Oxyhydrogen type tertiary amine oxide anion exchange resin, preparation method thereof and purification method of NMMO (N-methylmorpholine N-oxide) aqueous solution

A technology of exchange resin and tertiary amine oxidation, which is applied in the direction of anion exchange, ion exchange, ion exchange treatment device, etc., can solve the problems of low transition metal removal rate, low anion exchange efficiency, low recycling rate, etc., and achieve good resin Recycling rate, high removal rate of transition metal ions, effect of improving removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] As described in the background technology section, when the NMMO aqueous solution is purified in the existing process, there are problems of poor ion exchange effect of the ion exchange resin, low recycling rate and low removal rate of transition metals. The invention provides a method for preparing an oxidized tertiary amine anion exchange resin, the preparation method comprising the following steps: S1, oxidizing the tertiary amine anion exchange resin to obtain an oxidized tertiary amine anion exchange resin; S2, oxidizing the tertiary amine anion exchange resin The tertiary amine oxide anion exchange resin is reacted with an aqueous alkali solution to obtain a hydroxide type tertiary amine oxide anion exchange resin.

[0031] The active group structure of this hydroxide type tertiary amine oxide anion exchange resin is as follows:

[0032]

[0033]When this resin is used to purify NMMO solution, its binding strength with cellulose anion and cellulose colloid in N...

Embodiment 1

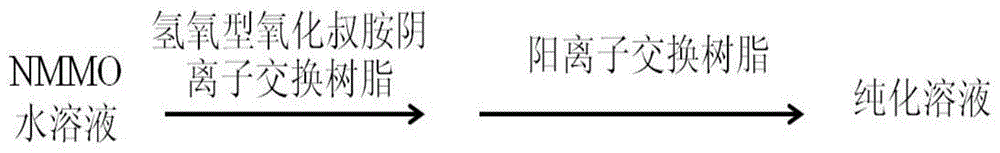

[0054] The resin exchange bed used in series in this embodiment is used to purify the NMMO aqueous solution, and the resin exchange bed includes a tertiary amine oxide type anion resin exchange bed and a cation resin exchange bed successively connected in series.

[0055] The preparation process of hydroxide type tertiary amine oxide anion resin is as follows:

[0056] will be 3m 3 Add D301 resin with volume exchange capacity of 1.4mol / L to 5m 3 enamel reactor, then add 1m 3 Then add hydrochloric acid to adjust the pH value to 6.5, and heat up to 75°C; then add 54kg of hydrogen peroxide with a mass concentration of 35% every 20 minutes, add 10 times altogether, and add up to 540kg of hydrogen peroxide (the number of moles added is the resin volume exchange 1.4 times the capacity), and continue to react for 30 minutes after adding all of it, and then cool to below 40°C.

[0057] Fill the resin and water in the reactor to a resin filling capacity of 4m 3 In the exchange bed,...

Embodiment 2

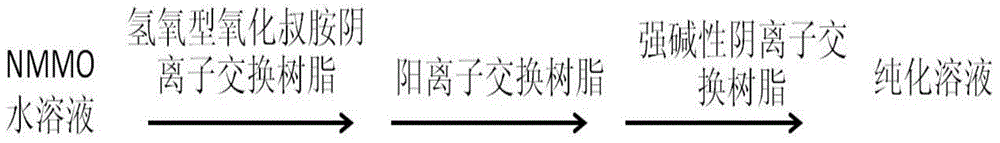

[0068] In this embodiment, the NMMO aqueous solution is purified by using series-connected resin exchange beds. The resin exchange beds include a series-connected hydroxyl-type tertiary amine oxide anion resin exchange bed, a cation resin exchange bed, and a strong alkaline resin exchange bed. Anion resin exchange bed.

[0069] The preparation process of hydroxide type tertiary amine oxide anion resin is as follows:

[0070] will be 0.5m 3 Add D370 type resin with a volume exchange capacity of 1.4mol / L to 1m 3 enamel reactor, then add 0.2m 3 Add hydrochloric acid to adjust the pH value to 5, be warming up to 62 ℃; Then in 1 hour, add 825kg mass concentration dropwise at a constant speed and be 12% sodium hypochlorite aqueous solution (the number of moles added is 1.9 times of resin volume exchange capacity) After the dropwise addition, gradually raise the temperature to 75°C, keep the temperature for 30 minutes, then raise the temperature to 100°C, keep the temperature for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com