Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Good removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

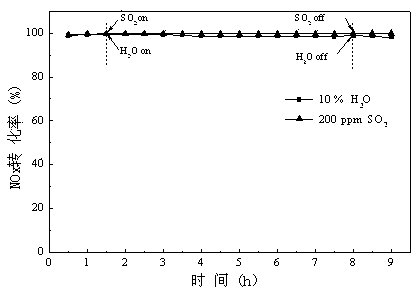

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

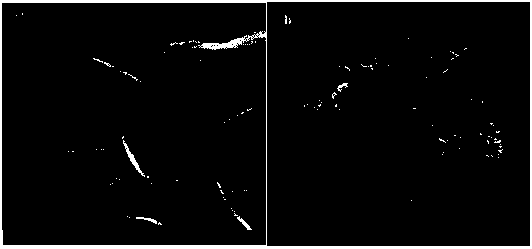

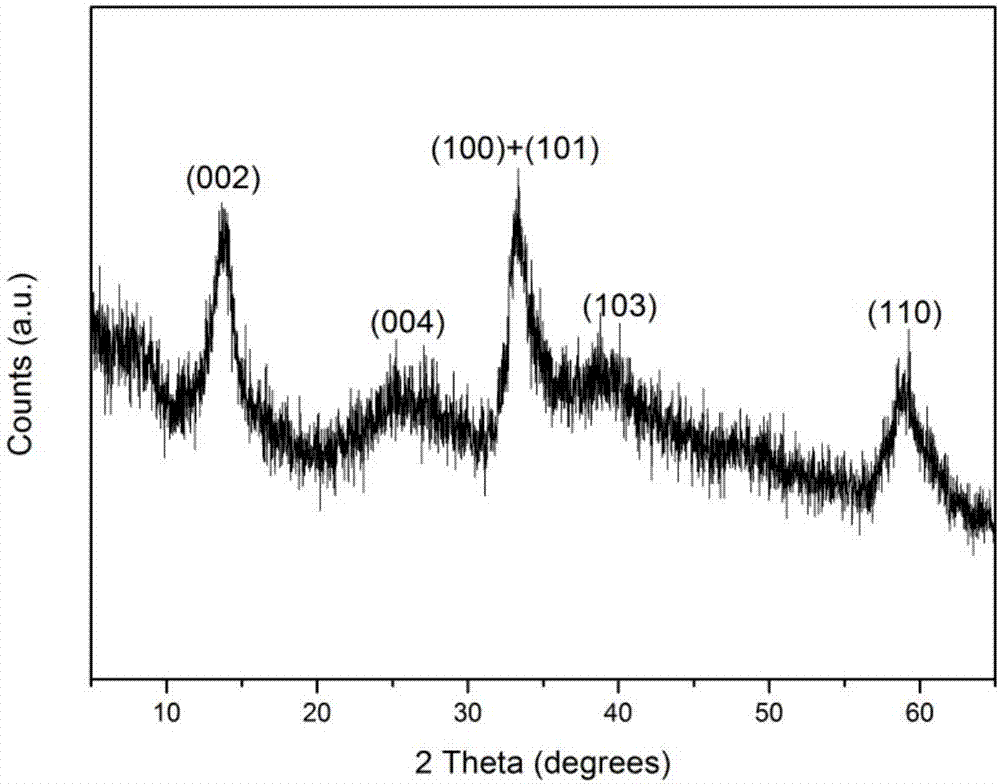

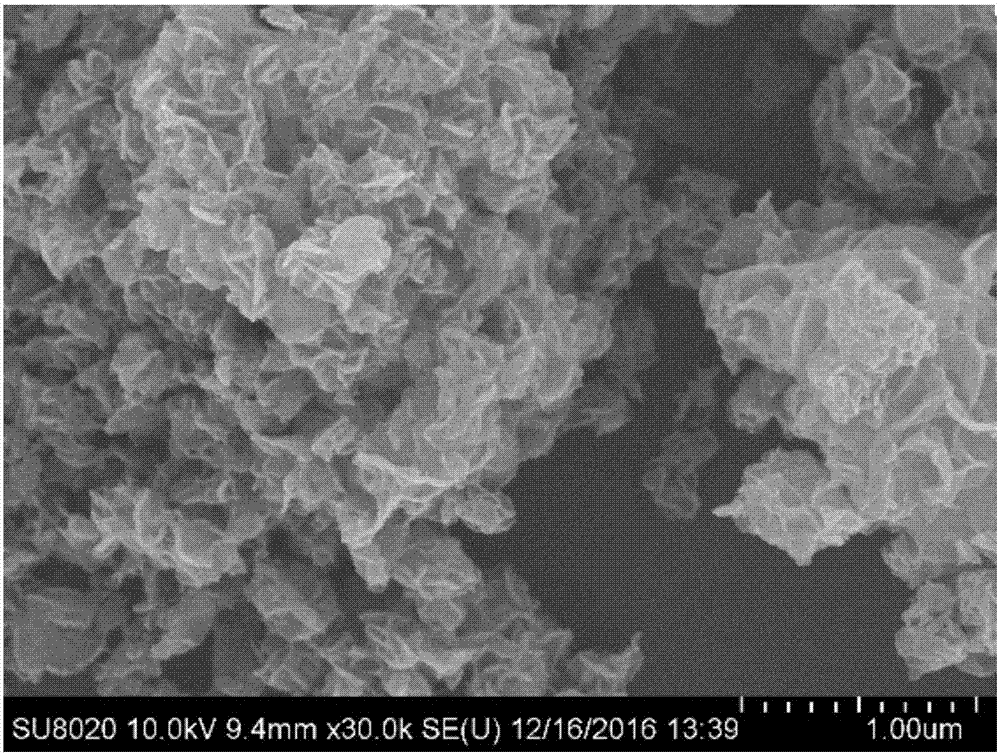

Ferro-tungsten composite oxide denitrification catalyst with flower petal structure and preparation method and application of ferro-tungsten composite oxide denitrification catalyst with flower petal structure

ActiveCN103877986AEasy to prepareLow costInternal combustion piston enginesDispersed particle separationComposite oxideFlue gas

The invention discloses a ferro-tungsten composite oxide. The ferro-tungsten composite oxide comprises three elements including ferrum (Fe), tungsten (W) and oxygen, wherein Fe and W are highly dispersed in the composite oxide with molar ratio of (5.8-12.9):1, preferentially, with molar ratio of 6.8:1. The ferro-tungsten composite oxide has a total or partial three-dimensional flower petal structure, and the flower petal structure is composed of multiple petals. The invention also discloses preparation and application of the ferro-tungsten composite oxide. The preparation method is simple and practicable, the adopted precursor is commonly used metal salt such as sulfate, tungstate, is low in cost, is easy to obtain, and can reach industrial production conveniently. The obtained ferro-tungsten composite oxide with the flower petal structure as the denitrification catalyst has high catalytic activity and N2 selectivity, is wide in temperature range, and high in sulfur dioxide and water poisoning resistance, and is used for purifying or eliminating nitric oxide in flue gas from a regular source, diesel exhaust and tail gas from a lean-burning gasoline engine.

Owner:UNIV OF JINAN

Thermosetting resin grinding pad and preparation method thereof

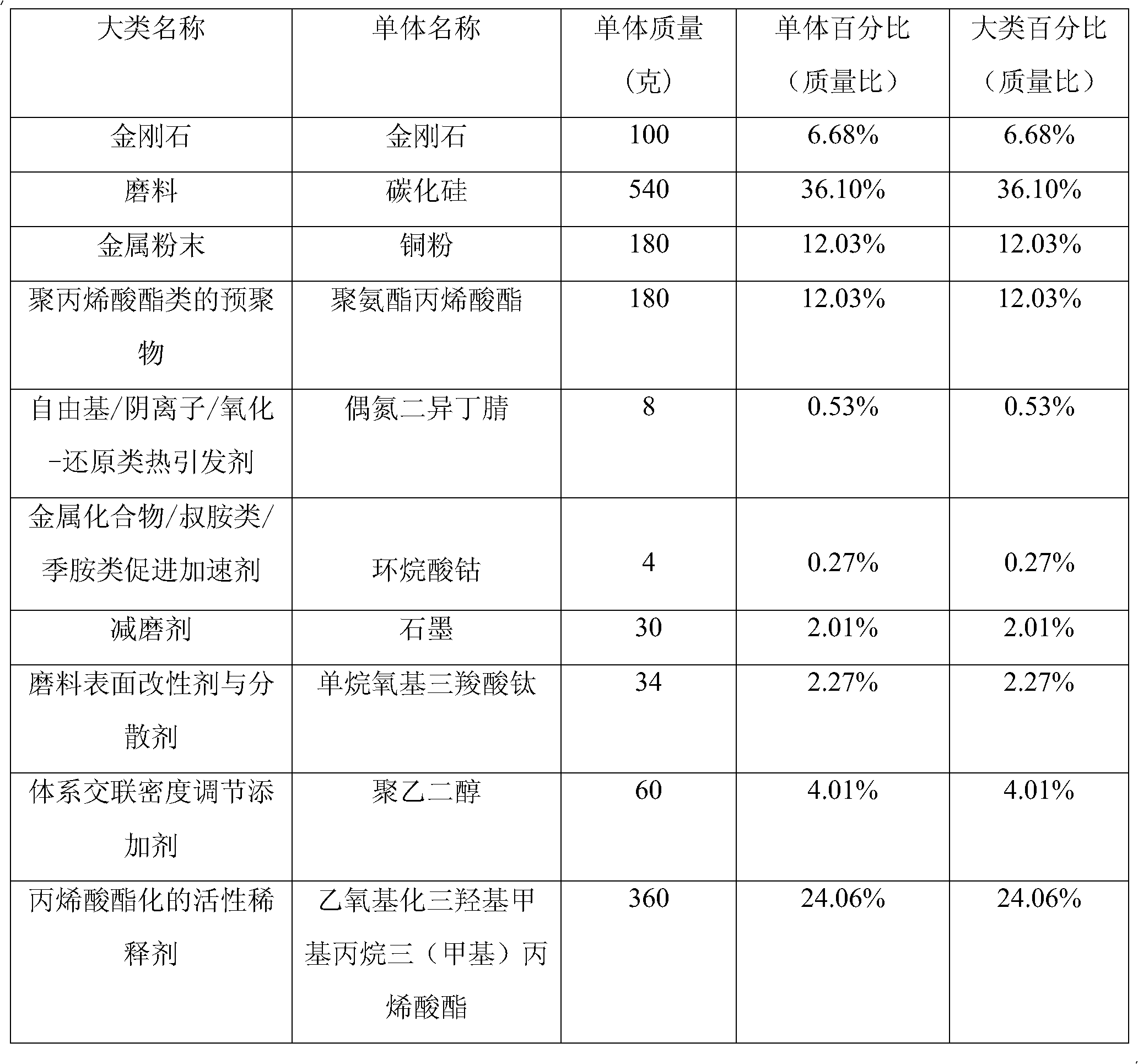

InactiveCN102632453AHigh densityHigh hardnessGrinding devicesLapping toolsReactive diluentMetal powder

The embodiment of the invention discloses a thermosetting resin grinding pad and a preparation method thereof. The thermosetting resin grinding pad comprises a diamond, a grinding material and a resin base body and contains the following components in percentage by mass of: 4 to 7 percent of diamond with the particle size being between 40 and 50 microns, 9 to 40 percent of grinding material with the particle size being between 20 and 70 microns, 10 to 55 percent of metal powder with the particle size being between 20 and 70 microns, 10 to 60 percent of polyacrylic prepolymer, 0.1 to 1 percent of radical / anion / oxidation-reduction thermal initiator, 0 to 0.7 percent of metal compound / tertiary amine / quaternary amine promote accelerator, 0.5 to 5 percent of antifriction composition, 0 to 4 percent of grinding material surface modifier and dispersing agent, 0 to 20 percent of system crosslinking density adjustment additive and 5 to 40 percent of acyclic acid esterification reactive diluent. According to the thermosetting resin grinding pad, the density, the mechanical strength and the abrasion resistance of the thermosetting resin grinding pad are improved.

Owner:ZHEJIANG PUJIANG MINRUI PRECISION MACHINERY TECH

Mesoporous silicon material as well as preparation method and application thereof

ActiveCN103464140AHigh catalytic activityImprove dispersionHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsIonSol-gel

The invention relates to a mesoporous material and particularly relates to a functionalized ordered mesoporous silicon material which is synthesized by taking polyacid-type ionic liquid as a raw material as well as an application of the mesoporous silicon material in oxidation desulfuration of fuel oil. According to the mesoporous silicon material, the polyacid-type ionic liquid is not only used as a template agent of the mesoporous material, but also used as a catalytic activity center, and transition metal is introduced into the mesoporous material structure in situ. A simple and nontoxic synthesis method of the metal-doped green mesoporous material is searched, has a favorable academical research value and also has a wide application prospect in the industrial production. The mesoporous silicon material as well as the preparation method and the application thereof have the advantages that the method is simple in process, and the mesoporous silicon material which is narrow in pore size distribution, regular and ordered in pore duct and good in thermal stability and has the pore size of 2-50nm is self-assembled under the guidance action of inorganic matters and organic matters by adopting a sol-gel method. The purpose of deep desulfuration can be achieved when the mesoporous silicon material is used as a catalyst for an oxidation removing reaction process of organic sulfides.

Owner:泰州市海创新能源研究院有限公司

MoS2/polyelectrolyte hybrid nanofiltration membrane and production method thereof

ActiveCN107486045AImprove dispersion stabilityExcellent removal and fluxSemi-permeable membranesChemistryNanofiltration

The invention discloses a MoS2 / polyelectrolyte hybrid nanofiltration membrane and a production method thereof, and belongs to the technical field of membrane separation. The production method comprises the following steps: preparing a PDDA surface-modified nano-MoS2; preparing an anionic polyelectrolyte solution and a cationic polyelectrolyte solution containing the PDDA surface-modified nano-MoS2; and carrying out an electrostatic layer-by-layer self-assembling on the anionic polyelectrolyte and the cationic polyelectrolyte solution containing the PDDA surface-modified nano-MoS2 to obtain the MoS2 / polyelectrolyte hybrid nanofiltration membrane. MoS2 is a graphene-like two-dimensional layered material, and has a unique lamellar structure. Polydimethyldiallylammonium chloride (PDDA) is added during the preparation of MoS2 to make the surface of the MoS2 positively charged and improve the dispersion stability, so the MoS2 can be uniformly dispersed in a membrane in the self-assembling process to obtain the hybrid nanofiltration membrane having an excellent MoS2 dispersion performance, and the hybrid nanofiltration membrane has excellent separation removal rate and excellent flux to an aqueous dye solution.

Owner:BEIJING UNIV OF TECH

Low-temperature SCR (selective catalytic reduction) smoke gas efficient denitration catalyst and preparation method thereof

InactiveCN106861674ALow denitrification efficiencyGood activity at low temperatureGas treatmentHeterogenous catalyst chemical elementsRare earthWater resistant

The invention relates to a low-temperature SCR (selective catalytic reduction) smoke gas efficient denitration catalyst and a preparation method thereof, and belongs to the technical field of catalyst manufacturing. The catalyst uses titanium dioxide as carriers, and contains tungsten oxide, vanadium oxide and antimony oxides or contains rare earth metal cerium oxide; the catalyst without rare earth metal cerium oxide has a little lower denitration efficiency than the catalyst containing rare earth metal cerium oxide. The denitration efficiency of the catalyst reaches 85 percent or more at the low temperature of 130 degrees; the value is much higher than the current condition of the denitration efficiency of being less than 50 percent in the prior art. The low-temperature activity of the catalyst is good; a good oxynitride removal rate and water-resistant and sulphur-resistant performance can be realized within the temperature range of 130 to 250 DEG C; the catalyst has high activity and toxicity resistance at 130 to 250 DEG C, so that the catalyst can be installed behind a coal-fired boiler dust remover; the defects of the existing smoke gas denitration technology are overcome; the catalyst can also be applied to the smoke gas denitration of industrial kilns and the like.

Owner:大连瑞克科技股份有限公司

Fume oxidation denitration catalyst prepared by sol-gel method and preparation process thereof

ActiveCN106732543AGood dispersionSimple preparation processGas treatmentHeterogenous catalyst chemical elementsPtru catalystNitrogen oxides

The invention relates to a fume oxidation denitration catalyst prepared by a sol-gel method and a preparation process thereof. The catalyst is prepared from the following components in percentage by weight: 19-70 wt% of manganic oxide, 10-40 wt% of transition metal oxide and 10-60 wt% of cerium oxide. The preparation process comprises the steps: under the effect of polyethylene glycol and citric acid, performing sol-gel reaction of the soluble salt of manganese, the soluble salt of transition metal and the soluble salt of cerium; through aging, drying and calcining to obtain the fume oxidation denitration catalyst. The catalyst has the advantages that a required instrument for preparation is simple; the raw materials can be easily obtained; the cost is low; the activity under low temperature is good; the good nitrogen oxide removal rate and anti-water and anti-sulfur performances at 150-207 DEG C are maintained; the catalyst can be applied to the fume oxidation denitration of thermal power plants and industrial furnaces and the like.

Owner:SHANDONG UNIV

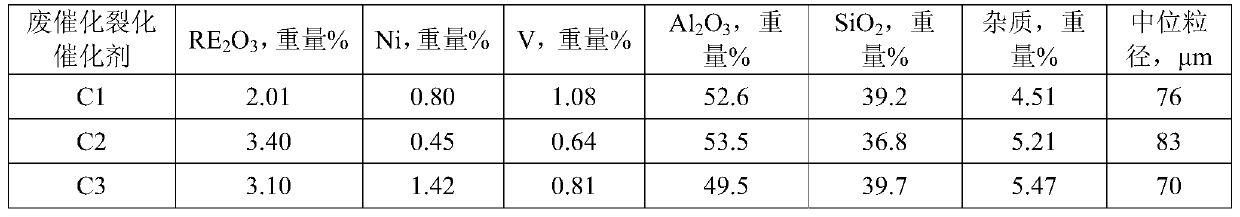

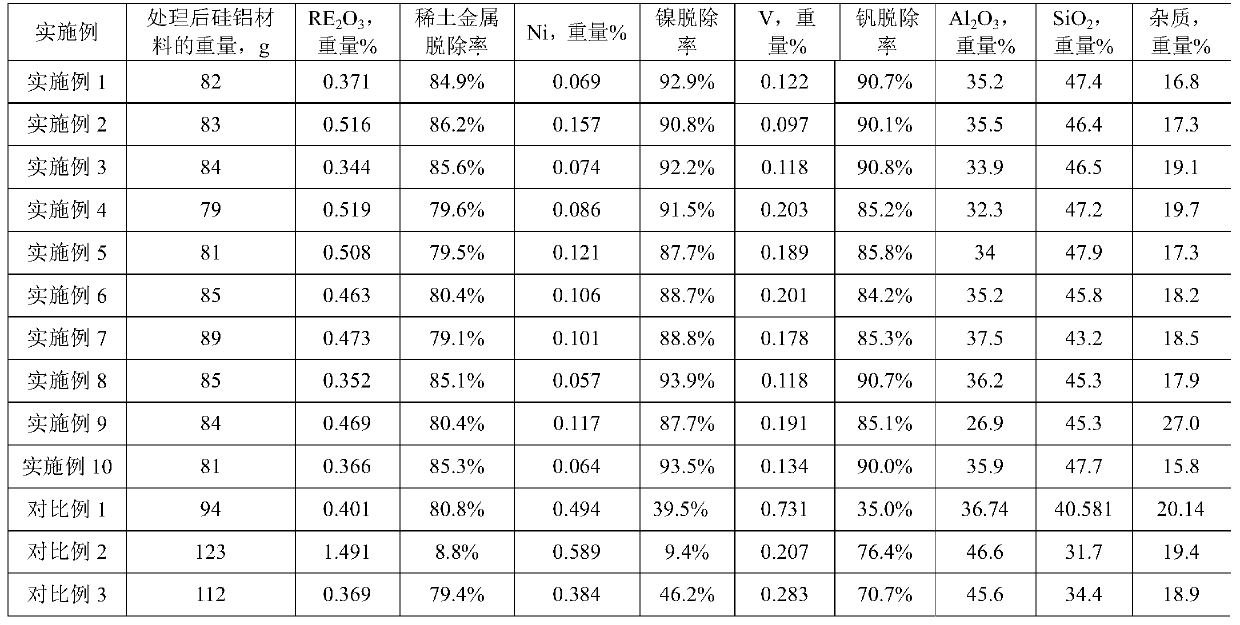

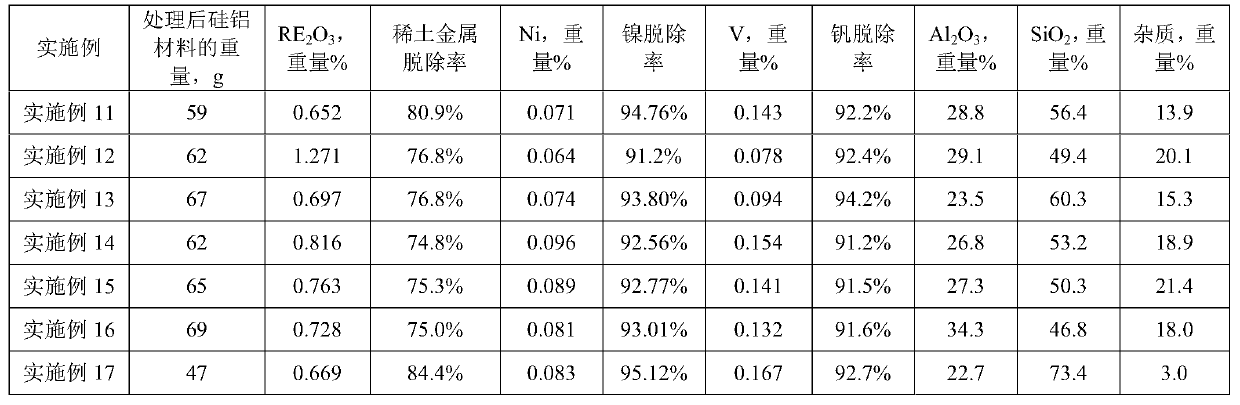

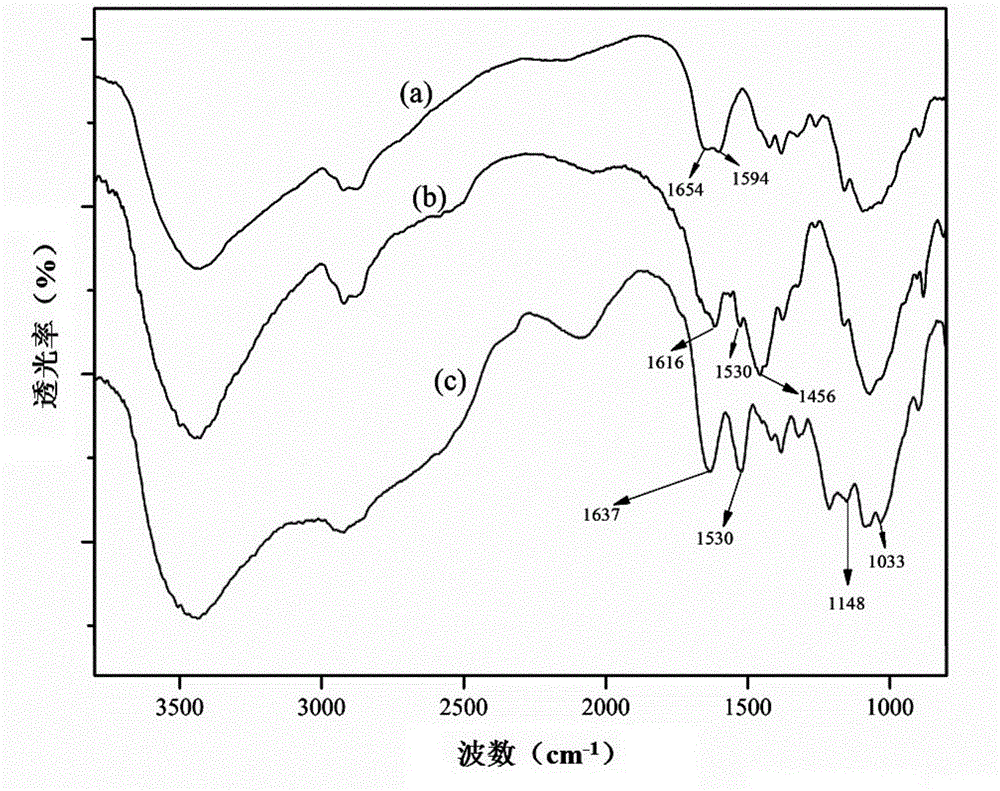

Treatment method for waste catalytic cracking catalyst, obtained silicon-aluminum material and application of silicon-aluminum material

ActiveCN110387470AReduce nickel contentGood removal rateTransportation and packagingSolid waste disposalAfter treatmentSilicon

The invention relates to a treatment method for a waste catalytic cracking catalyst, an obtained silicon-aluminum material and application of the silicon-aluminum material. The method comprises the following steps that a, the waste catalytic cracking catalyst and an alkaline solution are mixed and then are dipped at the temperature of 70-220 DEG C, or the waste catalytic cracking catalyst and an alkali-containing material are mixed and then are roasted at the temperature of 500-1000 DEG C so as to obtain a roasted catalyst; b, the dipped catalyst or the roasted catalyst are washed with water for 0.1-3 h so as to obtain a washed catalyst; c, the washed catalyst and acid are mixed and are subjected to acid leaching treatment at the temperature of 50-185 DEG C for 0.1-3 h so as to obtain a catalyst subjected to acid leaching treatment; and d, the catalyst subjected to acid leaching treatment is washed to neutral, and a solid product is collected. According to the method, the contents of nickel and vanadium in the waste catalytic cracking catalyst can be effectively decreased, and the silicon-aluminum material obtained after treatment can be reused as a building material and / or a catalyst carrier material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Covalent organic framework film material for removing triclosan in environmental water as well as preparation method and application of same

ActiveCN111647184AImprove performanceResilientOther chemical processesWater contaminantsTriclosanPtru catalyst

The invention discloses a covalent organic framework film material for removing triclosan in environmental water as well as a preparation method and application of same. In particular, terephthalaldehyde and 1,3,5-tri-(4-aminophenyl) benzene are used as bridging monomers, p-toluenesulfonic acid monohydrate is used as a catalyst, an acetonitrile-water solution and an ethyl acetate solution are usedas two-phase solvents, and the novel TAPB-TPA-COFs film is polymerized at room temperature through a liquid phase interface method. The prepared film material is prepared into a small solid-phase extraction column, an excellent adsorption effect on triclosan in environmental water is achieved, the maximum adsorption capacity can reach 12.21 mg / g, and the optimal removal rate of TCS can reach 99.72%. The TAPB-TPA-COFs membrane is relatively good in crystallinity, high in thermal stability and low in cost, has efficient adsorption performance on TCS, can be repeatedly utilized, and has a greatapplication prospect in the field of environmental pollutant enrichment and separation.

Owner:MINJIANG UNIV

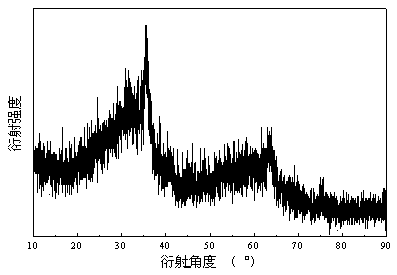

Preparation method of manganese series low-temperature SCR denitration catalyst

InactiveCN105817233AGood activity at low temperatureGood removal rateGas treatmentHeterogenous catalyst chemical elementsRare earthManganese

The invention discloses a preparation method of a manganese-based low-temperature SCR denitrification catalyst, which comprises: first preparing a manganese salt solution, adding transition metal salts or rare earth metal salts to the prepared manganese salt solution to obtain a metal salt mixed solution, and ultrasonically treating Mix the solution evenly, prepare the ammonium salt solution, add the metal salt mixed solution to a certain weight of titanium dioxide, stir evenly to obtain a solid, slowly add the pre-prepared ammonium salt solution to the obtained solid, stir evenly, and wash , dried, and calcined to obtain a manganese-based low-temperature SCR denitration catalyst. Beneficial effects of the present invention: the obtained catalyst has good low-temperature activity, and can maintain a good nitrogen oxide removal rate and water and sulfur resistance at 120-250 ° C. This catalyst can be applied to thermal power plant dust collectors and after desulfurization As well as low-temperature fields such as industrial kilns where the flue gas temperature is between 120-250 ° C, a breakthrough in denitrification catalyst technology and application has been achieved.

Owner:北京科林佰德环保有限公司

Method for pretreating, decalcifying and dephosphorizing high-calcium and high-phosphorus vanadium slag

The invention discloses a method for pretreating, decalcifying and dephosphorizing high-calcium and high-phosphorus vanadium slag, and belongs to the technical field of metallurgy. The method for pretreating, decalcifying and dephosphorizing high-calcium and high-phosphorus vanadium slag aims to overcome the problems that high-calcium and high-phosphorus vanadium slag influences the productivity and cost during vanadium extraction. The method comprises the steps: mixing and leaching the high-calcium and high-phosphorus vanadium slag with an ammonium chloride solution, carrying out solid-liquidseparation after leaching, and drying the solid to obtain the decalcified and dephosphorized vanadium slag. The method adopts the ammonium chloride solution to leach and pretreat the high-calcium andhigh-phosphorus vanadium slag, so that insoluble calcium oxide in the high-calcium and high-phosphorus vanadium slag reacts with the ammonium chloride to form soluble calcium chloride, meanwhile, thephosphorus content in the slag is reduced, the decalcified low-phosphorus vanadium slag is obtained, and the subsequent processes of roasting, leaching and vanadium precipitation can be smoothly carried out.

Owner:PANZHIHUA UNIV +1

Protein-fouling-resistant zwitter-ion ultrafiltration membrane and preparation method thereof

ActiveCN105727761AGood hydrophilicityGood anti-fouling selectivityMembranesUltrafiltrationUltrafiltrationIon

The invention discloses a protein-fouling-resistant zwitter-ion ultrafiltration membrane and a preparation method thereof. The zwitter-ion ultrafiltration membrane is prepared by coating gel, prepared through sol-gel reaction of zwitterionization chitosan and polyvinyl alcohol, on a supporter to form a membrane, and soaking the membrane into water for phase conversion reaction. The zwitter-ion ultrafiltration membrane prepared from the polyvinyl alcohol modified by the zwitterionization chitosan is highly resistant to water, remarkable in hydrophilicity and antifouling performance and good in antifouling selectivity and particularly achieves the ratio of removing bovine serum albumin up to 97.6%; the zwitter-ion ultrafiltration membrane capable of achieving targeted protein fouling resistance can maintain high membrane flux and high bovine serum albumin removal rate through multiple experiments and is long in service life; additionally, the zwitter-ion ultrafiltration membrane is simple in preparation technology, highly repeatable and easy to achieve scale production, requires no strict control over reaction conditions and the like.

Owner:SHANGHAI UNIV OF ENG SCI

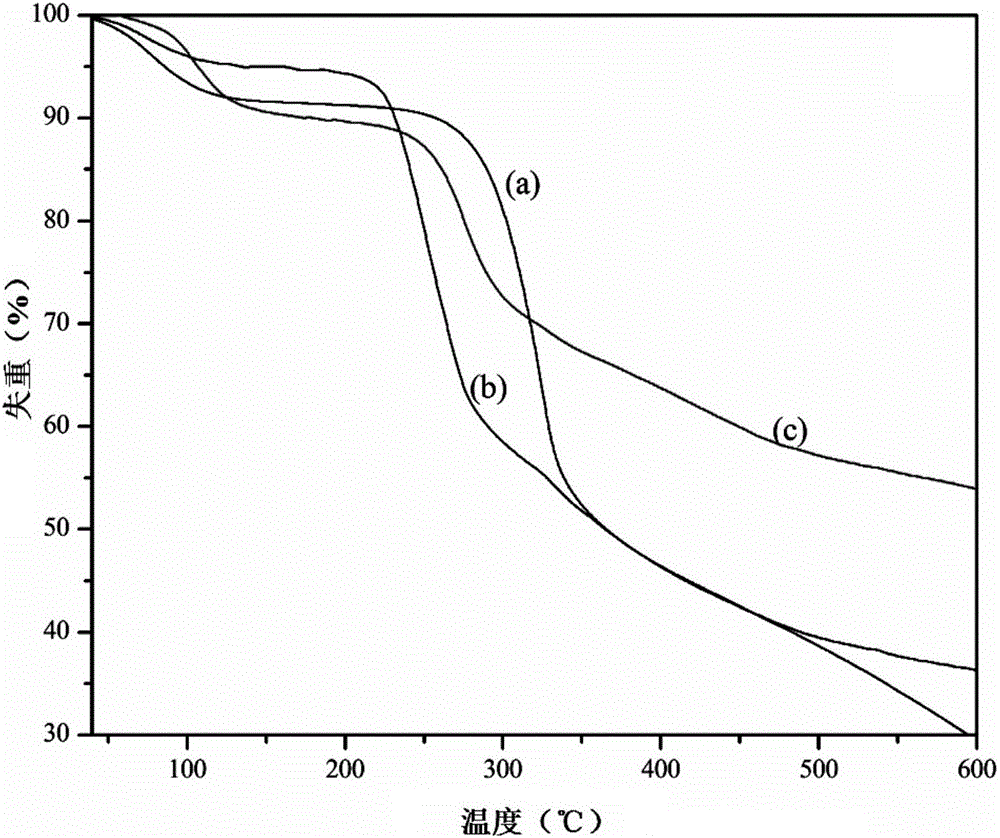

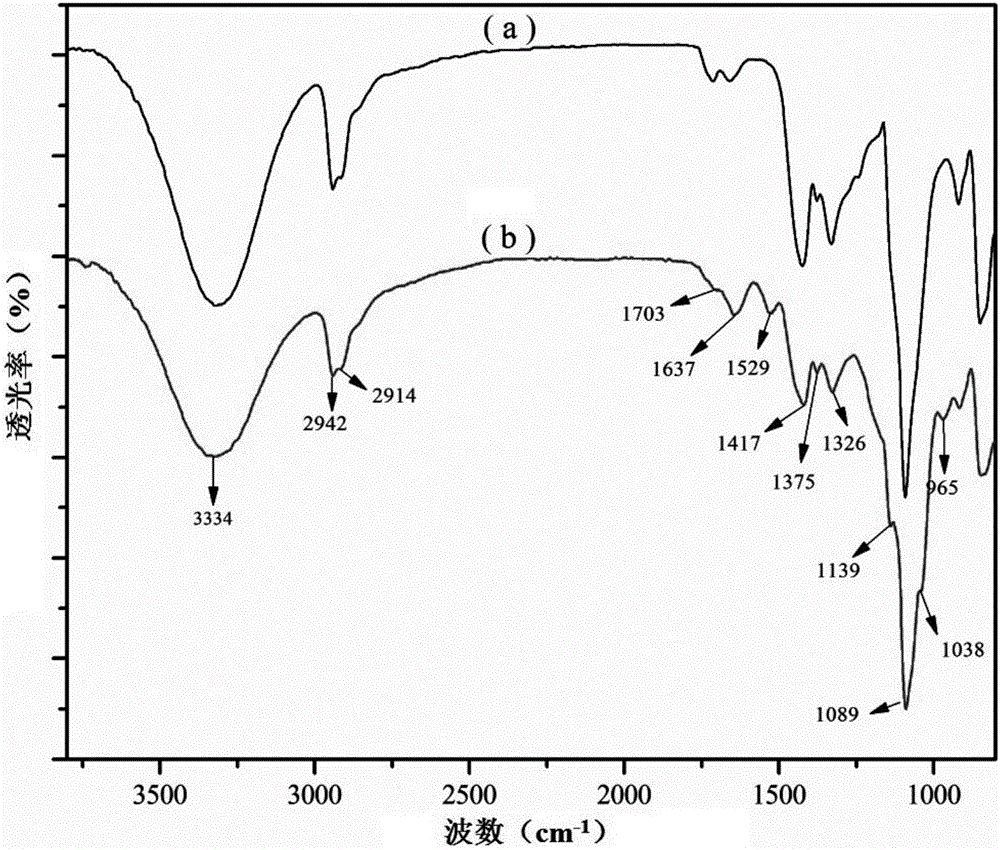

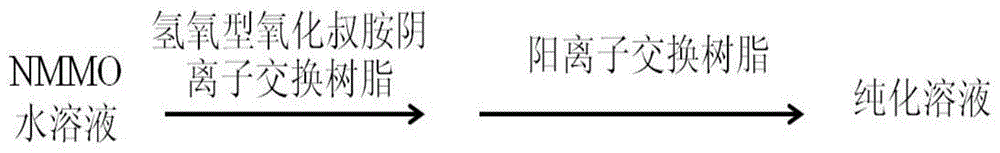

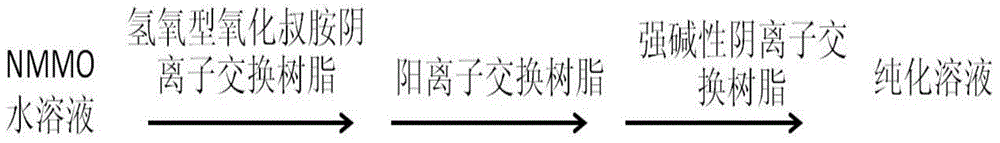

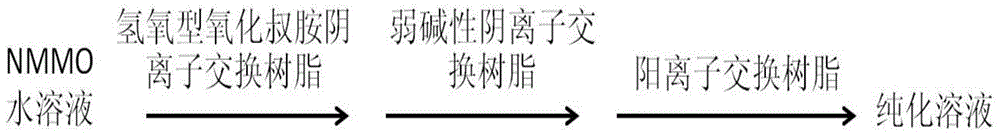

Oxyhydrogen type tertiary amine oxide anion exchange resin, preparation method thereof and purification method of NMMO (N-methylmorpholine N-oxide) aqueous solution

ActiveCN104801354AImprove recycling ratesGood recycling rateIon-exchange process apparatusAnion exchangersFiberPurification methods

The invention provides oxyhydrogen type tertiary amine oxide anion exchange resin, a preparation method thereof and a purification method of an NMMO (N-methylmorpholine N-oxide) aqueous solution. The preparation method comprises the following steps: S1, tertiary amine type anion exchange resin has an oxidation reaction to prepare the tertiary amine oxide anion exchange resin; S2, the tertiary amine oxide anion exchange resin reacts with aqueous alkali to prepare the oxyhydrogen type tertiary amine oxide anion exchange resin. When the oxyhydrogen type tertiary amine oxide anion exchange resin is adopted to purify the NMMO solution, impurities do not remain on the oxyhydrogen type tertiary amine oxide anion exchange resin, so that the oxyhydrogen type tertiary amine oxide anion exchange resin has higher recyclability; meanwhile, the exchange efficiency of ion exchange resin and the removal rate of transition metal anions in the NMMO aqueous solution can be increased substantially, and the economy and safety in a Lyocell fiber production process are improved.

Owner:CHINESE TEXTILE ACAD

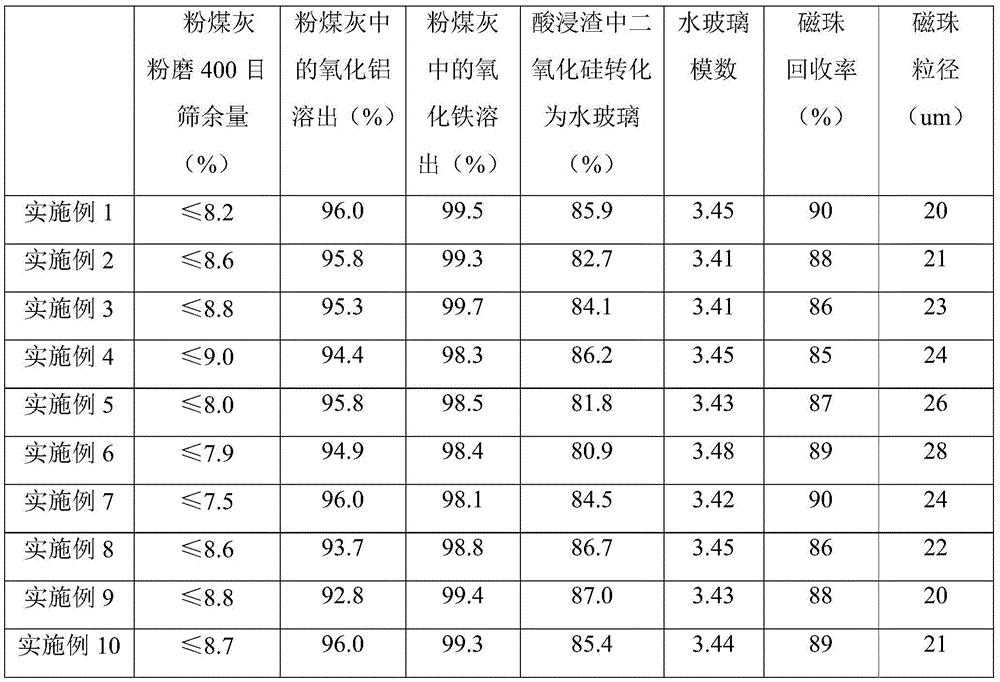

Method for preparing sodium silicate by using common pulverized fuel ash from circulating fluidized bed

PendingCN105621427AMake full use of resourcesSimple preparation processAlkali metal silicatesMagnetic separationFluidized bedPulverized fuel ash

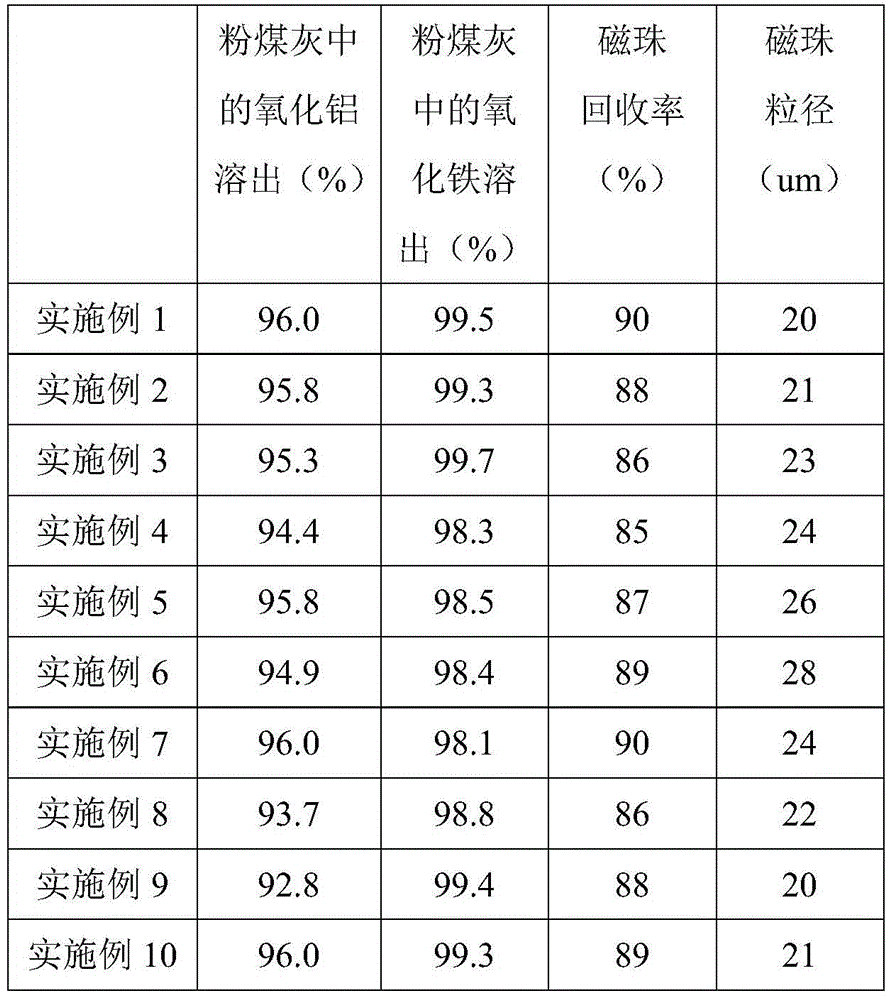

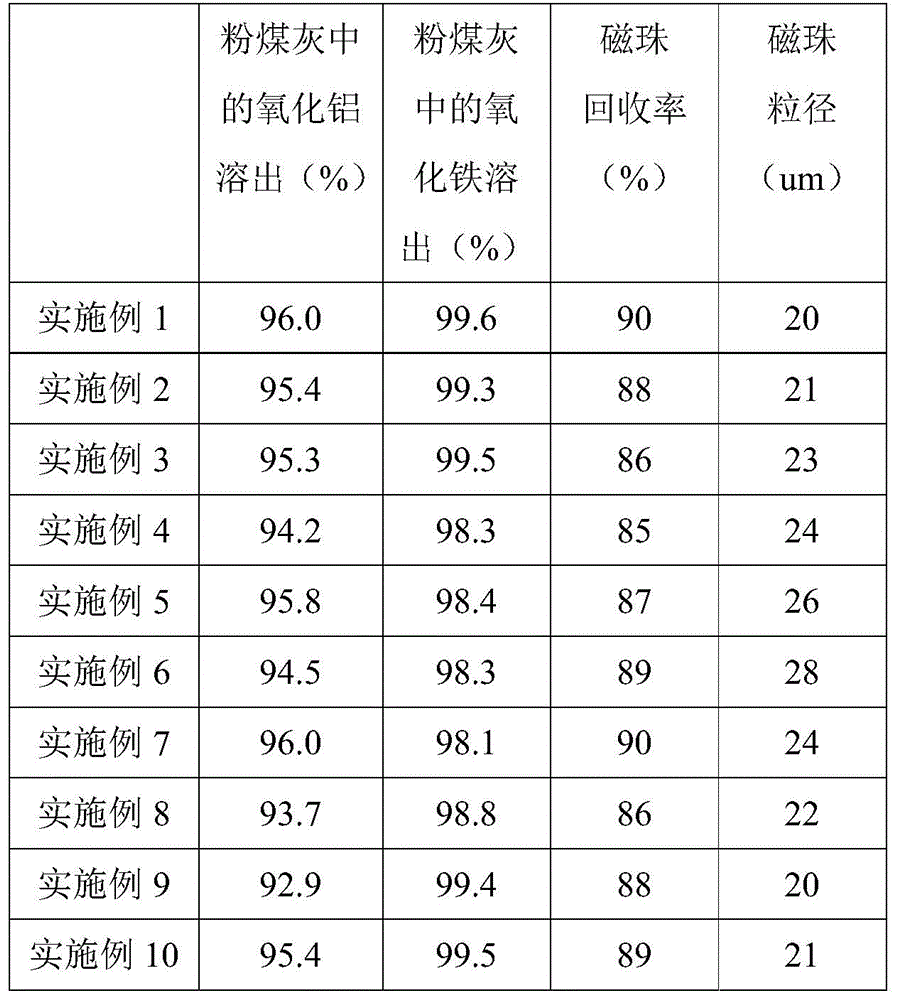

The invention provides a method for preparing sodium silicate by using common pulverized fuel ash from a circulating fluidized bed, comprising: reacting sulfuric acid with pulverized fuel ash under low-temperature roasting conditions, dissolving out Al2O3, Fe2O3 and F3O in the pulverized fuel ash, and using a caustic solution to hydrothermally extract at high temperature SiO2 in acid leaching residue. The method provided by the invention has no special requirement on equipment, capable of roasting at low temperature and efficient in utilizing SiO2 in pulverized fuel ash to prepare sodium silicate; the method provided by the invention can dissolve out 90-96% of aluminum oxide in pulverized fuel ash and 98-100% of iron oxide in the pulverized fuel ash; 80-87% of silicon dioxide in the acid leaching residue is converted into liquid -1-type sodium silicate greater than 3.4 in modulus. The technical scheme provided by the invention makes full use of pulverized fuel ash resources, and the manufacture process is simple and low in production cost and is suitable for large-scale production.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Lead removal method for porphyra haitanensis

The invention discloses a lead removal method for porphyra haitanensis, which includes that fresh porphyra haitanensis and deionized water in weight volume ratio of 4.5-5.5:25 are placed in a container, the container is moved to an ultrasonic wave exactor for performing ultrasonic treatment on the porphyra haitanensis with the ultrasonic lasting time of 0.3-0.6 and interval of 0.7-0.4 sec and at the ultrasonic temperature of 25-45 DEG C and ultrasonic frequency of 25 KHz, and the total ultrasonic treatment time is 15-25 min; after the ultrasonic treatment with specific conditions, the lead removal rate of porphyra haitanensis can reach more than 92%, and the lead residual quantity of porphyra haitanensis is lower than the national standard requirement, the harmfulness to people on having porphyra haitanensis, in particular to children is reduced; besides, the lead removal method has no pollution to porphyra haitanensis, has slight influence on the quality of porphyra haitanensis, shorter removal time, high speed and higher removal rate.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

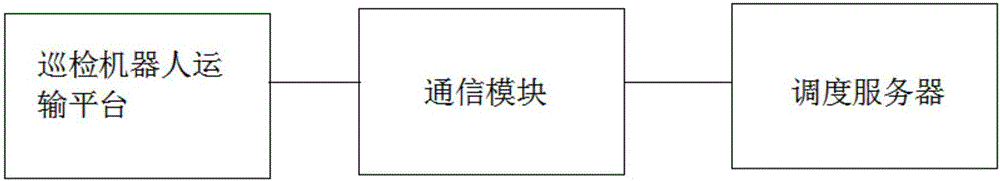

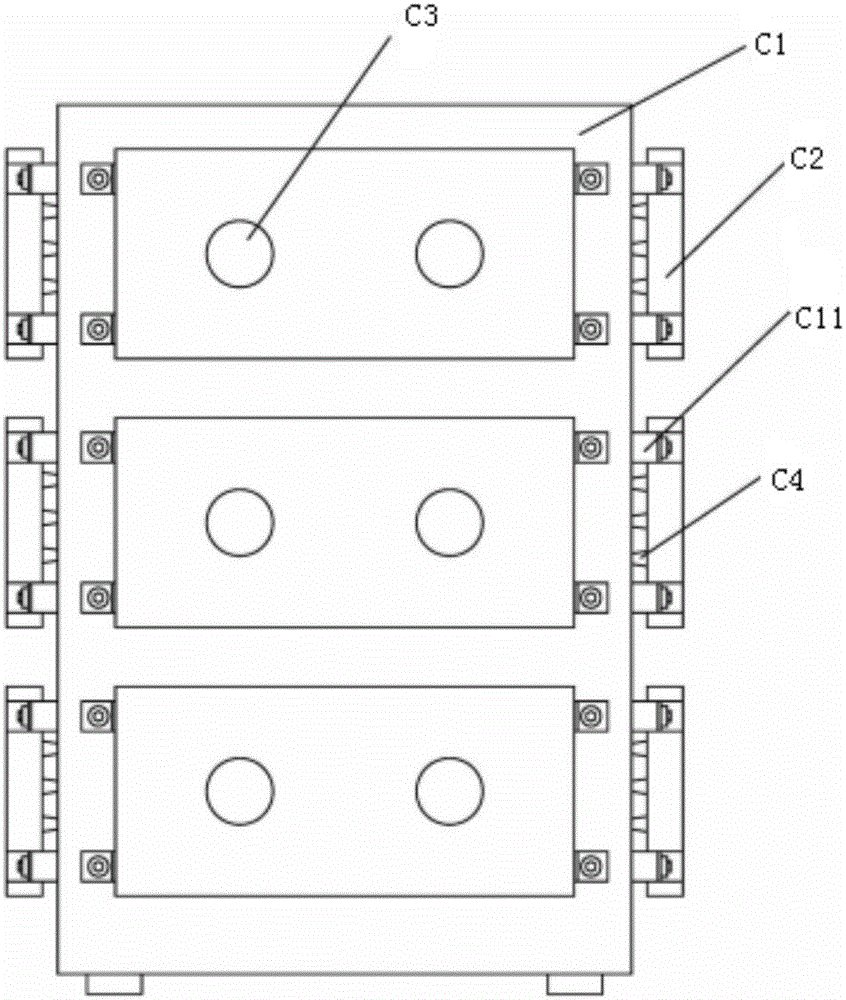

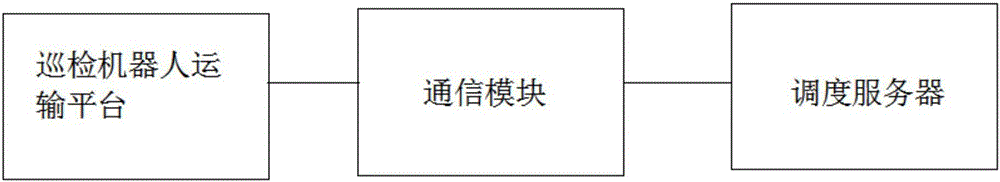

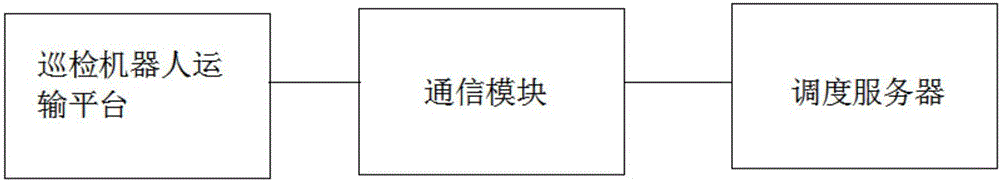

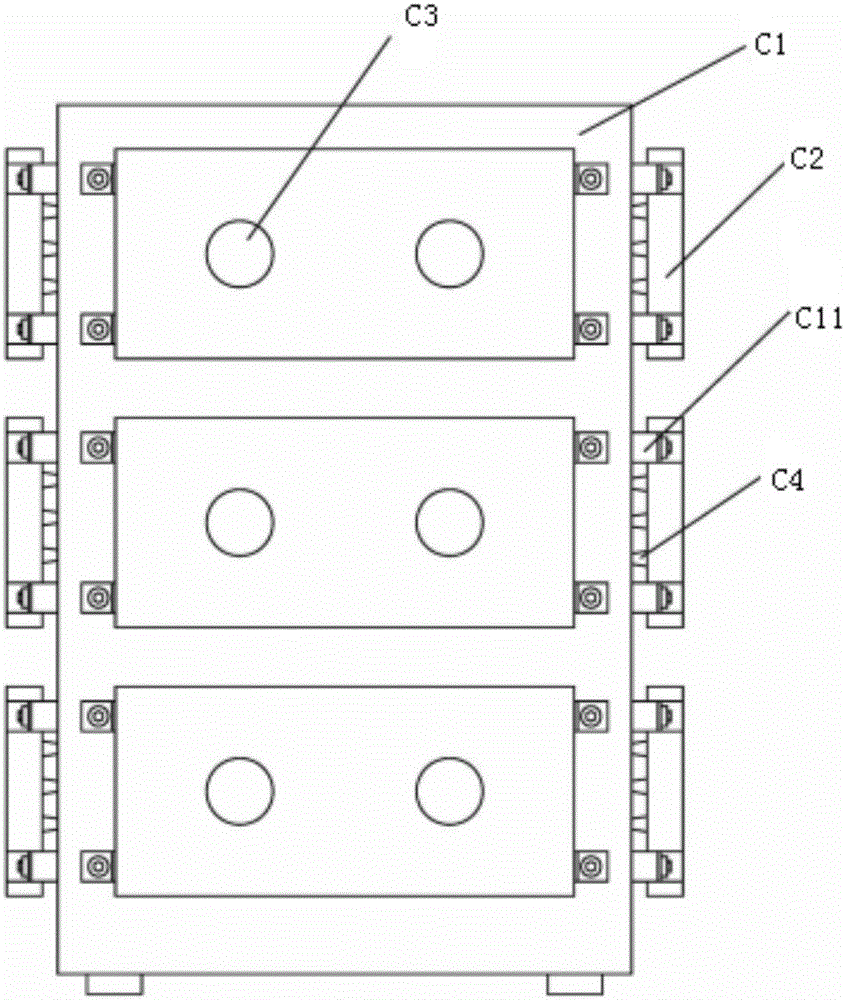

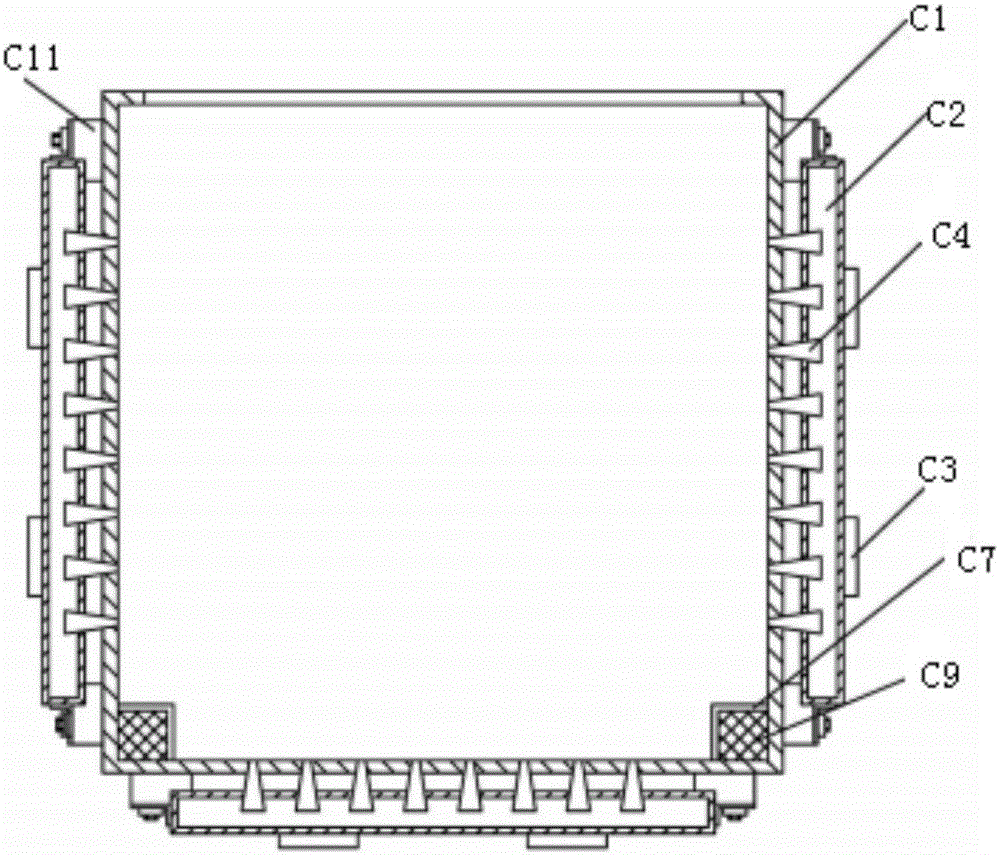

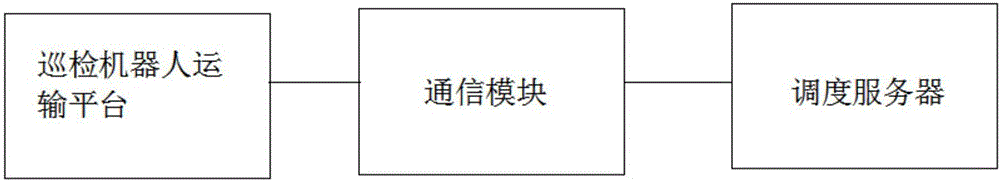

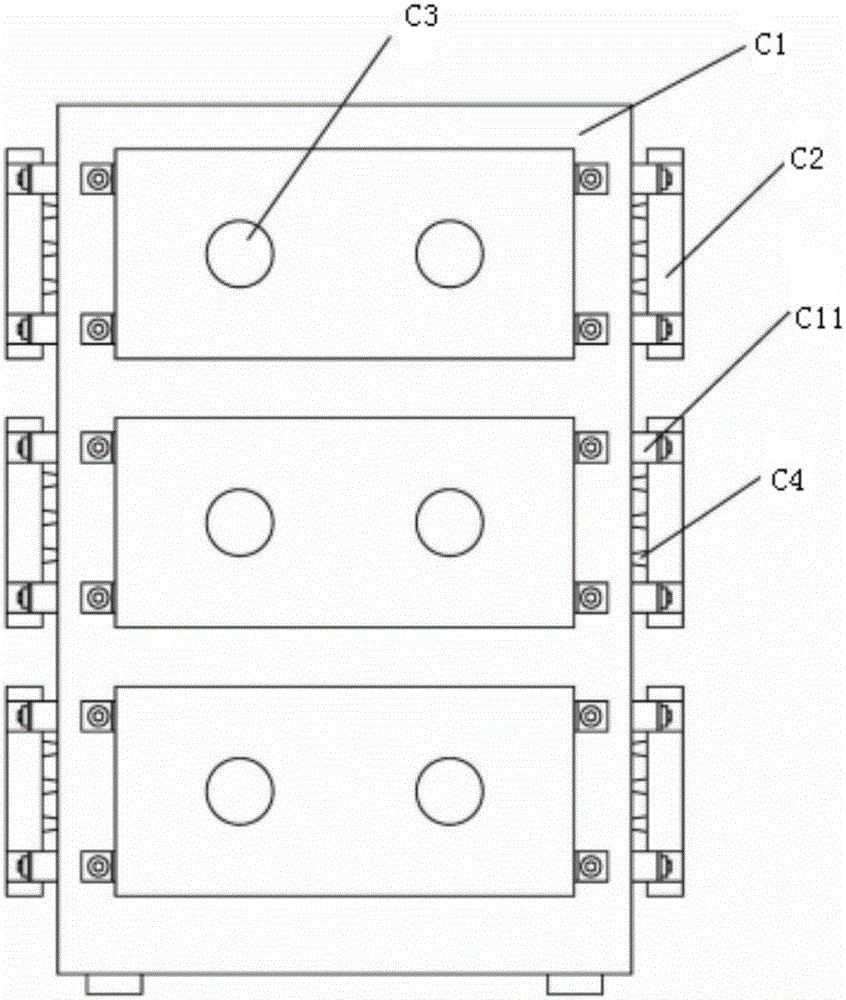

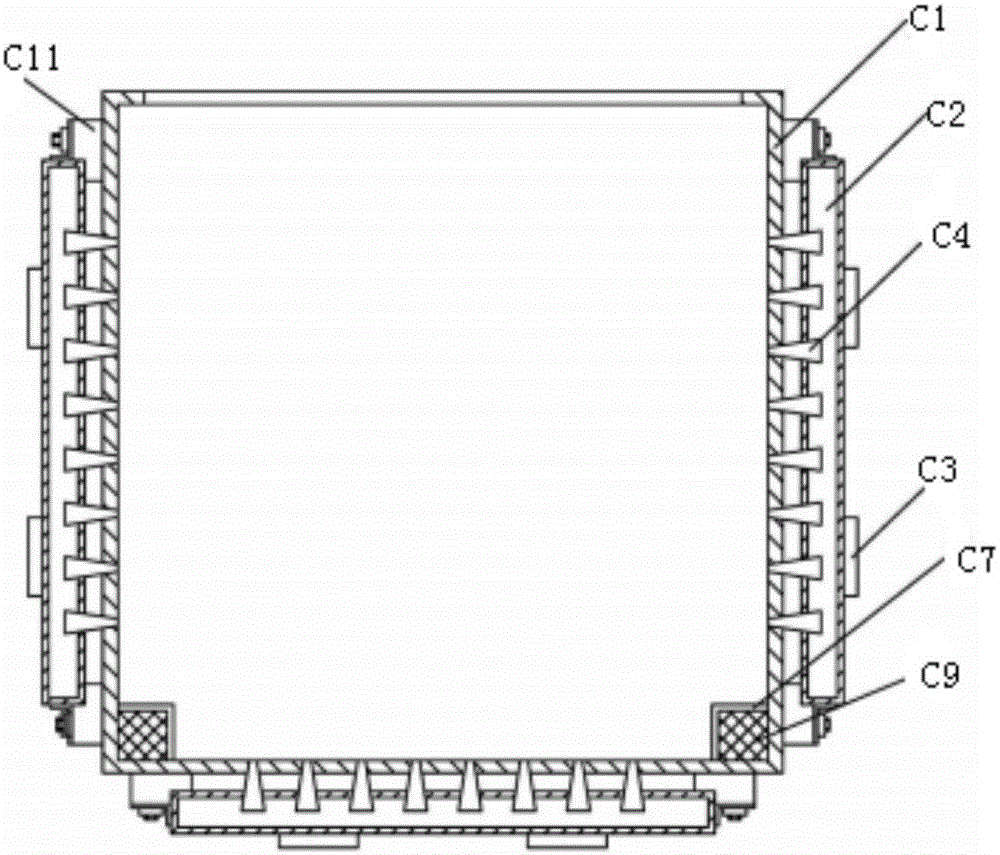

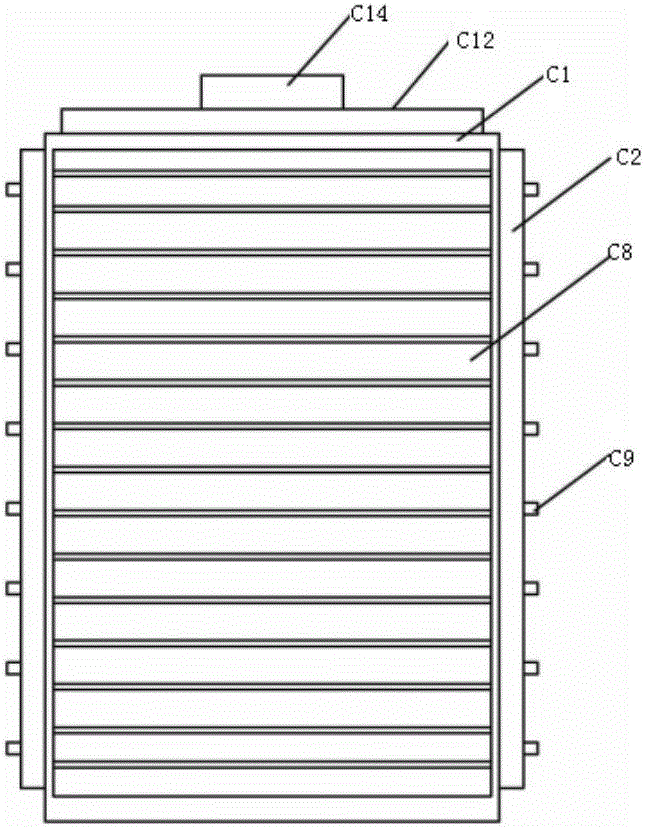

Cooling type transformer substation dispatching system and method thereof

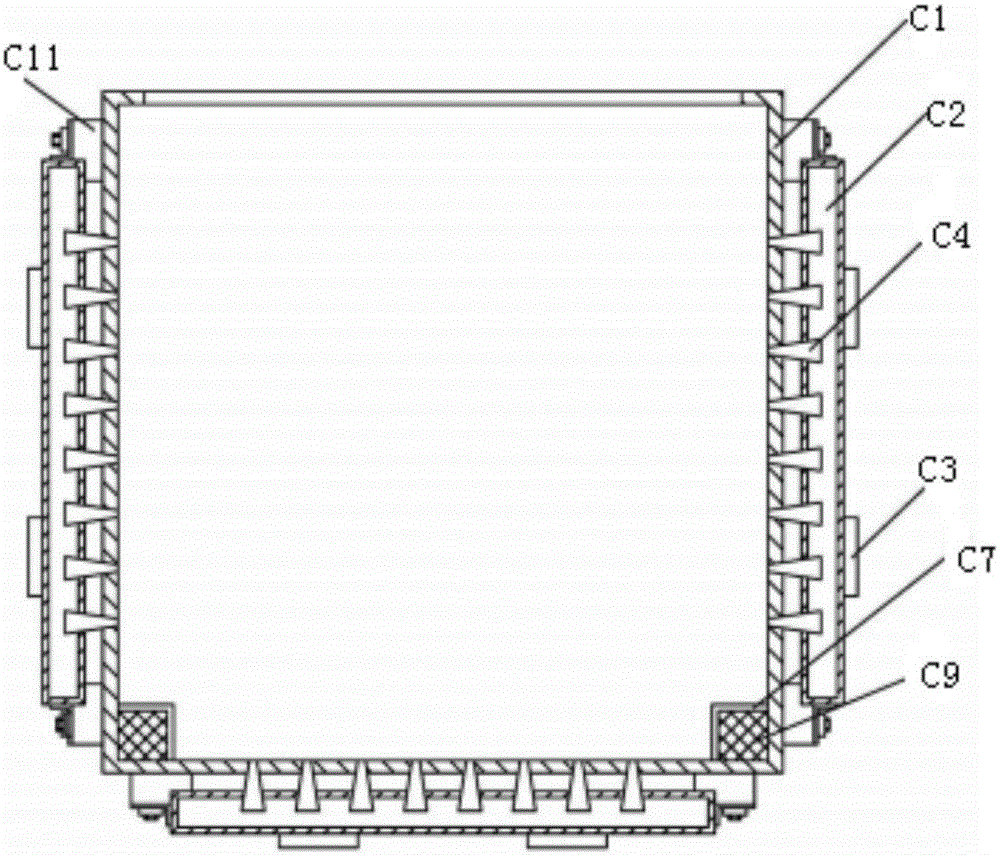

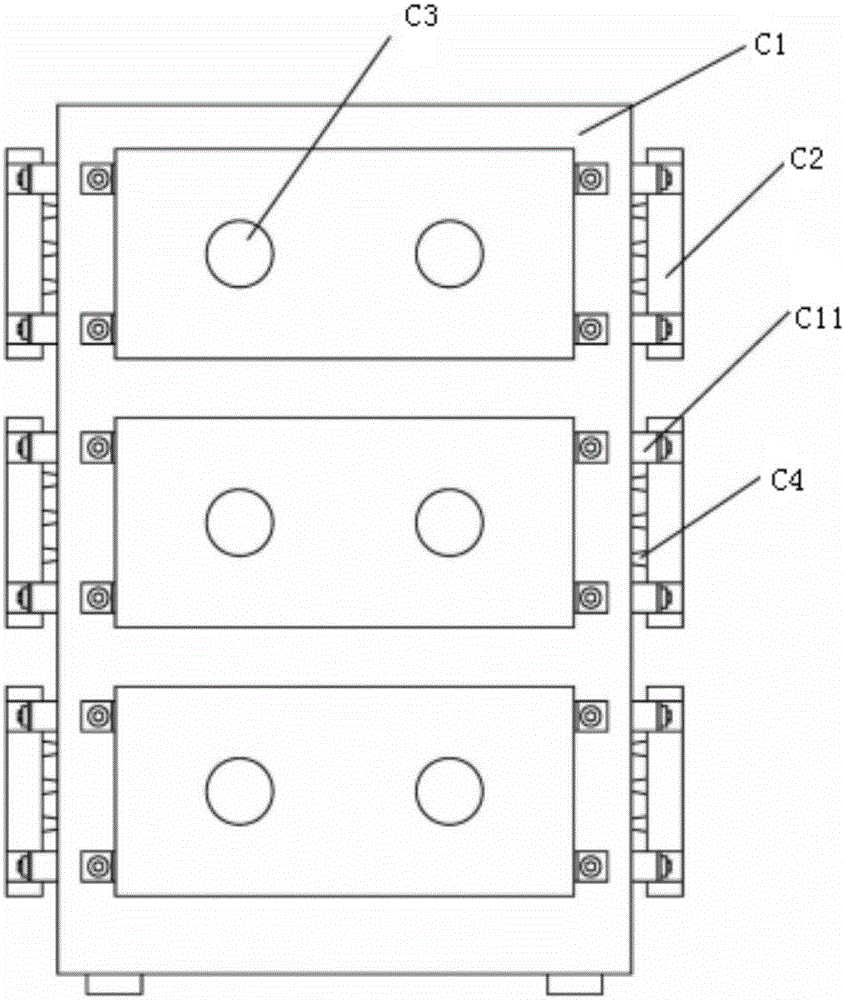

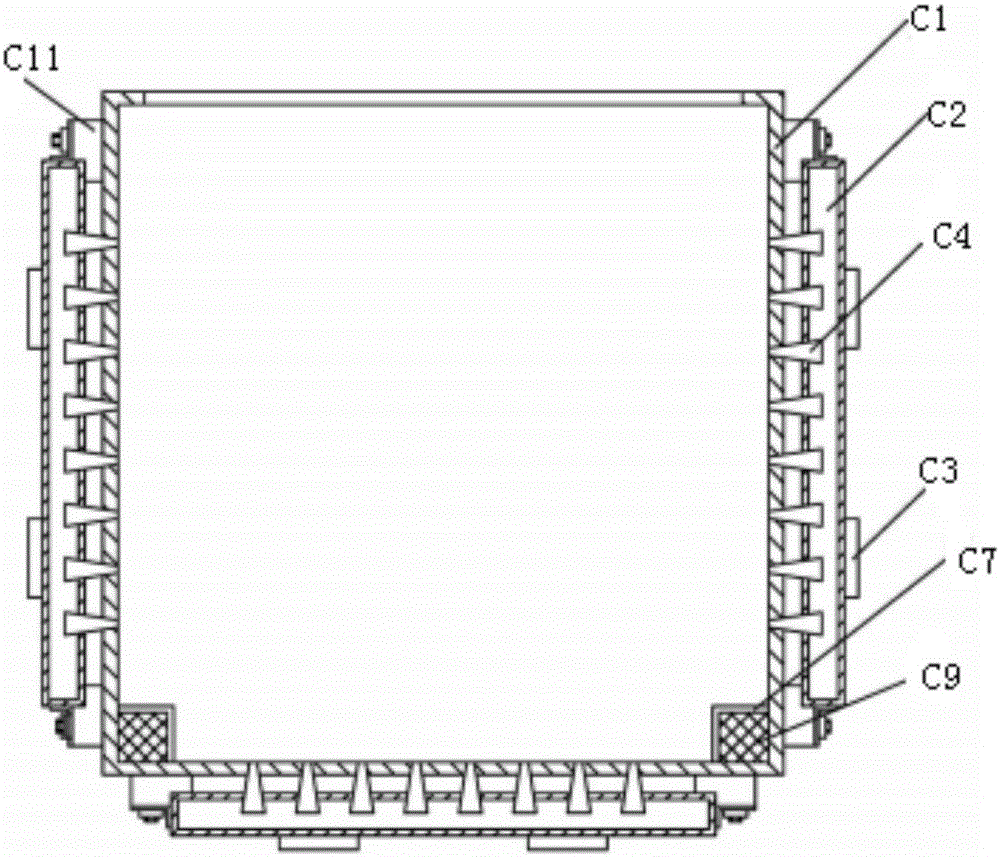

InactiveCN106364861AHigh originalityAchieve clearingCooling/ventilation/heating modificationsMechanical conveyorsStopped workTransformer

The invention discloses a cooling type transformer substation dispatching system and a method thereof. The cooling type transformer substation dispatching system comprises an inspection robot transportation platform, a lifting platform, a lifting control device, a fixing device, a communication module and a dispatching server; a cabinet body consists of a bottom wall plate, a left wall plate, a right wall plate, a front wall plate and a rear wall plate which surround the bottom wall plate and are respectively connected with the left side, the right side, the front end and the rear end of the bottom wall plate; vertical sleeves which extend into the cabinet body are respectively arranged at the two pairs of vertex positions of the upper end surface of the cabinet body; the vertical sleeves are fixed to the interior of the cabinet body; in addition, an accommodating cavity which extends into each vertical sleeve is formed in the upper end surface of the corresponding vertical sleeve. Combining the method thereof, the defects that an adverse effect generated on the operating of the dispatching server caused by the interference on the operating of the dispatching server in the cuboid-shaped shell produced by the accumulation of particular impurities, the working state of the communication module cannot be kept well, and the consequence of stopping working can be caused in the prior art are effectively avoided.

Owner:NANJING INST OF RAILWAY TECH

Convenient-to-connect transformer substation dispatching system and method

A convenient-to-connect transformer substation dispatching system and method are disclosed. The convenient-to-connect transformer substation dispatching system comprises a tour inspection robot transport platform, an elevating platform, a communication module and a dispatch server, wherein the dispatch server is arranged in a cuboid-shaped shell body, the communication module is connected onto a pedestal, the pedestal is welded on an inner wall of a control cabinet, an upper part of the pedestal is provided with a rotation part which can rotate, a front side fo the rotation part is provided with more than two embedding joints that protrude ahead, the embedding joints are shaped like right angle folding rules, front ends of the embedding joints are provided with bending parts that face upward, and a back face of a lower part of the communication module is provided with more than two embedding openings that are connected with the embedding joints in an embedded manner; defects that unfavorable factors for the operation of the dispatch server are generated due to interference in operation of the dispatch server in the cuboid-shaped shell body caused by accumulation of particle impurities, screw-in and screw-out of parts of a screw connection structure requires a lot of time and energy, and the communication module is not easy to assemble and disassemble via technologies of the prior art can be effectively prevented via the convenient-to-connect transformer substation dispatching system and method.

Owner:郑州通晓数据技术有限公司

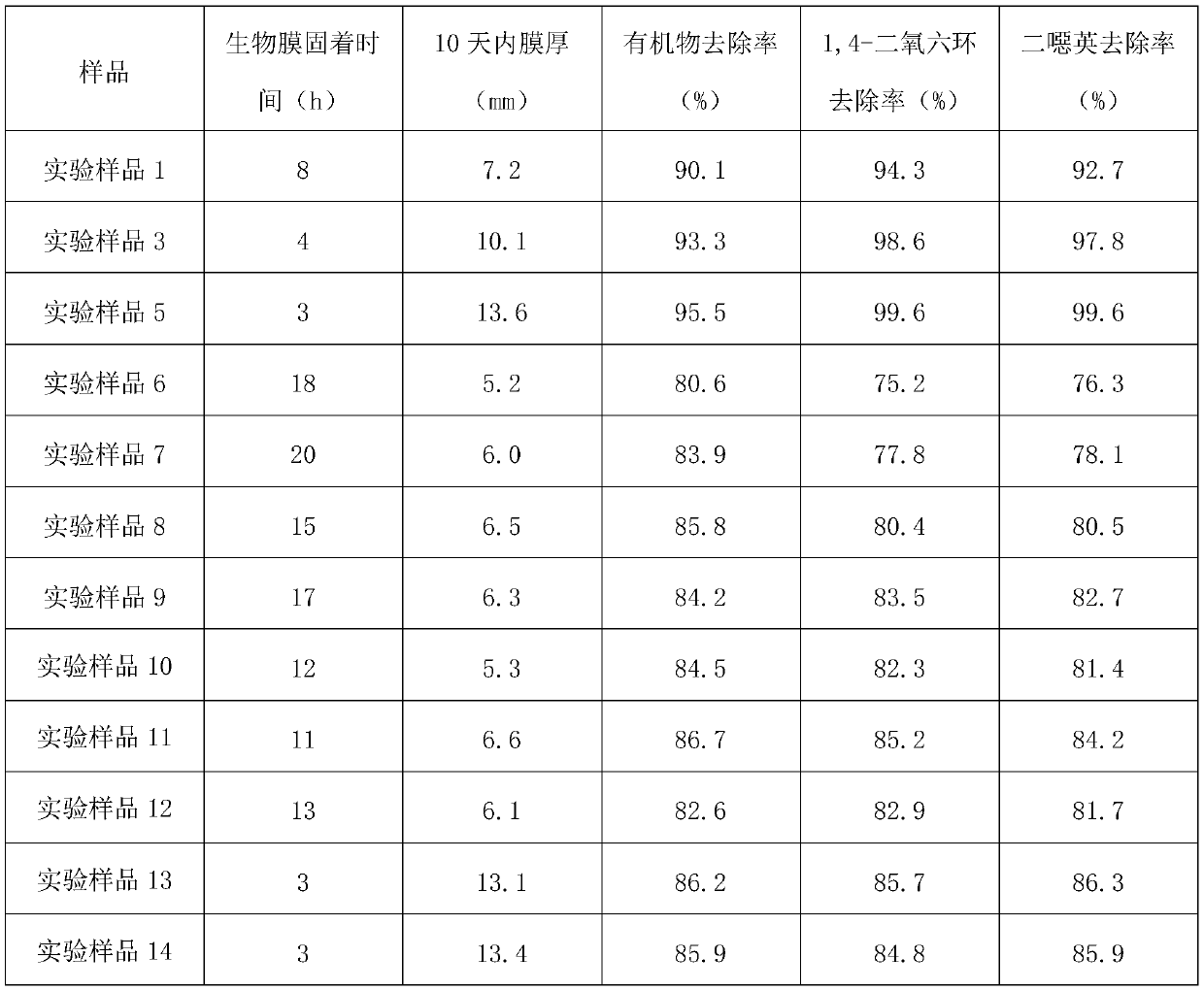

Biological membrane used for waste gas treatment, and preparation method of biological membrane

InactiveCN110237695AGood compatibilityGood removal rateDispersed particle separationOn/in organic carrierNutrientIndustrial waste

The invention provides a biological membrane used for waste gas treatment, and a preparation method of the biological membrane, and in particular relates to the technical field of waste gas purification. According to the preparation method, biotrickling filter filler is obtained by using formic acid to perform catalytic polymerization on polylactic acid and polyvinyl alcohol, and the biological membrane used for the waste gas treatment is prepared by inoculating the filler with nutrient mud and spraying the filler with a nutrient solution. The biological membrane prepared by the method has good compatibility with the filler, and can stably adhere to the filler, so that the fixation time is shortened to 3h at most; the biological membrane has a high removal rate for refractory pollutants; after the biological membrane is used, the removal rate of organic matters in industrial waste gas is 90% or above, the removal rate of 1, 4-dioxane is 94% or above, and the removal rate of dioxin is 92% or above. The invention also provides the preparation method of the biological membrane; the method is stable and controllable, and is easy to implement, thus being suitable for large-scale production.

Owner:广西霸普环保科技有限公司

Through silicon via copper film polishing solution

ActiveCN113789127AHigh speedHigh chelation efficiencyPolishing compositions with abrasivesGlycineMembrane surface

The invention relates to a through silicon via copper film polishing solution, which comprises an abrasive material, two or more chelating agents and a dish pit inhibitor, and is characterized in that the abrasive material is composed of large, medium and small particles mixed together according to a ratio, the particle size of the large particles is 70-120nm, the particle size of the medium particles is 50-80nm, the particle size of the small particles is 30-50nm, and the particles of the three grades are selected within the corresponding ranges according to an arithmetic progression mode during selection; and the chelating agent is a mixture of glycine and basic amino acid. In the CMP process, the polishing solution can quickly remove a copper film, and meanwhile, inhibit the step height between concave and convex platforms on the surface of the copper film.

Owner:博力思(天津)电子科技有限公司

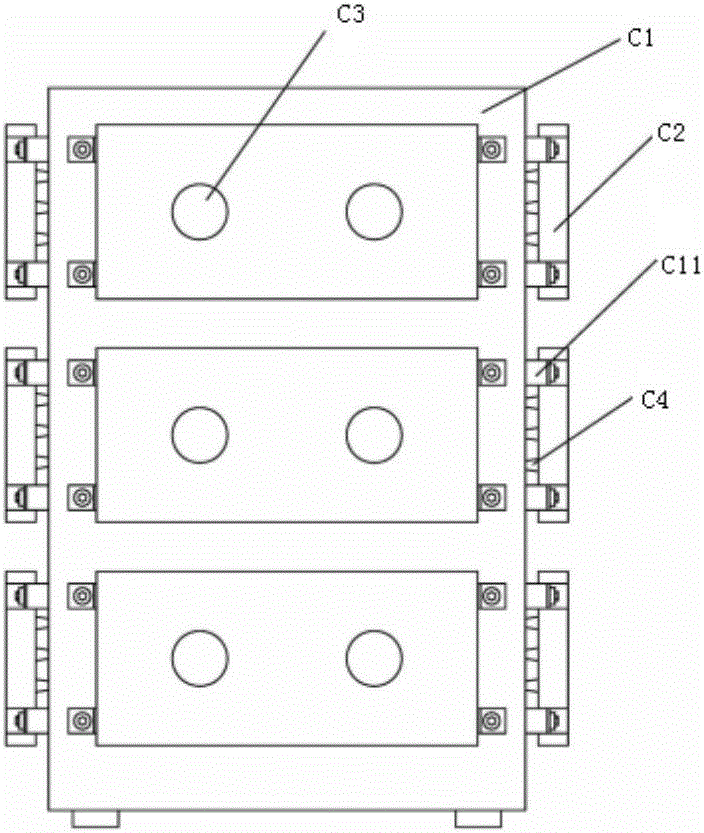

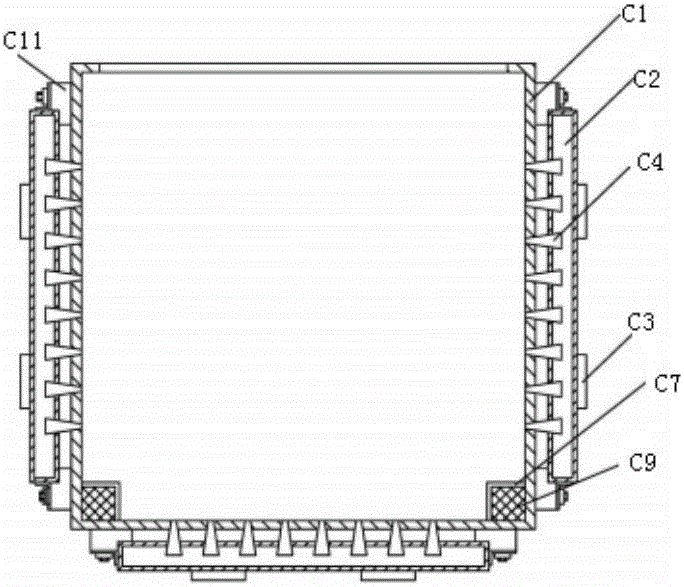

Anti-interference smart search system based on mobile terminal and method thereof

InactiveCN106506652AImprove transmission performanceAchieve clearingDigital processing power distributionTransmissionParticulatesComputer terminal

The invention discloses an anti-interference smart search system based on a mobile terminal and method thereof. The smart search system comprises a mobile terminal for acquiring environment information related to a user and sending the environment information; and a cloud server arranged in a cuboids shell, wherein more than two containers for feeding airflows are arranged on each of outer walls of a pair of opposite side wallboards and the outer wall of a back wallboard of the cuboids shell, the containers arranged on all outer walls for feeding the airflows are in equally spaced distribution from high to low, and the container for feeding the airflow is a cuboids container with an inner chamber. In combination with the smart search method disclosed by the invention, the defect that the interference manufactured by the accumulation of particulate impurities is bad for the running of the cloud server in the cuboids shell in the prior art is effectively avoided.

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

Refrigeration transformer station scheduling system and method thereof

The present invention provides a refrigeration transformer station scheduling system and a method thereof. The system comprises a polling robot transportation platform, a lifting platform, a lifting control device, a fixing device, a communication module and a dispatch server. The dispatch server is arranged in cuboid housing; a box is provided with a box body, a cover plate located at the right panel of the box body and a support plate; the size of the support plate is larger than the size of the lower wall plate of the box body; the box body is riveted on the support plate; one side portion of the box body is riveted with one ends of a pair of slides; and the other ends of the slides are riveted with the cover plate located at the right panel of the box body. The refrigeration transformer station scheduling system and the method thereof effectively avoid the defects that the accumulation of the particulate matter impurities disturbs the operation of the dispatch server in the cuboid housing so as to have negative effects on the operation of the dispatch server and allow the communication module to frequently have faults in this environment even have the bum-out trouble to generate the difficulty for the maintenance.

Owner:NANJING INST OF RAILWAY TECH

Method for preparing flue gas desulfurization powder adsorbent from liquid-solid wastes

ActiveCN112892467AMicropore intactLarge hole volumeOther chemical processesDispersed particle separationSulfate radicalsSorbent

The invention discloses a method for preparing a flue gas desulfurization powder adsorbent from liquid-solid wastes, which comprises the following steps of: performing acidolysis on ferromanganese solid wastes by using copper electrolysis wastewater, and separating to obtain a sulfate solution; then removing sulfate ions in the sulfate solution by using lime milk and acid, and separating to obtain a metal salt solution; adding carbide slag into the metal salt solution for precipitation reaction, standing for aging, and separating to obtain a gelatinous product; and finally, drying, calcining, crushing and finely grinding the gel to obtain the desulfurization powder adsorbent. The active components of the desulfurization powder adsorbent prepared by the method are CaO and MnO, and the auxiliaries are Fe3O4 and ZnO; the catalyst contains catalytic active components CuO and NiO, and can catalyze SO2 and O2 in the flue gas to react to generate SO3; the desulfurization powder adsorbent is small in particle size, complete in micropores, large in pore volume and high in desulfurization activity; and the method is suitable for dry dedusting device desulfurization or flue gas spray drying desulfurization, does not need a desulfurization packed tower, and reduces the investment cost of enterprises.

Owner:WUHAN KELIN FINE CHEM

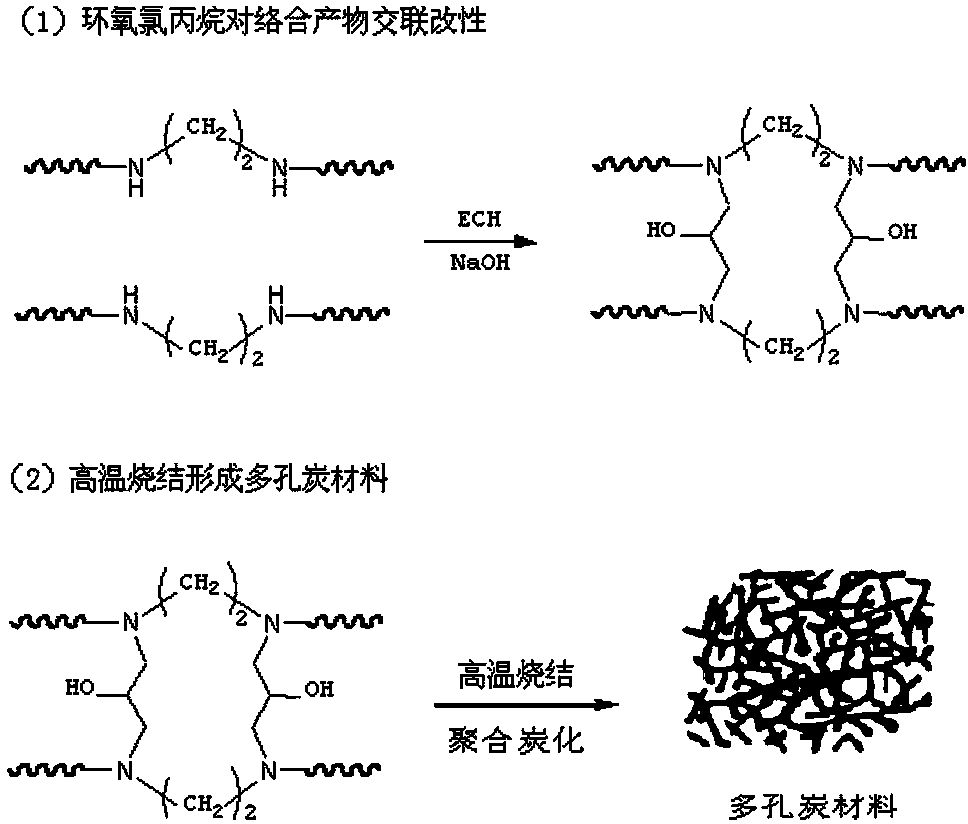

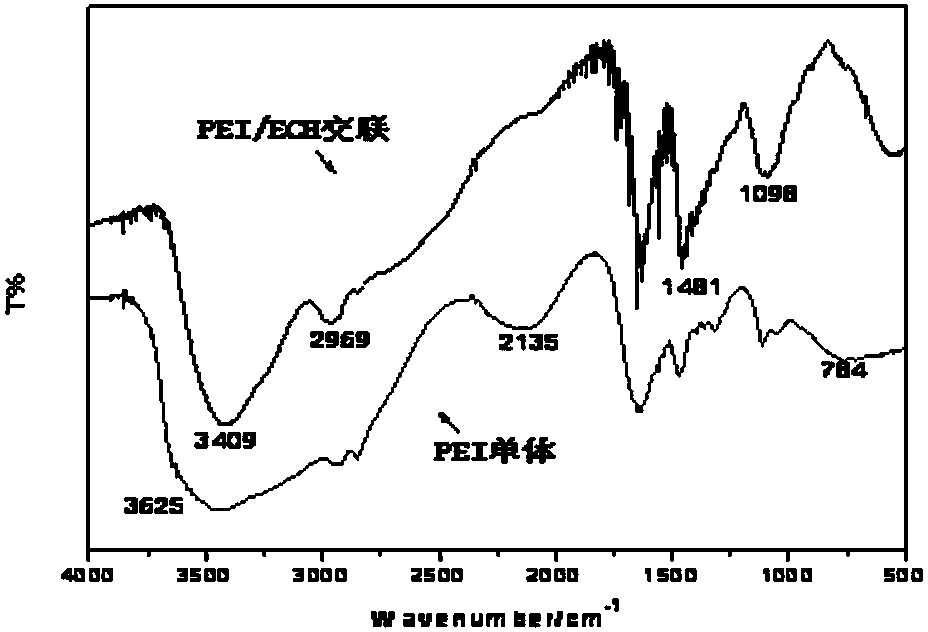

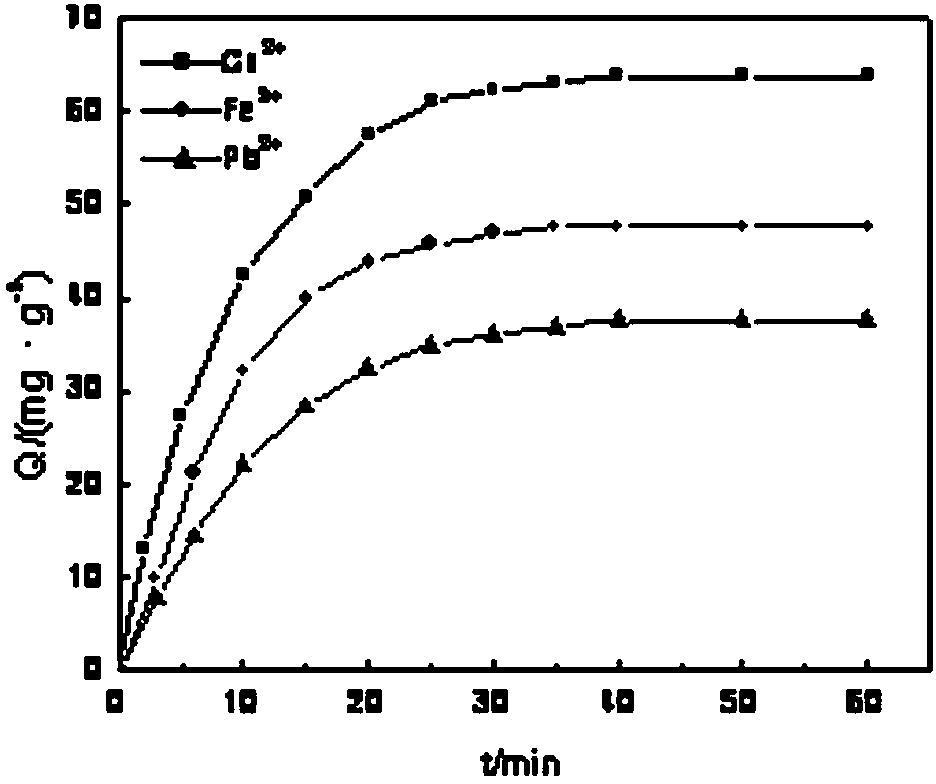

Metal ion carbonized adsorption material and preparation method thereof

ActiveCN103586007AHigh adsorption rateGood removal rateOther chemical processesWater/sewage treatment by sorptionPoly ethyleneEthylene imine

The invention discloses a metal ion carbonized adsorption material and a preparation method thereof, belongs to the technical field of functional adsorption materials and solves the problem that polymine can not be reclaimed while being used for treating heavy metal wastewater. The metal ion carbonized adsorption material is prepared by crosslinking polymine with epichlorohydrin to modify polymine, and carbonizing, wherein the mass ratio of polymine to epichlorohydrin is 1: (0.5 to 0.6). The metal ion carbonized adsorption material provided by the invention is an adsorbent containing an active amino functional group and possessing a portion of properties of carbon materials, so that the metal ion carbonized adsorption material has a higher adsorption rate to metal ions and a higher removal rate, and can be reutilized.

Owner:ZHONGBEI UNIV

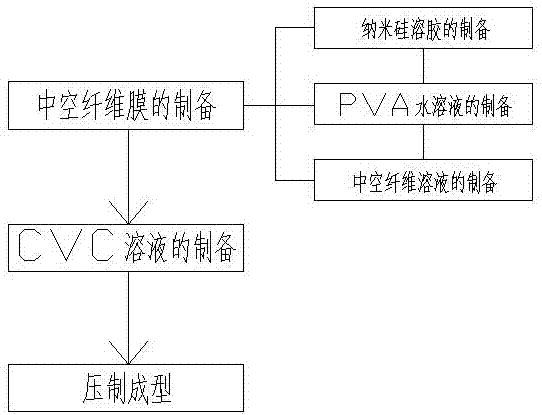

Method for preparing water treatment filtering membrane

InactiveCN107441945AGood removal rateGood water productionGeneral water supply conservationWater contaminantsDesalinationBrackish water

The invention discloses a method for preparing a water treatment filtering membrane. The method is characterized by comprising the following steps: preparing a hollow fiber membrane, preparing a CMC (Carboxy Methyl Cellulose) solution, and performing pressing molding, thereby obtaining the water treatment filtering membrane. Due to specific processes, the produced water treatment filtering membrane has high removal rates for sodium chloride and magnesium sulfate and has high water yield, and by adopting the method disclosed by the invention, continuous industrial production is achieved, nanofiltration functional layers are uniform and stable, and the water treatment filtering membrane has wide application prospects in fields of sweater and brackish water desalination, sewage treatment and ultrapure water preparation.

Owner:深圳市树立水处理设备有限公司

Reinforcing-type transformer substation dispatching system and method thereof

InactiveCN106364863AHigh originalityAchieve clearingCooling/ventilation/heating modificationsMechanical conveyorsForeign matterParticulates

The invention provides a reinforcing-type transformer substation dispatching system and a method thereof. The reinforcing-type transformer substation dispatching system comprises a communication module and a dispatching server. A through hole from one head to the other head of a rod piece is formed in the rod piece. One head of the rod piece is inserted into a cabinet body. A photovoltaic plate is installed on an upper cover plate and charges a rechargeable battery through a charging circuit. The rechargeable battery is connected with an air feeder. An air outlet of the air feeder is communicated with the other head of the rod piece. In combination with the method, the defects that in the prior art, accumulation of particulate impurities interferes with operation of the dispatching server in a cuboid-shaped shell, thus, the unfavorable condition is generated to operation of the dispatching server, the communication module cannot work in a good state, the consequence of stopping working occurs, and foreign matter impurities often intrude into an electric cabinet and damage the communication module are avoided.

Owner:NANJING INST OF RAILWAY TECH

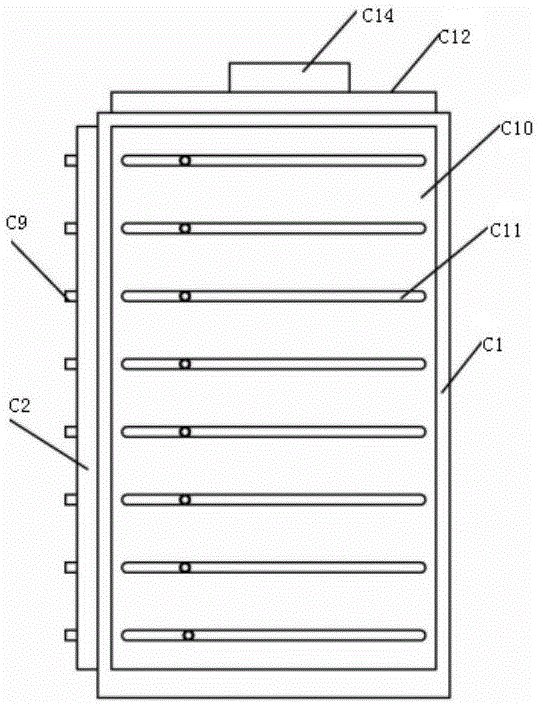

Intelligent searching system based on mobile terminal and used for removing impurities

InactiveCN106391573AHigh originalityGood removal rateDirt cleaningSubstation equipmentWall plateComputer engineering

The invention discloses an intelligent searching system based on a mobile terminal and used for removing impurities. The intelligent searching system comprises a mobile terminal and a cloud-end server, wherein the mobile terminal is used for acquiring user-related environmental information and sending the user-related environmental information; the cloud-end server is used for receiving the environmental information sent by the mobile terminal, and is arranged in a rectangular housing; a rectangular bracket which is formed by connecting two pairs of connecting plates pairwise is arranged on each of wall surfaces of a pair of side wall plates opposite to the rectangular housing and the wall surface of a back wall plate; and a plurality of transverse baffle plates are uniformly arranged in each rectangular bracket. The intelligent searching system disclosed by the invention effectively avoids the defect that the cloud-end server in the prior art cannot remove particulate matter impurities when continuously operating.

Owner:NANJING RUIQI ELECTRONICS TECH CO LTD

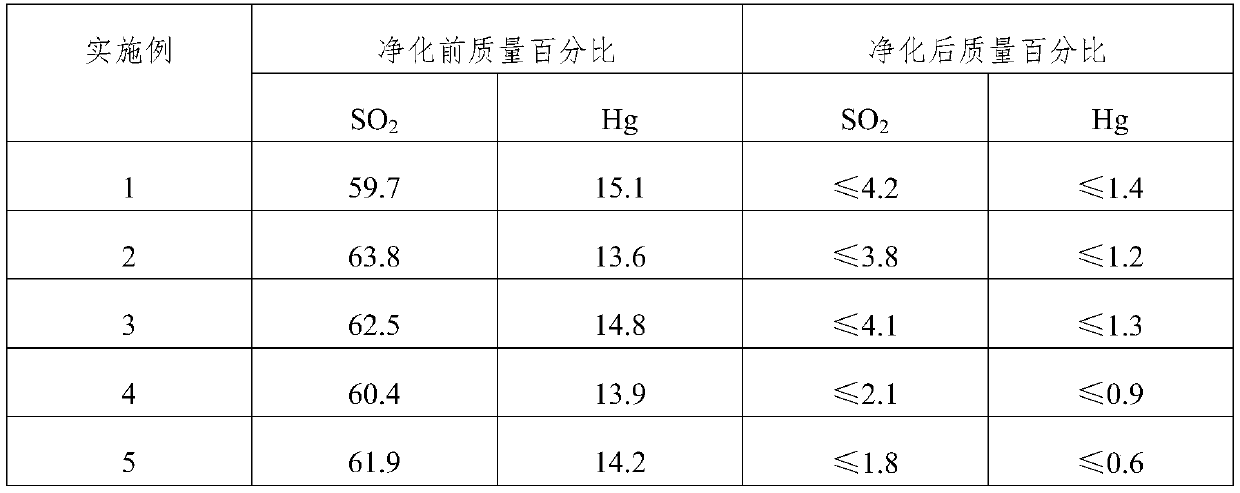

A method for preparing coal-fired flue gas desulfurization and mercury removal agent with tartaric acid as raw material

Owner:GUIZHOU UNIV

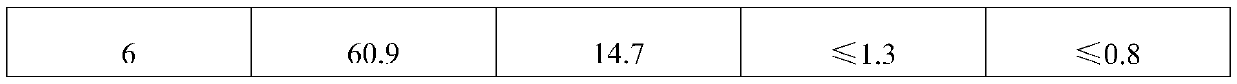

Method for removing magnesium from ultralow-quality phosphate rock and producing magnesium hydroxide

InactiveCN103073034BReduce lossesLower magnesium levelsMagnesium hydroxidePhosphateProcess conditions

The invention discloses a method for removing magnesium from an ultralow-quality phosphate rock and producing magnesium hydroxide. The method comprises the steps as follows: mixing phosphate rock powder with a magnesium remover for magnesium removal reaction, carrying out solid-liquid separation, obtaining solid-phosphate concentrate, and adding a neutralization and sedimentation agent into liquid to obtain a magnesium byproduct. The method is characterized by taking the ultralow-quality phosphate rock as a raw material and mixed acid of sulphurous acid, sulfuric acid and fluorosilicic acid as the magnesium remover, carrying out solid-liquid separation, mixing washing water for washing a solid phase with a solution obtained after separation, and carrying out neutralization and sedimentation reaction. According to the method, mixed acid of sulphurous acid, sulfuric acid and fluorosilicic acid is adopted as the magnesium remover, so that the P2O5 loss is reduced; the process route is short, the operation is simple and the one-time investment cost is low; the magnesium removal rate can reach more than 80% and the content of magnesium in the obtained concentrate is lower than 1%; and the obtained phosphate concentrate is good in quality, the quality is improved by 5-10%, the P2O5 yield is high and can reach more than 99% under the optimal process conditions, and the P2O5 content is increased by 3-5% in general.

Owner:GUIZHOU KAILIN GRP MINERAL FERTILIZER CO LTD

Method for separating Fe2O3 in pulverized coal ash of circulating fluidized bed

The method provides a method for separating Fe2O3 in pulverized coal ash of a circulating fluidized bed.The method includes the steps that sulfuric acid and pulverized coal ash are subjected to a low-temperature hydrothermal reaction so that all Fe2O3 and FeO and part of amorphous Al2O3 in pulverized coal ash can be dissolved out; then, Fe2O3 and FeO in the solution are separated and extracted with acetone to obtain high-purity Fe2O3.According to the method, no special requirement for equipment exists, only the low-temperature reaction is needed, and Fe2O3 in pulverized coal ash can be efficiently separated and extracted; Al2O3 in pulverized coal ash can be dissolved out by 90%-96%, and Fe2O3 in pulverized coal ash can be dissolved out by 98%-100%.By means of the technical scheme, the resource of pulverized coal ash is fully utilized, the manufacturing process is simple, the production cost is low, and the method is suitable for large-scale production.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Method for separating iron oxide from fly ash of pulverized coal furnace

InactiveCN105692709AMake full use of resourcesHigh purityFerroso-ferric oxidesAluminium chloridesIron oxideFly ash

The invention provides a method for separating iron oxide from the fly ash of a pulverized coal furnace. In the method, through low-temperature hydrothermal reaction between hydrochloric acid and fly ash, all Fe2O3 and FeO and part of amorphous Al2O3 in the fly ash are dissolved out; and Fe2O3 and FeO are separated and extracted from the solution using methanol to obtain high-purity iron oxide. The method provided by the invention imposes no special requirements on equipment, adopts low-temperature reaction and can efficiently separate and extract iron oxide from the fly ash; 90-96% of aluminum oxide and 98-100% of iron oxide in the fly ash can be dissolved out; and in the technical scheme provided by the invention, the fly ash resource is fully utilized, the preparation technology is simple, the production cost is low, and the method is suitable for large-scale production.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com