Method for separating iron oxide from fly ash of pulverized coal furnace

A technology of fly ash and iron oxide, which is applied in the direction of iron oxide/iron hydroxide, ferric oxide, aluminum chloride, etc., which can solve the problems of poor implementation effect of iron oxide, low recovery rate of iron oxide, and limitation of process conditions and other problems, to achieve the effect of broadening the scope of comprehensive utilization, large processing capacity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

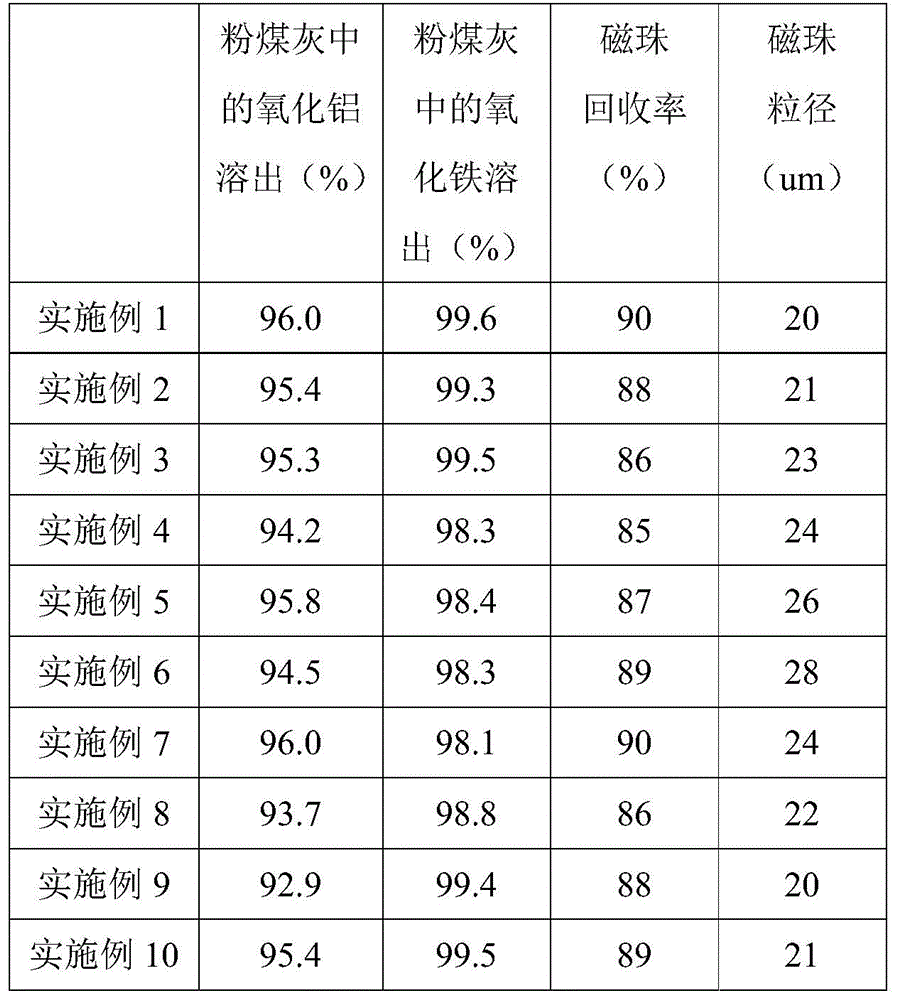

Examples

Embodiment 1

[0032] Example 1, the fly ash was subjected to 4 times of magnetic separation, then mixed with 3% hydrochloric acid at a solid-to-liquid ratio of 1:3, and reacted at 90°C for 3 hours; after the reaction was completed and cooled to room temperature, the filter cake was obtained by suction filtration, And wash with water with a solid-to-liquid ratio of fly ash to water of 1:1 to obtain a solution of iron hydrochloride and aluminum hydrochloride; add methanol according to the volume ratio of methanol to iron hydrochloride and aluminum hydrochloride solution at 5:1, and stir for 5 minutes , suction filtration to obtain aluminum hydrochloride filter cake, and reclaim the filtrate; mix aluminum hydrochloride filter cake with 80% methanol aqueous solution at a ratio of 1:3, stir for 15 minutes, and suction filter to obtain aluminum hydrochloride filter cake, and recycle Filtrate: Repeat this methanol water washing process for 6 times, and recover the filtrate; mix the hydrogen peroxid...

Embodiment 2

[0033] Example 2, after 3 times of magnetic separation, the fly ash was mixed with 5% hydrochloric acid at a solid-to-liquid ratio of 1:2, and reacted at 95°C for 2 hours; after the reaction was completed and cooled to room temperature, the filter cake was obtained by suction filtration, And wash with water with a solid-to-liquid ratio of fly ash to water of 2:1 to obtain a solution of iron hydrochloride and aluminum hydrochloride; prepare methanol at a volume ratio of 12:1 to the solution of iron hydrochloride and aluminum hydrochloride, add methanol, and stir for 3 minutes , suction filtration to obtain aluminum hydrochloride filter cake, and recycle the filtrate; mix aluminum hydrochloride filter cake with 70% methanol aqueous solution at a ratio of 1:5, stir for 30 minutes, and suction filter to obtain aluminum hydrochloride filter cake, and recycle Filtrate: Repeat this methanol water washing process 4 times, and recover the filtrate; mix the hydrogen peroxide and the reco...

Embodiment 3

[0034] Example 3, after 3 times of magnetic separation, the fly ash was mixed with 4% hydrochloric acid at a solid-to-liquid ratio of 1:4, and reacted at 100°C for 1 hour; after the reaction was completed and cooled to room temperature, the filter cake was obtained by suction filtration, And wash with water with a solid-to-liquid ratio of fly ash to water of 2:1 to obtain a solution of ferric hydrochloride and aluminum hydrochloride; add methanol according to the volume ratio of methanol to ferric hydrochloride and aluminum hydrochloride solution as 8:1, and stir for 5 minutes , suction filtration to obtain aluminum hydrochloride filter cake, and reclaim the filtrate; mix aluminum hydrochloride filter cake with 90% methanol aqueous solution at a ratio of 1:2, stir for 10 minutes, and suction filter to obtain aluminum hydrochloride filter cake, and recycle Filtrate: Repeat this methanol water washing process for 6 times, and recover the filtrate; mix hydrogen peroxide and recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com