Catalytic cracking desulfur method of faulty gasoline and device thereof

A low-quality gasoline, catalytic cracking technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of short reaction time, limited reduction of sulfur content in modified gasoline, etc., and achieve the effect of improving the overall activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

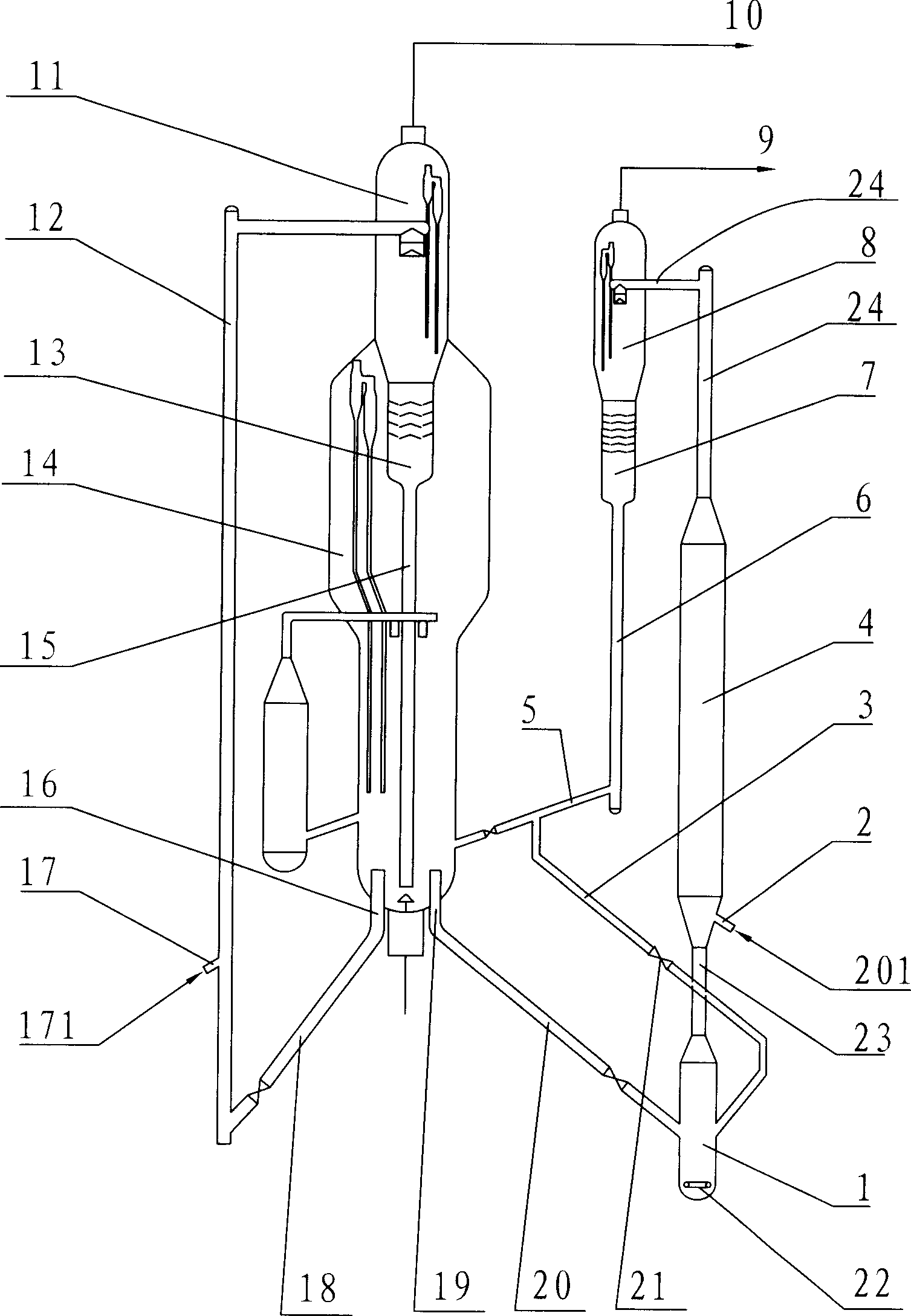

[0042] in such as figure 1 The test is carried out on the double-reactor catalytic cracking desulfurization test device of the present invention shown. The gasoline fast bed reactor has an inner diameter of Φ60mm and a length of 4200mm. The catalyst mixer has an inner diameter of Φ100mm and a length of 800mm. The delivery pipe for the raw catalyst is a metal pipe with a circular cross section, lined with a heat-insulating and wear-resistant lining, and the inner diameter is Φ12mm. The medium of the conveying wind which is passed into the conveying pipe of the standby catalyst through the conveying air pipe is water vapor, and the temperature of the water vapor is 200°C. The temperature of the water vapor fed through the steam distributor in the catalyst mixer is also 200°C. The heavy oil riser reactor processes Subei blended heavy oil, with a processing capacity of 30kg / d; the gasoline fast-bed reactor feeds low-quality gasoline with gasoline produced by the heavy oil riser...

Embodiment 2~ Embodiment 5

[0045] The test was carried out on the test device used in Example 1. The main operating conditions of the heavy oil riser reactor and the gasoline fast bed reactor are listed in Table 2, and the product distribution of the gasoline fast bed reactor and the main properties of the upgraded gasoline are listed in Table 3. In embodiment 2~embodiment 5, the processed feedstock and treatment capacity of test device, heavy oil riser reactor and gasoline fast bed reactor, test catalyst used and other unspecified main operating conditions are all the same as in embodiment 1. of the same.

[0046] As can be seen from Table 2, in Examples 2 to 5, the weight flow rate of the spent catalyst that enters the catalyst mixer through the spent catalyst delivery pipe is respectively the weight flow of the spent catalyst after stripping in the stripping section of the second settler. 20w%, 40w%, 60w% and 80w% of the amount.

Embodiment 6

[0051] The test was carried out on the test device used in Example 1. The heavy oil riser reactor processes Subei blended heavy oil, with a processing capacity of 30kg / d; the gasoline fast-bed reactor feeds low-quality gasoline with the gasoline produced by the heavy oil riser reactor (self-produced gasoline 2), with a processing capacity of 15kg / d d. The catalyst used in the test is LRC-99 industrial balance agent, the balance catalyst has a microreaction activity of 62 and a carbon content of 0.09w%. The weight flow rate of the spent catalyst entering the catalyst mixer through the spent catalyst delivery pipe is 5w% of the weight circulation of the spent catalyst after stripping in the stripping section of the second settler. The main properties of the heavy oil riser reactor feed and the inferior gasoline feed of the gasoline fast bed reactor are listed in Table 1. The main operating conditions of the heavy oil riser reactor and the gasoline fast bed reactor are listed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com