Garbage compression leachate comprehensive waste water treatment device and technological method

A technology that integrates waste water and treatment equipment. It is used in filtration treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of high cost of cleaning chemicals, high equipment cost, harsh application conditions, etc. Economical and effective, high utilization rate of regeneration cycle, and the effect of improving hydraulic shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Now the present invention is further described in conjunction with description of drawings and embodiments:

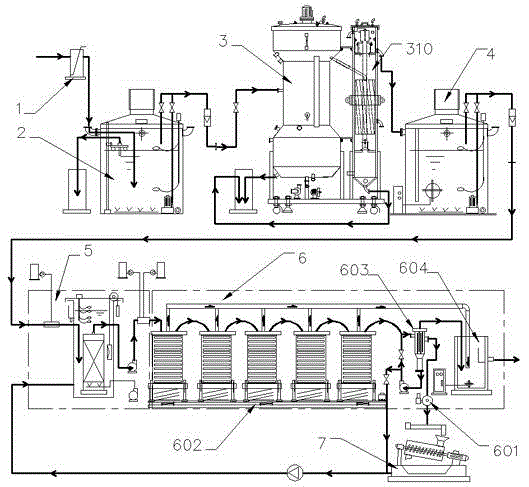

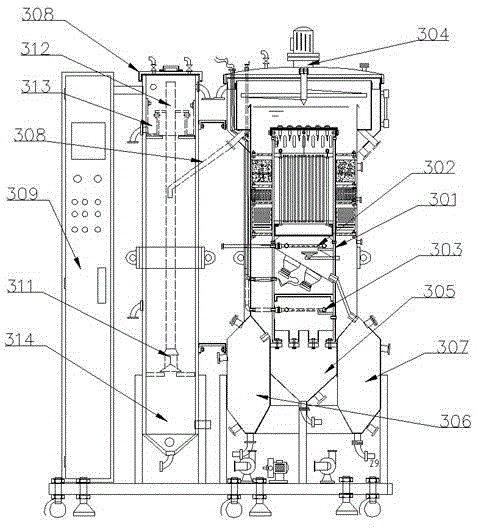

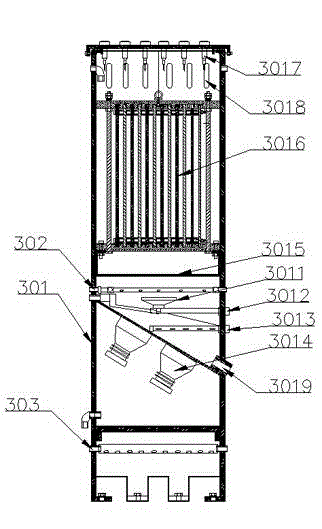

[0030] refer to figure 1 A comprehensive waste water treatment equipment and process method for waste press filtrate, including a grid 1, a waste water storage tank 2, an ultrasonic electro-Fenton reactor 3, an intermediate water storage tank 4, an ultrasonic vibrating membrane reactor 5, and a vortex vibrating membrane filtration system 6 are connected sequentially, and also include a sludge dehydration and drying tank 7, the sludge dehydration and drying tank 7 is connected with the vortex energy-saving heat pump flasher 601 of the vortex vibrating membrane filtration system 6, and is provided with a circuit and ultrasonic vibration The membrane reactors 5 are connected, wherein: the sewage enters the waste water storage tank 2 for pre-precipitation through the grid 1, and the waste water is pumped from the waste water storage tank 2 to the ultrasonic electro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com