Treatment method for waste catalytic cracking catalyst, obtained silicon-aluminum material and application of silicon-aluminum material

A technology of catalytic cracking and silicon-aluminum materials, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as limited nickel removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

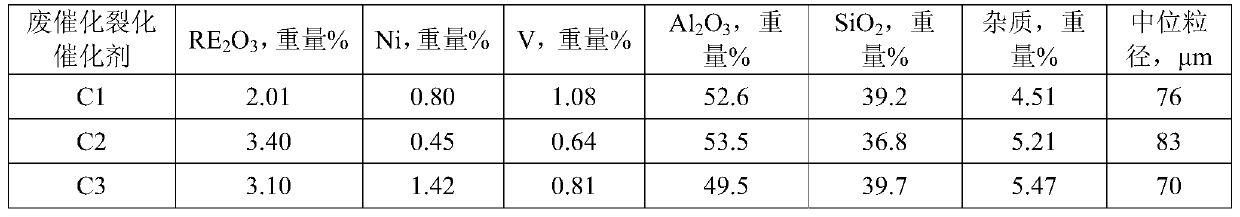

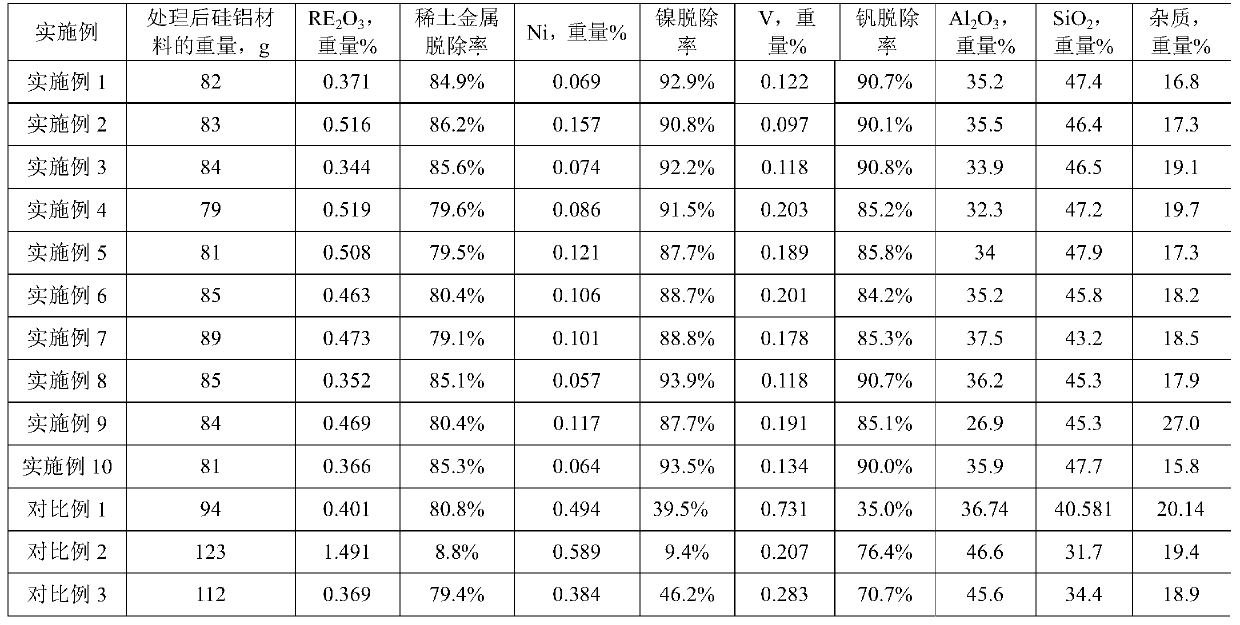

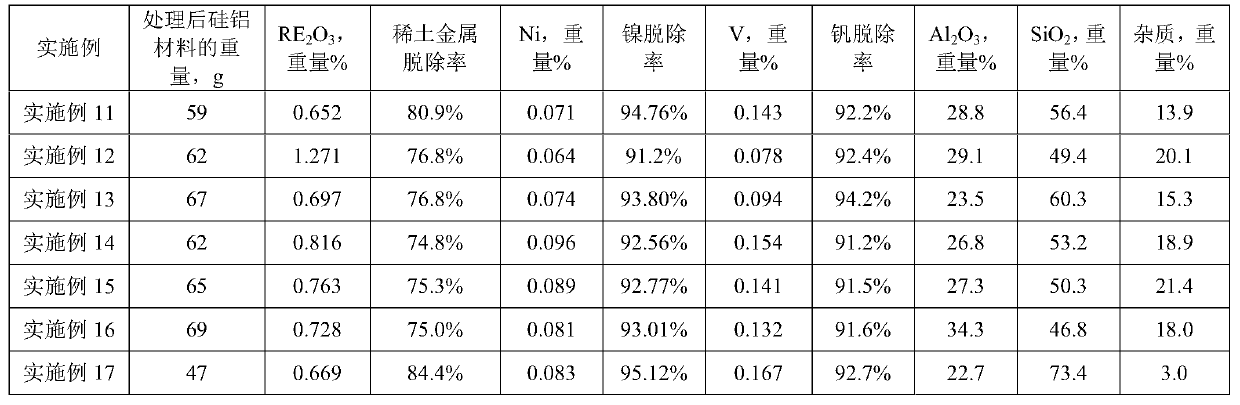

Embodiment 1

[0073] Weigh 100g of spent catalytic cracking catalyst C1 and 500g of sodium carbonate solution with a concentration of 200g / L and mix them uniformly, then stir at 120°C and 1.8Mpa at 500r / min for 2h for impregnation treatment, and then filter to obtain impregnated catalyst. This was added to 500 g of deionized water, stirred at 400 r / min for 30 minutes at 85° C., and washed with water. Then filter to obtain 121g filter cake (dry basis weight, the same below), that is, the catalyst after washing treatment, and the washing treatment leachate is sent to recovery equipment. Add the catalyst after water washing treatment to 500g concentration of 25% by weight hydrochloric acid solution, add 5g ethylenediaminetetraacetic acid (EDTA) at the same time, and carry out acid leaching at 95°C and 400r / min under the pressure of 0.1MPa in a water bath for 120 minutes For treatment, the molar ratio of EDTA to nickel metal in the spent catalytic cracking catalyst is 2:1. Then filter to obtai...

Embodiment 2

[0075] The spent catalytic cracking catalyst was replaced with C2, and treated according to the method of Example 1 to obtain the treated silicon-aluminum material, and its basic chemical composition was tested and listed in Table 2.

Embodiment 3

[0077] Weigh 100g of spent catalytic cracking catalyst C1 and 300g of potassium carbonate solution with a concentration of 280g / L and mix them uniformly, stir at 160°C and 2.6Mpa at 500r / min for 1h for impregnation treatment, and then filter to obtain impregnated catalyst. This was added to 500 g of deionized water, stirred at 400 r / min for 30 minutes at 85° C., and washed with water. Then filter to obtain 115g filter cake, that is, the water-washed catalyst, and the water-washed leachate is sent to a recovery device. The catalyzer after the washing process is added to 500g concentration in the nitric acid solution of 20% by weight, and 6g ammonium sulfate is added simultaneously, and is carried out acid leaching treatment with 400r / min stirring 30 minutes under 85 ℃, water bath 0.1MPa pressure, ammonium sulfate and waste The molar ratio of nickel metal in the catalytic cracking catalyst is 5:1. Then filter to obtain 86g filter cake, which is the catalyst after acid leaching,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com