Mesoporous silicon material as well as preparation method and application thereof

A technology of mesoporous silicon and mesoporous structure, applied in the field of mesoporous materials, to achieve the effects of high catalytic activity, high dispersion, easy recovery and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for synthesizing functionalized ordered mesoporous silicon material using polyacid type ionic liquid as raw material, comprising the following steps:

[0033] 1) Weigh the polyacid ionic liquid [C 16 mim] 3 PW 12 O 40 0.1420 g was dissolved in 4 mL of acetonitrile, stirred for 30 min to dissolve; the above solution was added to 26.2 mL of deionized water, and then 2 mL of tetraethyl orthosilicate (TEOS) and 0.52 mL of ammonia water were added to it, and copolycondensation was carried out for 3 h.

[0034] 2) Filter and wash the product obtained in the above process; dry at 120°C for 3 hours, and grind into powder; heat the powder to 550°C at a rate of 5°C / min in a programmed temperature tube furnace, and keep it for 6 hours to obtain a functionalized product. Ordered mesoporous silicon material.

example 1

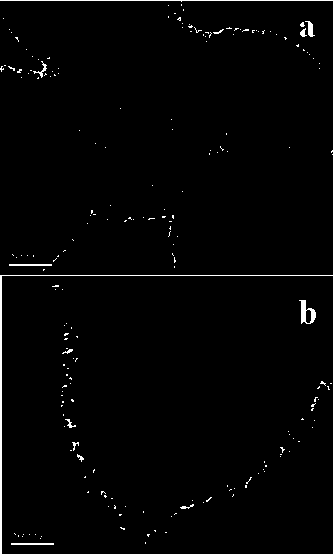

[0036] Small-angle XRD pattern of the functionalized ordered mesoporous silicon material obtained in Example 1 ( figure 1 ) and TEM images ( figure 2 ) and from the BET data, it can be seen that the prepared functionalized ordered mesoporous silicon material has an ordered mesoporous structure, a relatively uniform pore size distribution, and a large specific surface area.

Embodiment 2

[0038] A preparation method for synthesizing functionalized ordered mesoporous silicon material using polyacid type ionic liquid as raw material, comprising the following steps:

[0039] 1) Weigh the polyacid ionic liquid [C 16 mim] 3 PW 12 O 400.2840 g was dissolved in 24 mL of acetonitrile, stirred for 30 min to dissolve; the above solution was added to 40.2 mL of deionized water, and 5 mL of ethyl orthosilicate (TEOS) and 1 mL of ammonia water were added to it, and copolycondensed for 1 h.

[0040] 2) The product obtained in the above process was filtered and washed; dried at 80°C for 1 hour, and ground into powder; the powder was heated to 800°C at a rate of 10°C / min in a programmed temperature tube furnace, and kept for 3 hours to obtain a functionalized product. Ordered mesoporous silicon material.

[0041] The product of the above example 2 was determined by the BET method, and the structural parameters of the functionalized ordered mesoporous silicon material were:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com