Method for decreasing sulfur content of hydrocarbon

A technology of sulfur content and hydrocarbon oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation process, etc., can solve the problems of long time and achieve the effect of increasing octane number and less construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

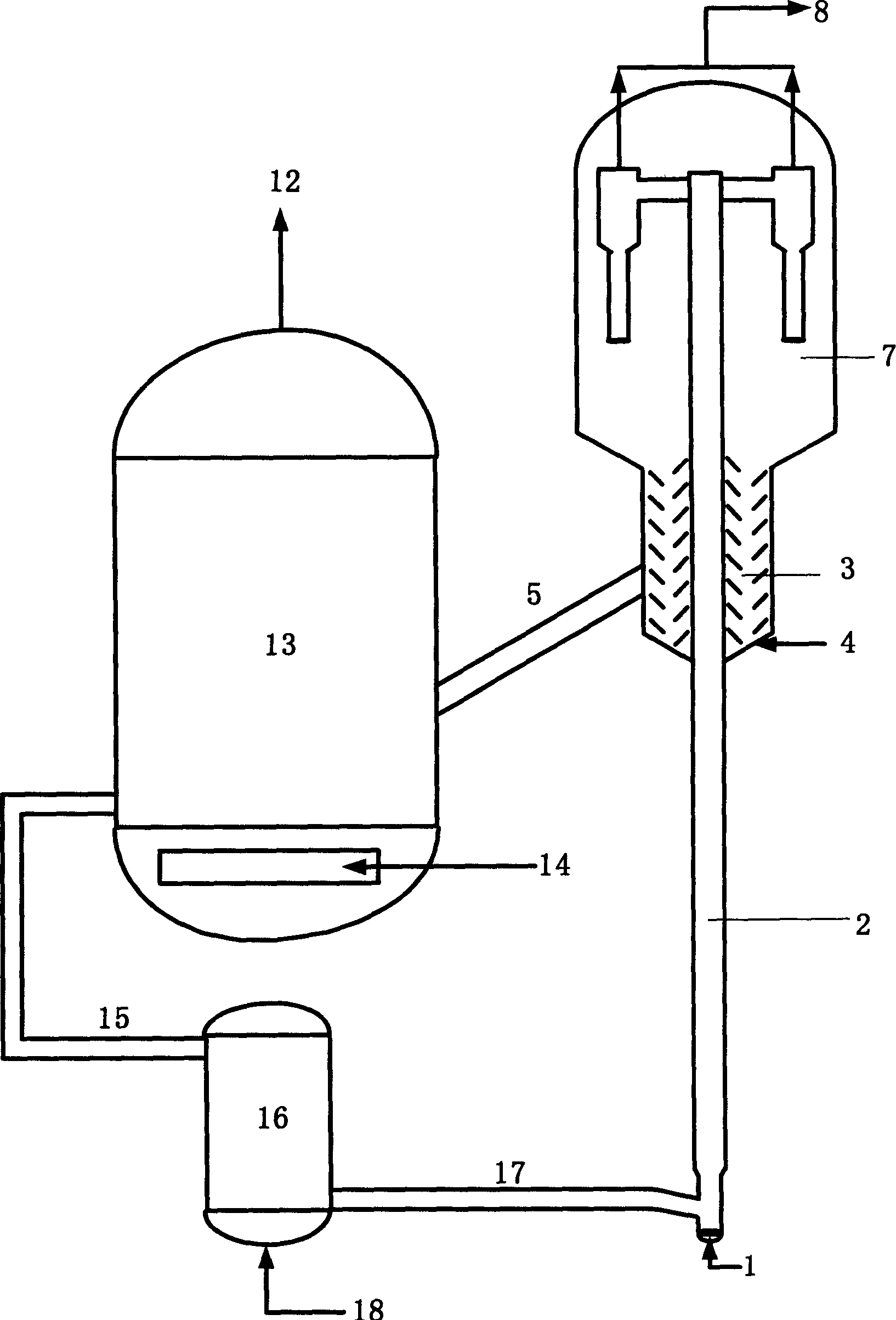

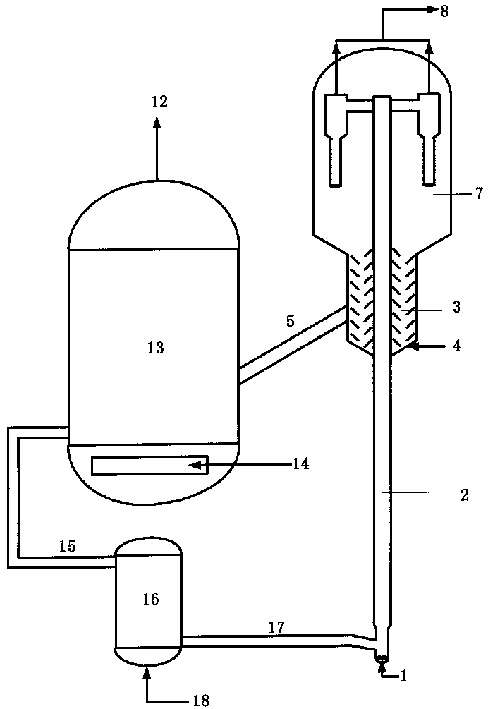

Image

Examples

preparation example Construction

[0021] The preparation method of the desulfurizing agent provided by the present invention is as follows: mix the precursor of the inorganic oxide with the clay in a predetermined amount and prepare it into a slurry with a solid content of 10-50% by weight with decationized water, and adjust its pH with an inorganic acid Adjust and maintain to 2-4, stand and age at 20-80°C for 0-2 hours, add a predetermined amount of zeolite, homogenize, spray molding, wash to remove free Na + ,dry.

[0022] Wherein the precursor of the inorganic oxide is selected from: alumina sol, pseudo-boehmite, silica sol and mixtures thereof, and silica-alumina sol or gel, preferably a mixture of aged pseudo-boehmite and alumina sol, The weight ratio (calculated as alumina) of the aged pseudo-boehmite to the alumina sol binder is 0.1-10, preferably 0.5-7.0.

[0023] The aged pseudo-boehmite slurry can be prepared by a conventional method, such as beating pseudo-boehmite and water, stirring evenly, adjus...

Embodiment 1

[0034] This example illustrates: using the method provided by the present invention, high-sulfur gasoline is reacted and adsorbed in contact with a desulfurizer in a small fluidized bed reactor.

[0035] Two types of high-sulfur gasoline A and B listed in Table 1 are used as raw materials, and the above-mentioned gasoline raw materials are contacted with desulfurizer DS2 in a small fluidized bed reactor operated by continuous reaction regeneration for reaction and adsorption. The test conditions are that the reaction temperature is 350°C, the pressure at the top of the reactor is 0.2 MPa, and the weight hourly space velocity is 4 hours. -1 , the agent-oil ratio is 10, and the water-oil ratio is 0.03. The reaction product, steam and raw desulfurizing agent are separated in the settler, and the reaction product is separated to obtain gas products and liquid products, while the raw desulfurizing agent enters the stripper, and the hydrocarbon products adsorbed on the raw desulfuri...

Embodiment 2

[0039] This example illustrates: adopting the method provided by the present invention and adopting different operating conditions, gasoline raw materials are reacted and adsorbed in contact with a desulfurizer in a small fluidized bed reactor.

[0040] The gasoline B listed in Table 1 is used as the raw material, and it is contacted with the desulfurizer DS2 in a small fluidized bed reactor for continuous reaction regeneration for reaction and adsorption. The test conditions are: the reaction temperature is 250-450°C, the pressure at the top of the reactor is 0.2-0.6 MPa, and the weight hourly space velocity is 2-15 hours -1 , The agent-oil ratio is 6-30, and the water-oil ratio is 0.03-0.05. Concrete test procedure is identical with embodiment 1. The test conditions, test results and sulfur content in gasoline are listed in Table 4.

[0041] It can be seen from Table 4 that the desulfurizer has different catalysis and adsorption degrees on gasoline raw materials under diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com