Preparation method of clean gasoline

A gasoline, clean technology, used in chemical instruments and methods, petroleum industry, processing hydrocarbon oil, etc., can solve problems such as high energy consumption and complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

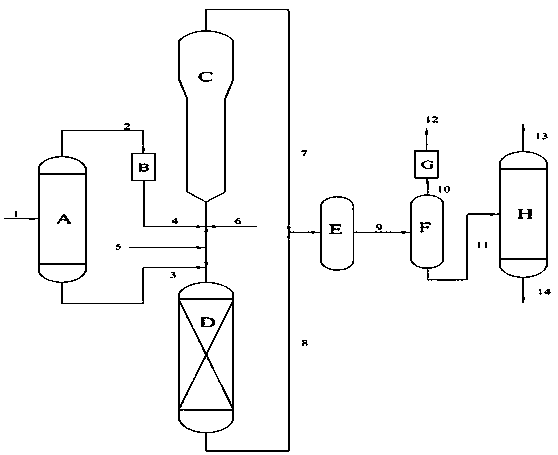

Method used

Image

Examples

Embodiment 1

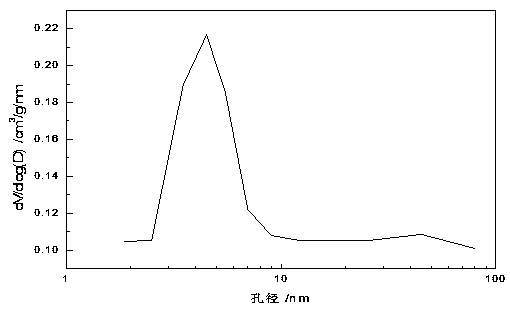

[0072] In this example, the aromatization catalyst OTA-F-1 adopts ZSM-5 / ZSM-22 composite molecular sieve CM-1, and in ZSM-5 / ZSM-22 composite molecular sieve CM-1, zinc isomorphously substituted nanometer ZSM-5 Molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 120, the Zn content is 3.5wt%, and the particle size is 80nm) accounting for 60wt% of the total weight of the composite molecular sieve. The ZSM-22 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 90) accounting for 40wt% of the total weight of the composite molecular sieve. In ZSM-5 / ZSM-22 composite molecular sieve CM-1, the most probable pore diameter of mesopores is 4.5nm, and the mesopore volume accounts for 60% of the total pore volume.

[0073] The composition of aromatization catalyst OTA-F-1 is as follows: ZSM-5 / ZSM-22 composite molecular sieve CM-1 content is 65.0wt%, P content is 2.0wt%, La 2 o 3 The NiO content is 2.0wt%, the NiO content is 3.0wt%, and the balance is the binder alumina.

[0074] OT...

Embodiment 2

[0078] The ZSM-5 / ZSM-22 composite molecular sieve CM-1 used in the aromatization catalyst OTA-F-2 in this example is the same as in Example 1.

[0079] The composition of catalyst OTA-F-2 is as follows: ZSM-5 / ZSM-22 composite molecular sieve CM-1 content is 70.0wt%, P content is 2.0wt%, La 2 o 3 The content is 1.0wt%, the CoO content is 3.5wt%, and the balance is the binder alumina.

[0080] The preparation method of OTA-F-2 catalyst is as follows:

[0081] Put the ZSM-5 / ZSM-22 composite molecular sieve CM-1 into the spray immersion tank, spray the solution containing hydrogen phosphate, lanthanum nitrate, and cobalt nitrate on the composite molecular sieve within 30 minutes, and dry it at room temperature. Dry at 120°C for 10 hours, and roast at 500°C for 8 hours to obtain molecular sieves loaded with active metals; add molecular sieves loaded with active metals to aluminum sol, and spray dry at 120°C to make microsphere catalyst OTA-F -2.

Embodiment 3

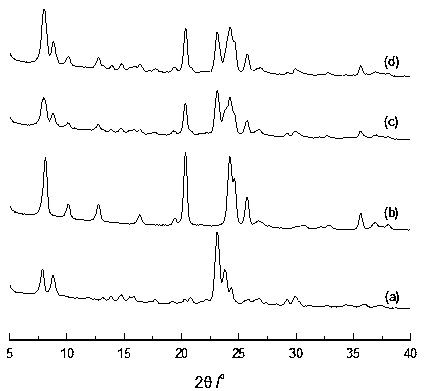

[0083] The difference between this embodiment and Example 1 is that ZSM-5 and ZSM-22 mixed molecular sieves are used, wherein ZSM-5 molecular sieves are not added when preparing CM-1 in Example 1, and the obtained product is analyzed by XRD diffraction (see figure 2 ) shows that it is ZSM-22 molecular sieve. The low-temperature liquid nitrogen adsorption analysis shows that the ZSM-5 and ZSM-22 mixed molecular sieves have a micropore-mesopore structure. The aromatization catalyst OTA-F-3 of this embodiment is composed as follows: nanometer ZSM-5 molecular sieve (same as Example 1) substituted by zinc isomorphism has a content of 39wt%, ZSM-22 molecular sieve (SiO 2 / Al 2 o 3 Molar ratio is 90) content is 26wt%, P content is 2.0wt%, La 2 o 3 The NiO content is 2.0wt%, the NiO content is 3.0wt%, and the balance is the binder alumina.

[0084] OTA-F-3 catalyst preparation method is as follows:

[0085] Mix the ZSM-5 molecular sieve and ZSM-22 molecular sieve substituted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com