Deoxidizing alloying agent capable of purifying molten steel and preparation method thereof

A deoxidizing alloying and deoxidizing technology, applied in the field of iron and steel smelting, can solve the problems of difficult to ensure alloy homogeneity, no segregation at the end of difficult solidification, time waste, etc. Fully even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

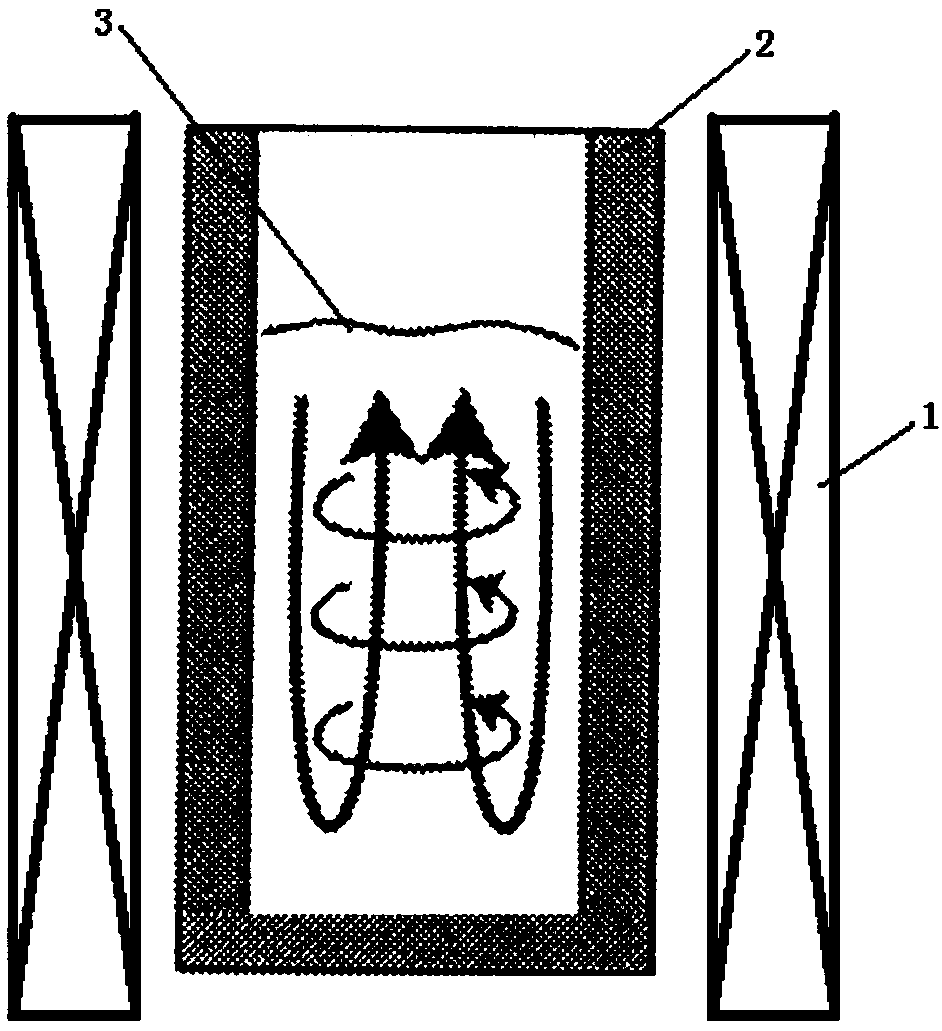

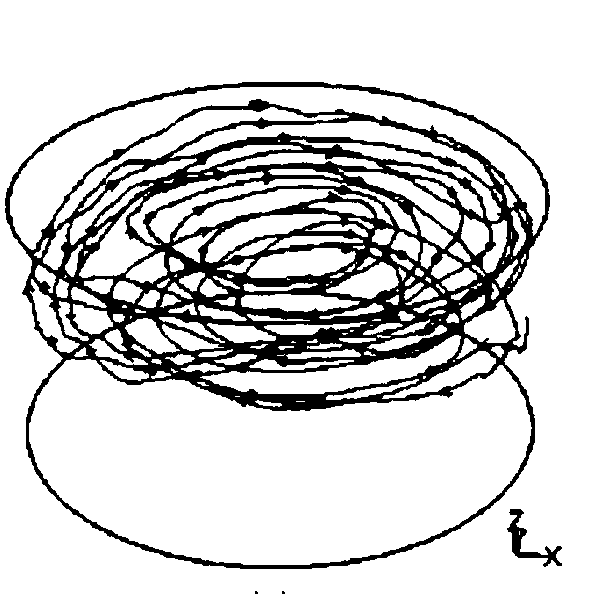

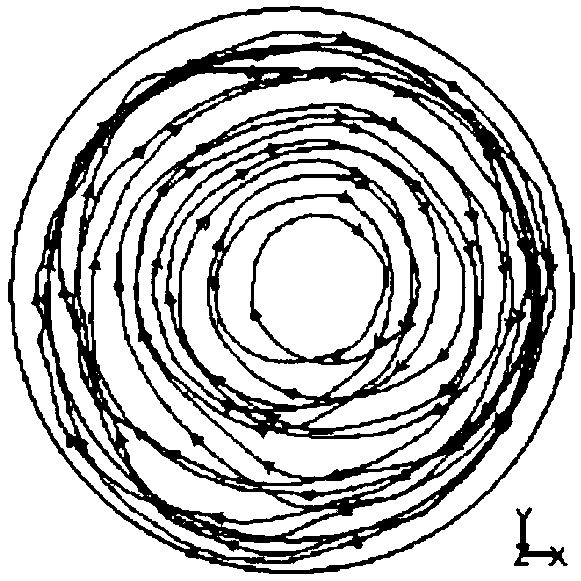

Method used

Image

Examples

Embodiment 1

[0026] Deoxidation alloying agent preparation:

[0027] (1) The weight percent of the deoxidizing alloying agent is 35% for aluminum, 6% for silicon carbide, 6% for calcium aluminate, 14% for silicon, 27% for manganese, and the rest is iron.

[0028] (2) Metal aluminum, silicon carbide fine powder, calcium aluminate fine powder, metal silicon, metal manganese, and industrial pure iron are used as raw materials for the deoxidation alloying agent. The purity of metal raw materials reaches 99.1%, and the content of phosphorus and sulfur is 0.04%. The silicon carbide fine powder and calcium aluminate fine powder have a purity of 99.2%, and the particle diameters of the silicon carbide fine powder and calcium aluminate fine powder are 100-300 microns.

[0029] (3) Melt metal aluminum and industrial pure iron in the crucible of the induction furnace according to the finished product content, then add metal silicon and metal manganese according to the finished product content, and a...

Embodiment 2

[0040] Deoxidation alloying agent preparation:

[0041] (1) The weight percent of the deoxidizing alloying agent is that the aluminum content is 36%, the silicon carbide content is 3%, the calcium aluminate content is 5%, the silicon content is 3.2%, the manganese content is 30%, and the titanium content is 0.36%, The niobium content is 0.62%, the rest is iron.

[0042](2) Metal aluminum, silicon carbide fine powder, calcium aluminate fine powder, metal silicon, metal manganese, metal titanium, metal niobium and industrial pure iron are used as raw materials for the production of deoxidation alloying agent. The purity of metal raw materials reaches 99.2%, and the content of phosphorus and sulfur is 0.03%. The purity of the silicon carbide fine powder and calcium aluminate fine powder reaches 99.1%, and the particle size of the silicon carbide fine powder and calcium aluminate fine powder is 300-500 microns.

[0043] (3) In the crucible of the induction furnace, metal aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com