A method for preparing coal-fired flue gas desulfurization and mercury removal agent with tartaric acid as raw material

A technology of coal-burning flue gas and tartaric acid, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as easy scaling and blockage of equipment, waste residues with little application value, and emissions, and achieve the removal rate of elemental mercury Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

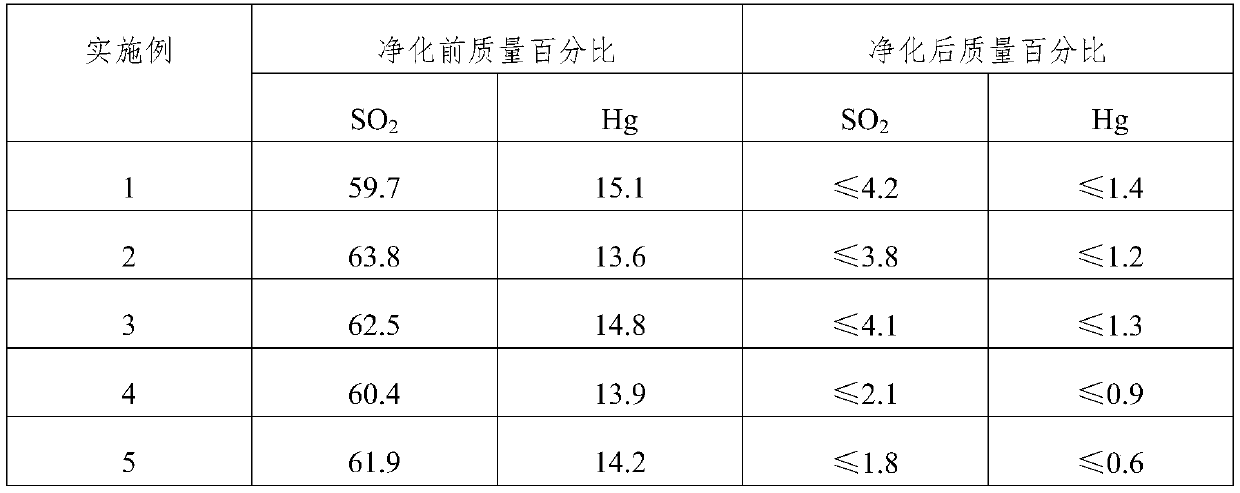

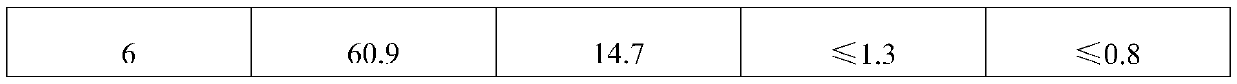

Examples

Embodiment 1

[0041] Tartaric acid is a method for preparing a coal-fired flue gas desulfurization and mercury removal agent as a raw material, comprising the following steps:

[0042] (1) Grinding the pyrolusite into 6-mesh particles, heating it to 300° C., watering it, causing a hydrothermal reaction to occur, pulverizing, and obtaining mineral powder;

[0043] (2) Add tartaric acid to the mineral powder in an amount of 20% of the mass of the mineral powder, raise the temperature to 80°C, stir for 5 minutes, add copper oxide powder, the addition amount accounts for 1% of the mass of the mineral powder, stir evenly, add water, adjust The liquid-solid ratio is 11:1.

Embodiment 2

[0045] Tartaric acid is a method for preparing a coal-fired flue gas desulfurization and mercury removal agent as a raw material, comprising the following steps:

[0046] (1) The pyrolusite is treated with microwave radiation, the microwave radiation power is 400W, the microwave radiation time is 10min, pulverized into 10-mesh particles, heated to 600°C, watered, so that hydrothermal reaction occurs, pulverization, get mineral powder;

[0047] (2) Add tartaric acid to the mineral powder in an amount of 50% of the mass of the mineral powder, raise the temperature to 130°C, stir for 9 minutes, add copper oxide powder, the addition amount accounts for 3% of the mass of the mineral powder, stir evenly, add water, adjust The liquid-solid ratio is 17:1.

Embodiment 3

[0049] Tartaric acid is a method for preparing a coal-fired flue gas desulfurization and mercury removal agent as a raw material, comprising the following steps:

[0050] (1) The pyrolusite is treated with microwave radiation, the microwave radiation power is 700W, the microwave radiation time is 40min, pulverized into 7-purpose particles, heated to 500°C, watered, so that hydrothermal reaction occurs, pulverization, Pass through a 20-mesh sieve to obtain mineral powder;

[0051] (2) Add tartaric acid to the mineral powder in an amount of 40% of the mass of the mineral powder, heat up to 90°C, stir for 7 minutes, add copper oxide powder with a particle size of 30 mesh, and add 2% of the mass of the mineral powder, and stir evenly , add water, and adjust the liquid-solid ratio to 15:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com