Device for removing fine particles by joint action of acoustic agglomeration and mist spray and method of device

A joint action, fine particle technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of not particularly obvious effects, increased energy consumption, and large pressure drop, so as to improve the efficiency of acoustic wave agglomeration and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

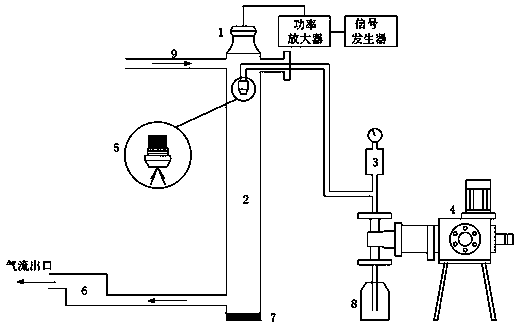

[0017] Such as figure 1 As shown, the device for the removal of fine particles by the combination of sound wave agglomeration and spraying includes a compression driving sound source 1, a reunion chamber main body 2, a buffer tank 3, a plunger metering pump 4, a nozzle 5, an induced draft fan 6, and a sound-absorbing sponge 7 , water storage tank 8, flue gas inlet 9, power amplifier, signal generator; the top of the reunion room main body 2 is provided with a compression driving sound source 1, and the compression driving sound source 1 is connected to the power amplifier and signal generator in sequence, The upper side wall of the reunion chamber main body 2 is provided with a flue gas inlet 9, and the upper part of the reunion chamber main body 2 is provided with a nozzle 5, and the nozzle 5 is respectively connected with the buffer tank 3, the plunger type metering pump 4, and the water storage tank 8. The lower side wall of the chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com