Ammonia-spraying grid device for SCR-method flue gas denitrification, and SCR-method flue gas denitrification process

An ammonia injection grille and flue gas technology, applied in separation methods, greenhouse gas capture, climate sustainability, etc., can solve the problems affecting the mixing distance and denitration efficiency of the ammonia injection grille, increase the resistance of flue gas, poor injection rigidity, etc. To achieve the effect of reducing smoke resistance and mixing distance, reducing smoke resistance and reducing mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0031] It should be noted that this embodiment is described by taking a coal-fired boiler in a power station as an example, but it is not limited to other combustion equipment.

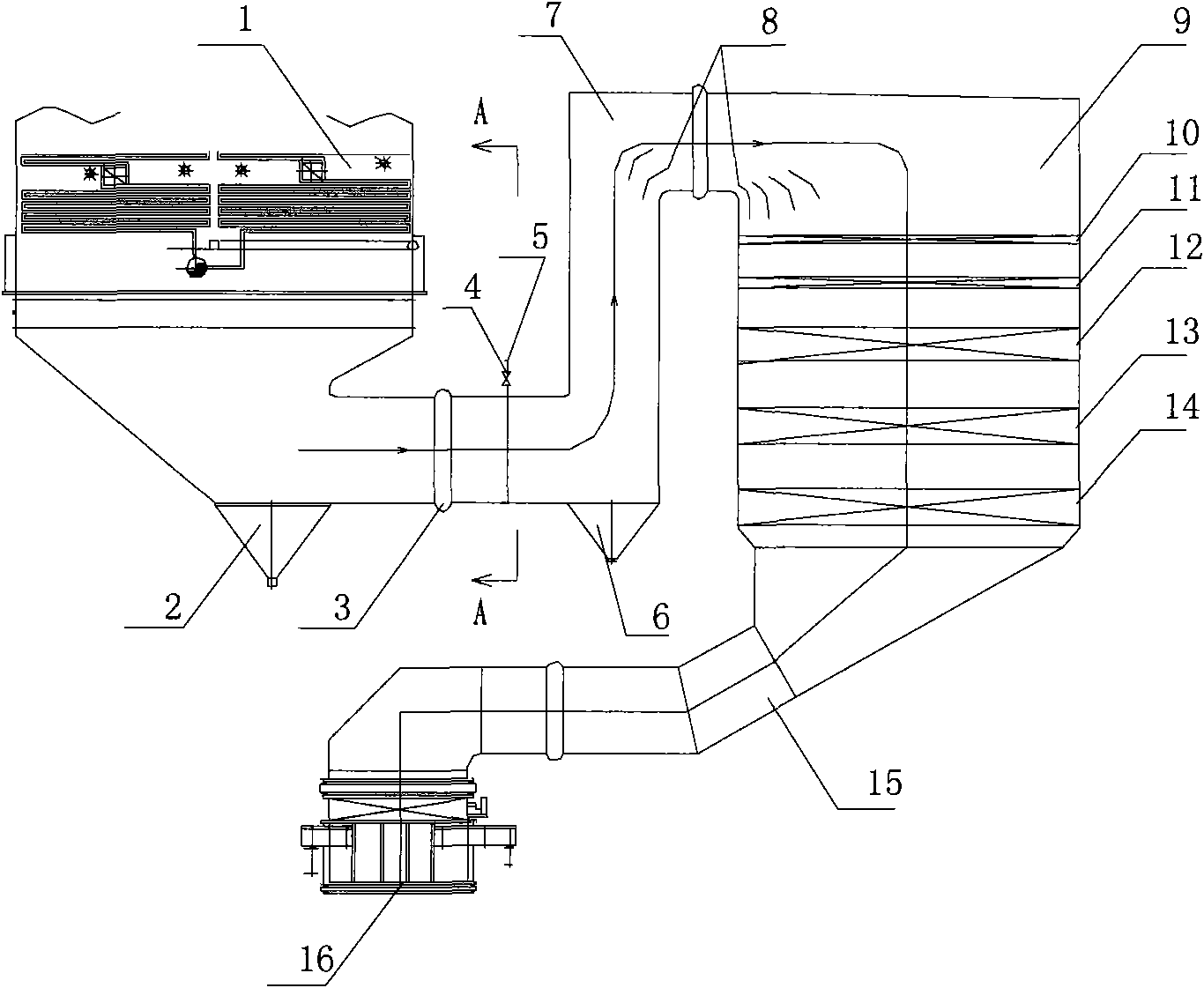

[0032] like figure 1 The schematic diagram of the flue gas denitrification process of the SCR method is shown. The flue gas after boiler combustion is discharged from the economizer 1 and then enters the flue 7 at the entrance of the denitrification reactor. The reactor inlet flue ash hopper 6 is arranged at the corner of the reactor inlet flue, the purpose of which is to collect the smoke and discharge the flue gas system to prevent the dust from abrading and clogging the catalyst and the downstream equipment of the denitrification device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com