Method for producing clean gasoline by naphtha upgrading

A naphtha and gasoline technology, which is applied in the field of clean gasoline and high-quality liquefied gas, can solve the problems of low yield of modified gasoline and high content of aromatics, and achieve the effects of increased liquid yield, high octane number, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

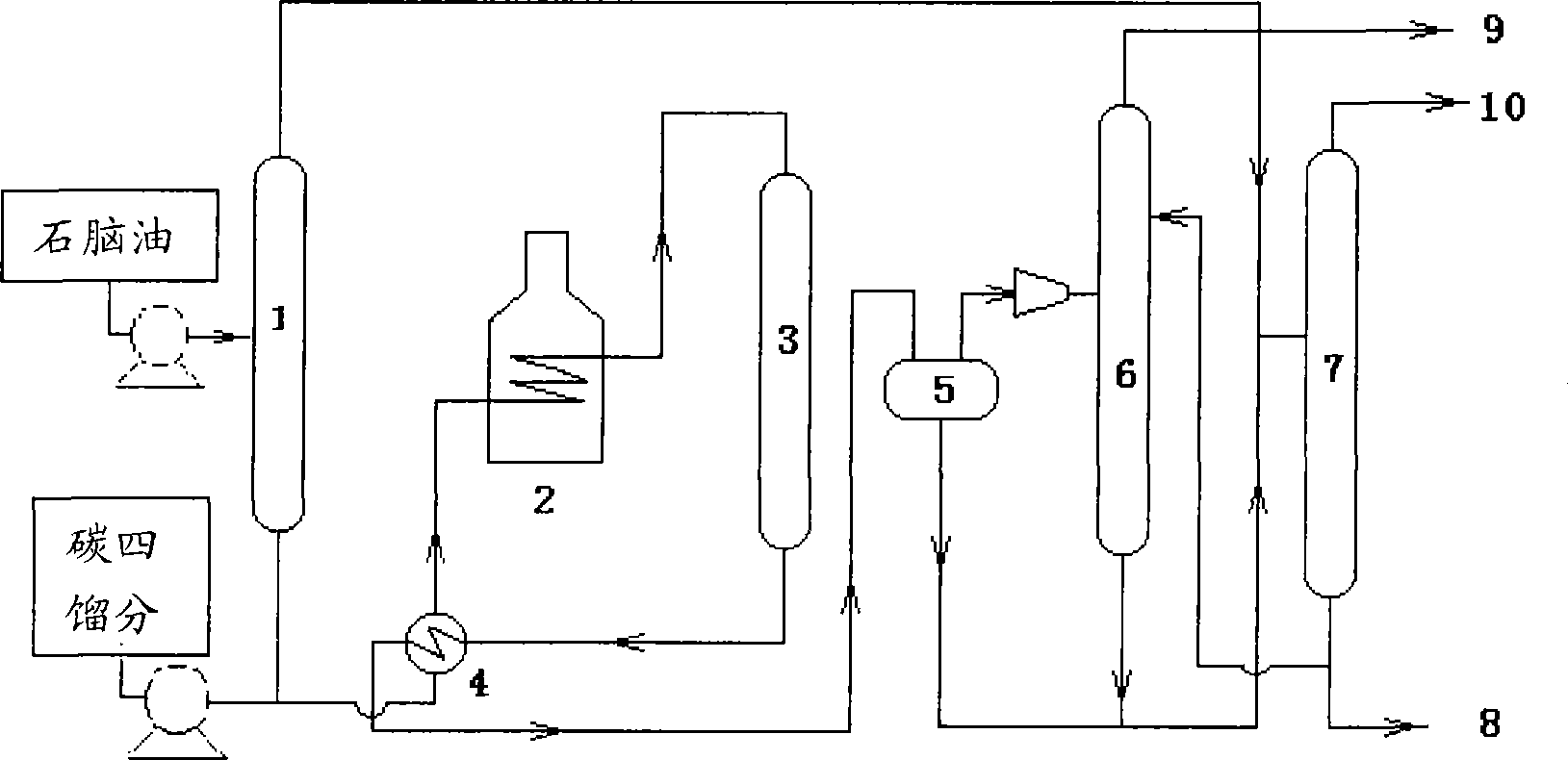

Method used

Image

Examples

example 1

[0032] Preparation of naphtha upgrading catalyst.

[0033] Take 130g of HZSM-5 zeolite powder (Shanghai Huaheng Chemical Plant) with a silica / alumina molar ratio of 56, 70g of aluminum hydroxide powder (German SASOL), add 6ml of nitric acid with a concentration of 50% by mass and 95g of water. The carrier was prepared by drying at 120°C for 4 hours and calcining at 550°C for 4 hours.

[0034] Take 100g of the carrier and impregnate it with 100ml of an aqueous solution containing 1.0g of mixed rare earth chloride (produced by Inner Mongolia Baotou Rare Earth Industry Co., Ltd., which contains 14.6% by mass lanthanum oxide, 24.0% by mass cerium oxide, 6.6% by mass praseodymium oxide, and 1.9% by mass neodymium oxide) 2hr, 120°C drying for 8 hours, 550°C roasting for 4hr to prepare catalyst A, in which the mixed rare earth oxide content is 0.43% by weight (fluorescence analysis), the HZSM-5 content is 70.4% by mass, and the γ-alumina content is 29.17% by mass .

[0035] The catalyst A...

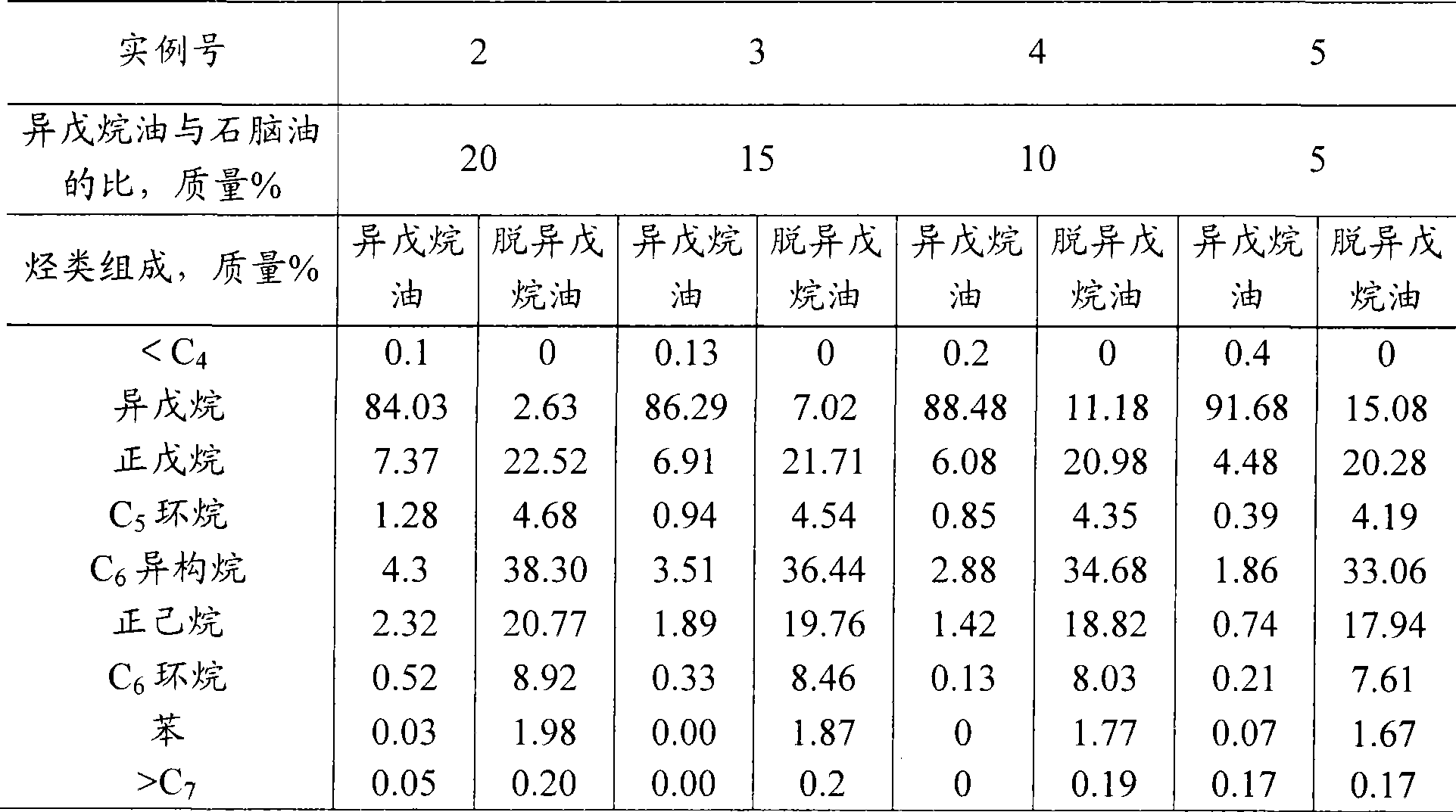

example 2~5

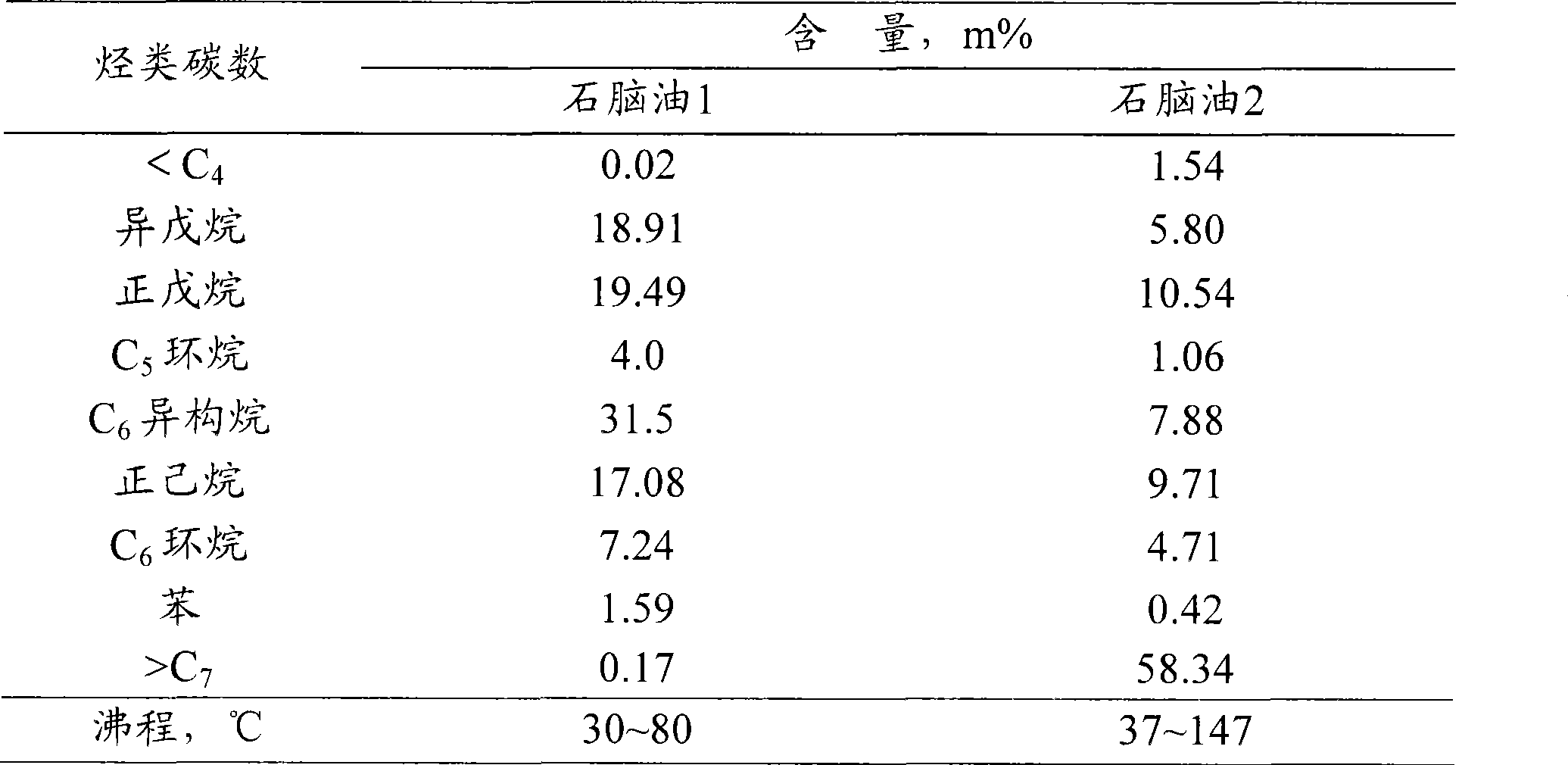

[0037] The following example uses light naphtha as a raw material to carry out a non-hydrogen upgrading reaction according to the method of the present invention.

[0038] Pass the naphtha 1 shown in Table 1 into the fractionation tower for fractionation, and appropriately control the temperature at the top of the tower so that the isopentane oil fractionated from the top of the tower accounts for 20%, 15%, and 10% of the total naphtha respectively. % And 5%, and then pass the deisopentane oil into a 20 ml fixed-bed continuous flow reactor filled with 14 grams of catalyst A, at 350°C, 0.3 MPa and feed mass space velocity 0.4 hr -1 The non-hydrogen upgrading reaction is carried out under the conditions of, and the gasoline obtained by the upgrading reaction is blended with isopentane oil to obtain clean gasoline. The composition of isopentane oil and deisopentane oil obtained by fractional distillation in each example is shown in Table 2, and the product composition and gasoline pr...

example 6~8

[0043] The following example uses light naphtha and carbon four fractions as raw materials for non-hydrogen upgrading reactions according to the method of the present invention.

[0044] A 20 ml fixed bed continuous flow reactor was charged with 14 g of catalyst A. First, fractionate the naphtha 1 shown in Table 1 to separate 20% isopentane oil and 80% deisopentane oil, and then divide the C4 fraction and deisopentane oil shown in Table 5 into The modified raw materials are mixed in different proportions and passed into the reactor at 350℃, 0.3MPa, and the feed mass space velocity is 0.4hr -1 The non-hydrogen upgrading reaction is carried out under the conditions of, the reaction product is sent to the water cooler, separated into gas-liquid two phases, respectively measured and calculated composition, the upgraded gasoline and isopentane oil are blended to obtain clean gasoline components. The content of the C4 fraction in the modified raw material and the composition and proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com