Catalytic cracking conversion method with relay use of catalyst curd its device

A catalytic cracking and catalyst technology, applied in the petroleum industry, dealing with hydrocarbon oil, etc., can solve the problem that the gasoline reaction is not fully utilized, and achieve the effects of inhibiting the thermal cracking reaction, increasing the ratio of agent to oil, and improving the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

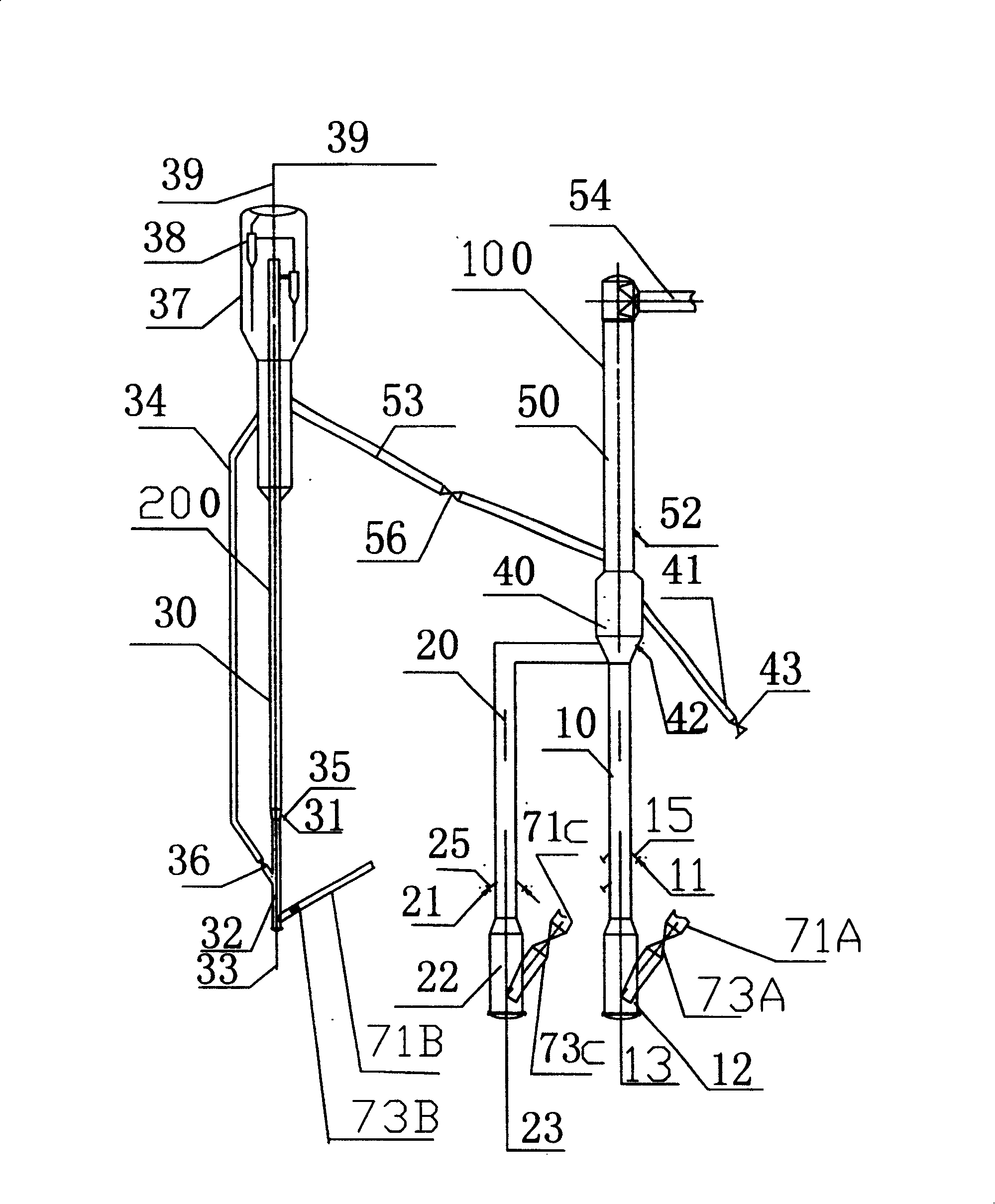

[0034] Embodiment 1, the catalytic cracking conversion unit that catalyst relay uses (see figure 1 ), including a heavy oil reactor 100 and a gasoline reactor 200 arranged in parallel therewith. The heavy oil reactor 100 is composed of a lower cracking reaction section, a middle separation and stripping section 40 and an upper upgrading reaction section 50 in series. The cracking reaction section includes a feedstock oil riser 10 and a re-refined oil riser 20 arranged in parallel, and the re-refined oil The riser 20 is arranged outside the raw oil riser 10, and its upper ends are connected. The separation and stripping section 40 is provided with a catalyst separation and stripping mechanism and a standby catalyst riser 41, 41 is the catalyst stripping medium of the heavy oil cracking reaction section, and 43 is a slide valve to be produced. Technology; upgrading reaction section 50 is in the form of a riser, 54 is the outlet pipe of the heavy oil reactor, and the cooling med...

Embodiment 2

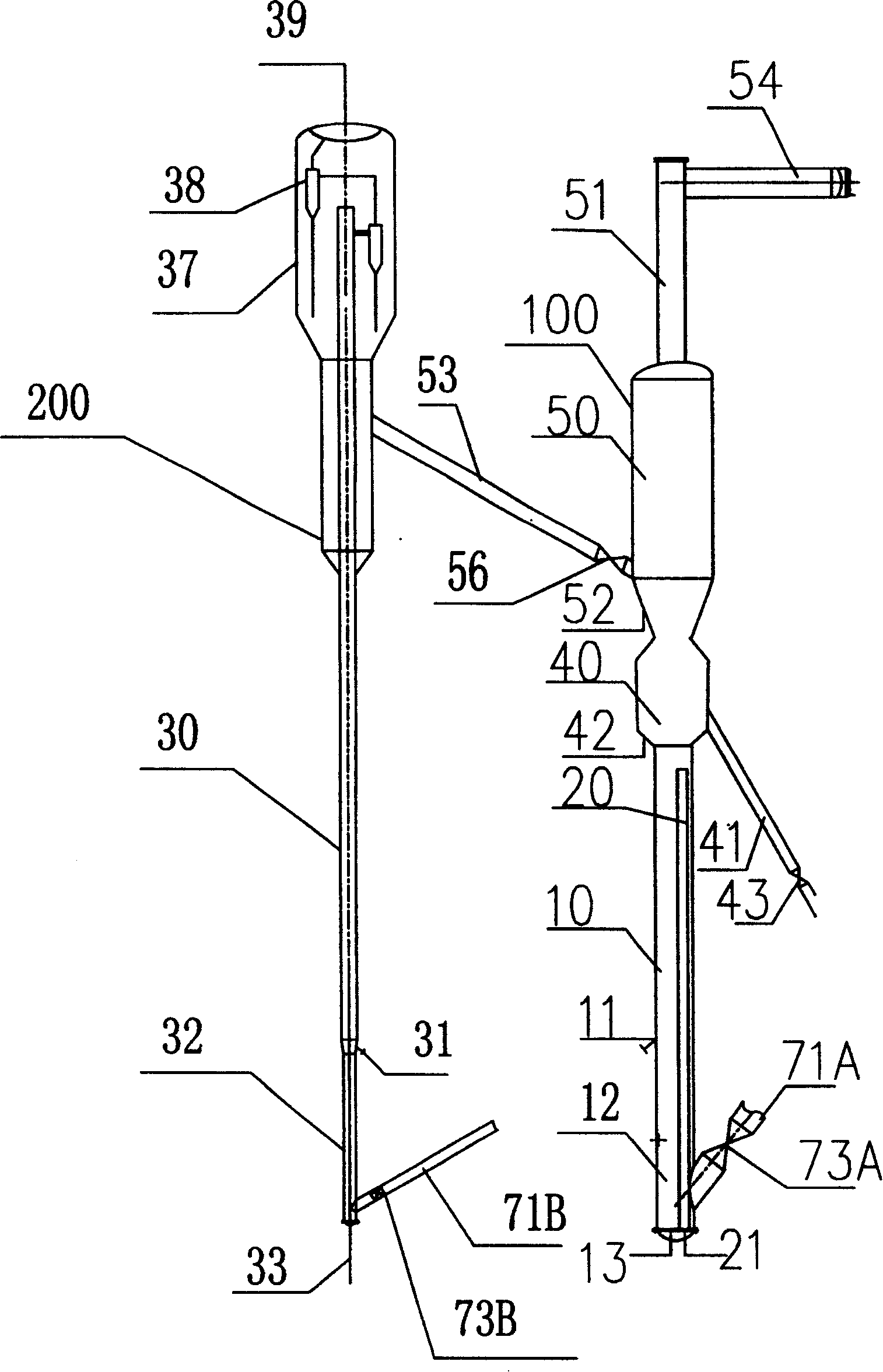

[0044] Embodiment 2. The difference between the device of this embodiment and that of Embodiment 1 is that the recycled oil riser 20 of the heavy oil reactor 100 is sleeved in the raw oil riser 10, and the two have the same axial direction; the recycled oil 21 enters from the bottom of the reactor. The recycled oil riser 20, the raw oil riser 10, and the recycled oil riser 20 share the regeneration standpipe 71A and the slide valve 73A. The upgrading reaction section 50 is in the form of a fluidized bed, and the section 51 is a heavy oil reaction delivery pipe. There is no catalyst return pipe between the gasoline settler 37 and the bottom of the gasoline reactor 200 .

Embodiment 3

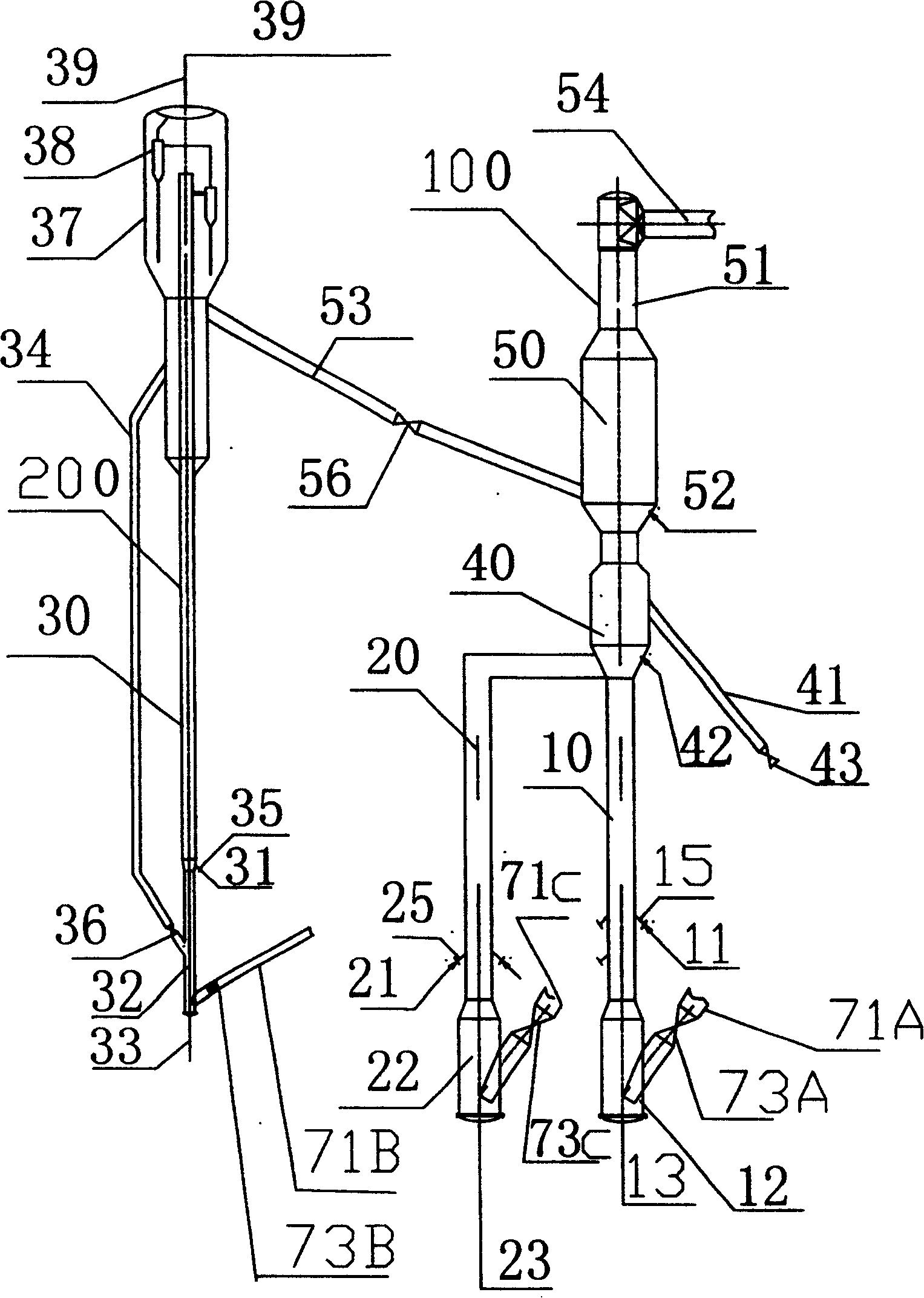

[0045] Embodiment 3. The device of this embodiment is different from that of Embodiment 1 in that: the reforming reaction section 50 is in the form of a fluidized bed, and 51 is a heavy oil reaction delivery pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com