Device and method for controlling fine particulate matter from desulfurized smoke

A technology of fine particles and control devices, which is applied in the field of exhaust gas desulfurization exhaust gas treatment devices and desulfurization flue gas fine particle control devices. It can solve the problems of increasing energy consumption of desulfurization devices, increasing desulfurization costs, and unsatisfactory effects. The effect is good, the operation is convenient, and the impact effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

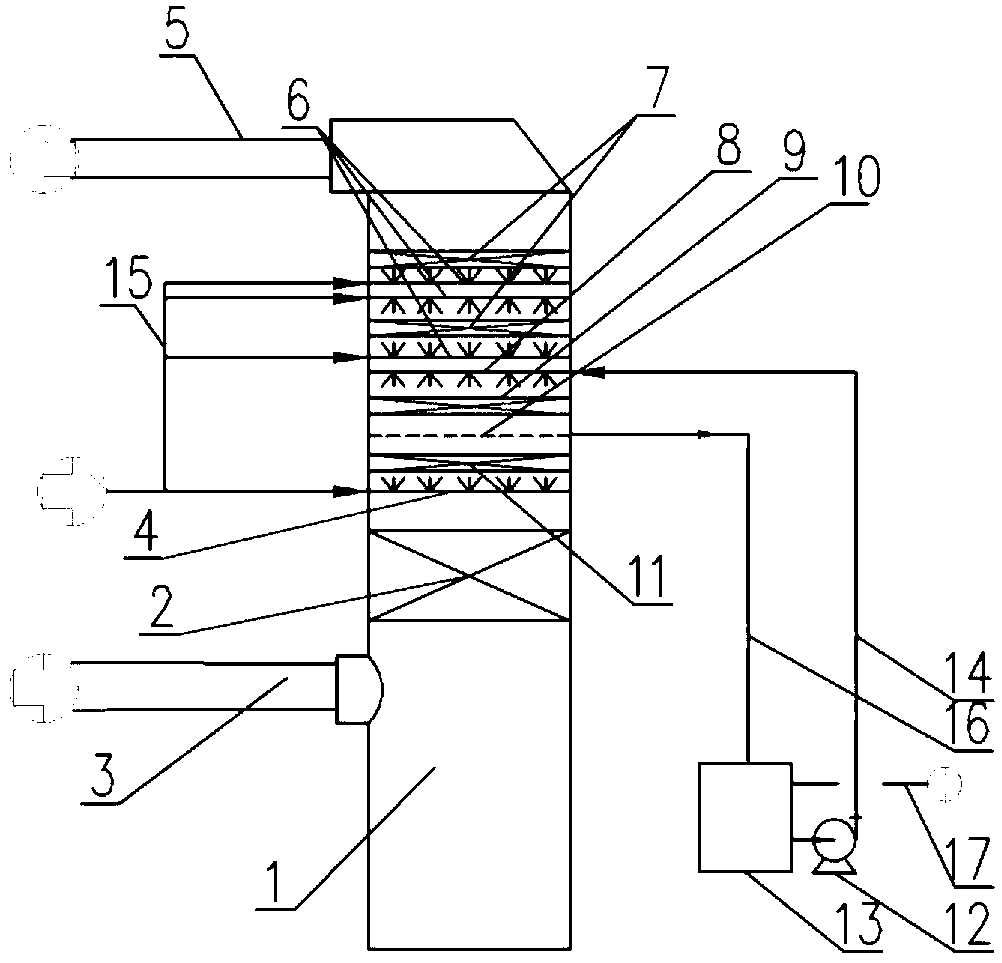

[0022] see figure 1 Flow chart:

[0023] After the original flue gas passes through the absorption layer 2 of the absorption tower in the desulfurization absorption tower 1 from the flue 3 of the original flue gas, the sulfur dioxide in the flue gas is removed by the absorption liquid, and the flue gas carries substances such as absorption liquid droplets, smoke dust, and absorbent. The flue gas rises in the absorption tower and enters the absorbing liquid demister 11, and most of the liquid droplets with a particle size larger than 10 μm are removed. The water washing liquid sprayed down by the device 8 is contacted, where the particle size of the absorption liquid droplets, smoke and absorbent and other fine particles are increased and washed and captured, and the flue gas enters the water washing demister 7 to remove the particle size after being washed with water. For droplets larger than 10 μm, the clean flue gas is discharged from the clean flue 5.

[0024] In order to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com