Method for producing the clean diean diesel oil with low sulfur and low arene

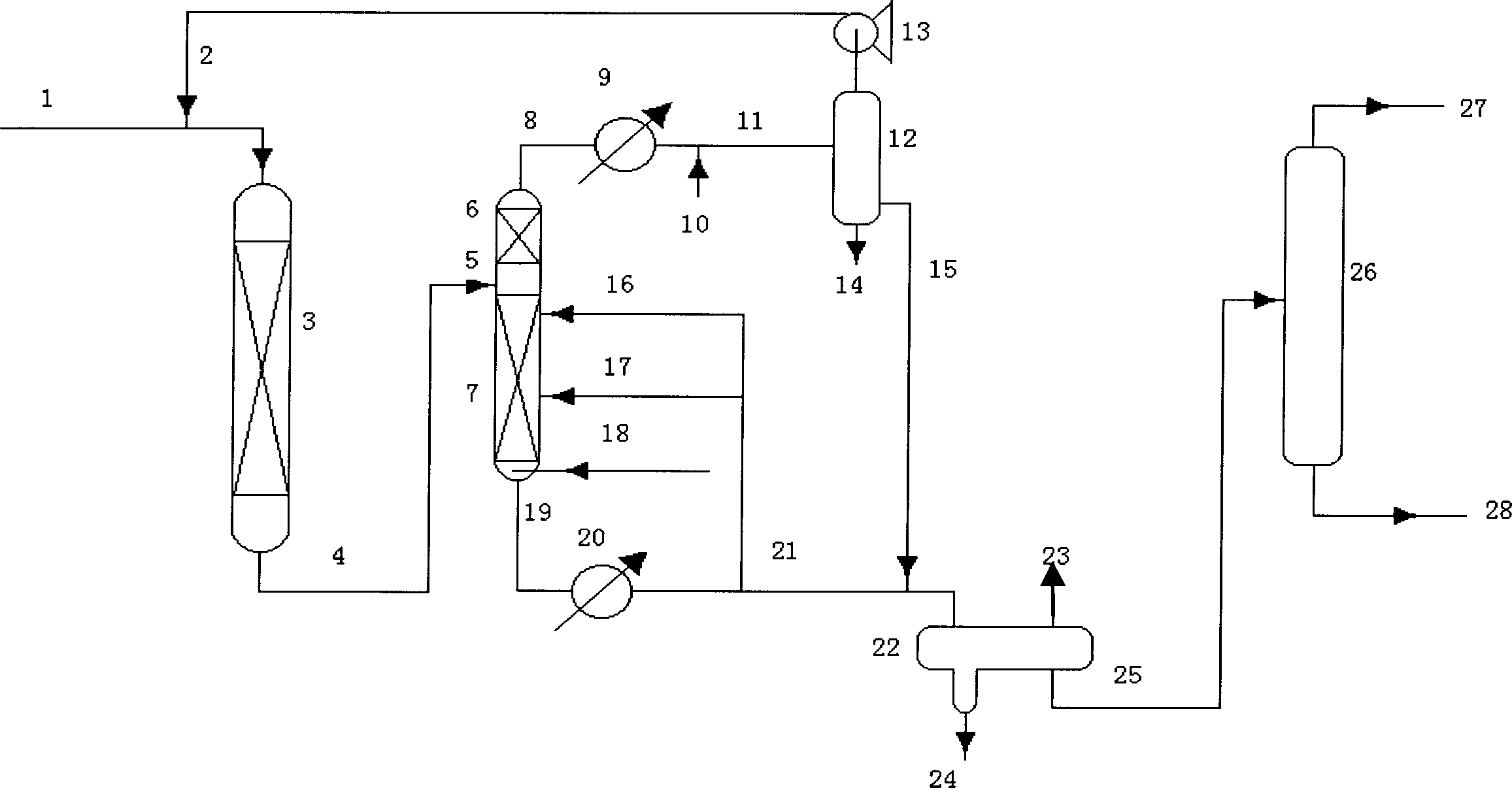

A technology for dearomatization and clean fuel, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc. It can solve the problems of narrow reaction temperature adjustment range, impossibility of good mixing effect, and incomplete reaction, etc., to achieve The effect of widening the source of raw materials, enhancing the adaptability of raw materials, and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The raw material processed in this embodiment is: straight-run diesel oil: coked diesel oil=0.56:0.44 (as shown in Table 1), as can be seen from Table 1, the sulfur content of this raw material is 1.059%, the nitrogen content is 915ppm, and the aromatic hydrocarbon content Up to 49.3v%.

[0036] composition

56% coked diesel: 44% catalytic diesel

S, wt%

1.059

N, μg / g

915

Density (20℃), g / cm 3

0.8689

43.1

Total aromatics, m%

49.3

Bicyclic and above aromatic hydrocarbons, m%

28.4

Distillation range (D-86), ℃

IBP

68

10%

181

30%

236

50%

266

70%

302

90%

340

95%

353

FBP

366

[0037] The first reaction zone of this example adopts conventional hydrofinishing technology and is filled with FH-98 hydrofinishing catalyst developed by Fushun Petrochemical Resea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com