Gas turbine generating coke oven gas comprehensive purification system and purification method thereof

A coke oven gas and gas turbine technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as failure to reach, gas turbine cannot operate normally, and achieve extended replacement cycle, ideal purification effect, Good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

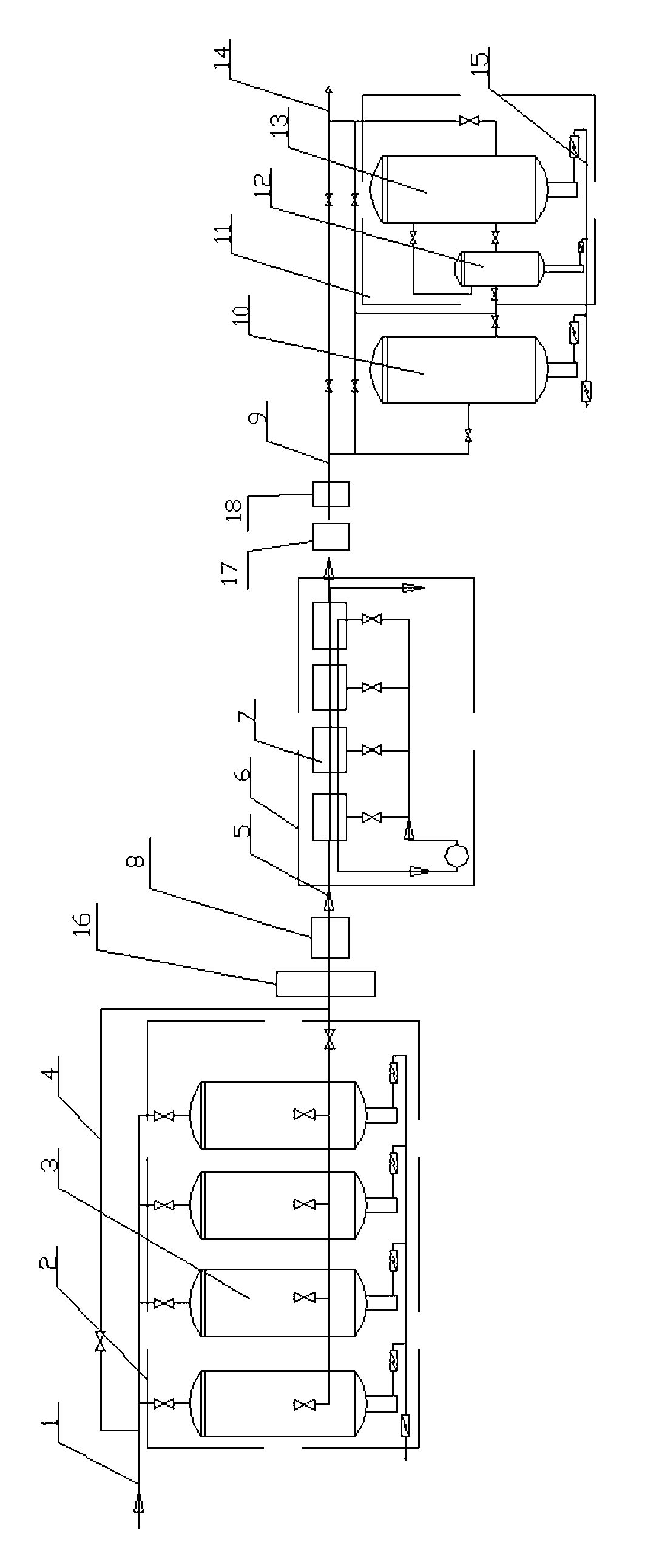

[0027] Such as figure 1 As shown, the structural schematic diagram of the system of the present invention, the coke oven gas in the gas pipe 1 enters the gas turbine through the desulfurization system 2, the compressor filter system 6 and the gas filter system 11 successively, and the desulfurization system is four groups of dry desulfurization towers 3 connected in parallel On the gas pipe 1, the compressor filter system 6 is connected in series by four compressor filters on the first gas pipeline 5 from the desulfurization system, and the second gas pipeline 9 from the compressor filter system 6 passes through a heat exchanger After the Heheng control device 10 enters the gas filtration system 11, the gas filtration system 11 is composed of a pre-stage filter 12 and a post-stage filter 13, the pre-stage filter 12 is a double high-pressure secondary pre-filter, Two sets of secondary filters are adopted, which can be used for mutual backup or isolation. The post-stage filter 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com