Process for producing calcium carbonate by absorbing carbon dioxide with ardealite decompose slag

A carbon dioxide, phosphogypsum technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems such as patents for inventions that have not yet been seen, and achieve the effect of protecting the ecological environment, reducing CO2 emissions, and realizing circular economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

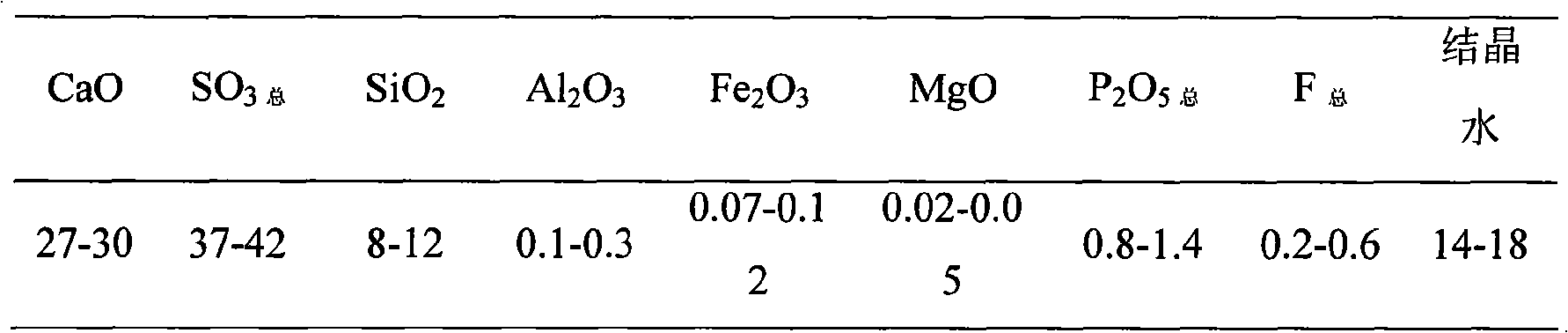

Embodiment 1

[0020] Grind the phosphogypsum and anthracite finely, pass the phosphogypsum through a standard sieve with a hole diameter of 0.037mm, and pass through the standard sieve to separate the anthracite according to different particle sizes, and mix the coal and phosphogypsum with a particle size of 0.037mm according to the C / S molar ratio = 0.75 Evenly, put it into the decomposition furnace whose temperature has been raised to 850°C, and continue to raise the temperature so that the time for the material temperature to rise to 1000°C is less than 15s. Medium SO 2 The reaction ends when the volume percentage reaches 15%-17%, containing SO 2 The flue gas is used for sulfuric acid production through the gas collection system, and the solid slag is naturally cooled to obtain the composition expressed in wt.%, mainly: CaO 55%-65%, CaS 12%-20%, SiO 2 8%-12%, Al 2 o 3 0.1%-0.3%, Fe 2 o 3 0.07%-0.12%, MgO 0.02%-0.05%, total phosphorus (existing as solid eutectic phosphorus) 0.3-0.6...

Embodiment 2

[0022] Grind phosphogypsum and high-sulfur coal finely, pass the phosphogypsum through a standard sampling sieve with an aperture of 0.037mm, and take 0.037mm coal through a standard sieve, then mix the coal and phosphogypsum according to the C / S molar ratio = 0.9, and put it in the temperature In the reaction furnace that has been raised to 950°C, the time for raising the temperature of the material to 1100°C is less than 15s. After achieving rapid temperature rise, it is calcined at 1100°C. 2 The reaction ends when the volume percentage reaches 15%-17%, containing SO 2 The flue gas is used for sulfuric acid production through the gas collection system, and the solid slag is naturally cooled, and its composition is expressed in wt.%, mainly: CaO: 50%-65%, CaS: 16%-22%, SiO 2 : 8%-12%, Al 2 o 3 : 0.1%-0.3%, Fe 2 o 3 : 0.07%-0.12%, MgO: 0.02%-0.05%, total phosphorus (existing as solid eutectic phosphorus): 0.2-0.6% phosphogypsum decomposition slag.

example 1

[0024] The phosphogypsum decomposition slag prepared in Example 1, the composition is mainly expressed in wt.%: CaO 55%-65%, CaS12%-20%, SiO 2 8%-12%, Al 2 o 3 0.1%-0.3%, Fe 2 o 3 0.07%-0.12%, MgO 0.02%-0.05%, total phosphorus (existing as solid eutectic phosphorus): 0.3%-0.6%. It is placed in a fixed-bed carbonization tower with a height:diameter ratio of 8:1 and a packing factor of 0.7. After humidification, the CO 2 (wt.% of water content is 1-15%) at a gas velocity of 1.6-2.5m / s, solid volume m 3 The ratio of number to gas volume L is kept at 4.5L / m 3 In between, the carbonization reaction is carried out at a temperature of 30 ° C to obtain a CaCO 3 84wt.% product, the yield is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com