Hydro-upgrading method for FCC gasoline

A technology of catalytic cracking gasoline and hydrogenation upgrading, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem of poor hydrothermal stability catalyst regeneration performance, unsatisfactory catalytic stability, and complex preparation of nano-zeolite To improve octane number and anti-knock index, prolong life and reduce the formation of gum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

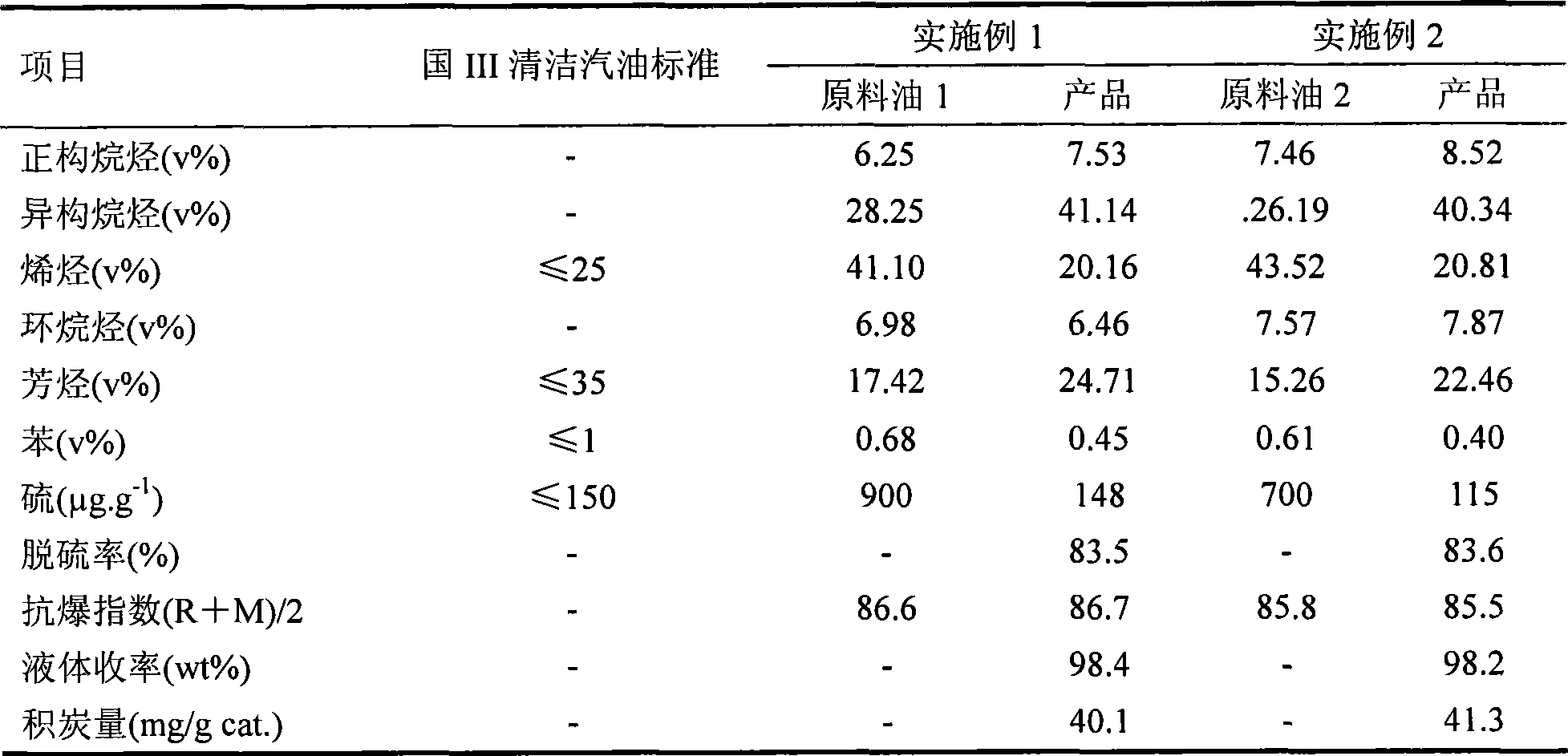

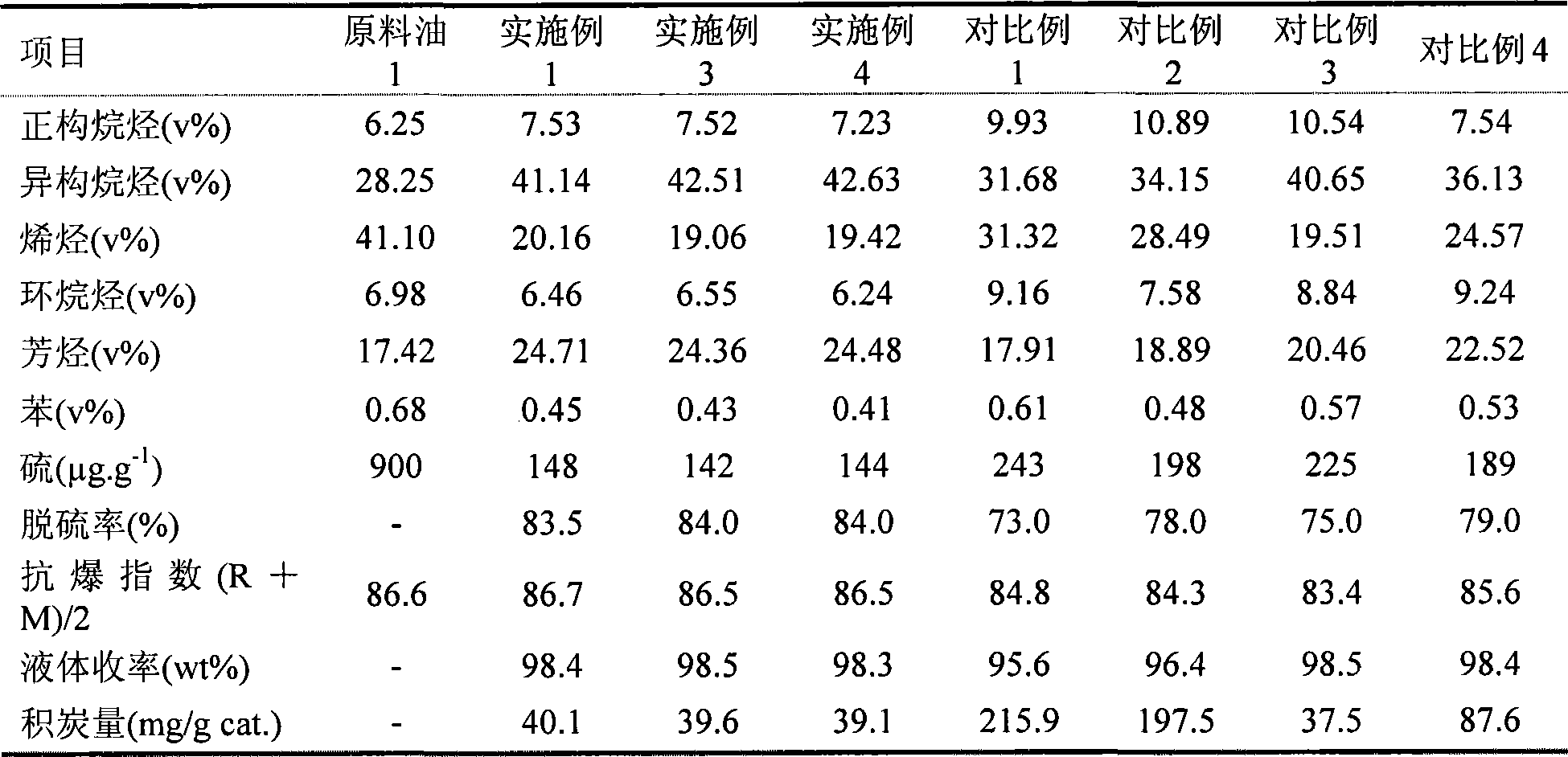

Embodiment 1

[0022] The preparation of this embodiment includes: based on the total weight of the catalyst, 2wt% NiO-8wt% MoO 3 —2wt%K 2 O—4wt%MgO / 84wt%γ-Al 2 o 3 The first-stage selective hydrodediene catalyst and 2wt% NiO—9wt% MoO 3 / 69wt%HZSM-5—20wt%γ-Al 2 o 3 The second-stage hydrothermal / citric acid modified HZSM-5 zeolite-based catalyst.

[0023] The preparation of the first-stage selective hydrodediene catalyst adopts the conventional equal-volume impregnation method, and an appropriate amount of K is sequentially loaded on the formed alumina carrier according to the stoichiometric ratio. 2 O and MgO, MoO 3 As well as NiO, aging, drying and roasting steps are required after each loading of active metal components.

[0024] The specific preparation steps of the second stage catalyst are as follows: Weigh 69 grams of HZSM-5 zeolite (SiO 2 / Al 2 o 3 The molar ratio is 50), 27 grams of pseudo-boehmite (water content 26wt%) and 1.4 grams of asparagus powder, which are ground an...

Embodiment 2

[0029] The difference between this example and Example 1 is that the raw material oil has an olefin content of 43v% and a sulfur content of 700μg.g -1 full distillate FCC gasoline.

Embodiment 3

[0031] The difference between this example and Example 1 is that in the second stage of preparation of the hydrothermal / citric acid modified HZSM-5 zeolite-based catalyst, the temperature of the hydrothermal treatment is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com