Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1224results about How to "Boost octane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

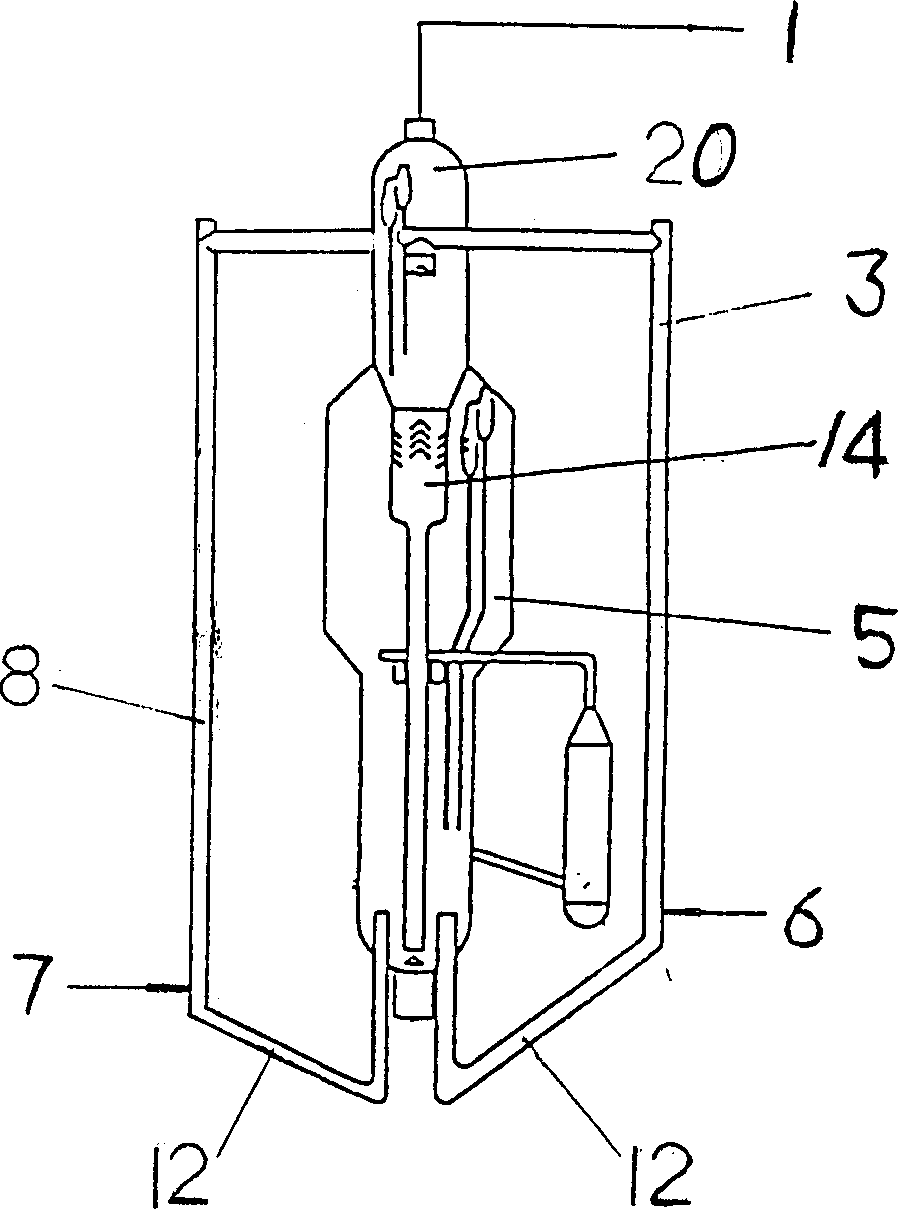

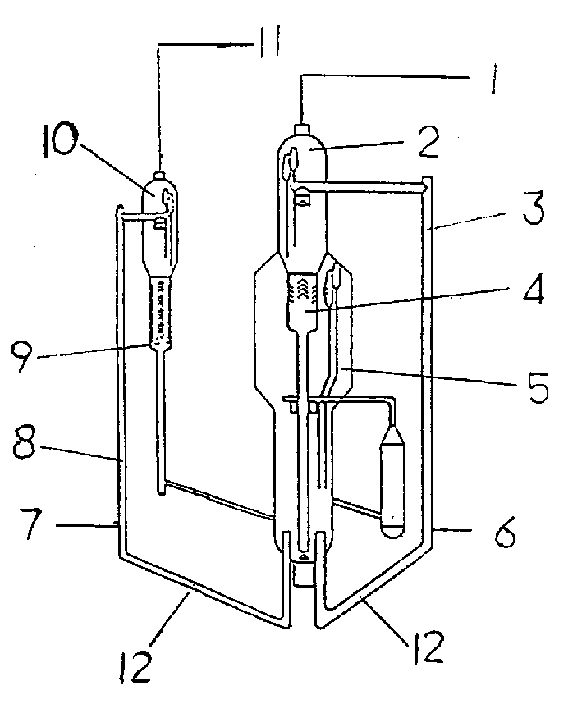

Method for manufacturing alkylate oil with composite ionic liquid used as catalyst

ActiveUS7285698B2High selectivityImprove production yieldOrganic chemistry methodsLiquid hydrocarbon mixtures productionAlkaneIonic liquid

The present invention pertains to a method for manufacturing alkylate oil using a composite ionic liquid as catalyst. A mixture of isobutane and C4 olefins is used as the raw material, and a composite ionic liquid is used as catalyst to carry out an alkylation reaction. The alkane / olefin ratio in the raw material is higher than 1:1. In the composition of the aforementioned composite ionic liquid catalyst, the cations come from a hydrohalide of an alkyl-containing amine or pyridine, while the anions are composite coordinate anions coming from two or more metal compounds. One of the metal compounds is an aluminum compound, while other metal compounds are compounds of Group IB and Group IIB elements of the Periodic Table and the transition metals. The present invention also provides a design of static mixer reaction apparatus that can realize the aforementioned manufacturing method. The method of the present invention increases the selectivity of the alkylation reaction to give the alkylation product a relatively high octane number and further increase the product yield. Also, the manufacturing operation is simplified, and the cost can be reduced. This method is an environmentally friendly method that will not pollute the environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

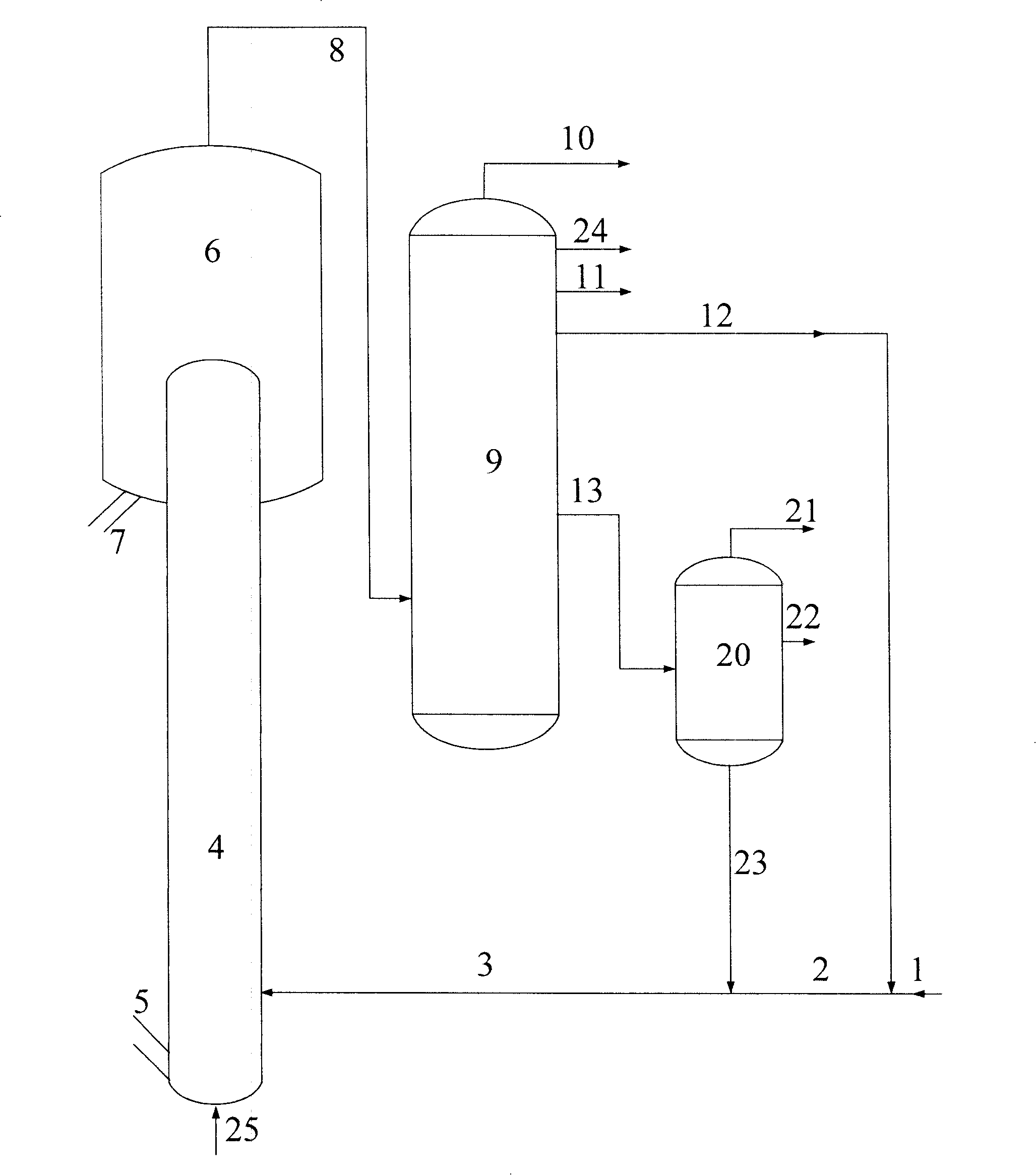

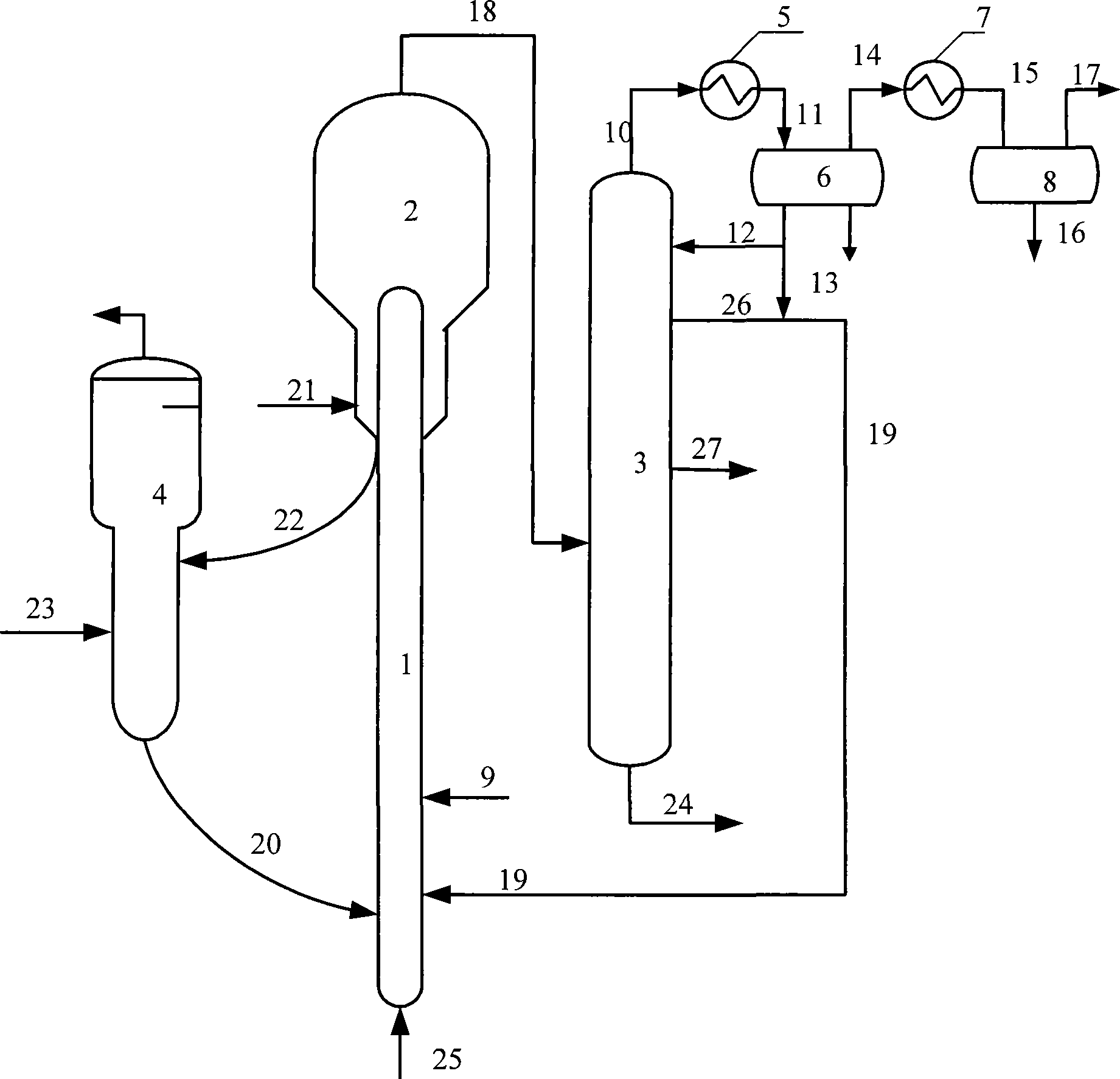

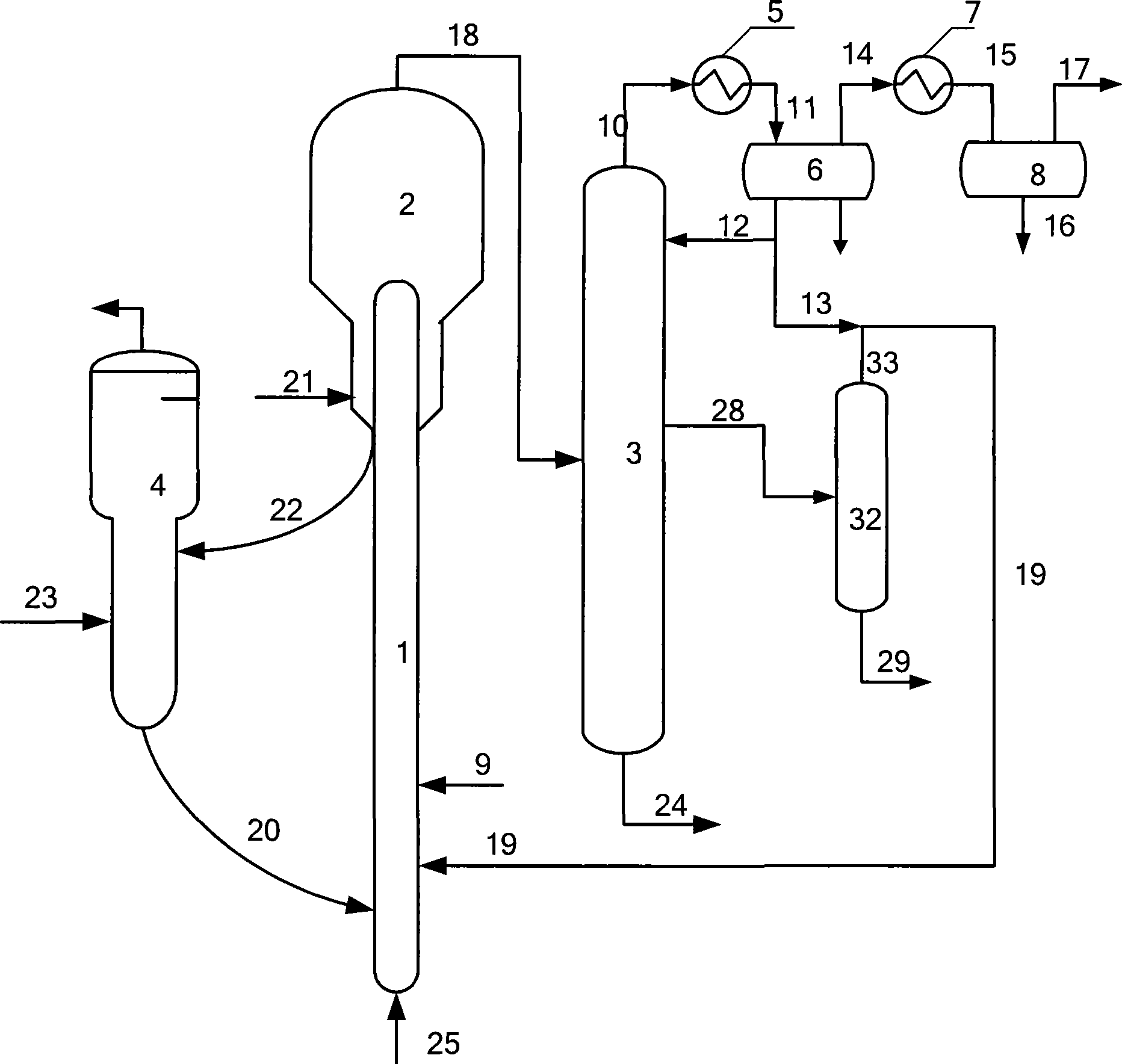

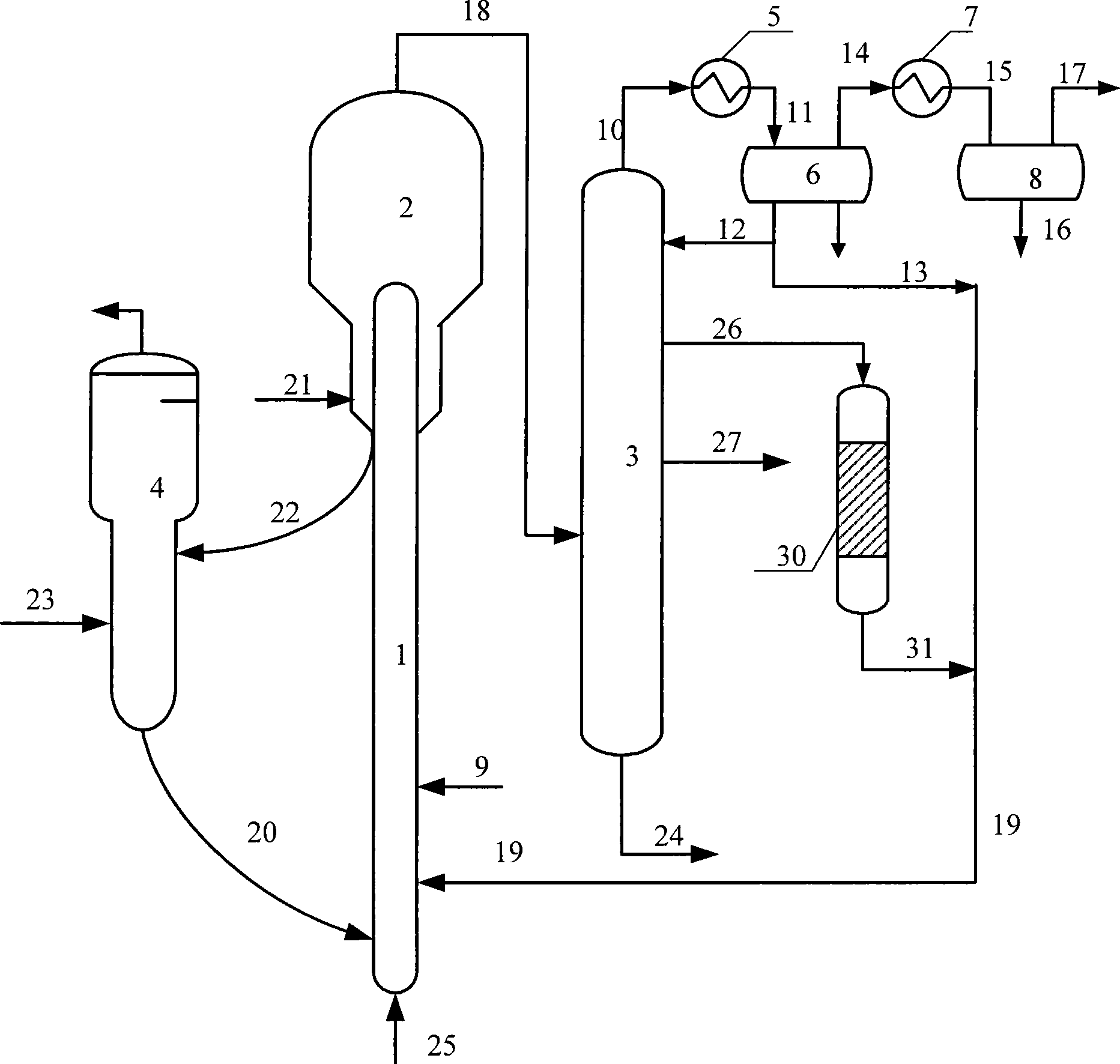

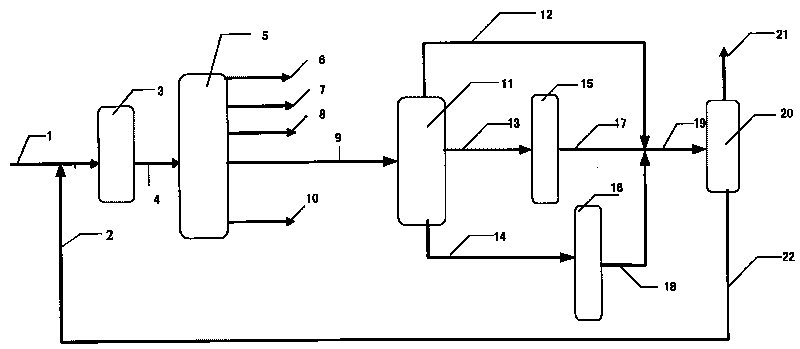

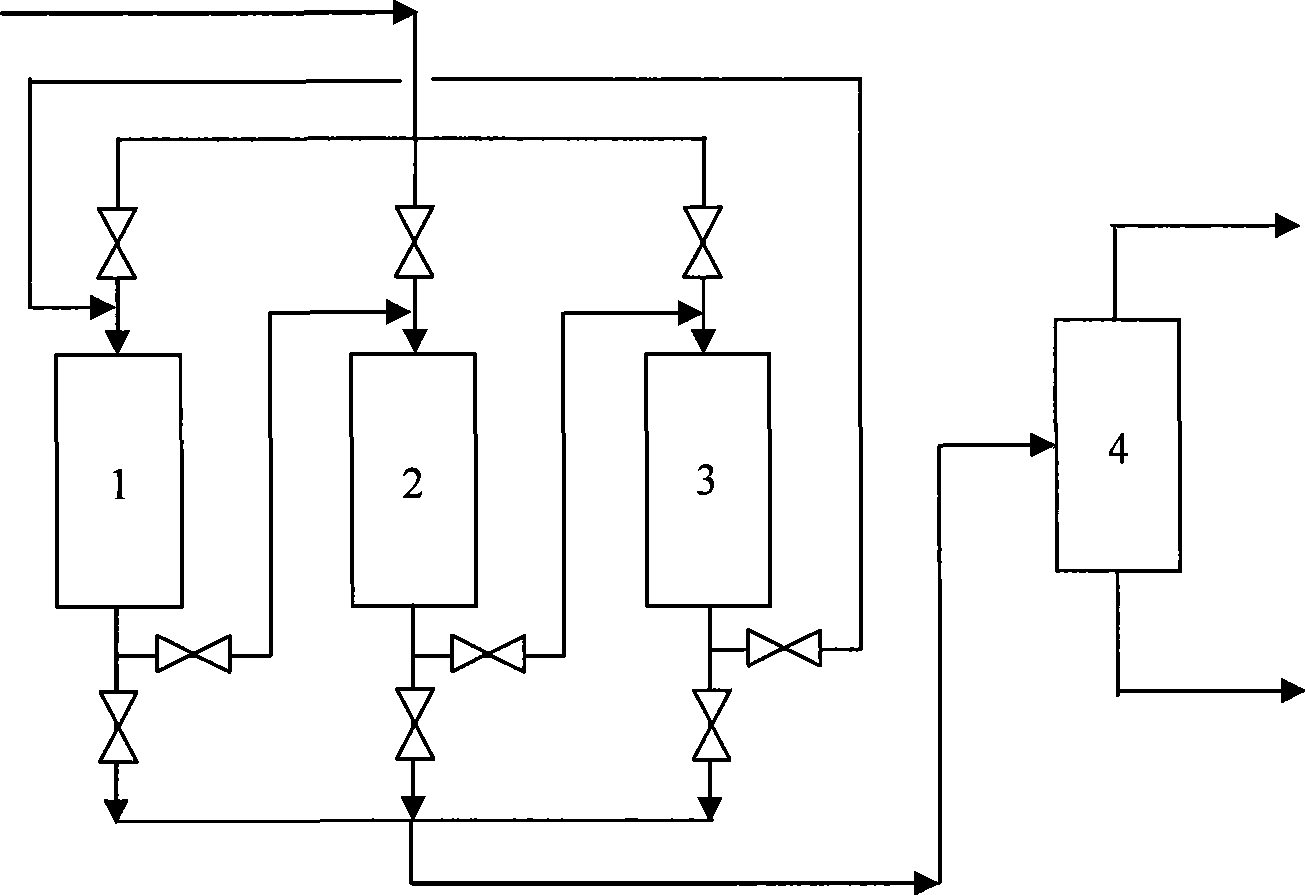

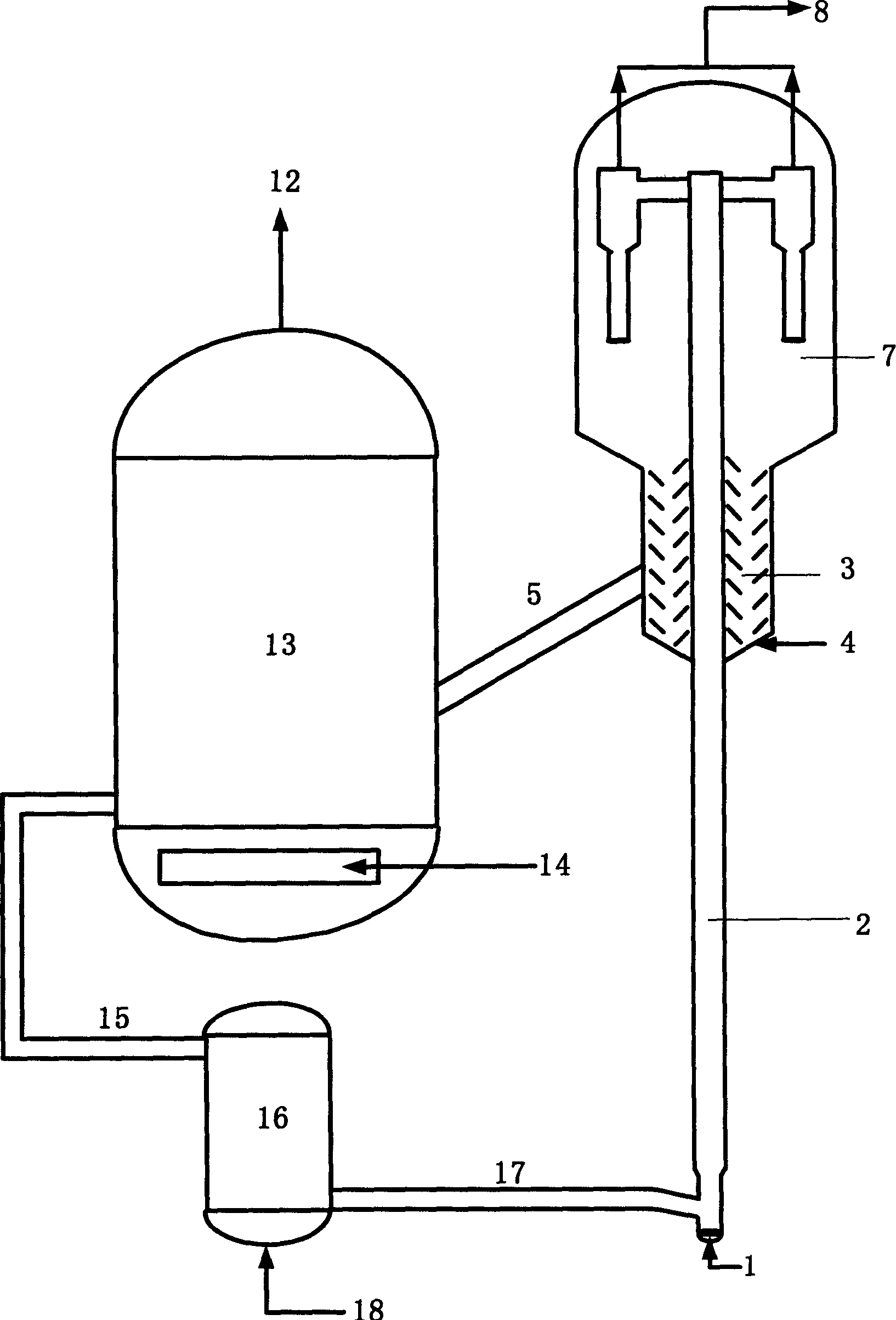

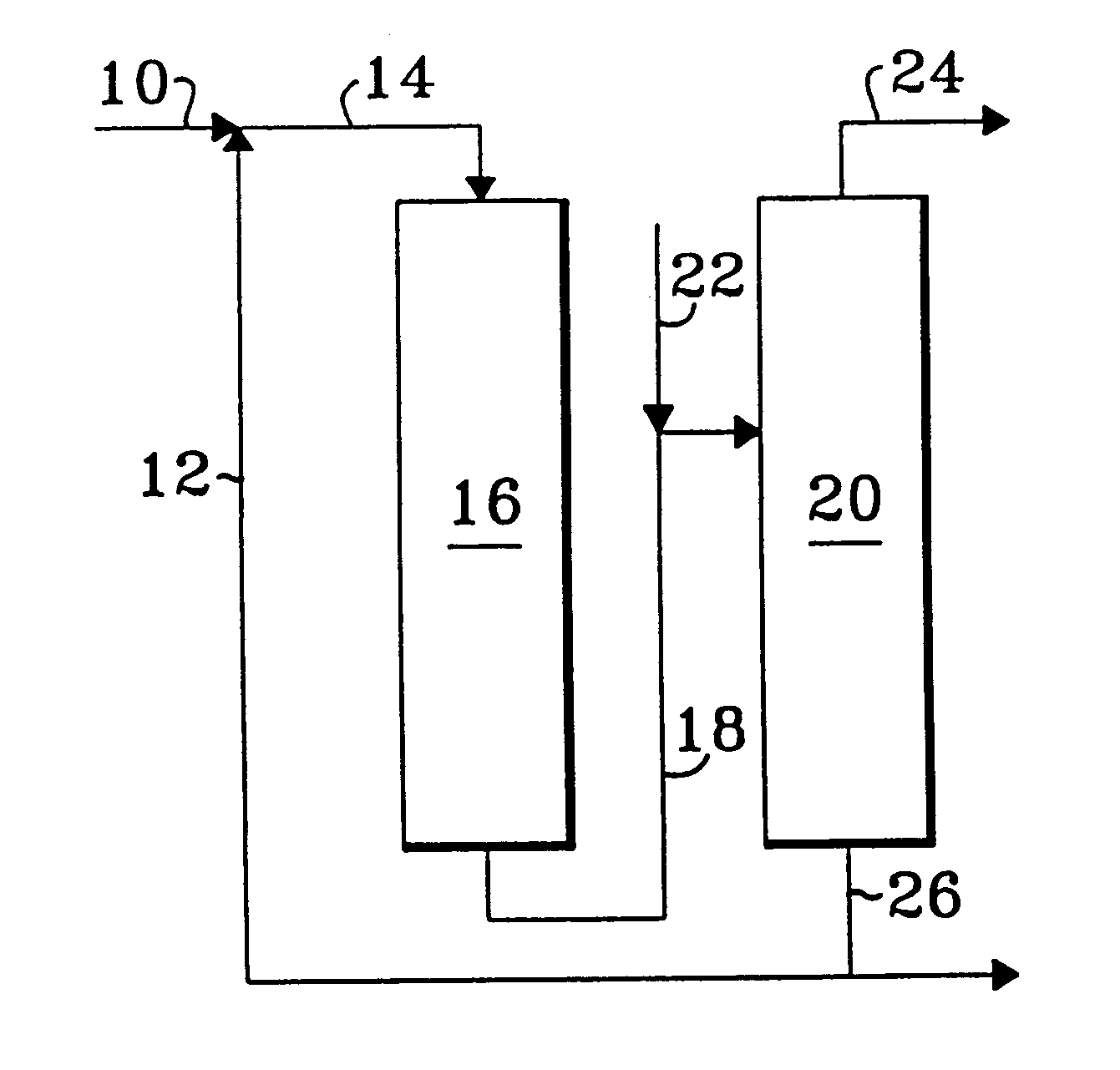

Catalytic conversion method and apparatus for upgrading poor gasoline

InactiveCN1401740AReduce olefin contentReduce sulfur contentTreatment with plural serial stages onlyCatalytic transformationFuel oil

A catalytic converting process for upgrading poor-quality gasoline with high olefine content incldues a conventional catalytic cracking step for heavy oil and a catalytic converting step for upgrading said gasoline. It is characterized by in that two steps a common catalyst regenerator and a same catalyst are used. It can decrease olefine content by 15-50 vol% and S content by 5-30% and increase RON by 0.2-2 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

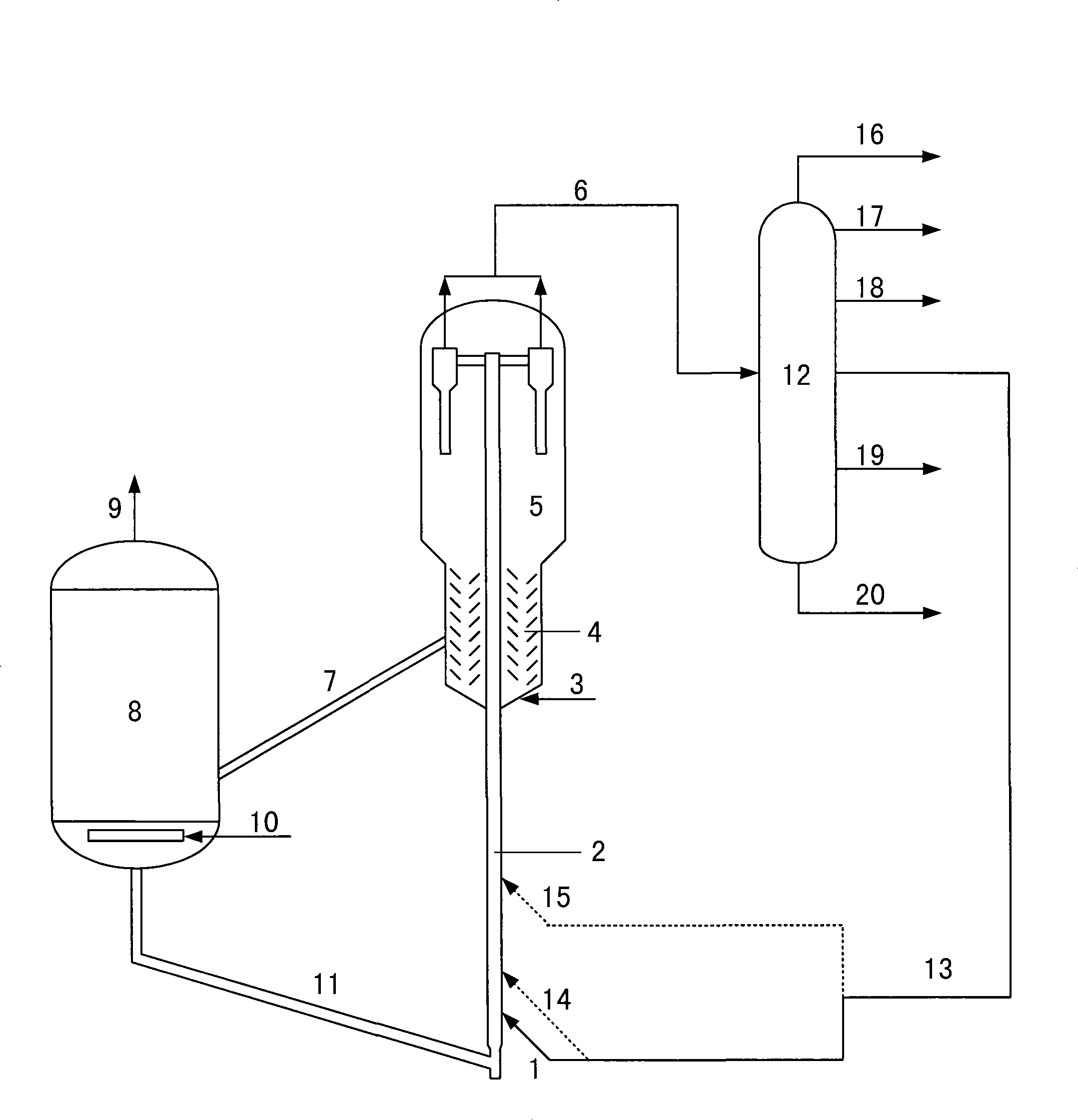

Sorbent for reducing sulfur content of light hydrocarbon oil

ActiveCN101434854AHigh desulfurization activityEvenly distributedHydrocarbon oils refiningSorbentRare earth

The invention provides a sorbent used for reducing the content of sulfur in light hydrocarbon oil. According to weight percentage, the sorbent comprises 1-30 percent of phosphorus-modified rare earth faujasite, 5-40 percent of active metal oxide and 30-94% of carrier; wherein, the carrier comprises alumina and zinc oxide; the rare earth faujasite is modified by phosphorus and is pre-formed into porous heat-resistance solid grains together with carrier mixture; subsequently, the active metal oxide is led into the solid grains, thus preparing the sorbent; the light hydrocarbon oil raw material containing the sulfur and hydrogen donor enter a reactor filled with the sorbent; the materials are separated after reaction; the reaction products are sent to a subsequent separation system so that the product is separated; the sorbent to be regenerated after reaction is stripped, burned and regenerated; and the regenerated sorbent is reduced by the hydrogen donor and subsequently returns to the reactor so as to be circularly used. The sorbent realizes that the sulfur of light hydrocarbon oil is deeply removed, and simultaneously, the octane number of the outcome gasoline is higher, while thebenzene content is lower and the strength is higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

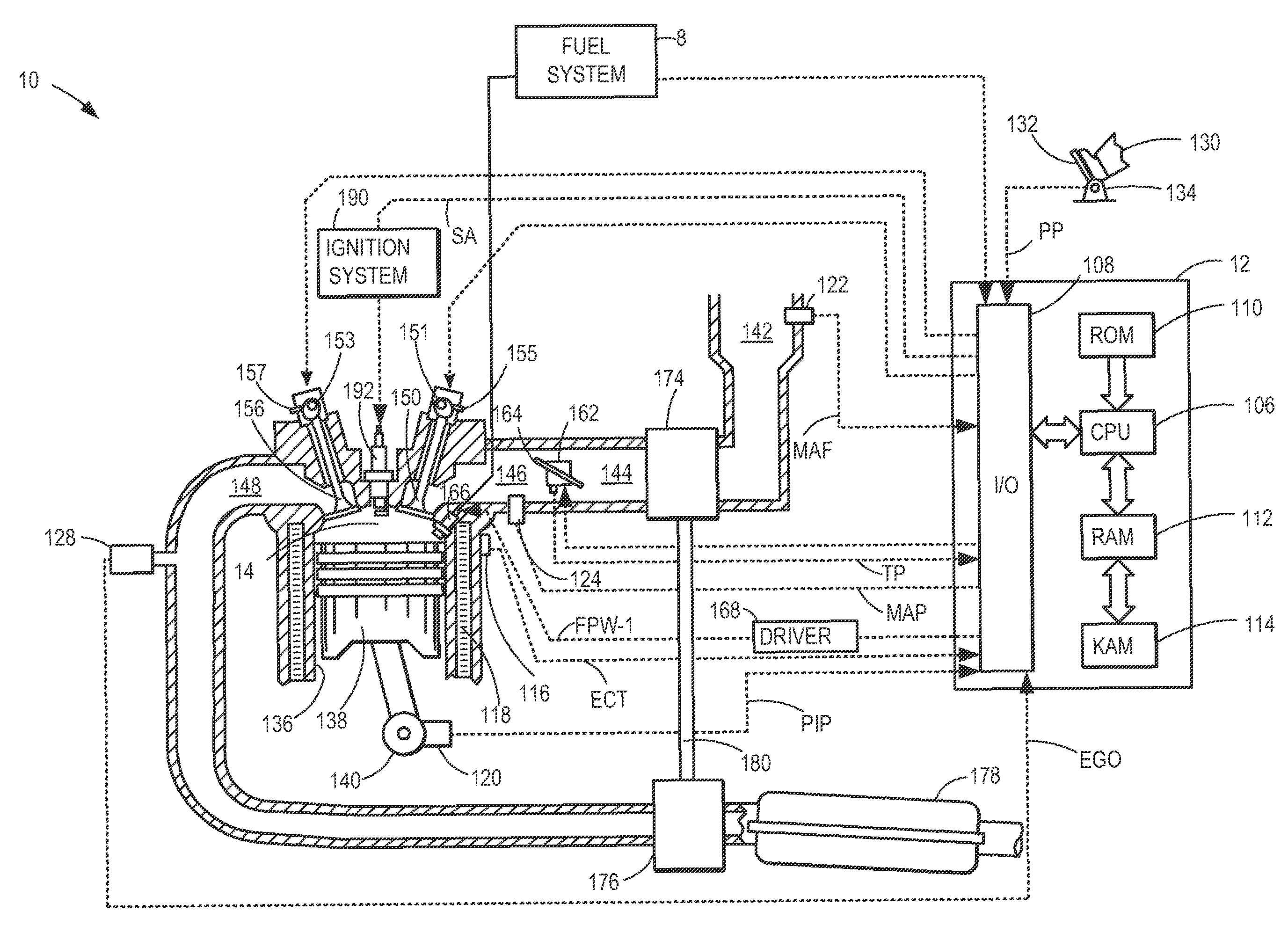

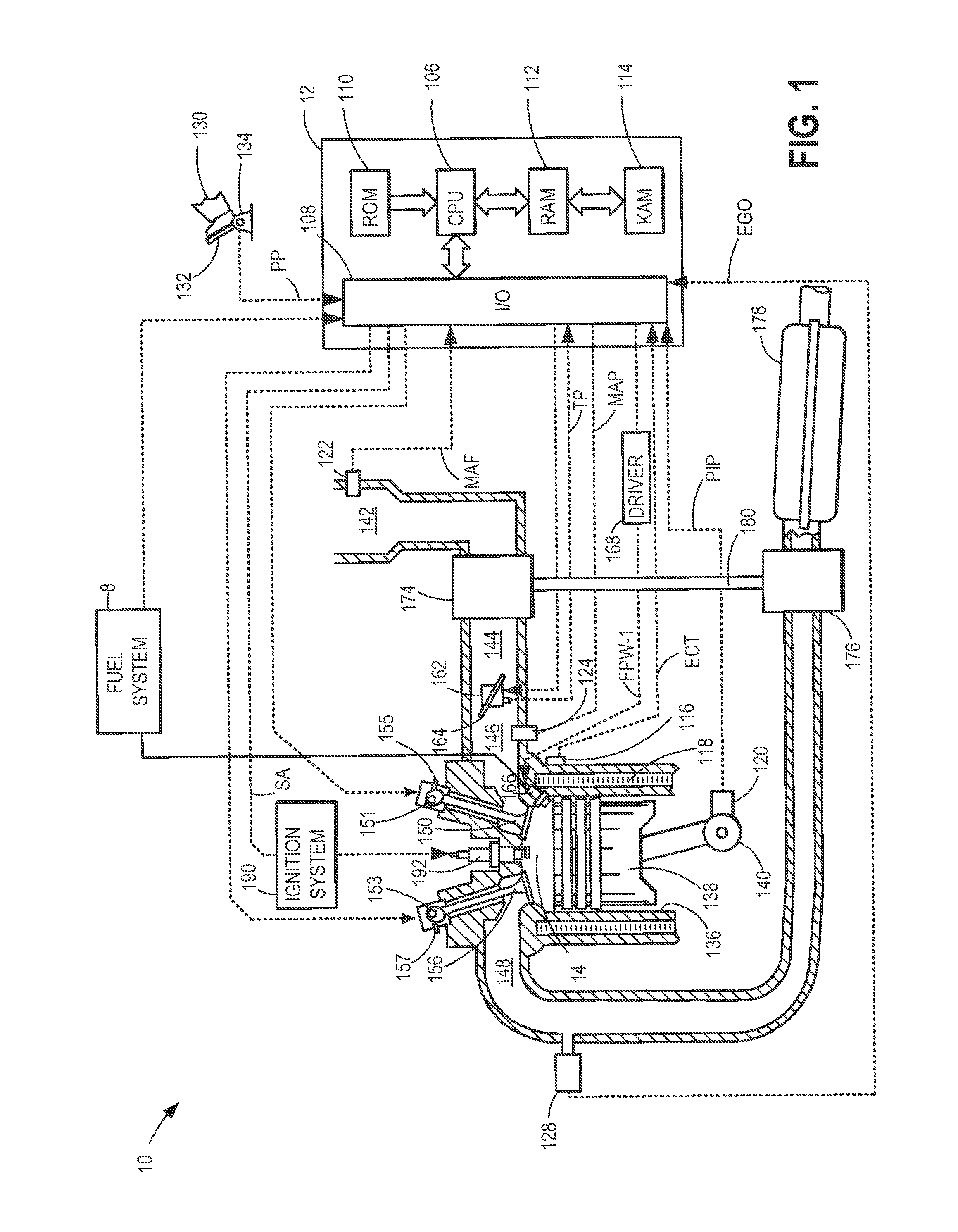

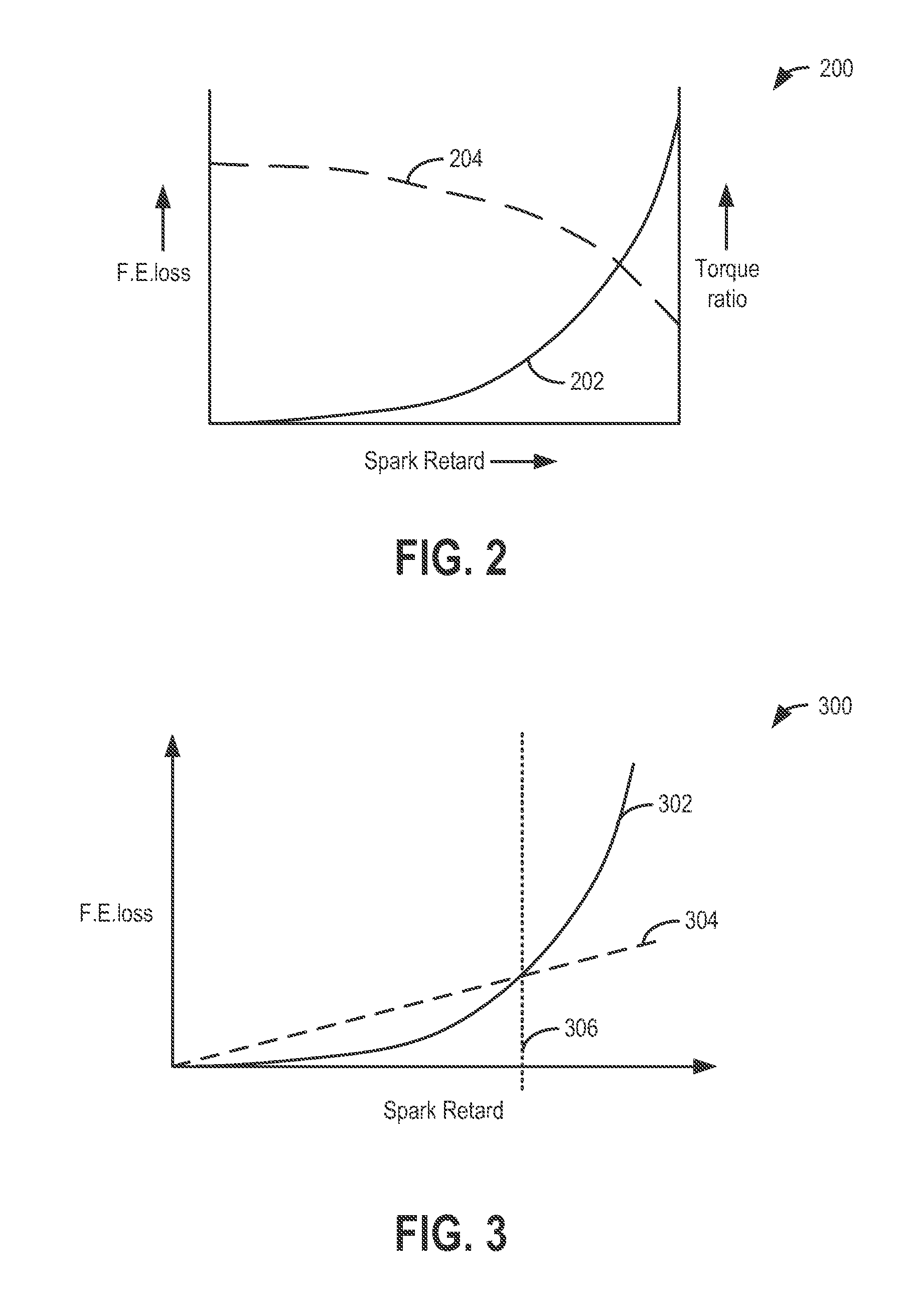

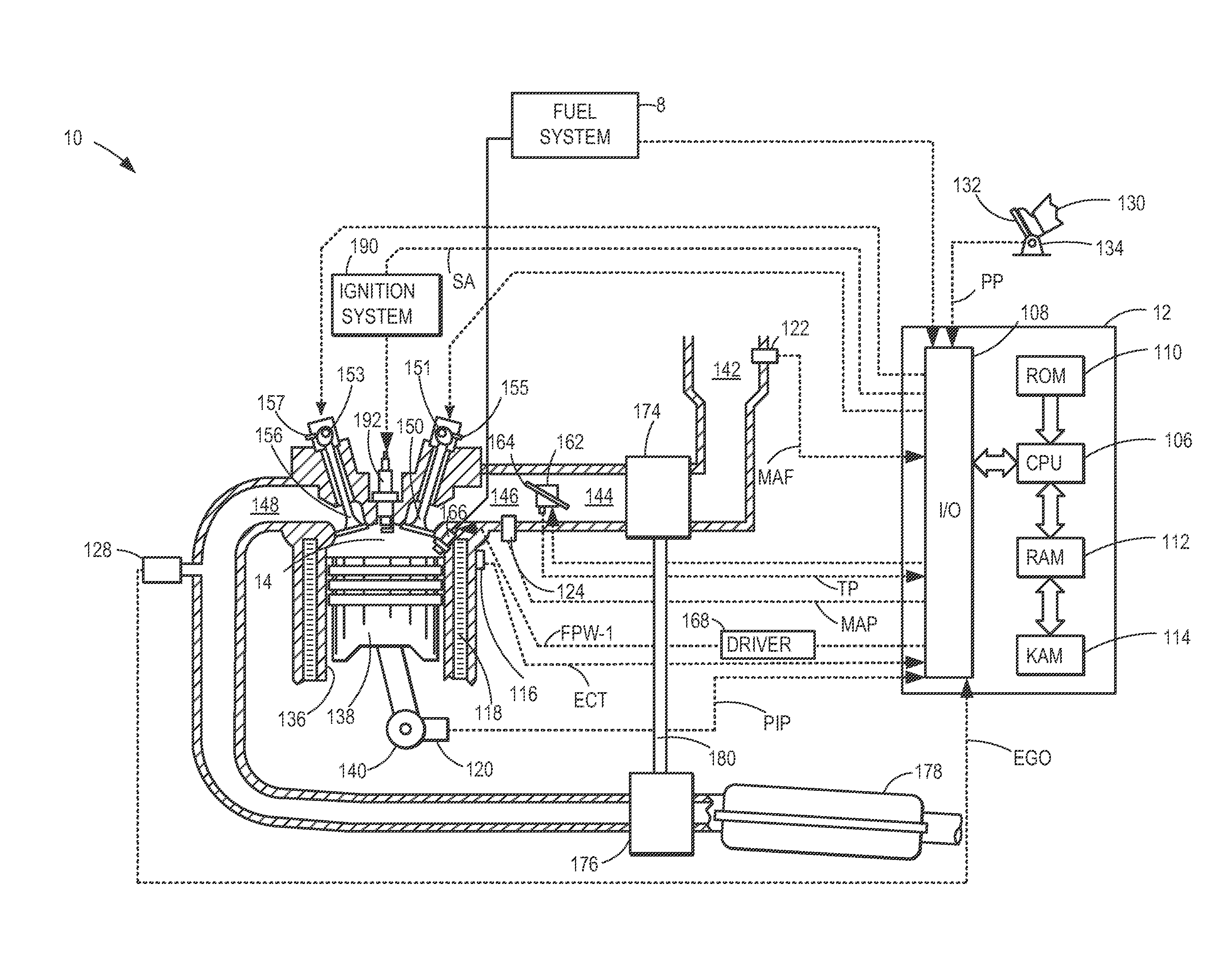

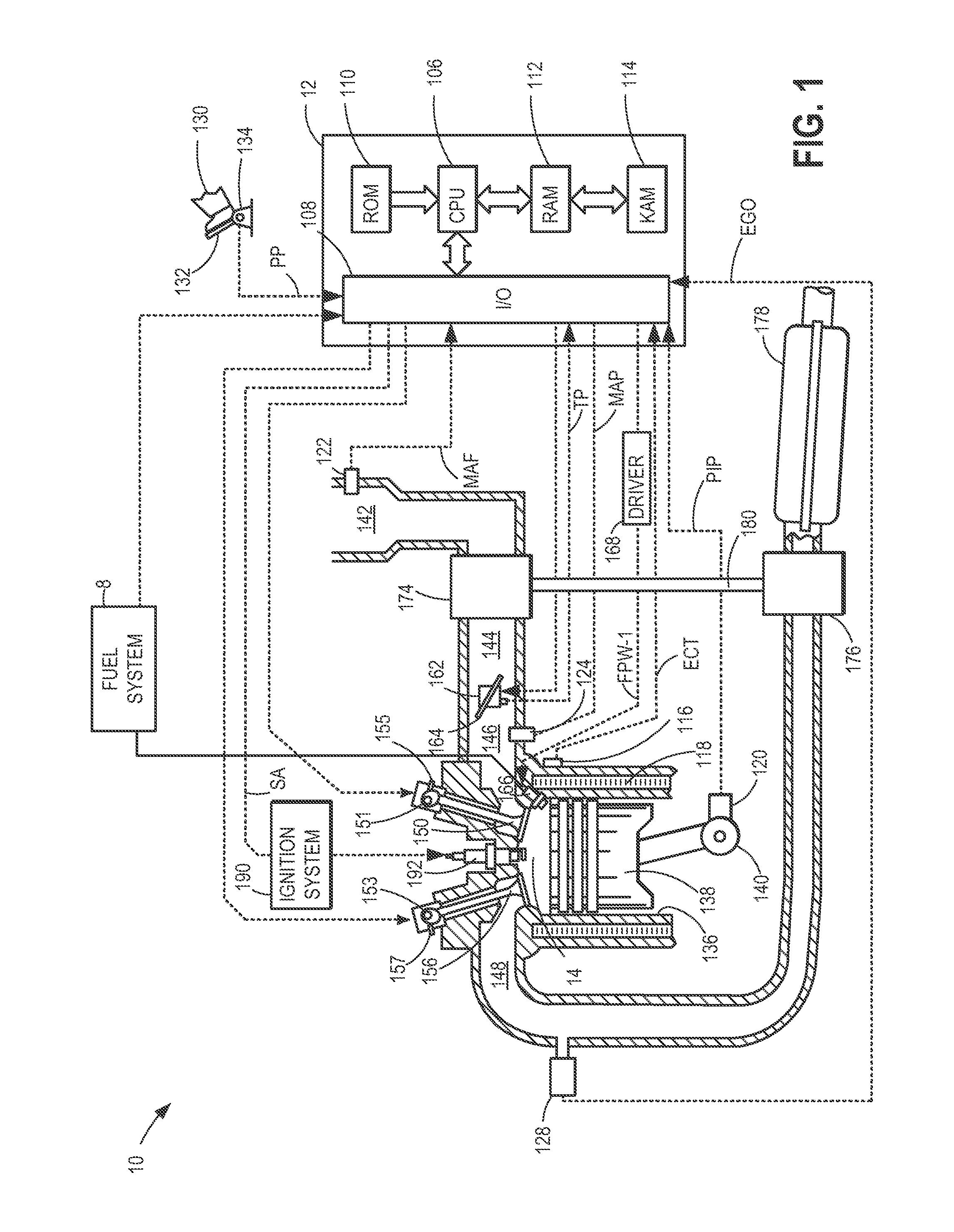

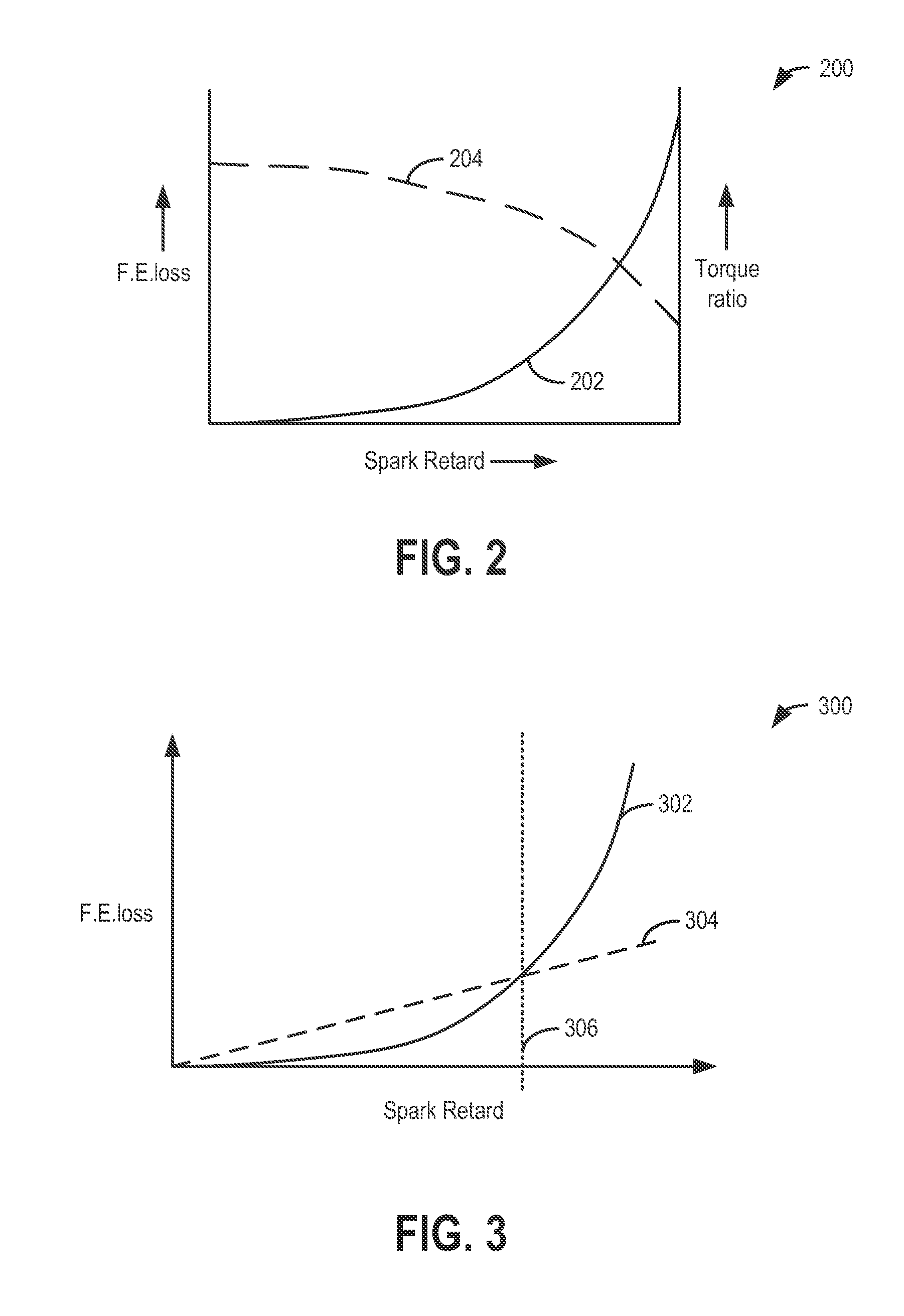

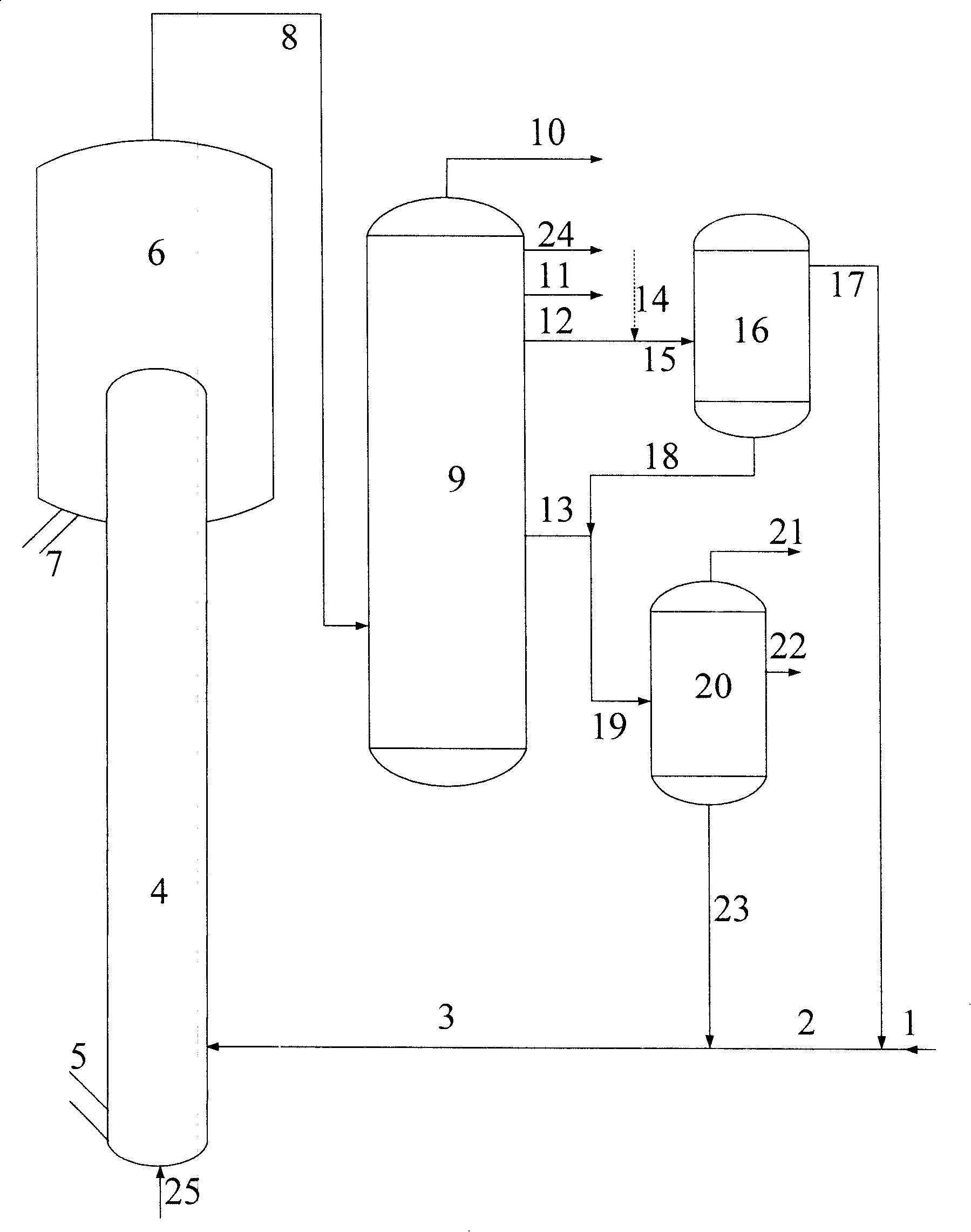

Method and system for controlling fuel usage

ActiveUS8127745B2Boost octaneVery high cooling effectValve arrangementsElectrical controlControl theoryThrottle

Methods and systems are provided for improving fuel usage while addressing knock by adjusting the use of spark retard and direct injection of a knock control fluid based on engine operating conditions and the composition of the injected fluid. One or more engine parameters, such as EGR, VCT, boost, throttle position, and CMCV, are coordinated with the direct injection to reduce torque and EGR transients.

Owner:FORD GLOBAL TECH LLC

Method and system for controlling fuel usage

ActiveUS20110174268A1Reduce exhaust emissionsHigh priceValve arrangementsElectrical controlControl theoryThrottle

Methods and systems are provided for improving fuel usage while addressing knock by adjusting the use of spark retard and direct injection of a knock control fluid based on engine operating conditions and the composition of the injected fluid. One or more engine parameters, such as EGR, VCT, boost, throttle position, and CMCV, are coordinated with the direct injection to reduce torque and EGR transients.

Owner:FORD GLOBAL TECH LLC

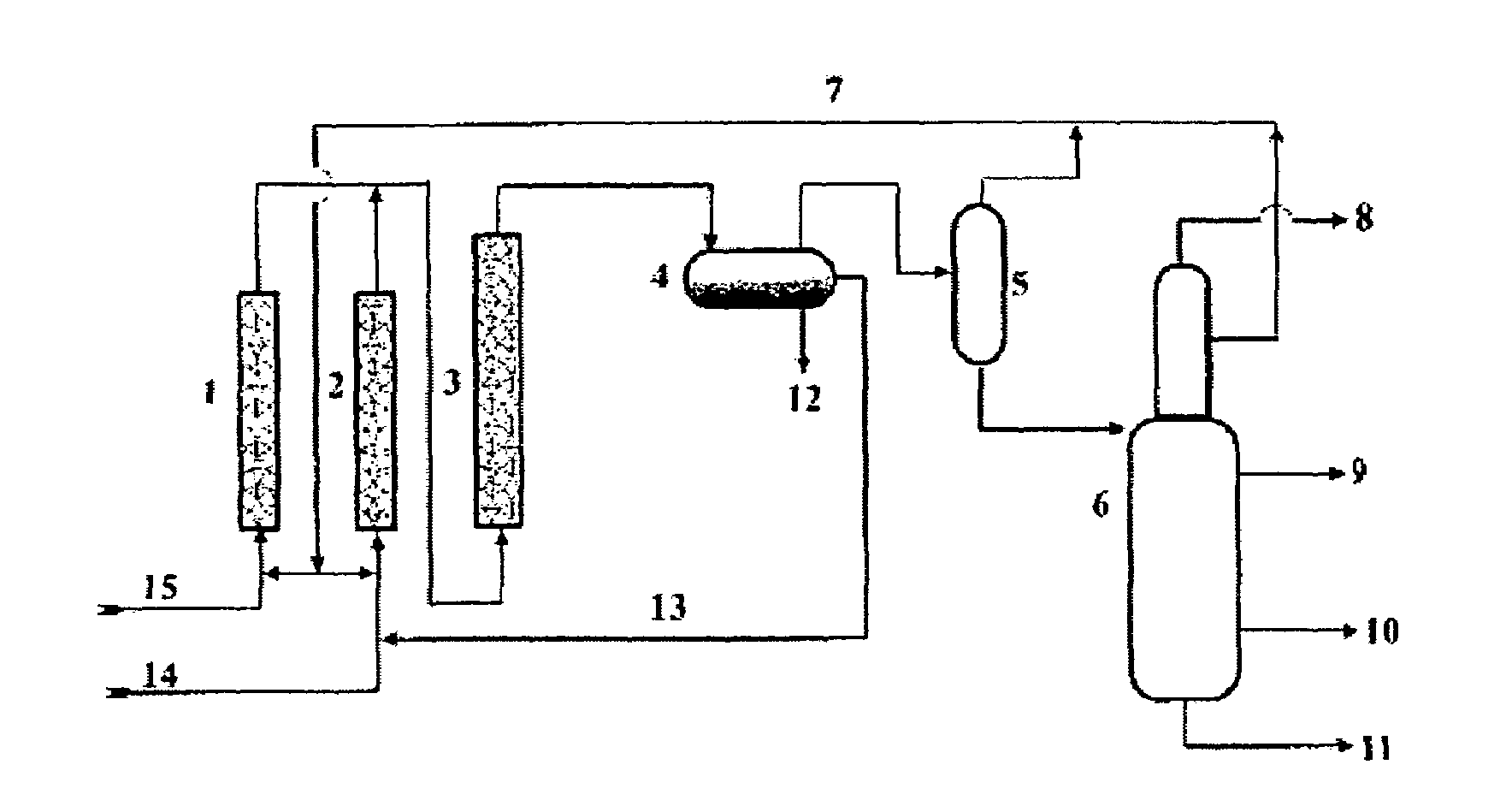

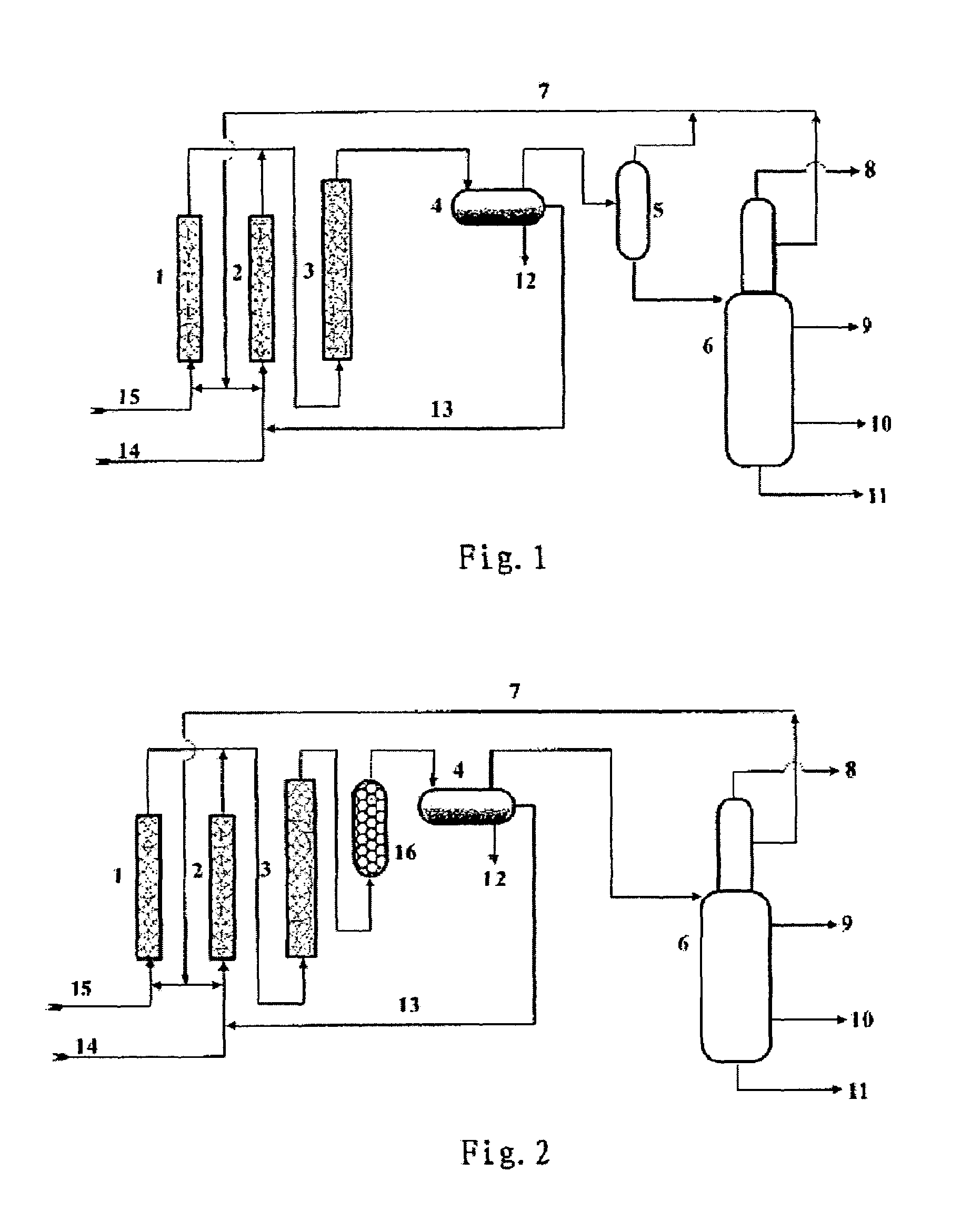

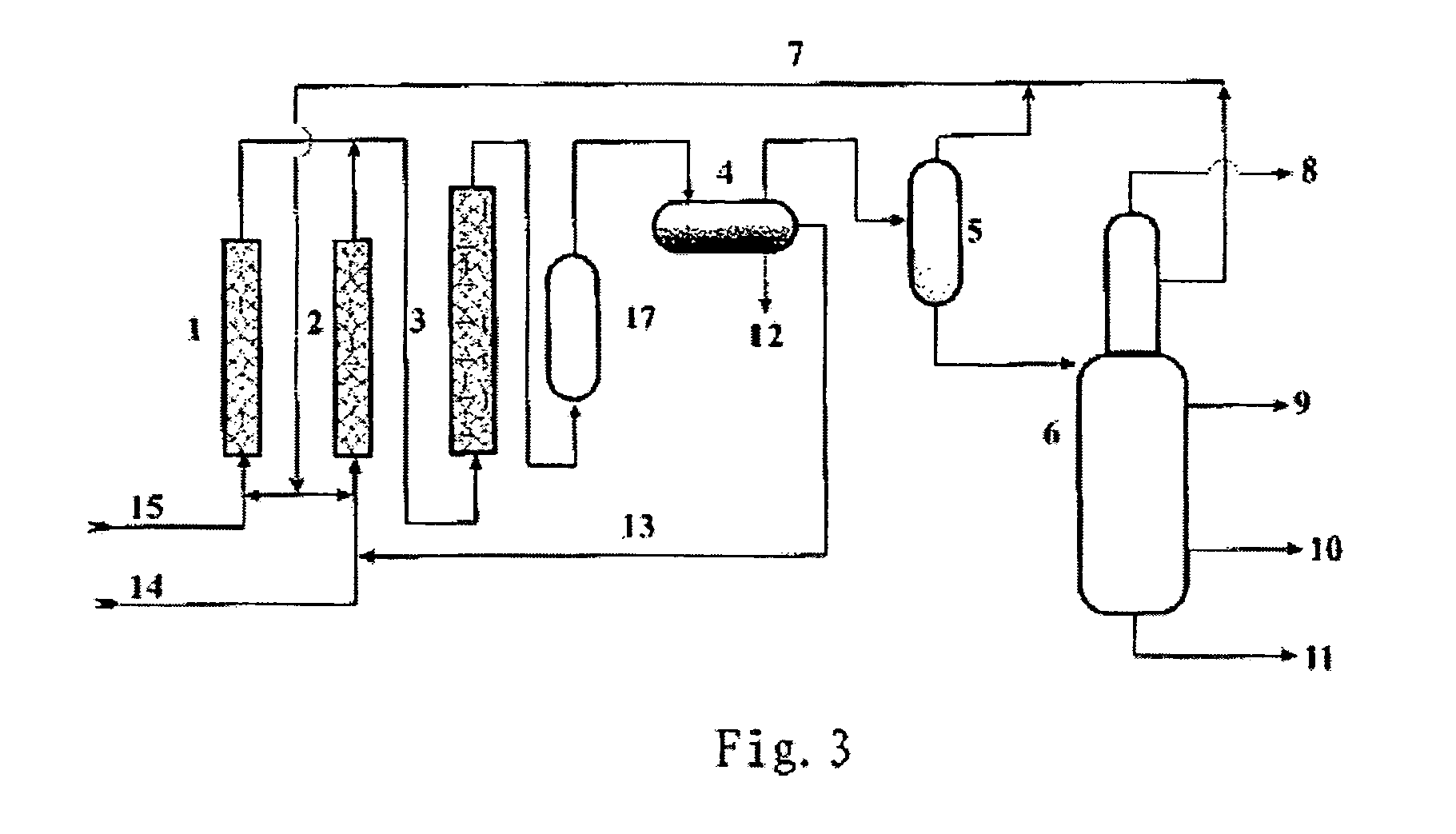

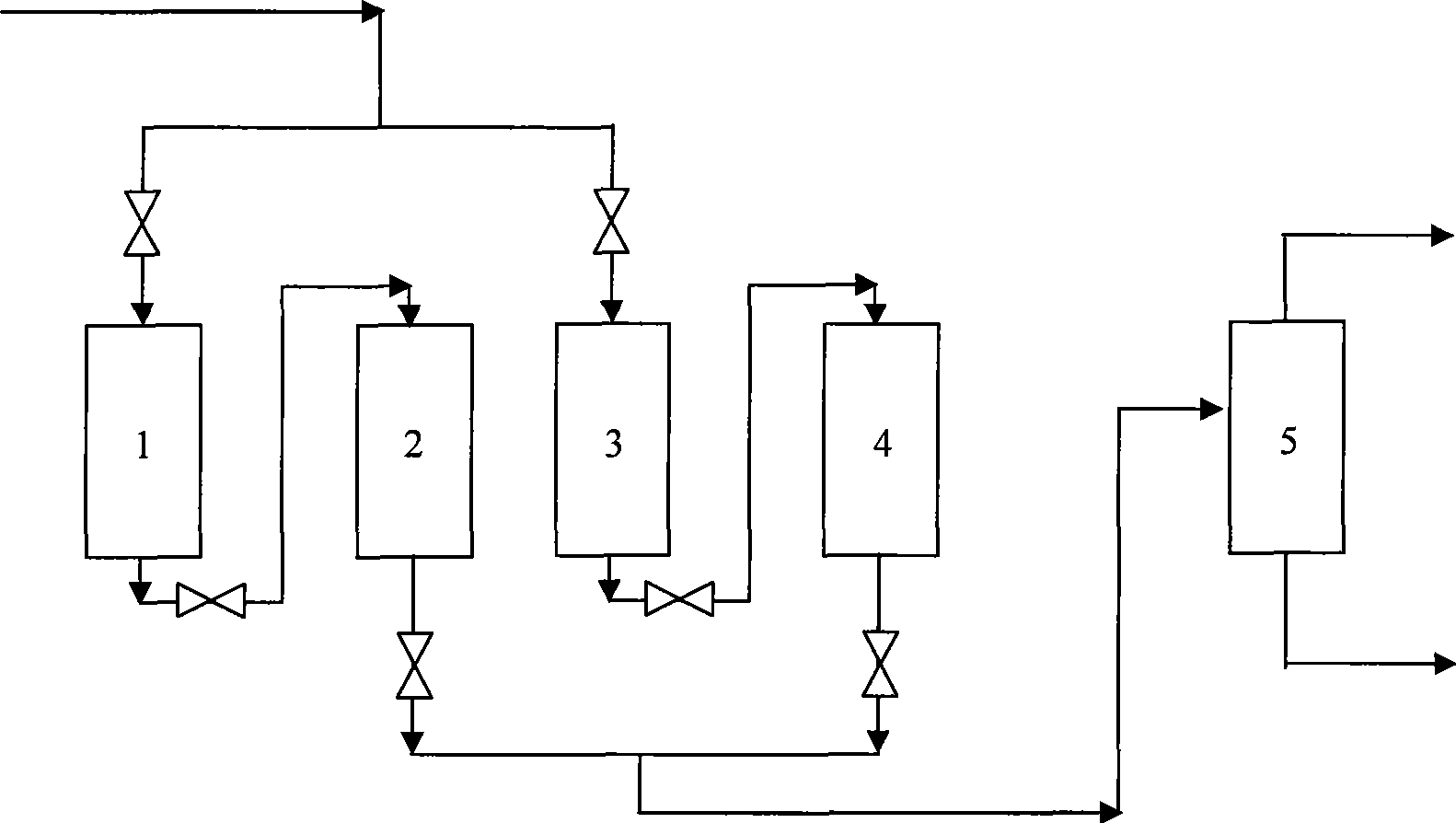

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

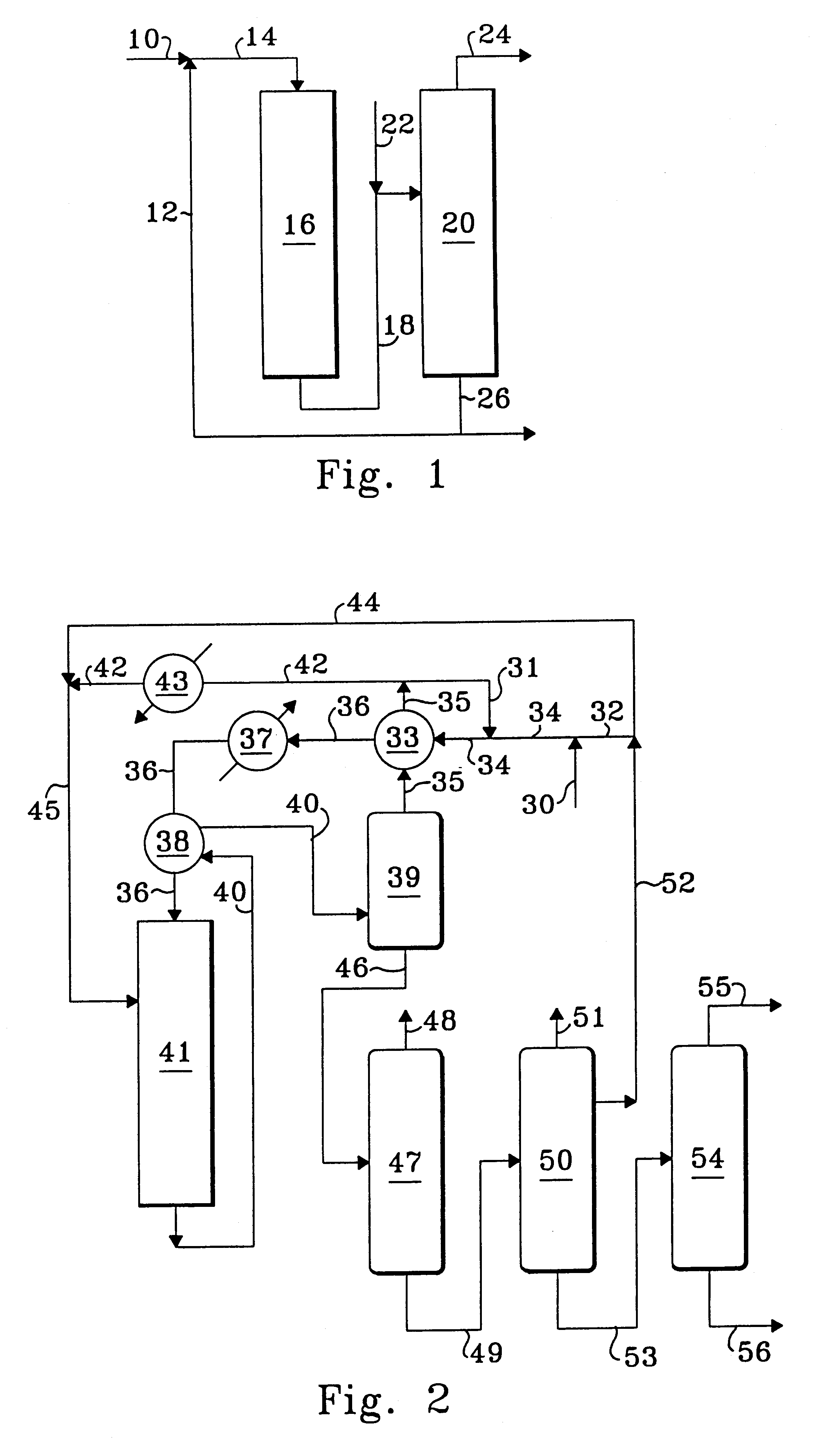

Catalytic conversion method for hydrocarbon oil raw material

ActiveCN101191081AReduce olefin contentBoost octaneTreatment with hydrotreatment processesLiquid gasRaw material

The invention discloses a catalytic conversion method for a hydrocarbon oil raw material. The hydrocarbon oil raw material contacts the catalytic cracking catalyst in a catalytic cracking reactor, the reaction oil gas and a spent catalyst are separated, then the spent catalyst is made steam stripping and regeneration and then returns to the catalytic cracking reactor for repeated use, the reaction oil gas is fractionated to obtain dry gas, liquefied gas, gasoline, light circulating oil, heavy circulating oil and heavy oil; the light circulating oil and any diesel fraction are cut into the light fraction of the light circulating oil and the heavy fraction of the light circulating oil; the heavy fraction of the light circulating oil is mixed with the heavy circulating oil and contacts the hydrogen and the hydrorefining catalyst, the reaction effluent is separated to obtain gas, naphtha and hydrogenated diesel, the hydrogen is reclaimed and then is circularly used; the light fraction of the light circulating oil independently or the light fraction of the light circulating oil along with the hydrogenated diesel returns to the catalytic cracking reactor. The method converts the catalytic cracking circulating oil into the gasoline with low olefin content and high octane value, and improves the yield of the gasoline and the yield of the propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-octane petrol

ActiveCN101469274AIncrease gasoline yield and octane ratingAvoid excessive loss of olefinsCatalytic crackingGasoline stabilisationTransalkylationDistillation

The invention relates to a method for producing high-octane petrol, which comprises the following steps: introducing raw oil into a catalytic cracking reactor to be contacted with a catalyst and react under the catalytic cracking reaction condition; separating the reaction oil gas and the catalyst to be generated which is reclaimed after steam stripping and regeneration; introducing the reaction oil gas into a subsequent fractionation part; and separating out heavy petrol and light diesel fuel fractions with the distillation range of between 100 and 300 DEG C by the fractionation part, and pouring the fractions with or without hydrogenation into the catalytic cracking reactor for freshening. By adopting the method, a common catalytic cracking unit and a common catalyst can be used, the prior device is unnecessary to be changed significantly, and the heavy petrol and the light diesel fuel fractions are introduced back into the catalytic cracking reactor respectively for freshening with major reactions of chain scission reaction of arene lateral chains and transalkylation reaction so as to improve the petrol yield and the octane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

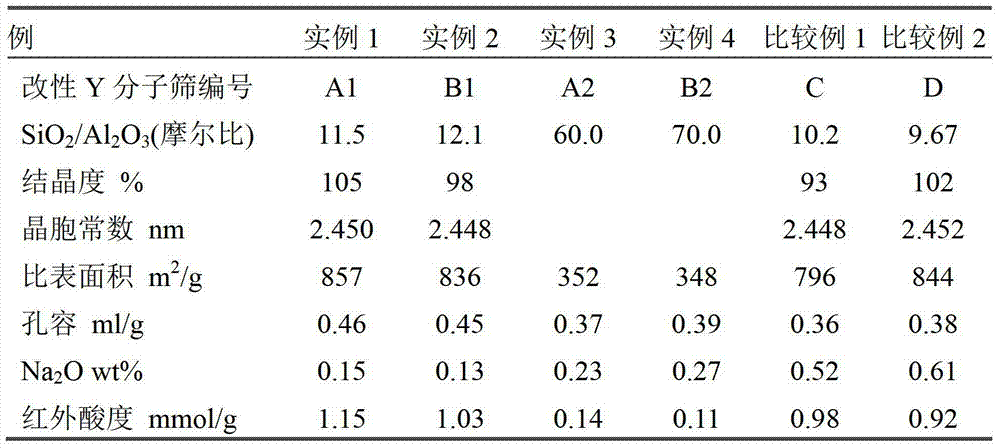

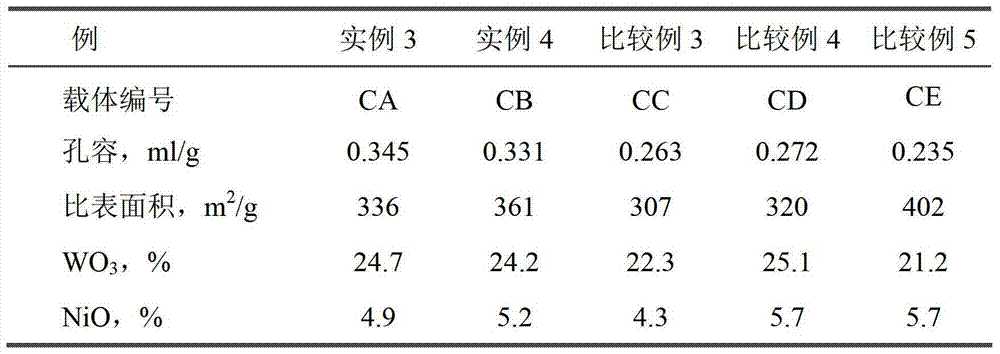

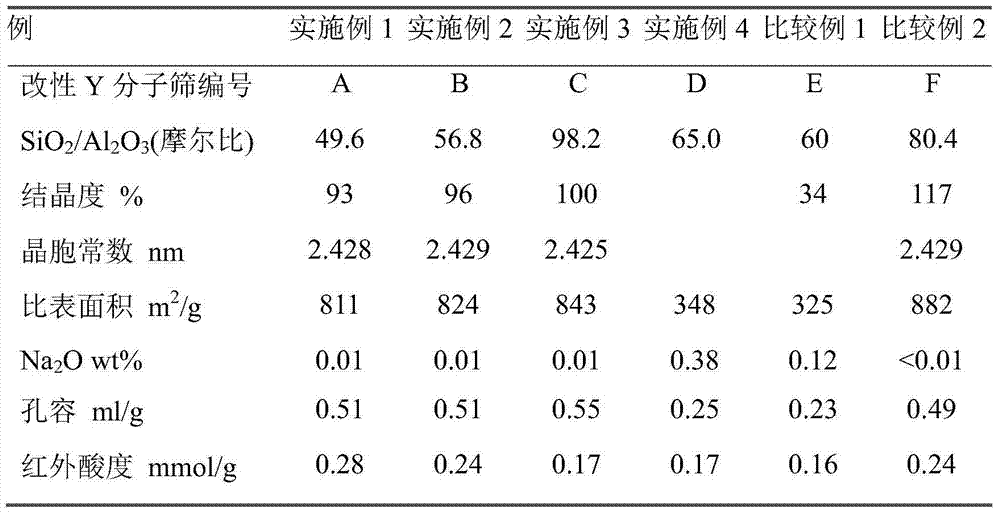

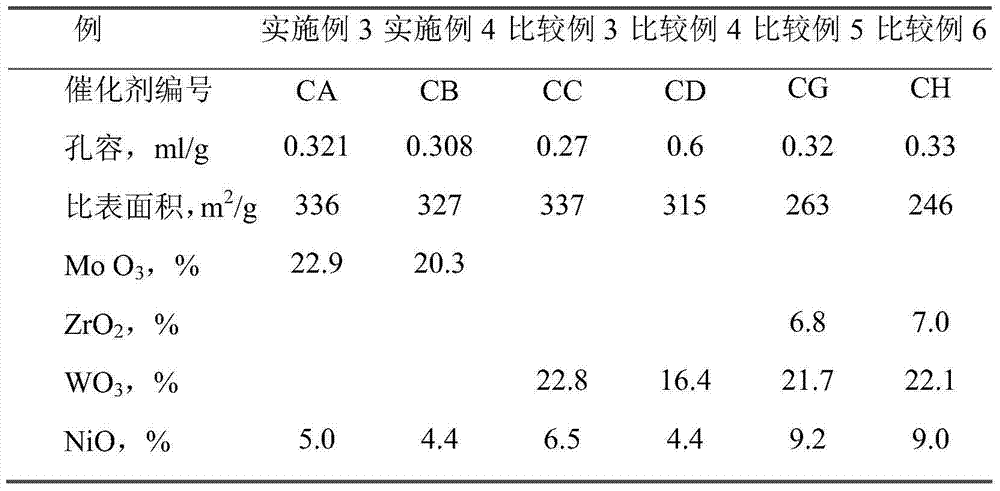

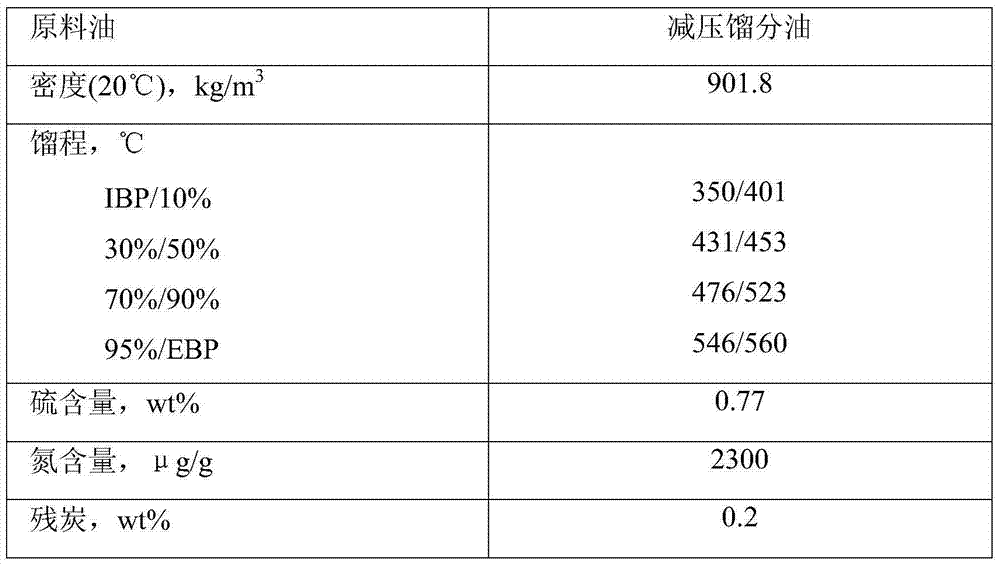

Light oil type hydrocracking catalyst with composite molecular sieve as well as preparation method and application thereof

ActiveCN103394368BGood catalytic cracking performanceGood catalyticMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a light oil type hydrocracking catalyst with a composite molecular sieve. The hydrocracking catalyst comprises the composite molecular sieve consisting of a modified Y-molecular sieve and a modified ZSM-23 molecular sieve, a carrier composed of micropore aluminum oxides, and a hydrogenation activity component composed of a VIB group metal and a VIII group metal. The hydrocracking catalyst is characterized in that the composite molecular sieve comprises the modified Y-molecular sieve and the modified ZSM-23 molecular sieve, and the Y-molecular sieve is modified and dealuminized, so that heat stability and hydrothermal stability are stably enhanced, the hydrophobicity is enhanced, the absorption and desorption properties of the molecular sieve are improved, and the catalyst achieves a high catalytic cracking property. The pore passages of the modified SM-23 molecular sieve are unobstructed, the number of the acid sites is small, the isomerism property is outstanding, and the octane value of the molecular sieve is increased because of light naphtha components. The modified Y-molecular sieve and the modified ZSM-23 molecular sieve are mixed and used according to a formula ratio of the hydrocracking catalyst, so that both the cracking activity and the isomerism property are considered, and the final catalyst achieves an ideal catalytic effect.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Composite molecular sieve-containing medium oil type hydrocracking catalyst, preparation method and application thereof

ActiveCN103551186BHigh crystallinityIncrease surface areaMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention relates to a composite molecular sieve-containing medium oil type hydrocracking catalyst, which comprises an active component and a binder, wherein the active component adopts amorphous SiO2-Al2O3 as a carrier, adopts a composite molecular sieve as an acid component, and adopts a group VIB metal and a group VIII metal as hydrogenation activity components, and the composite molecular sieve comprises a Y molecular sieve and a ZSM-23 molecular sieve. According to the present invention, the deep dealuminzation modified Y molecular sieve has characteristics of high crystallinity, large surface area, high silica-alumina ratio, low cell constant, rich secondary pore, low acid center density, high moderate-intensity acid center ratio, and the like; the modified ZSM-23 molecular sieve has characteristics of smooth pore channel, less acid center and outstanding isomerism performance, wherein a light naphtha component is isomerized so as to increase an octane number of naphtha; the composite molecular sieve compounded from the Y molecular sieve and the ZSM-23 molecular sieve is adopted as the acid cracking component so as to provide advantages of the Y molecular sieve and the ZSM-23 molecular sieve, and compounding is performed according to the ratio of the present invention, such that the best catalysis effect can be obtained, and the obtained catalyst is suitable for the medium oil type hydrocracking catalyst; and the catalyst prepared from the composite molecular sieve has characteristics of excellent medium oil selectivity, good activity and good stability.

Owner:CHINA NAT OFFSHORE OIL CORP +3

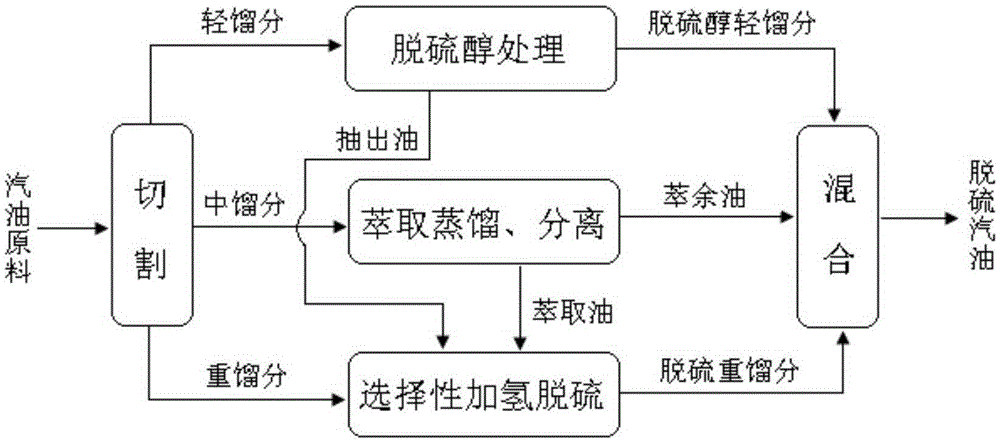

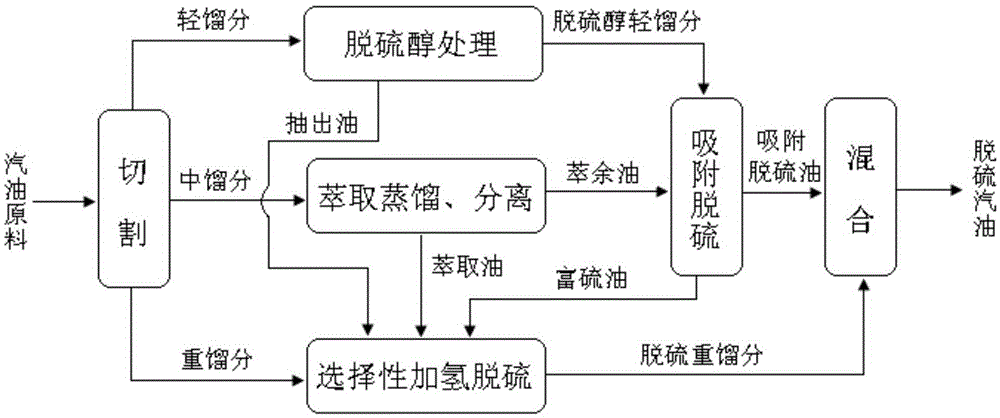

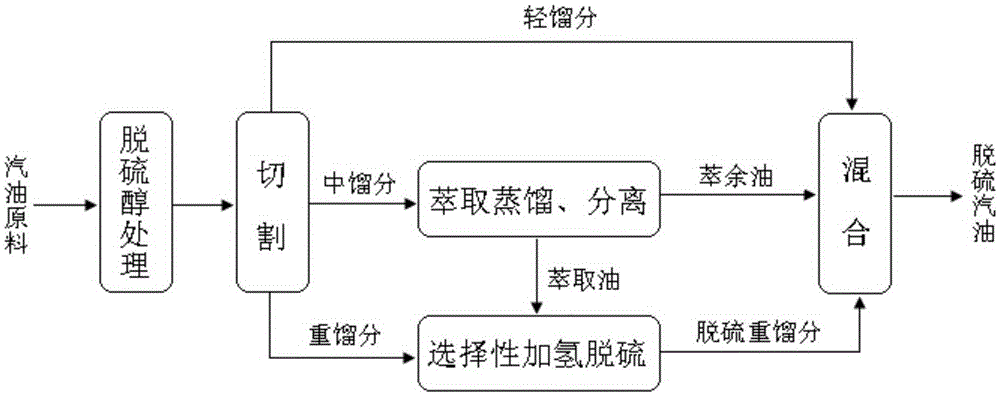

Coupling method of catalytic cracking gasoline desulfurization

ActiveCN105296000AEasy to removeRemoval is not easy to achieveTreatment with hydrotreatment processesOrganic solventExtractive distillation

The invention provides a coupling method of catalytic cracking gasoline desulfurization. The coupling method comprises the following steps: cutting gasoline raw materials into light fractions, medium fractions and heavy fractions; carrying out extractive distillation on the medium fractions by an organic solvent to obtain olefin-contained raffinate and extracts which contain sulfide and arene; separating the organic solvent in the extracts to obtain extraction oil; carrying out selective hydrodesulfurization on the extraction oil and the heavy fractions to obtain the desulfurization heavy fractions; mixing the light fractions, the raffinate and the desulfurization heavy fractions to obtain desulfurization gasoline, wherein the cutting temperature of the light fractions and the medium fractions is 35 to 60DEG C, and the cutting temperature of the medium fractions and the heavy fractions is 140 to 160DEG C. According to the coupling method of the gasoline desulfurization, the octane value loss of a gasoline product can be obviously reduced, and desulfurization load is drastically lowered while deep desulfurization is realized. The yield of the product is greater than 95%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Utilization method of catalytic cracking diesel

ActiveCN101760239AHigh aromatic contentBoost octaneTreatment with hydrotreatment processesBoiling pointAromatic hydrocarbon

The invention relates to a utilization method of catalytic cracking diesel, wherein the method comprises the following steps: (1) separating the catalytic cracking diesel into a component with the boiling point being less than 230 DEG C and a component with the boiling point being more than 230 DEG C; (2) hydrogenering for the component with the boiling point being more than 230 DEG C obtained inthe step (1) under the condition that poly-aromatic hydrocarbon is inverted into monocyclic aromatic hydrocarbon; (3) separating the component with the boiling point being less than 230 DEG C obtained in the step (1) and hydrogenation product obtained in the step (2) to obtain diesel rich in the monocyclic aromatic hydrocarbon, and catalytically cracking the diesel rich in the monocyclic aromatichydrocarbon. In the method, firstly, the catalytic cracking diesel is separated into the component with the boiling point being less than 230 DEG C and the component with the boiling point being morethan 230 DEG C, and then the poly-aromatic hydrocarbon in the component with the boiling point being more than 230 DEG C can be hydro-fined into the monocyclic aromatic hydrocarbon, therefore, the hydrogenation selectivity can be improved, and the FCC gasoline with high content of aromatic hydrocarbon and high octane number can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

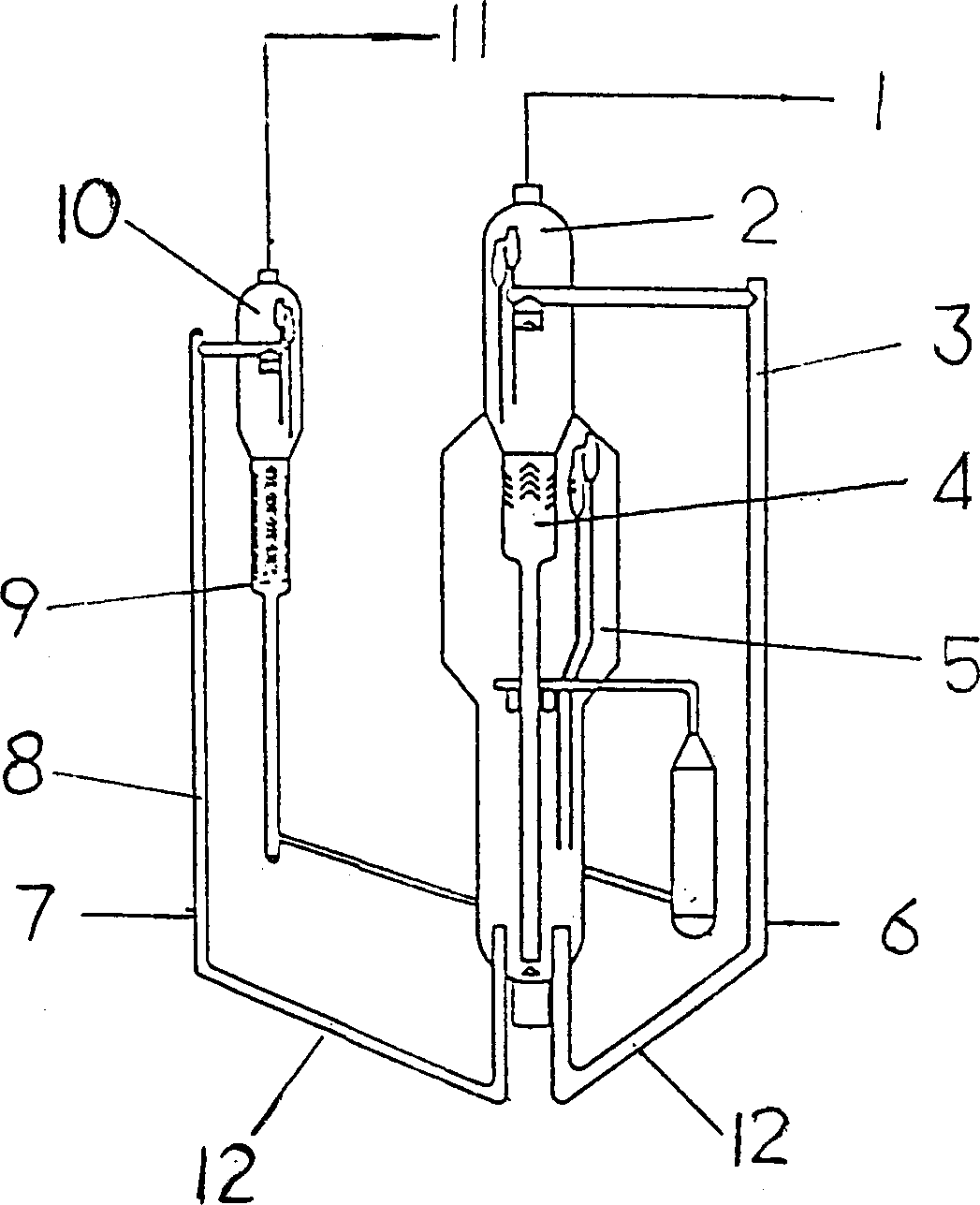

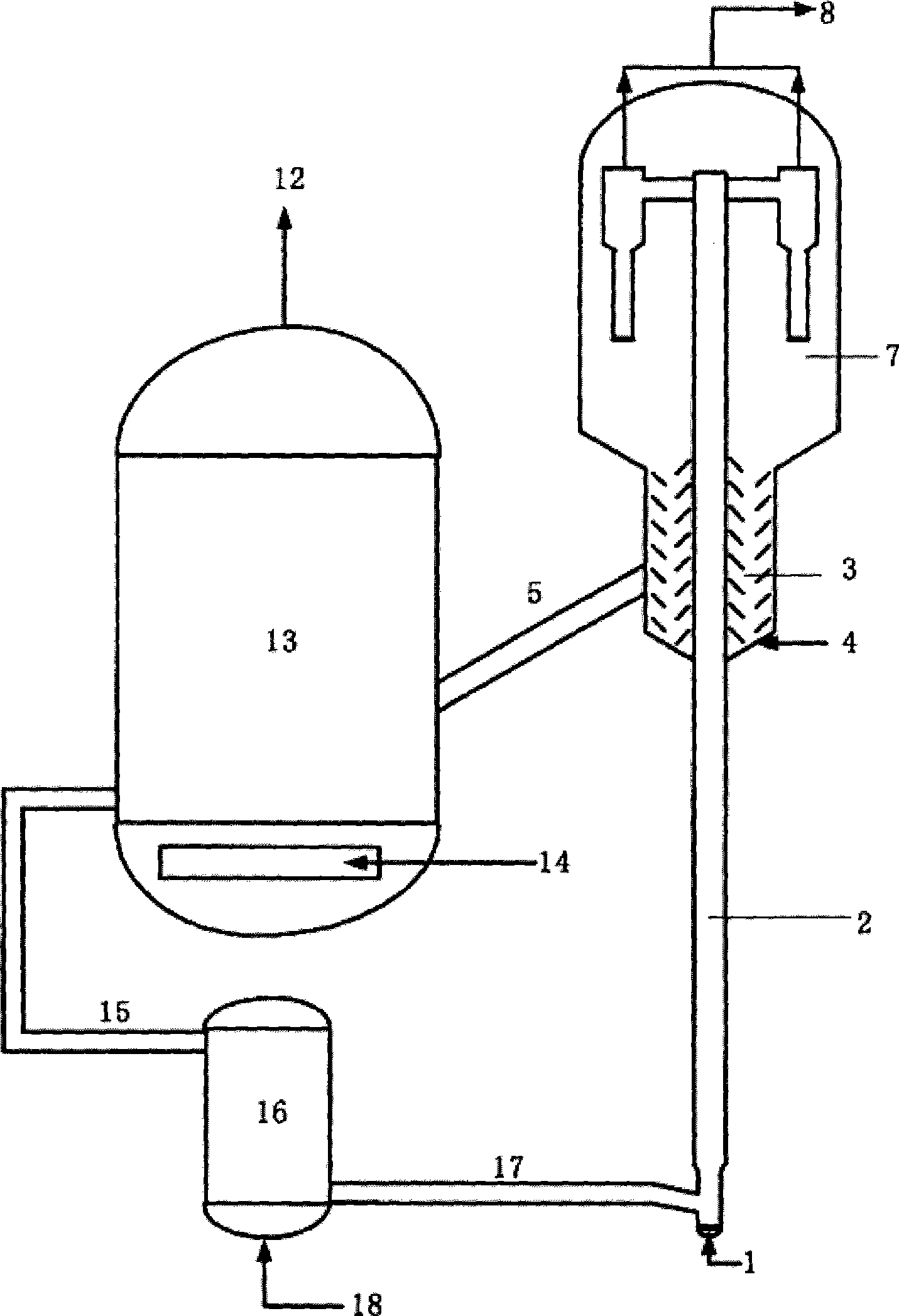

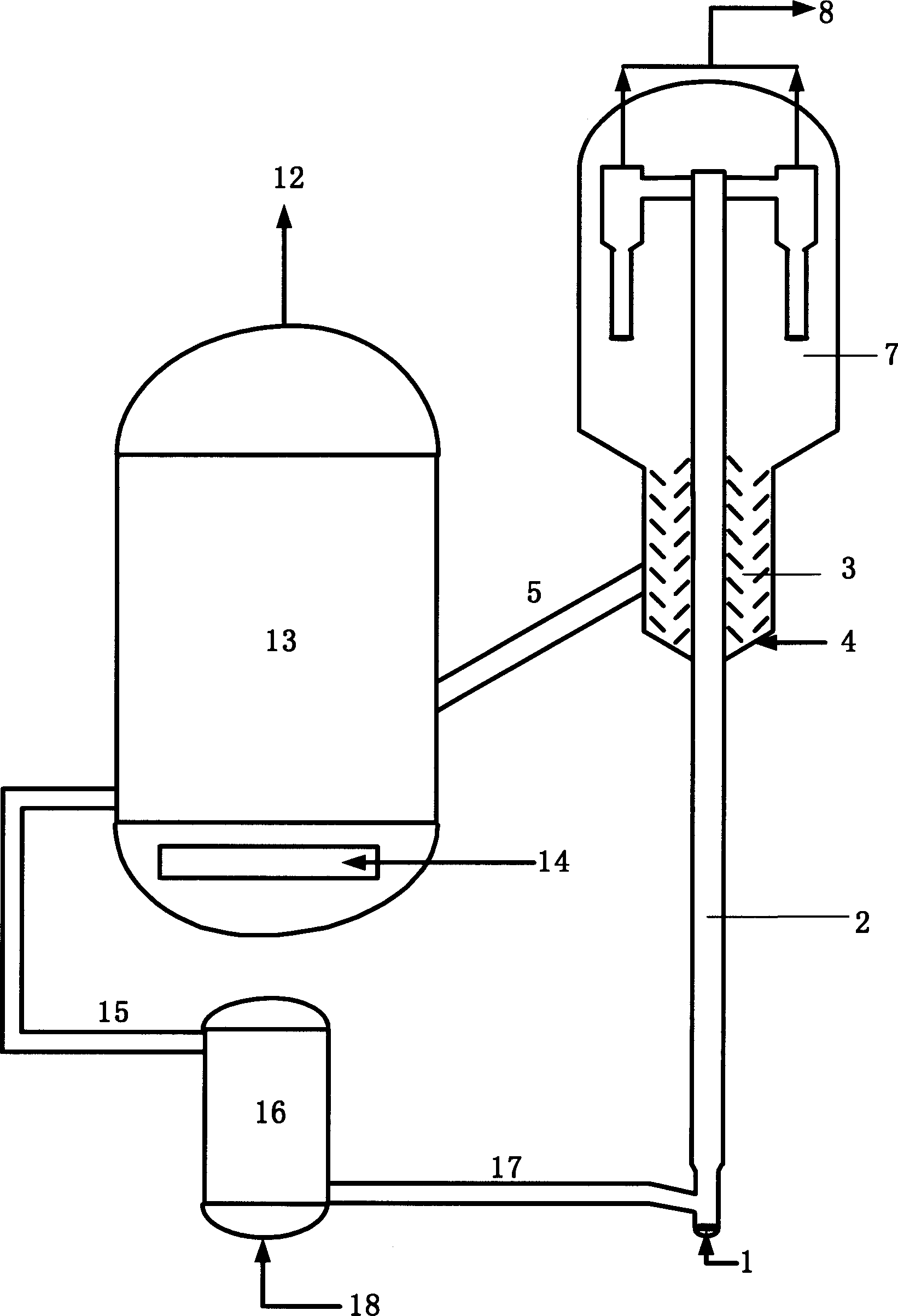

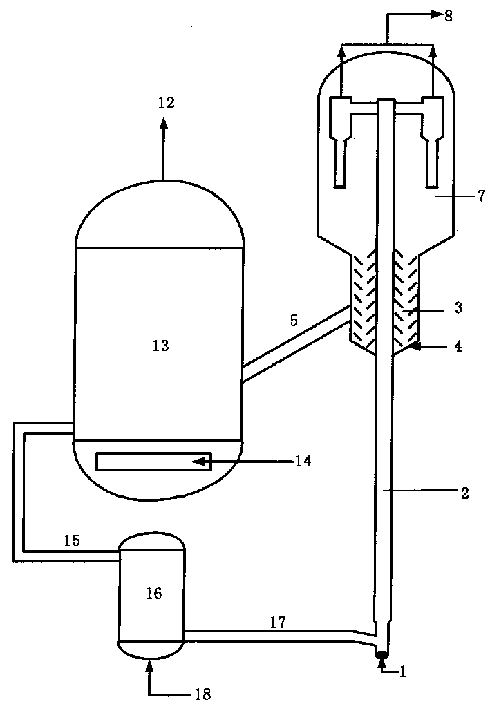

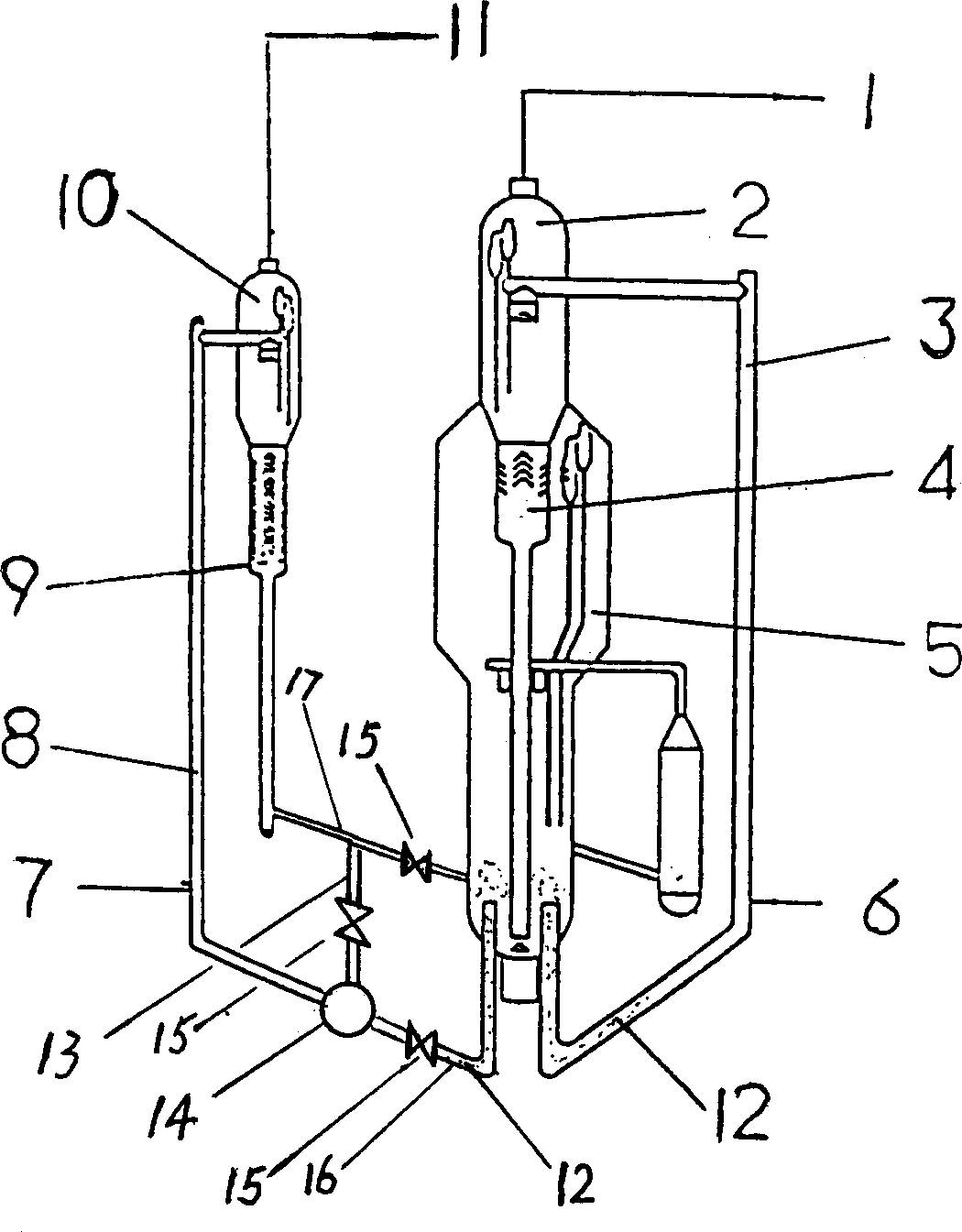

Method for decreasing sulfur content of hydrocarbon

ActiveCN1583972ABoost octaneSave construction investmentTreatment with plural serial refining stagesChemistryPetroleum

A method to reduce sulfur in hydrocarbon oil is that put the petroleum hydrocarbon and desulfuration agent into the fluid bed reactor and react with the fluid medium under following conditions: reaction temperature is 150-150 deg.C, heavy hourly space velocity is 0.1-60 per hour, the weight proportion of the desulfuration aget and cut fraction of gasoline is 3-40, and the reactive pressure is 130-1450 Kpa. The separate the production and desulfuration agent and transfer the production into downstream separation system. Moreover, transfer the desulfuration agent with carbon into regeneration equipment to regenerate after stripping and the regeneration temperature should be lower than 700 deg.C. Additionally, the desulfuration agent can be reused after being cooled down.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-octane gasoline

ActiveCN101429452AReduce gasoline olefin contentHigh aromatic contentCatalytic naphtha reformingRare-earth elementSimulated moving bed

The invention provides a method for producing high octane gasoline by aromatization reaction of a mixed raw material of catalytic gasoline and C4, and catalyst on an aromatization reactor after the mixed raw material contacts the catalyst. The method is as follows: the catalytic gasoline is mixed with the C4 olefin, and the mixed raw material enters into a fixed bed aromatization reactor or a simulated moving bed aromatization reactor which is filled with the molecular sieve catalyst, contacts the aromatizing catalyst, and undergoes olefin aromatization reaction, wherein the reaction conditions are as follows: the reaction temperature is between 250 and 340 DEG C; the pressure is between 0.5 and 3.0 MPa; the weight space velocity is between 0.5 and 10h<-1>; the mass ratio of the C4 olefin to the catalytic gasoline is between 90 to 10 and 2 to 98; and active ingredients of a molecular sieve carrier of the catalyst are one or more than one among rare earth element, No. 4B element and No. 8 element, and the weight of the active ingredients is 0.01 to 10 percent of that of the carrier. The method can obviously reduce the olefin content of the raw gasoline, effectively improve the octane number, and achieve the aim of production of the clean high-octane gasoline.

Owner:PETROCHINA CO LTD

Multifunctional alcohol fuel additives

InactiveCN101285010ABoost octanePowerfulLiquid carbonaceous fuelsFuel additivesAlcohol fuelEngineering

The invention relates to a multifunctional alcohol fuel additive, aiming at resolving such technical problems existing in prior alcohol fuel as the mutual solubility, the power performance and the stability are poor, cleaning degrees of oil products and fuel oil system are poor and the corrosion and the air resistance of methanol gasoline can not be effectively handled. The additive comprises following components in portion by volume: 50 to 60 portions of cosolvent, 5 to 10 portions of corrosion inhibitor, 0 to 30 portions of detergent dispersant, 0 to 10 portions of rubber plasticizer and 0 to 15 portions of vapor pressure inhibitor. The additive has the advantages of high octane value, strong power performance, good stability, desirable mutual solubility, environmental protection and energy conservation, and can effectively inhibit metallic corrosion, improve the cleanness of oil products and resolve the problems of air resistance.

Owner:山西丰喜新能源开发有限公司

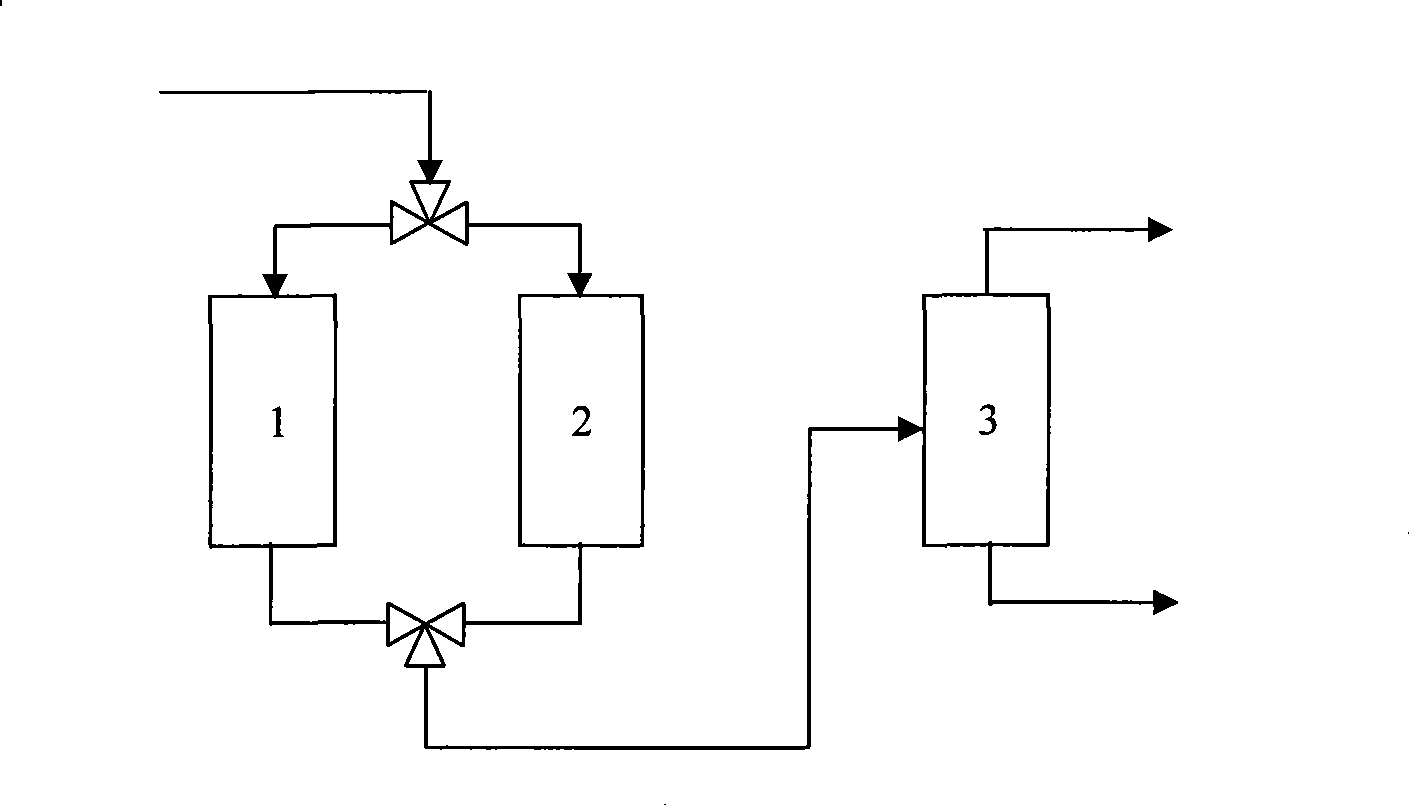

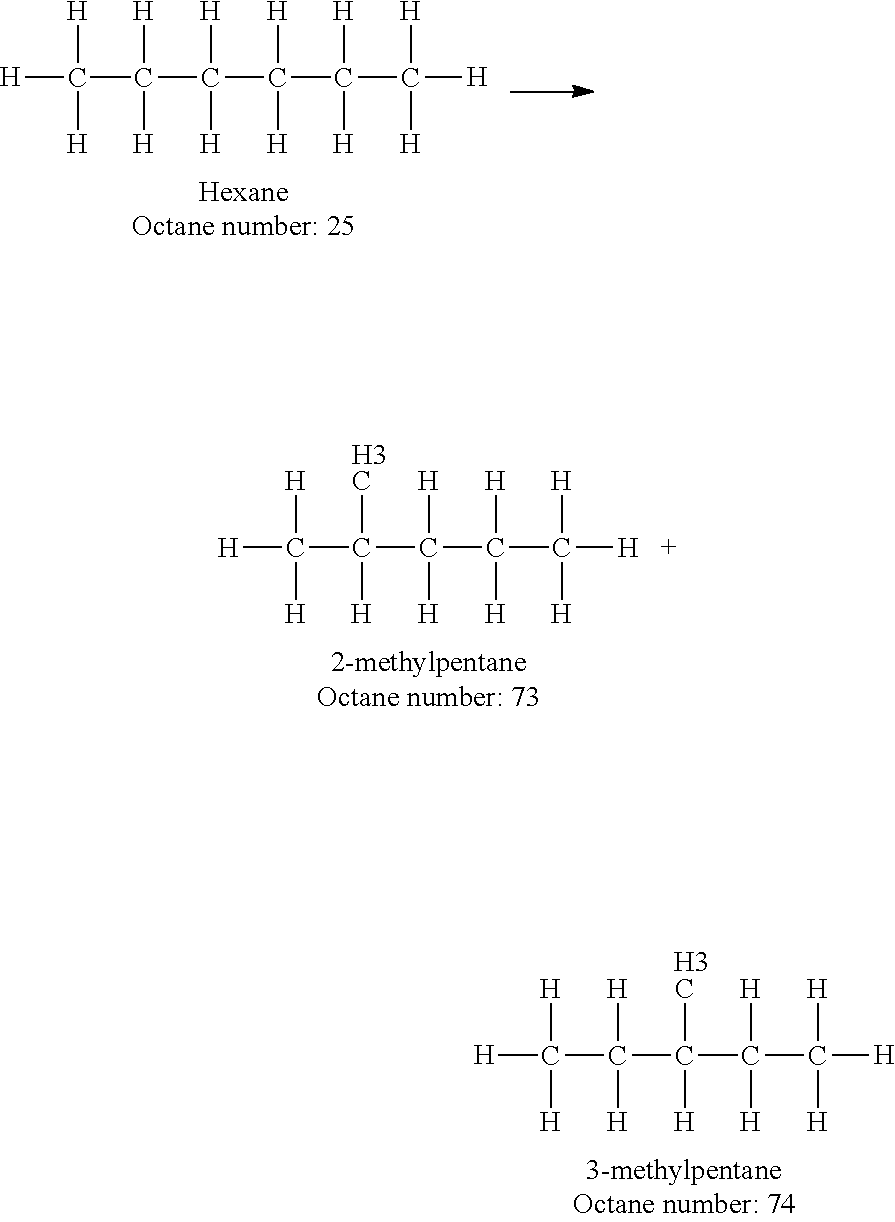

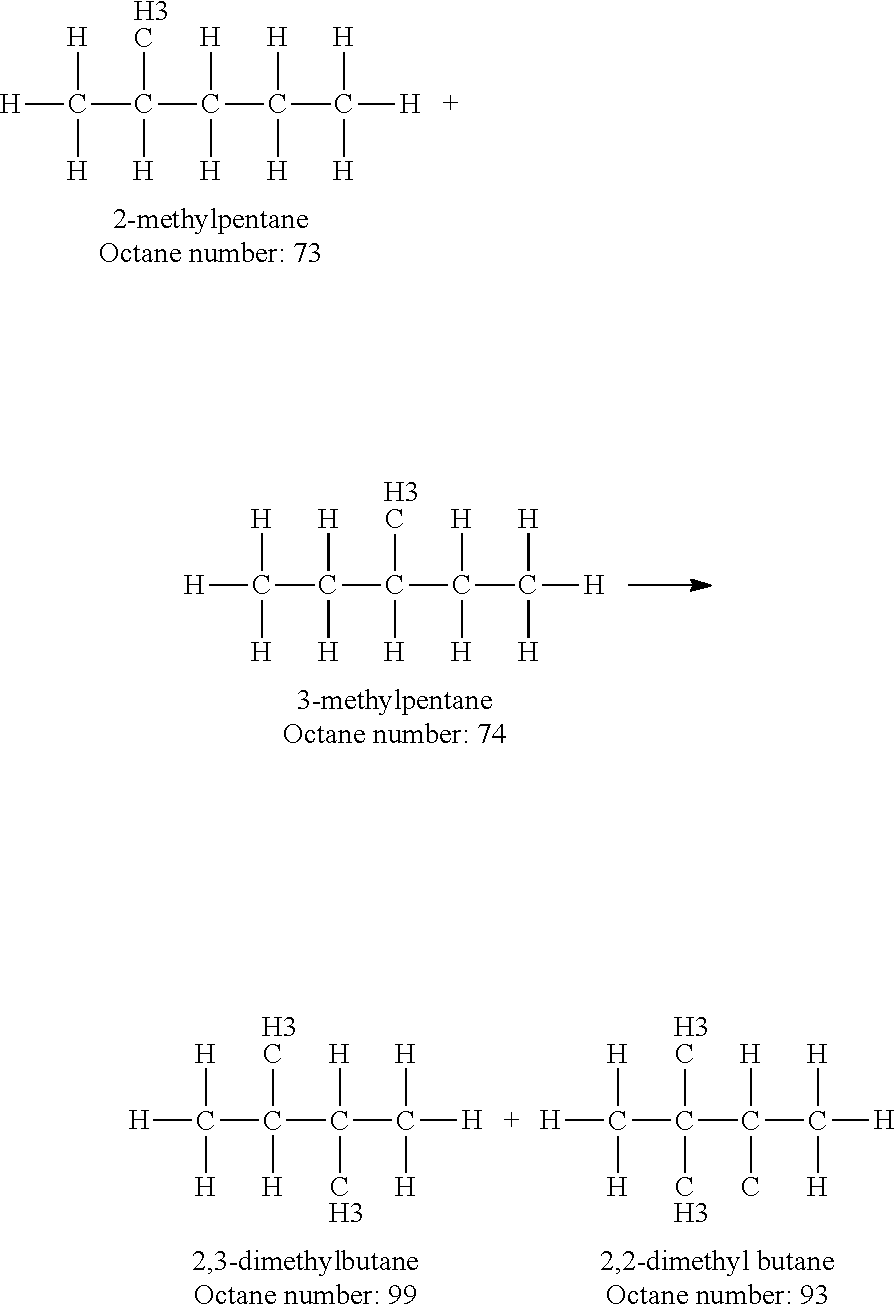

Increasing octane number of light naphtha using a germanium-zeolite catalyst

InactiveUS20110132804A1Boost octaneMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneAlkaline earth metal

This invention relates to a process for the increasing the octane number of a naphtha hydrocarbon feed having a predominantly paraffin content with a germanium-containing zeolite catalyst. The catalyst is a non-acidic germanium zeolite on which a noble metal, such as platinum, has been deposited. The zeolite structure may be of MTW, MWW, MEL, TON, MRE, FER, MFI, BEA, MOR, LTL or MTT. The zeolite is made non-acidic by being base-exchanged with an alkali metal or alkaline earth metal, such as cesium, potassium, sodium, rubidium, barium, calcium, magnesium and mixtures thereof, to reduce acidity. The catalyst is sulfur tolerant. The hydrocarbon feed may contain sulfur up to 1000 ppm. The present invention could be applicable to a feedstream which is predominantly naphthenes and paraffins.

Owner:SAUDI BASIC IND CORP SA

Method for preparing phosphor modified ZSM-5 sieve

InactiveCN1915821AImprove hydrothermal activity stabilityEasy to operatePentasil aluminosilicate zeoliteFixed bedActive component

This invention relates to a method for preparing P-modified ZSM-5 molecular sieve. The method comprises: (1) performing heat-exchange on synthesized ZSM-5 molecular sieve with ammonium solution; (2) placing in a fixed bed reactor; (3) heating to evaporate and sublimate phosphorus oxide at 250-600 deg.C; (4) introducing air or inert gas into the fixed bed reactor as the carrier gas, and uniformly depositing phosphorus oxide onto ZSM-5 molecular sieve by chemical vapor deposition to obtain P-modified ZSM-5 molecular sieve. The method can uniformly deposit phosphorus oxide onto ZSM-5 molecular sieve, thus improving the hydrothermal activity and stability of ZSM-5 molecular sieve. The catalytic cracking catalysts with P-modified ZSM-5 molecular sieve as the active component have better catalytic activity and can bring higher olefin yields. The method has such advantages as easy operation, high controllability.

Owner:北京盛大京泰化学研究所

Fluid catalytic cracking process

InactiveUS20090026112A1Boost octaneImproved RON octane numberCatalytic crackingLiquid carbonaceous fuelsAlkaneChemistry

A fluid catalytic cracking process for the preparation of cracked products by contacting in a reactor a hydrocarbon feedstock with a cracking catalyst, wherein the hydrocarbon feedstock comprises a paraffinic feedstock and triglycerides.

Owner:SHELL OIL CO

A kind of hydrocarbon oil desulfurization adsorbent and its preparation method and application

InactiveCN102294222AHigh desulfurization activityBoost octaneOther chemical processesAluminium silicatesSorbentManganese

The invention provides a hydrocarbon oil desulfurization adsorbent, a preparation method and an application method of the adsorbent. The adsorbent provided by the present invention, based on the total weight of the adsorbent, at least includes the following composition: 1) SAPO molecular sieve, with a content of 1-20wt%; 2) alumina binder, with a content of 3-35wt%; 3) oxidation 5-40wt% silicon source; 4) zinc oxide, 10-80wt% content; 5) at least one metal promoter selected from cobalt, nickel, iron and manganese, 5-30wt% content. The adsorbent of the invention has high desulfurization activity, and also has the advantage of obviously increasing the gasoline octane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fuel oil additive and fuel oil products containing the fuel oil additive

InactiveUS20040065002A1Improve performanceBoost octaneLiquid carbonaceous fuelsFuel additivesAlkaline earth metalKerosene

The present invention provides a fuel oil additive capable of effectively improving the quality of fuel oils, which comprises an oil-soluble metal salt of organic acid having the general formula MR, where R is an organic acid radical and the corresponding organic acid is a C1-C40 saturated or unsaturated fatty acid, naphthenic acid, aromatic acid or alkylphenol, M is a metal cation and the corresponding metal is an alkali metal, alkali-earth metal, rare-earth metal, transition metal, or the like. The present invention also provides fuel oil products added to the fuel oil additive, including gasoline, diesel oil, kerosene, heavy oil, resid, or the like. The present invention especially provides a gasoline antiknock agent and a gasoline having excellent antiknock property, and this kind of gasoline antiknock agent is characteristic of effectiveness, economy, safety, no environmental pollution, no toxicity to human body, no adverse effect on parts of automobile engine, use convenience, and the like.

Owner:HU SHIBIN

Method for decreasing sulfur content of hydrocarbon

InactiveCN1583973ABoost octaneSave construction investmentTreatment with hydrotreatment processesReaction temperatureGasoline

A method to reduce sulfur in hydrocarbon oil is that put the petroleum hydrocarbon and desulfuration agent into the fluid bed reactor and react with the fluid medium under following conditions: reaction temperature is 150-500 deg.C heavy hourly space velocity is 0.1-60 per hour, the weight proportion of the desulfuration agent and cut fraction of gasoline is 3-40, and the reactive pressure is 130-1450Kpa. Then separate the production and desulfuration agent and transfer the production into downstream separation system. Moreover, transfer the desulfuration agent with carbon into regeneration equipment to regenerate after striping and the regeneration temperature should be lower than 700 deg.C. Additionally, the desulfuration agent can be reused after being cooled down.

Owner:CHINA PETROLEUM & CHEM CORP +1

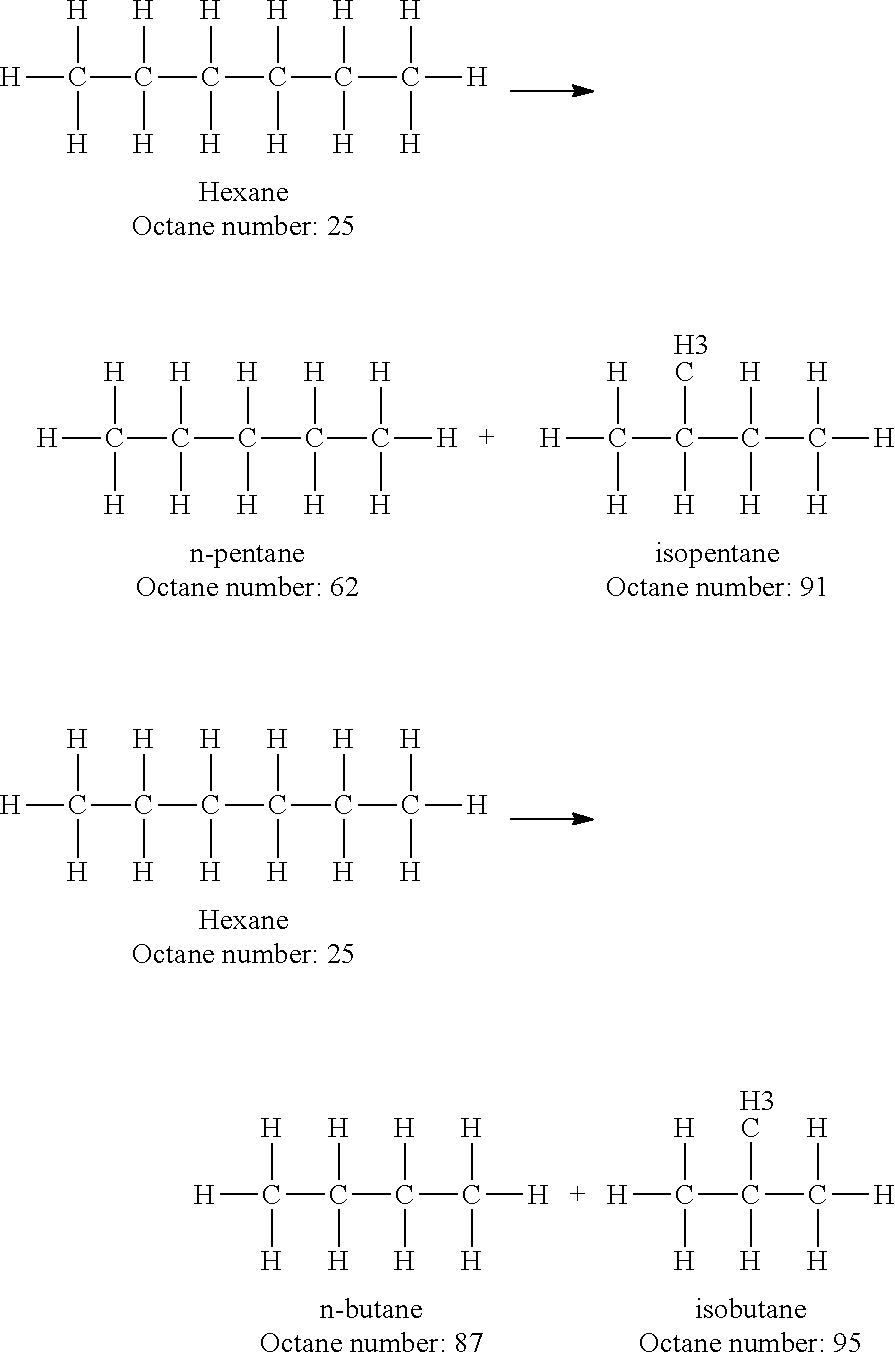

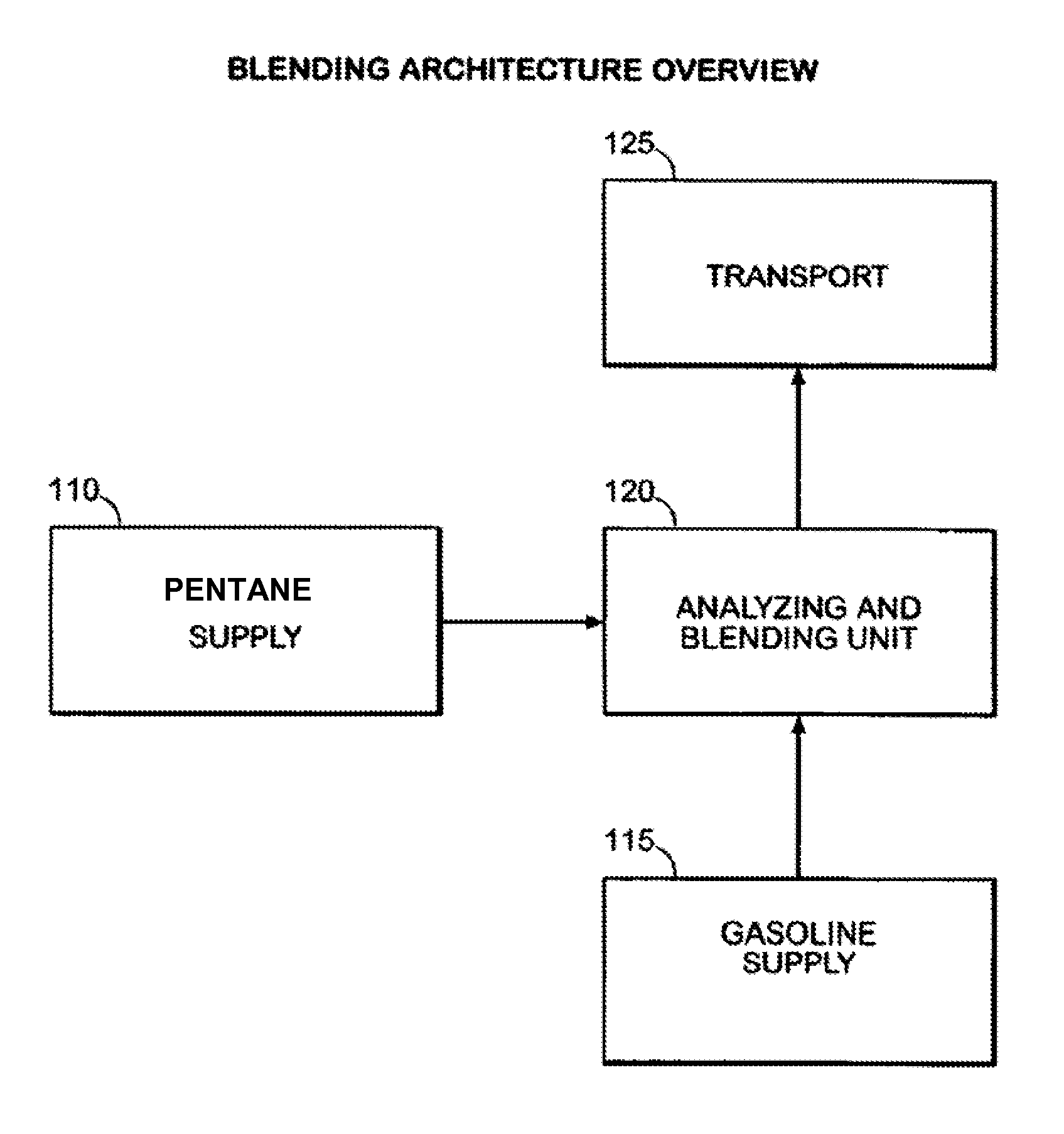

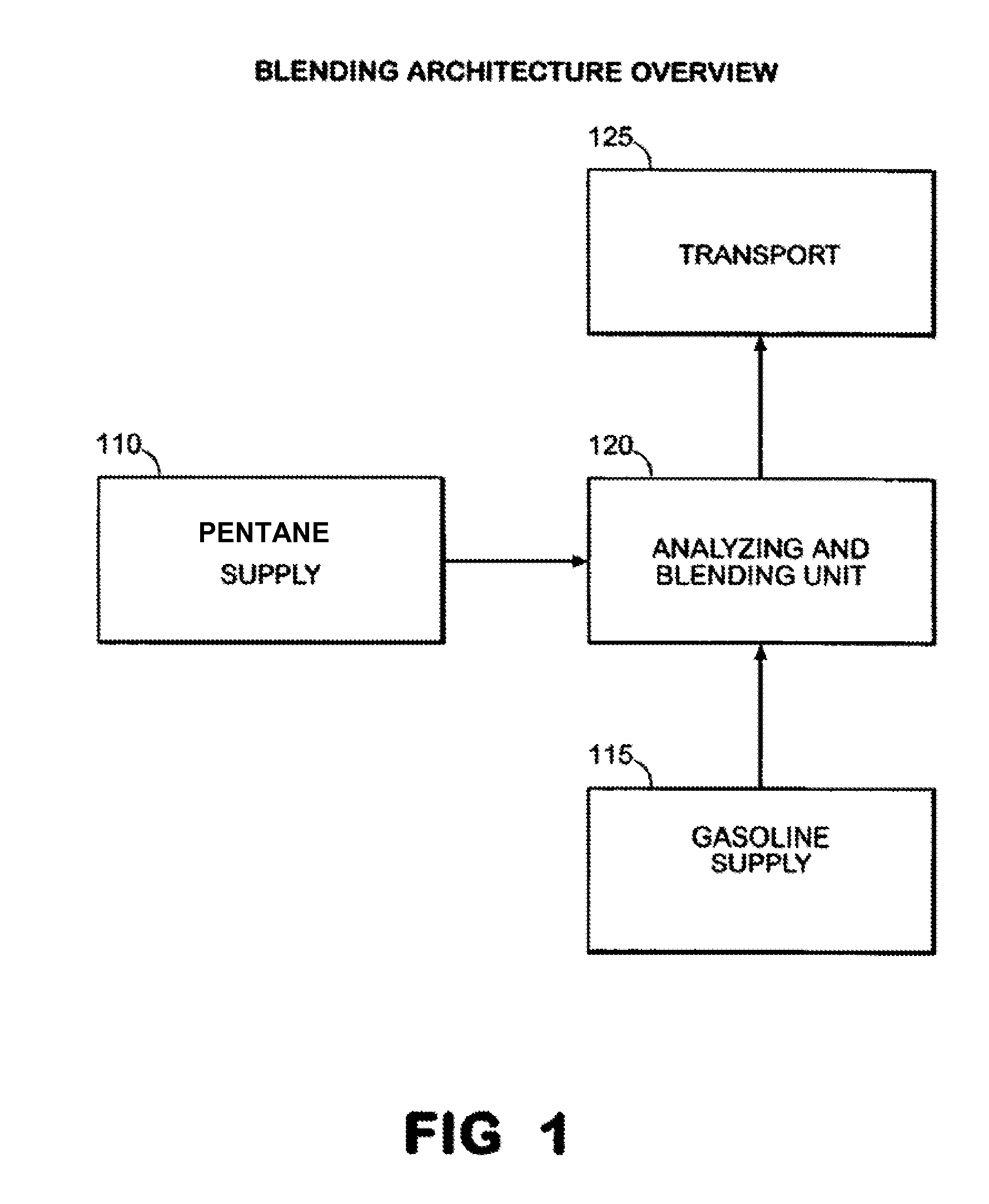

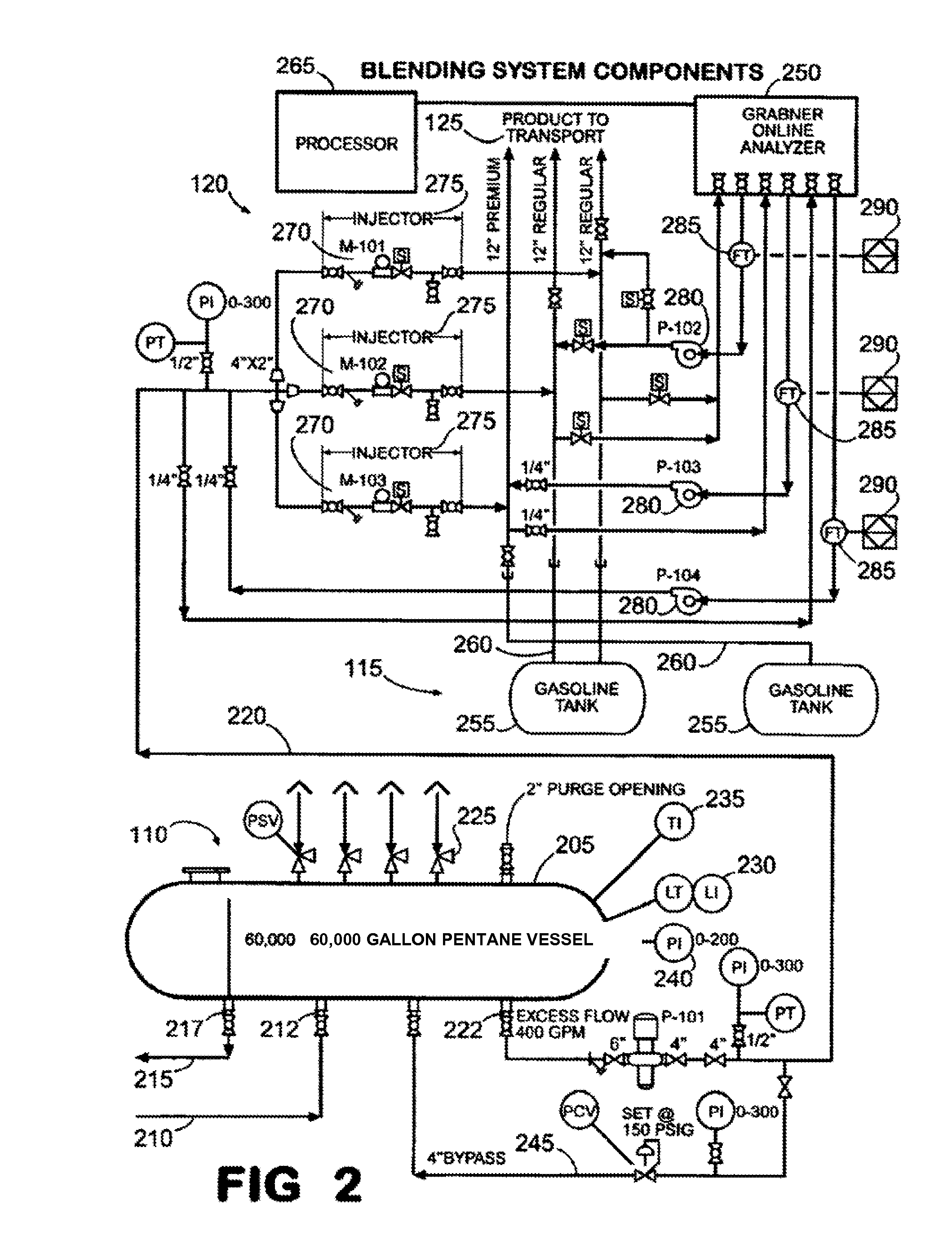

Expansion of fuel streams using mixed hydrocarbons

ActiveUS8597380B2Improve octaneReducing octaneLiquid fillingHydrocarbon purification/separationOil refineryHydrocarbon

Owner:SUNOCO PARTNERS MARKETING & TERMINALS LP

Depth hydrogenation treatment method of faulty gasoline

ActiveCN1718687AReduce saturation rateLow desulfurization activityTreatment with hydrotreatment processesOrganic sulfide compoundHydrodesulfurization

A process for deeply hydrorefining poor-quality gasoline includes such steps as removing biolefine from FCC full-fraction gasoline at lower temp, and modifying (arylisomerizing) and hydrodesulfurizing at higher temp. The hydrodesulfarizing catalyst is the hydrorefining catalyst containing copper oxide and / or zinc oxide.

Owner:CHINA PETROLEUM & CHEM CORP +2

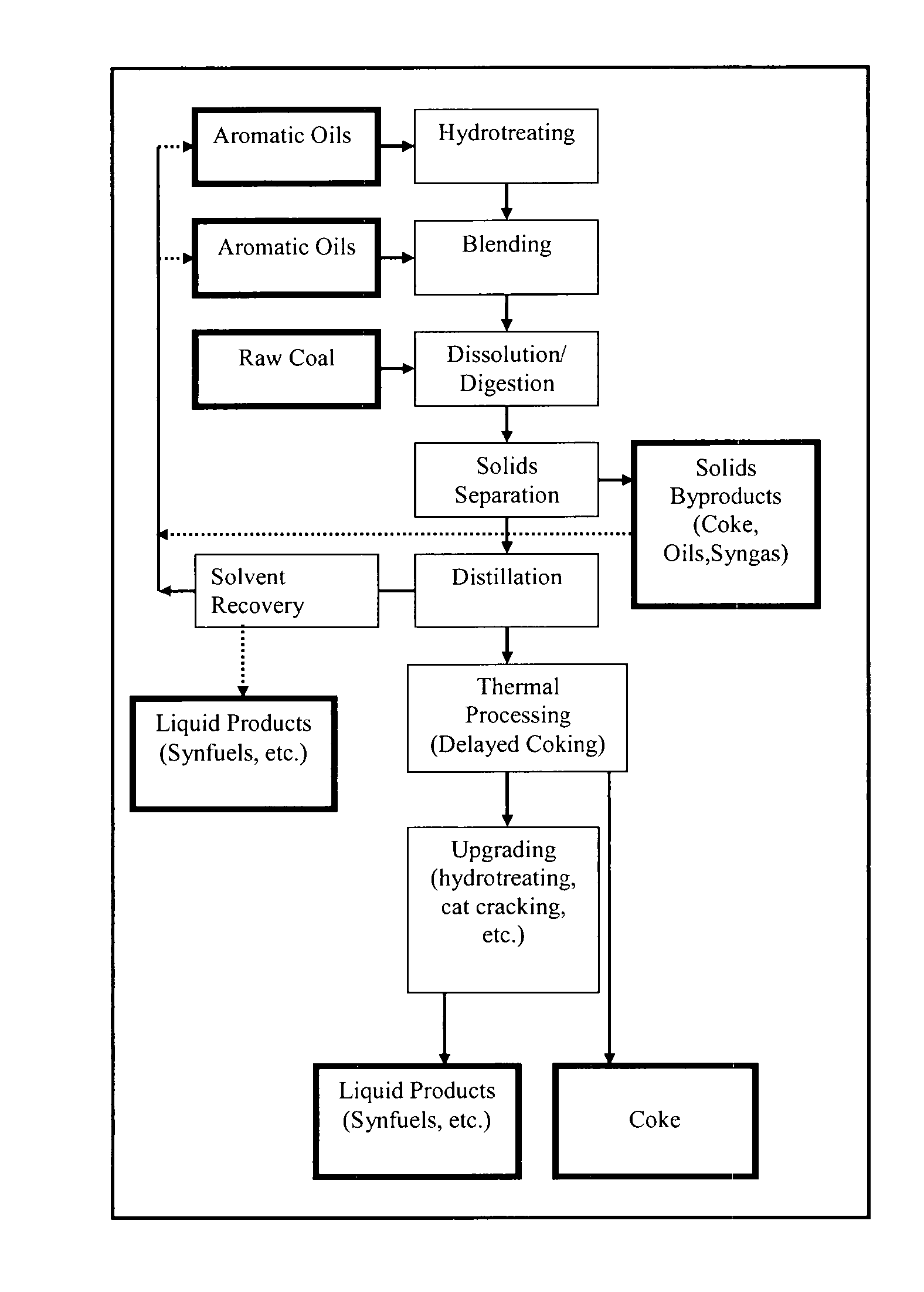

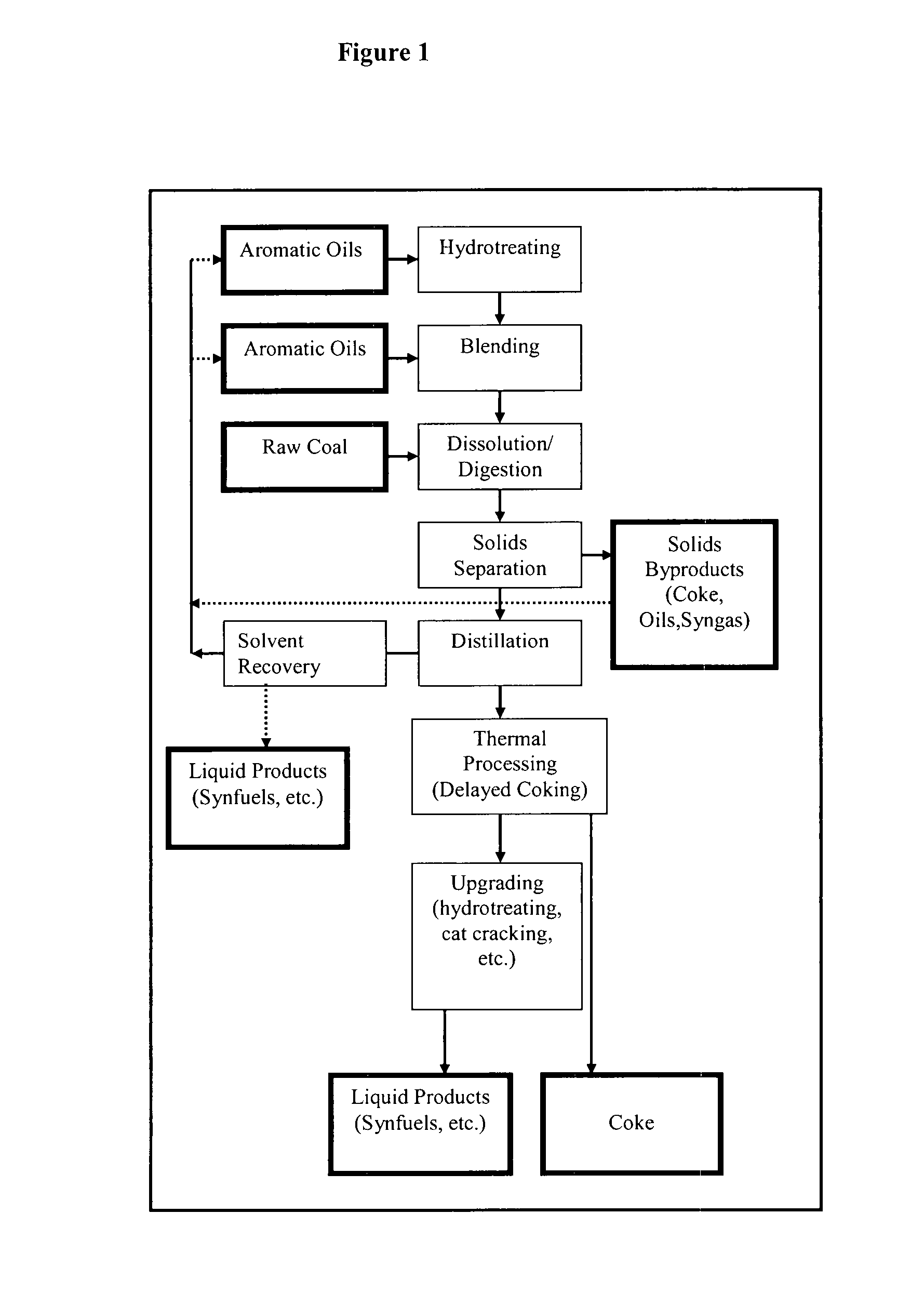

Process for producing coal liquids and use of coal liquids in liquid fuels

InactiveUS20080072476A1High rateEnhance combustionDirect heating destructive distillationIndirect and direct heating destructive distillationSolventPetroleum

The present invention provides for the use of coal liquid fuels blended with alcohols such as ethanol, as an alternative to gasoline and other fuels. The coal liquids are obtained by distilling coal tar, or by solvent extraction of coal. A further aspect is a solvent extraction process to create coal liquids to be used as a petroleum substitute. In addition the steps of delayed coking, hydrothermal cracking, hydrodelalkylation, and catalytic cracking and other refining techniques can be used to modify the aromatic coal liquids, making them more aliphatic and hence more similar to petroleum. A preferred embodiment of the coal liquid gasoline substitute is comprised of 85% ethanol and 15% coal-derived counterparts. It is a further object of the present invention to provide a method of solvent extraction for coal liquids to be processed for use as a petroleum replacement

Owner:KENNEL ELLIOT BYRON +1

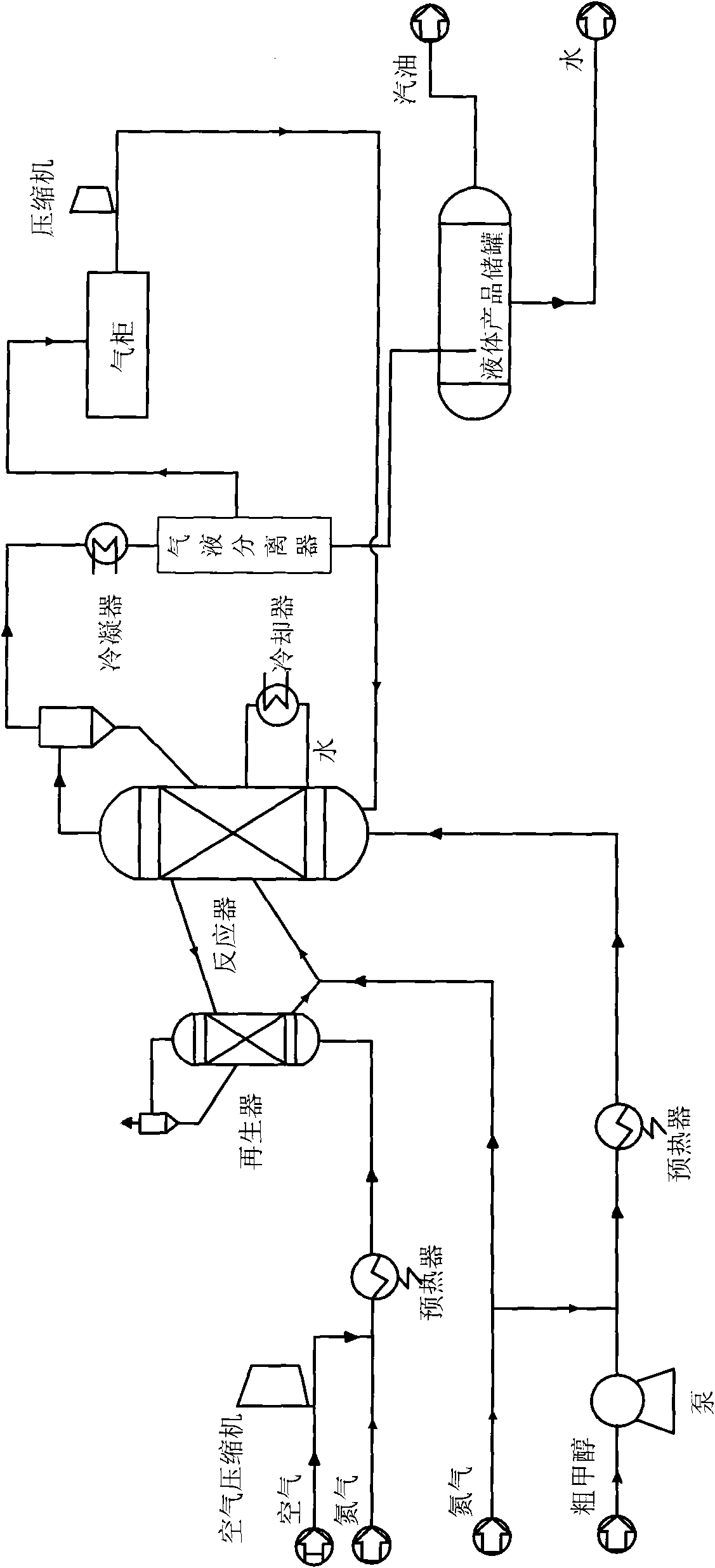

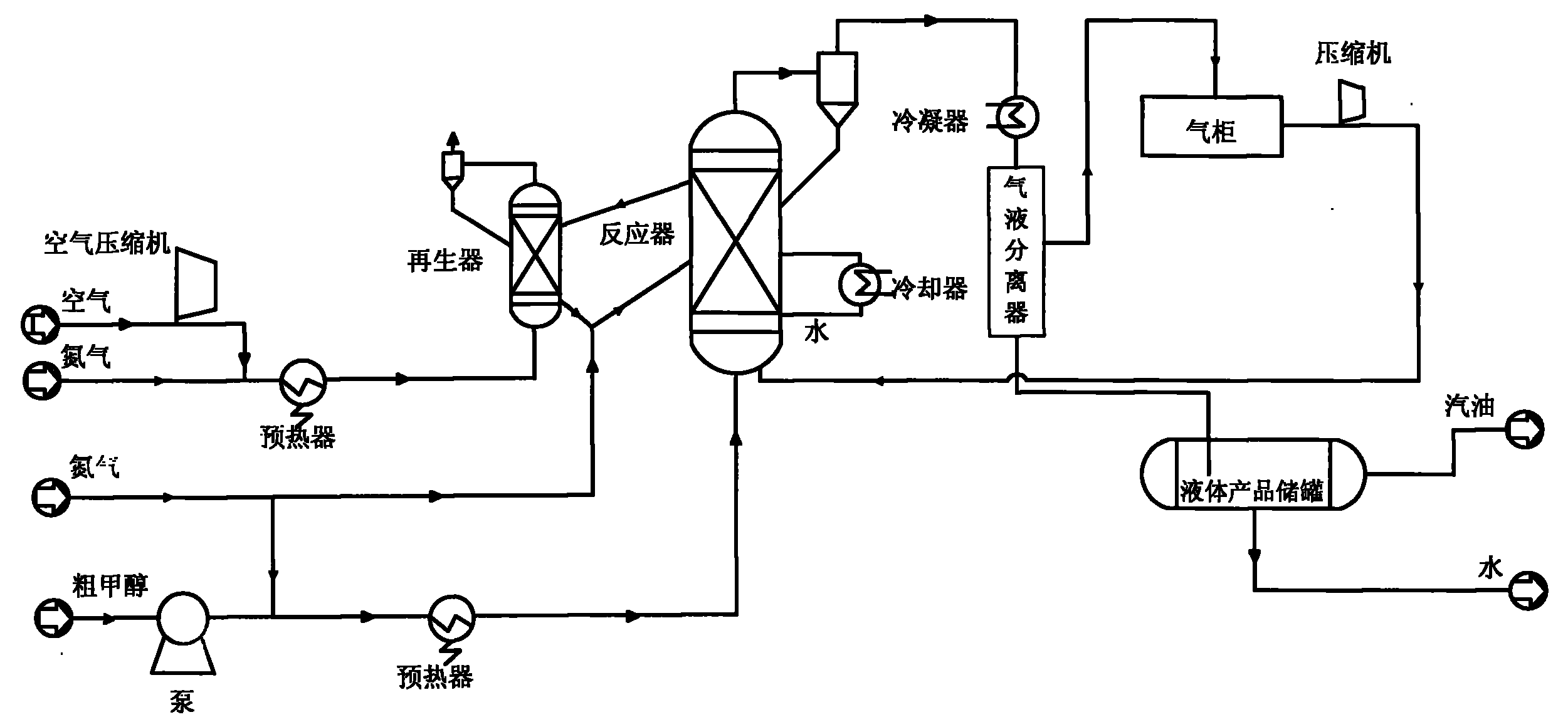

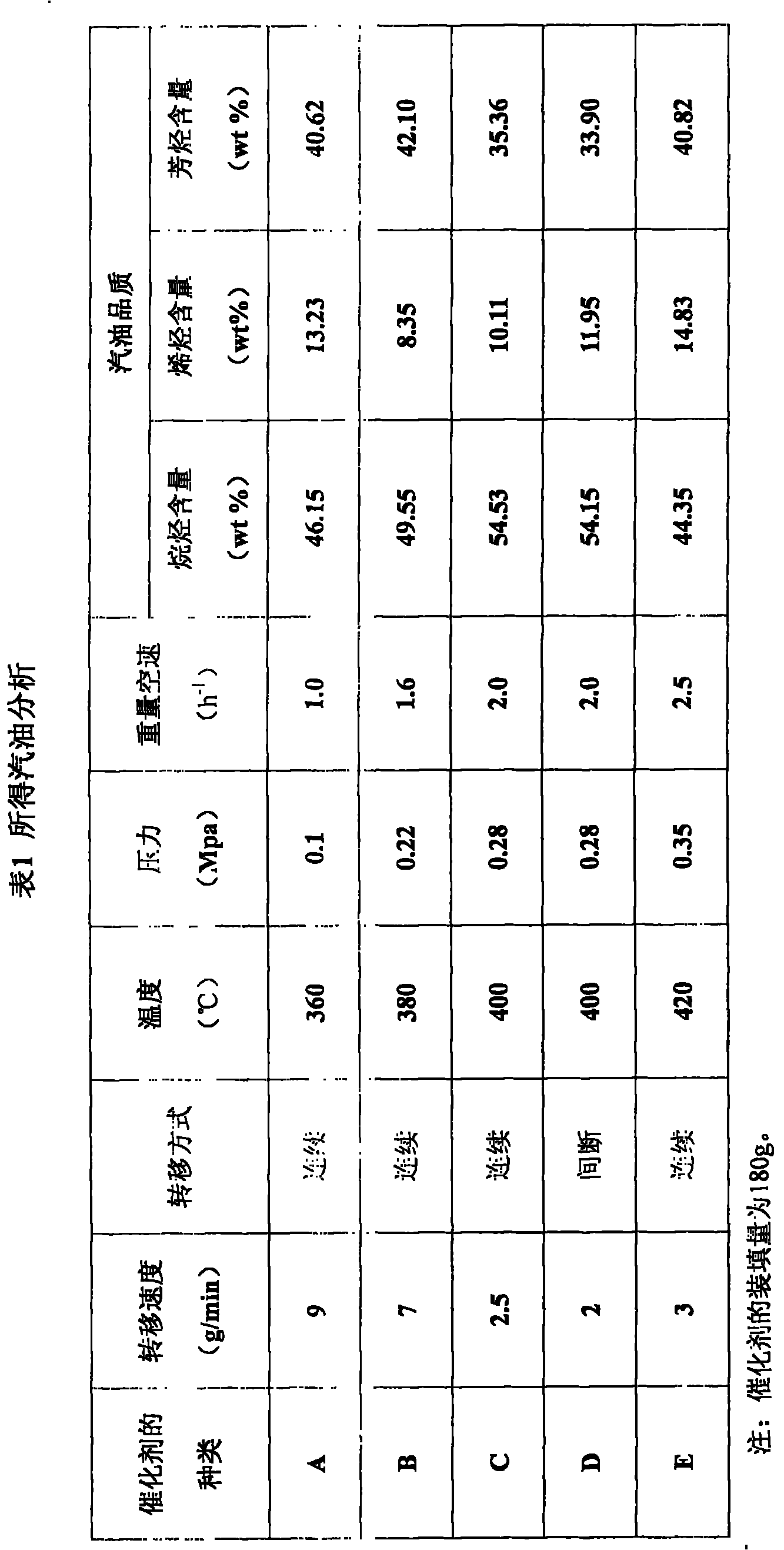

Method of producing gasoline by fluidized bed process methanol

InactiveCN101775310ASolve the problem of excess methanolSolve the problem of excessLiquid hydrocarbon mixture productionBio-feedstockFluidized bedGasoline

The invention relates to a method of producing gasoline by fluidized bed process methanol, in which crude methanol steam enters a fluidized bed reactor from the lower part to be contacted and reacted with a catalyst; a part of the catalyst after reaction is taken out continuously or discontinuously from the upper part of the reactor in a certain output amount for regeneration, and then the catalyst is supplemented with the same output amount from the lower part of the reactor by the regenerator, which is repeated and circulated. Reaction products flow out from the top of the fluidized bed reactor, and after gas-solid separation, the obtained catalyst powder enters the fluidized bed reactor again, gas firstly enters to be cooled, then gas-liquid separation is carried out, separated light hydrocarbon gas is collected by a gas holder and then is sent by compression into the fluidized bed reactor for light hydrocarbon circulation, and liquid separation is carried out on the separated liquid to obtain the gasoline and water. The technology used in the invention has the advantages that the catalyst can be regenerated continuously, a spare reactor is not needed, the nature of the catalyst is constant, the quality of the gasoline is high (octane value RON 93 plus), the conversion rate of the methanol is 100 percent, and the heat transfer intensity is high.

Owner:山西天和煤气化科技有限公司

Catalytic conversion method for preparing high-octane number gasoline

The invention provides a catalysis conversion method used for producing high octane gasoline; the distillate raw material with the distilling range of 160-260 DEG C contacts normal catalytic cracking catalyst, so as to carry out the cracking reaction inside a fluidized bed reactor under the conditions of 400-750 DEG C of temperature, 0.1-600h<-1> of weight hourly space velocity, 0.10-1.0MPa of pressure, 1-120 of weight ratio of catalyst to raw material and 0.05-1.0 of weight ratio of water vapour to raw material; a spent catalyst and reaction oil gas are separated, and the spent catalyst is returned to the reactor after regeneration; the reaction oil gas is separated so as to gain the object outcome: high octane gasoline. The method improves the octane number and yields of the gasoline and generates the byproducts: small molecule alkene such as ethane and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for oligomer production and saturation

InactiveUS6284938B1Reduce impactEasy to operateHydrocarbons from unsaturated hydrocarbon additionCatalystsAlkaneCarbon number

A process for the production of C8 and higher carbon number alkene oligomers by the oligomerization of light olefins to heavier olefins is improved by the addition of heavy paraffins to the oligomerization zone. The recycle of the heavy paraffins extends the catalyst activity and improves the catalyst life. The non-reactive paraffin stream may be recycled through the process with minimal losses and make-up.

Owner:UOP LLC

Catalytic cracking auxiliary agent for increasing heavy oil conversion performance and preparation method thereof

The invention provides a catalytic cracking additive for improving the transformation ability of heavy oil and the preparation method. The catalytic cracking additive is produced by spray shaping, roasting, in-situ crystallization and composite elements modification after natural sepiolite is mixed with natural kaolinite mineral or with one or two roasting kaolinite mineral. Provided with high activity, high heavy metal resistance and good selectivity in cracking reaction, the additive can improve the transformation ability of heavy oil and reduce the olefin content and increase gasoline octane number.

Owner:姚华

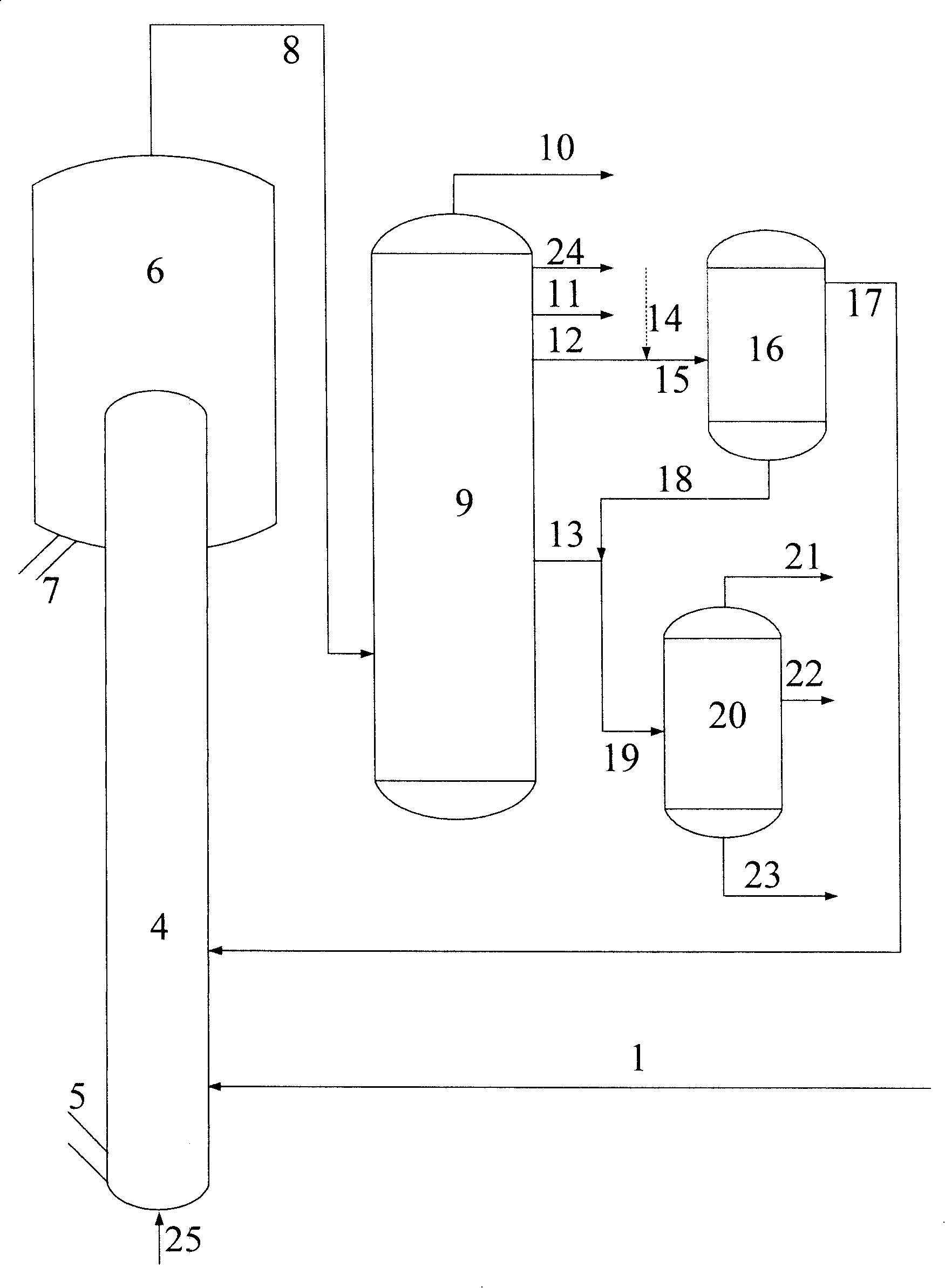

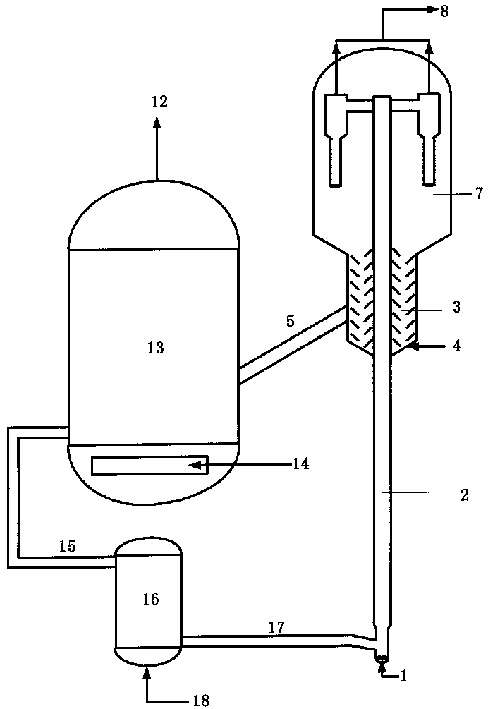

Method and device for reducing olefine in gasoline

InactiveCN1401741AReduce sulfur contentIdeal hydrogen transferTreatment with plural serial stages onlySulfurEngineering

A process for decreasing olefine content of poor gasoline includes a conventional catalytic cracking step for heavy oil performed in lift tube reactor and a catalytic converting step for upgrading the poor gaosline with high olefine content performed in the lift tube reactor. It is characterized by that in two steps a common catalyst generator and a same catalyst are used. It can decrease olefine content by 15-50 % and S content by 10-30% and increase RON by 0.2-2 units.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com