Nanocrystalline Ce-Ti composite oxide catalyst used for selective catalytic reduction of nitric oxide by utilizing ammonia

A composite oxide, nitrogen oxide technology, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problem of poor low temperature activity, narrow active temperature window, Respond to airspeed sensitivity and other issues to achieve the effect of reducing usage, reducing risks, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

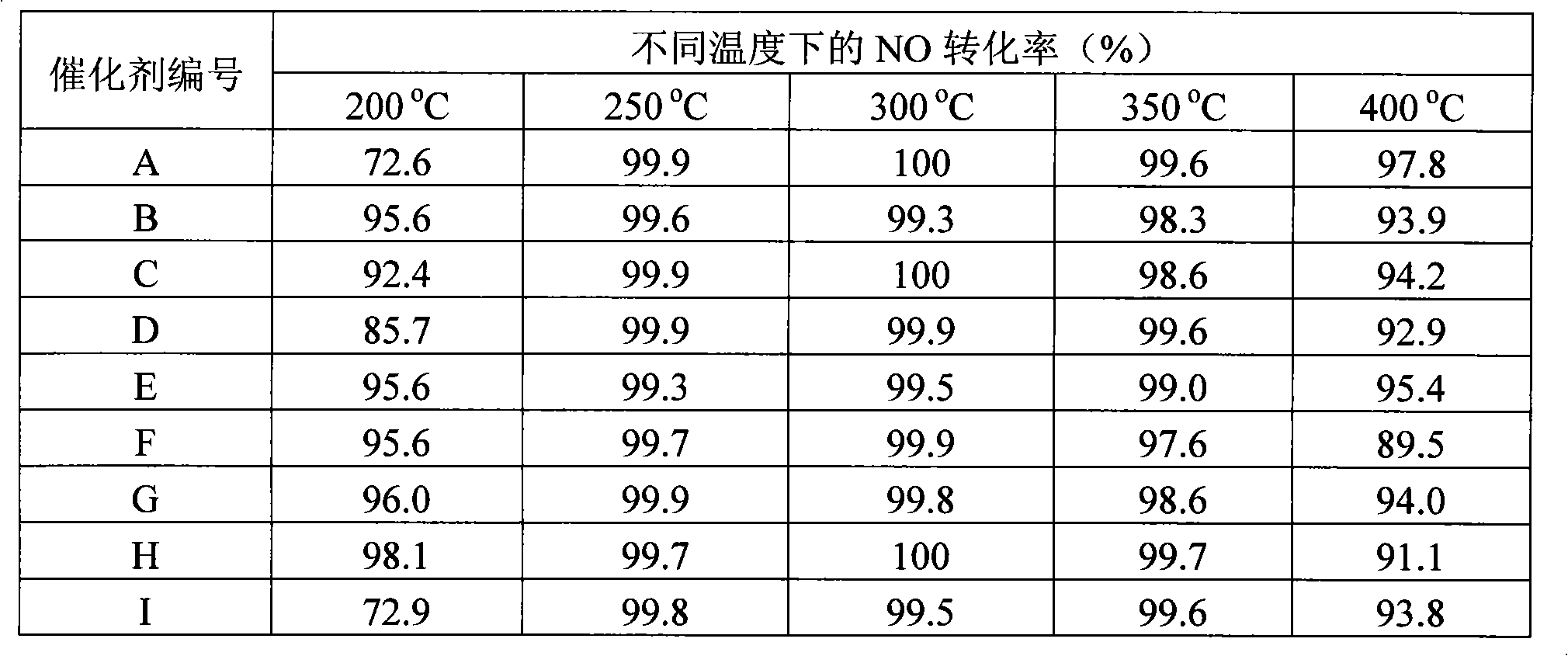

Embodiment 1-4

[0015] Use cerium nitrate hexahydrate and titanium sulfate as cerium salt and titanium salt respectively, prepare a solution with a Ce / Ti molar ratio of 0.1 and mix evenly, add excess urea solution to the solution (the molar ratio of urea to metal elements is 23:1 ), and continuously stirred at 90°C for 8 hours, then suction filtered and washed, put the filter cake in an oven and dried overnight at 100°C, and finally roasted in air at 500°C for 5 hours in a muffle furnace to obtain a powder catalyst. The prepared catalyst was pressed into tablets, crushed, sieved, and 60-80 meshes were taken for later use, which was called catalyst A. Catalysts B, C, and D were prepared by changing the Ce / Ti molar ratio to 0.2, 0.5, and 1.0, while other conditions remained unchanged.

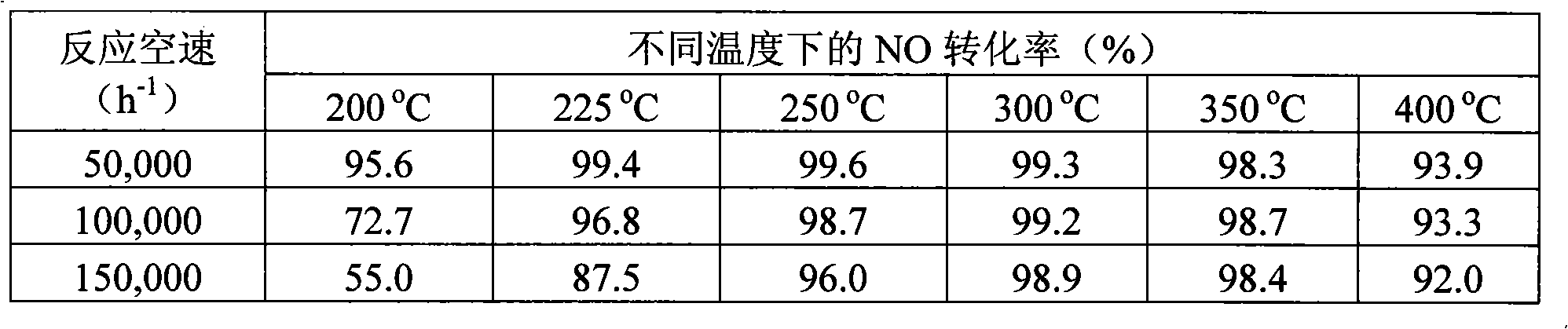

Embodiment 5-7

[0017] Use cerous chloride heptahydrate and titanium sulfate as cerium salt and titanium salt respectively, prepare the solution that Ce / Ti molar ratio is 0.2 and mix uniformly, add excessive urea solution (the molar ratio of urea and metal element is 23 : 1), and continuously stirred at 90°C for 8h, then suction filtered and washed, put the filter cake in an oven and dried overnight at 100°C, and finally roasted in air at 500°C in a muffle furnace for 5h to obtain powdered catalyst. The prepared catalyst was pressed into tablets, crushed, sieved, and 60-80 meshes were taken for later use, which was called catalyst E. Other conditions remained unchanged, and the cerium salt was changed to cerium sulfate tetrahydrate and ammonium cerium nitrate to prepare catalysts F and G respectively.

Embodiment 8-9

[0019] Use cerium nitrate hexahydrate and titanium sulfate as cerium salt and titanium salt respectively, prepare a solution with Ce / Ti molar ratio of 0.2 and mix evenly, add excess urea solution (the molar ratio of urea to metal element is 23:1) ), and continuously stirred at 90°C for 8h, then suction filtered and washed, put the filter cake in an oven and dried overnight at 100°C, and finally roasted in the air at 400°C for 5h in a muffle furnace to obtain a powder catalyst. The prepared catalyst is pressed into tablets, crushed, sieved, and 60-80 meshes are taken for later use, which is called catalyst H. Catalyst I was prepared by changing the calcination temperature to 600°C while keeping other conditions unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com