Preparation of bubbling bed hydrotreating catalyst

A hydrotreating and catalyst technology, applied in the refining of hydrocarbon oil, petroleum industry, refining to remove heteroatoms, etc., can solve the problems of harsh catalytic reaction conditions, high pressure drop of the catalyst bed, and short catalyst life cycle, and achieves a high level of performance. Mechanical strength and wear resistance, loss reduction, effect of reducing olefin and aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of modified alumina M-1

[0053] A. Set the concentration to contain 160gAl 2 o 3 / L NaAlO 2 Solution (caustic ratio 1.25-1.5) and concentration 40gAl 2 o 3 / L Al 2 (SO 4 ) 3 The solution was poured into the gel forming device equipped with 1L of bottom water under the condition of stirring, and the temperature was controlled at 60°C and the pH value was 8.5.

[0054] B. After the gelation is completed, age for 0.5-1 hour under stirring conditions.

[0055] C. After aging, the feed liquid is filtered, beaten and washed four times with water, and the ratio of water to filter cake is 30:1.

[0056] D, get 30g magnesium nitrate (Mg(NO 3 ) 2 6H 2 O) add distilled water to dissolve, dilute to 250ml with volumetric flask, be made into magnesium nitrate aqueous solution; Add magnesium nitrate aqueous solution prepared in step C gained slurry and carry out beating, stir for 0.8 hour, filter and dry to obtain magnesium nitrate of the present invention The...

Embodiment 2

[0058] Preparation of modified alumina M-2

[0059] A. Set the concentration to contain 160gAl 2 o 3 / L NaAlO 2 Solution (caustic molar ratio 1.25-1.5) and concentration 40gAl 2 o 3 / L Al 2 (SO 4 ) 3 The solution was poured into the gel forming device equipped with 1L of bottom water under the condition of stirring, and the temperature was controlled at 60°C and the pH value was 8.5.

[0060] B. After the gelation is completed, age for 0.5-1 hour under stirring conditions.

[0061] C. After aging, the feed liquid is filtered, beaten and washed four times with water, and the ratio of water to filter cake is 30:1.

[0062] D, get 84g magnesium chloride MgCl 2 Add distilled water to dissolve, dilute to 250ml with a volumetric flask, and make a magnesium-containing aqueous solution; add the prepared magnesium nitrate aqueous solution to the slurry obtained in step C for beating, stir for 0.5 hours, filter and dry to obtain the magnesium-containing alumina of the present i...

Embodiment 3

[0066] Preparation of ebullating bed hydrogenation catalyst C-1 for stable hydrogenation of heavy oil products of the present invention.

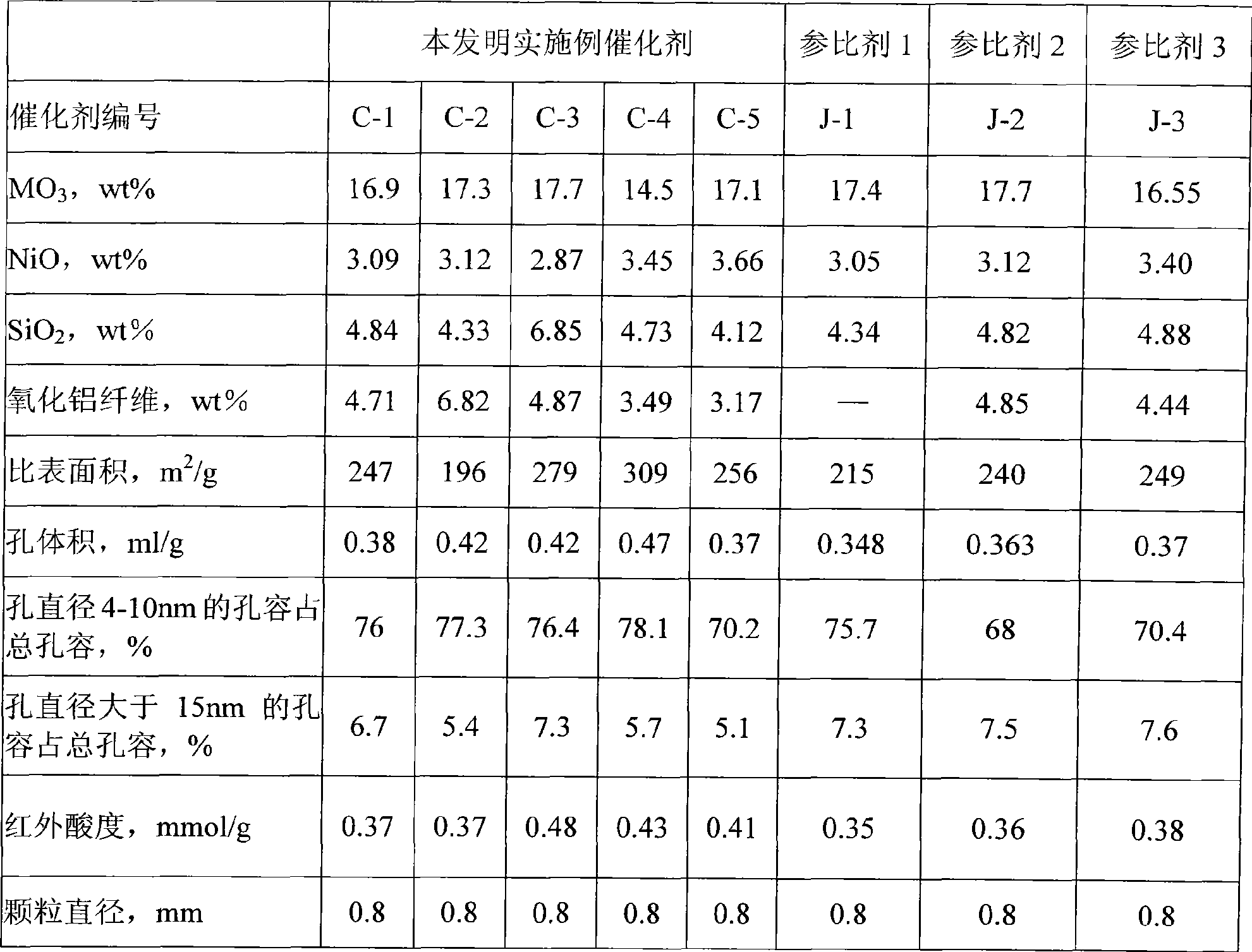

[0067] With 206.6 grams of M-1 and 22 grams of alumina fiber powder (length 30 microns, diameter 6 microns, specific surface 183m 2 / g, pore volume 0.08ml / g) is evenly wetted with 290ml S-1 solution; 0.454ml / g, specific surface area 258m 2 Add 51g aluminum dihydrogen phosphate in / g), add peptizing acid and make adhesive (dry basis 30wt%, acid-aluminum mol ratio is 0.3); , and then put it into a roller compactor, and grind until the paste can be extruded, extruded, dried at 110°C for 4 hours, and roasted at 550°C for 3 hours to obtain catalyst C-1. The physical and chemical properties of the catalyst are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Expansion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com