MoS2/polyelectrolyte hybrid nanofiltration membrane and production method thereof

A polyelectrolyte and nanofiltration membrane technology, applied in the field of membrane separation, can solve the problems of unreported dye wastewater separation performance, achieve excellent removal rate and flux, overcome the decline of membrane performance, and improve the effect of dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

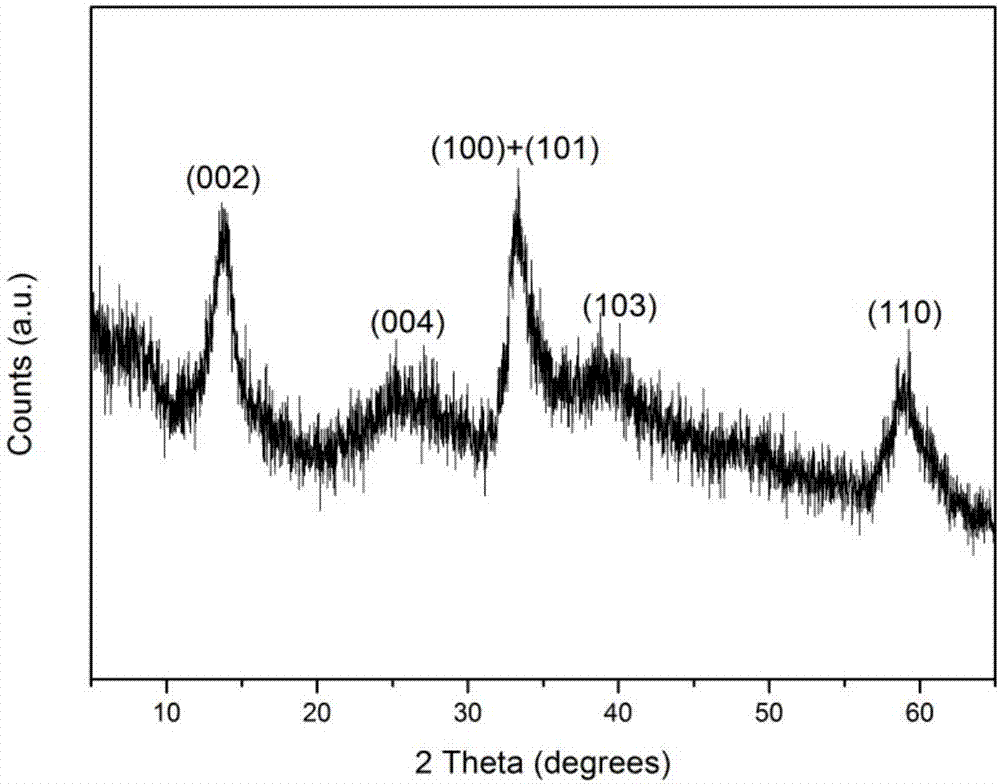

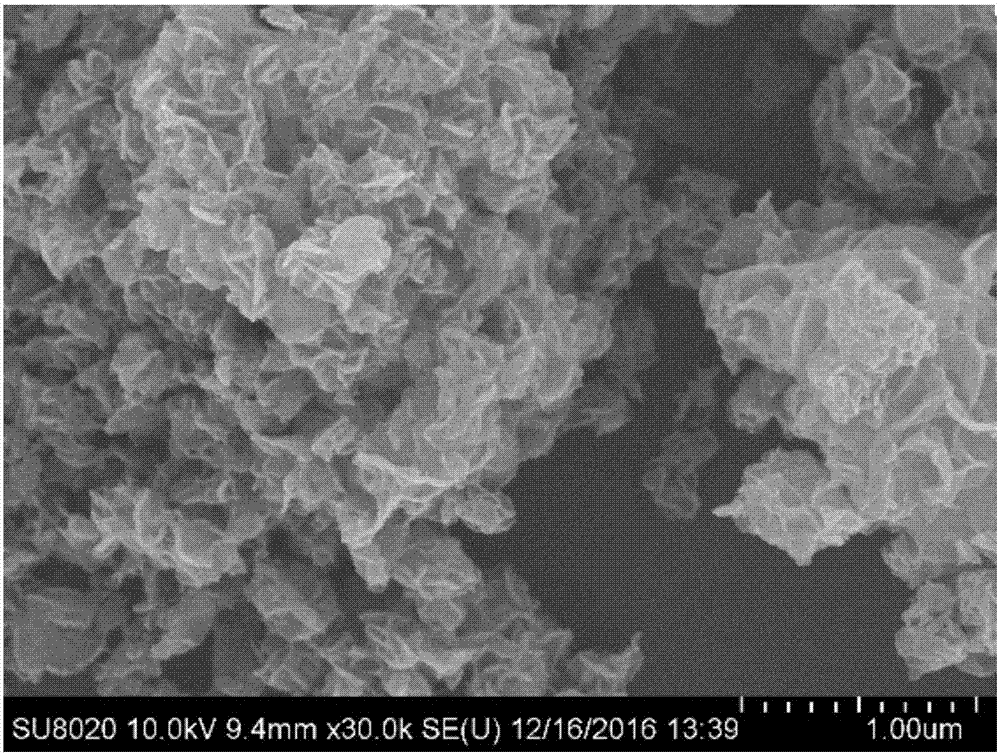

[0019] (1) Disperse 0.5g ammonium molybdate tetrahydrate and 1.0g thiourea into 9ml deionized water, stir until completely dissolved to form liquid A, add 1.0g PDDA to 9ml deionized water and stir for 2h to form liquid B, slowly dissolve liquid A Drop it into liquid B and stir for 24 hours, add it into a 25ml reaction kettle, react at 150°C for 36 hours, naturally cool to room temperature, wash with deionized water and absolute ethanol, dry in an oven at 40°C for 24 hours, and grind to obtain PDDA Modified MoS 2 two-dimensional layered particles;

[0020] (2) Prepare 100ml of PDDA solution with a concentration of 10.0g / L with deionized water, and add 0.1g / L of MoS prepared in step (1) 2 Add it into the PDDA solution and ultrasonicate for 0.5h; in addition, prepare 100ml of sodium lignosulfonate solution with a concentration of 10.0g / L;

[0021] (3) Wash the negatively charged polyacrylonitrile-based membrane with deionized water to neutrality after pretreatment, immerse it i...

Embodiment 2

[0024] (1) Disperse 0.5g ammonium molybdate tetrahydrate and 1.0g thiourea into 9ml deionized water, stir until completely dissolved to form liquid A, add 1.0g PDDA to 9ml deionized water and stir for 2h to form liquid B, slowly dissolve liquid A Drop into liquid B and stir for 24 hours, add it to a 25ml reaction kettle, react at 280°C for 15 hours, naturally cool to room temperature, wash with deionized water and absolute ethanol three times, dry in an oven at 110°C for 12 hours, and grind to obtain PDDA-modified MoS 2 two-dimensional layered particles;

[0025] (2) Prepare 100ml of PDDA solution with a concentration of 1.0g / L with deionized water, and add 1.0g / L of MoS prepared in step (1) 2 Add to the PDDA solution, ultrasonic 4h; In addition, prepare 100ml of sodium lignosulfonate solution with a concentration of 1.0g / L;

[0026] (3) Wash the negatively charged polyacrylonitrile-based membrane with deionized water to neutrality after pretreatment, immerse it in the PDDA ...

Embodiment 3

[0029](1) Disperse 0.5g of ammonium molybdate tetrahydrate and 4.0g of thiourea into 9ml of deionized water, stir until completely dissolved to form liquid A, add 1.5g of PDDA to 8.5ml of deionized water and stir for 2 hours to form liquid B, and dissolve liquid A Slowly drop it into liquid B and stir for 24 hours, add it into a 25ml reaction kettle, react at 220°C for 18 hours, naturally cool to room temperature, wash with deionized water and absolute ethanol three times, dry in an oven at 60°C for 18 hours, and grind to make Two-dimensional layered material MoS 2 ;

[0030] (2) Prepare 100ml of PDDA solution with a concentration of 5.0g / L with deionized water, and 0.08gMoS prepared in step (1) 2 Add PDDA solution and sonicate for 2 hours; in addition, prepare 100ml sodium lignosulfonate solution with a concentration of 5.0g / L;

[0031] (3) Wash the negatively charged polyacrylonitrile-based membrane with deionized water to neutrality after pretreatment, immerse it in the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com