Technological system for treating terrestrial heat tail water by utilizing tubular membrane

A process system and technology of geothermal tail water, which are applied in filtration treatment, degassed water/sewage treatment, water/sewage multi-stage treatment, etc. Low cost, high throughput and good finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

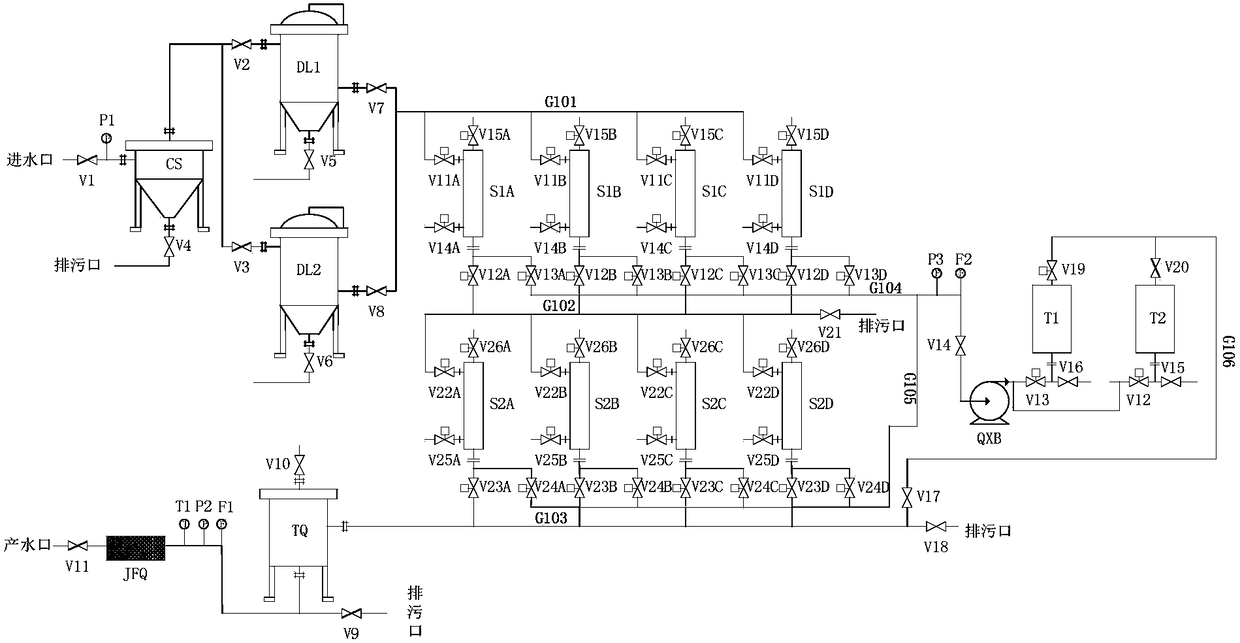

[0030] This embodiment is to provide a tubular membrane process system for treating geothermal tail water, which includes a cyclone desander connected in sequence through various valve bodies and pipelines, a bag filter, a tubular membrane filtration device, Degassing tank and metal descaling device; The tubular membrane filter unit includes a first-stage tubular membrane filter unit and a secondary tubular membrane filter unit connected in series through the second pipeline; the bag filter and the The first-stage tubular membrane filtration unit communicates with the first pipeline; the second-stage tubular membrane filtration unit communicates with the degassing tank through the third pipeline;

[0031] The first-stage tubular membrane filtration unit includes four first-stage tubular membrane filters connected in parallel, and the upper part of the first-stage tubular membrane filter is connected to the first pipeline through corresponding pipelines and valves, so The botto...

Embodiment 2

[0045] This embodiment provides the specific steps of using the process system in Embodiment 1 to treat geothermal tail water:

[0046] 1. Press figure 1 Connect the system piping as shown;

[0047] 2. Click the start button on the electric control box, the process system will automatically run the filtering and backwashing links according to the following steps:

[0048] (1) The geothermal tail water first enters the cyclone desander through the residual pressure to remove mechanical impurities such as large-size sediment and rust, and then enters the bag filter to further remove suspended solids, colloids and other particulate matter; this process The opening of the valve is as follows: in the automatic mode, the valve V1 needs to be opened manually first, and the valve opening of the bag filter depends on the bag filter used: if DL1 is used, V2 and V7 will be opened at the same time; if DL2 , then V3 and V8 are turned on at the same time;

[0049] (2) The geothermal tail...

Embodiment 3

[0081] In this embodiment, the geothermal tail water at 35°C is divided into 40m 3 The concrete steps that the process system of / h flow feeds embodiment 1 carries out filtering process:

[0082] (1) The geothermal tail water first passes through the residual pressure and enters the cyclone desander to remove mechanical impurities such as large-size sediment and rust blocks; then enters the bag filter to further remove suspended solids, colloids and other particulate matter;

[0083] (2) Afterwards, the geothermal tail water enters the first-stage tubular membrane filter to remove most of the suspended solids, microorganisms, colloids, rust and other impurities; the filtration accuracy of the first-stage filtration is 10 μm, and the designed membrane area is 40m 2 , the operating pressure is 0.2MPa, and after about 36 hours of operation, when the pressure difference between the inlet and outlet water reaches 0.12MPa, control the first-stage tubular membrane filters in differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com