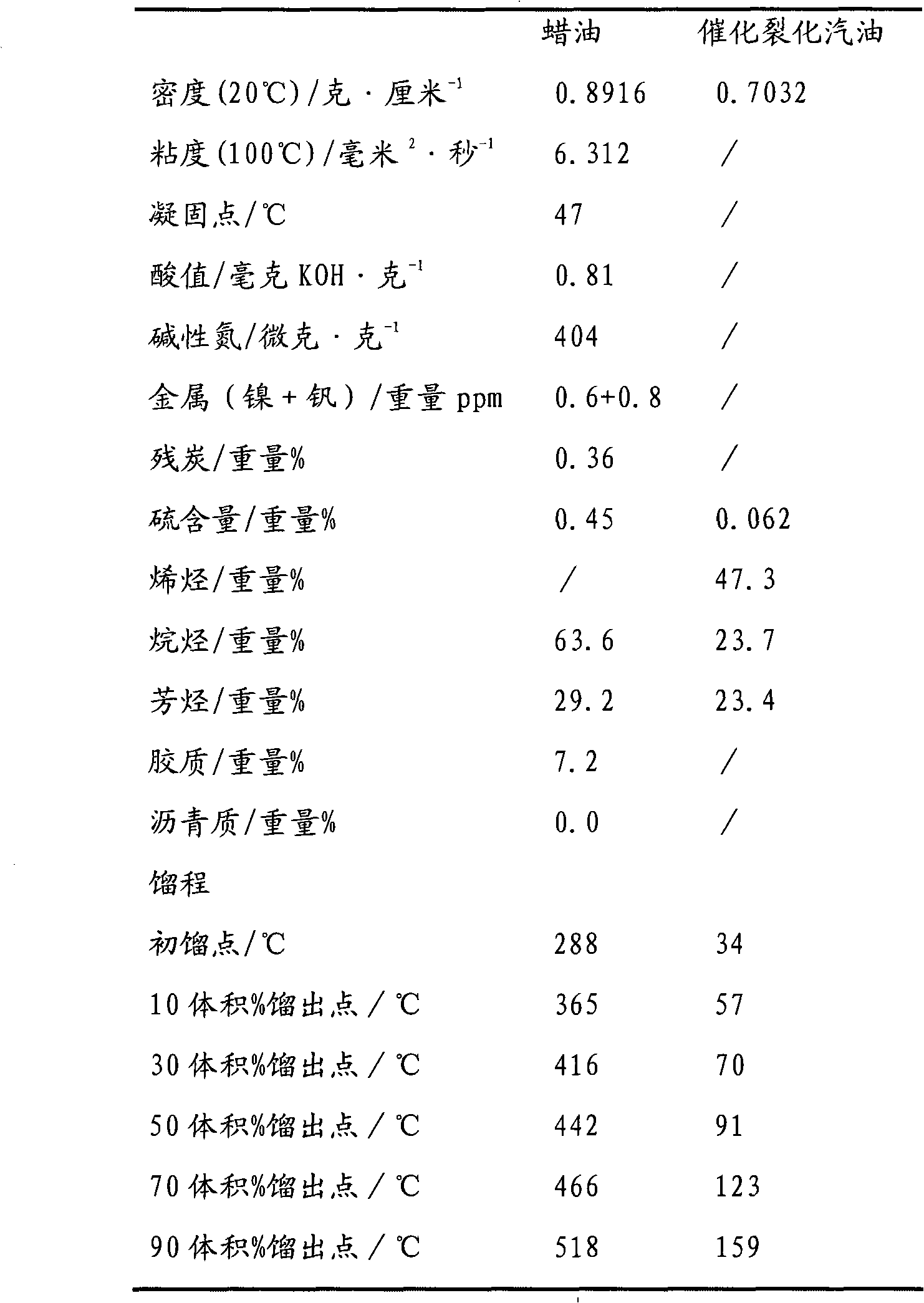

[0041] The raw material oil processed by the device is, the gasoline raw material introduced from the lower reaction zone is catalytic cracking gasoline; the heavy raw material introduced from the upper reaction zone is wax oil (vacuum gas oil). The feed amount of catalytically cracked gasoline is 15% by weight of the wax oil. The properties of various feedstock oils are listed in Table 1. The brand name of the catalyst is LV-23, which is produced by Qilu Catalyst Factory of China Petrochemical Corporation. The catalyst LV-23 is a cracking catalyst containing Y-type zeolite and ultra-stable Y-type zeolite.

[0042] Concrete steps are, as shown in the accompanying drawing, the gasoline raw material after the preheating enters t...

Embodiment 2

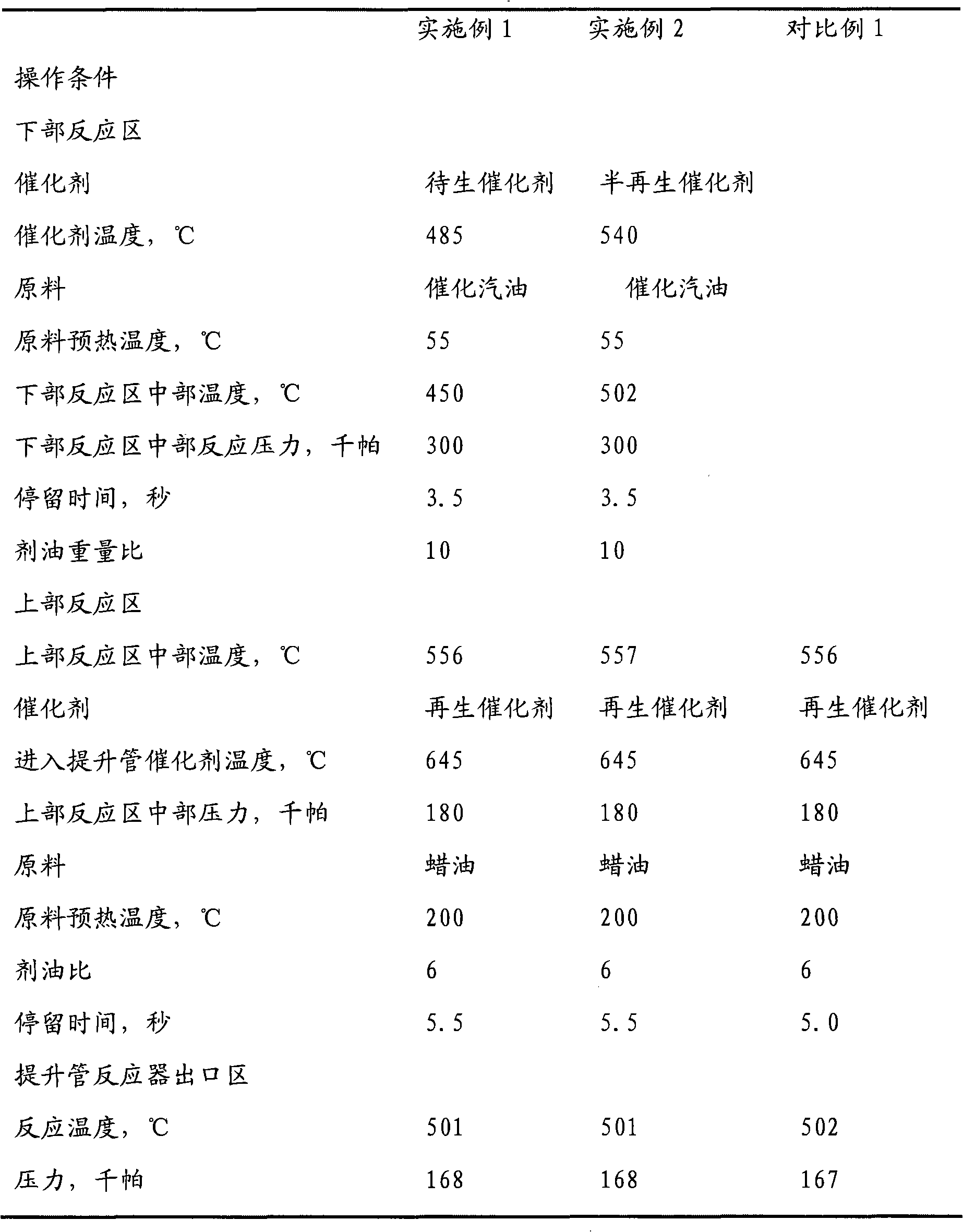

[0046] The method of Example 1 was repeated, except that the catalyst entering the lower reaction zone was the semi-regenerated catalyst from the first stage regenerator in the two-stage regenerator.

[0047] The specific operating conditions, product distribution and gasoline product properties are listed in Table 2, Table 3, and Table 4, respectively.

Embodiment 3

[0053] Repeat the steps of Example 1, except that the catalyst entering the upper reaction zone is the cooled regenerated catalyst from the external heat extractor of the second stage regenerator in the two-stage regenerator.

[0054] The specific operating conditions, product distribution and gasoline product properties are listed in Table 5, Table 6, and Table 7, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com