Flue gas dust removal and denitration integrated catalytic ceramic filter

A ceramic filter and flue gas technology, which is applied in the direction of physical/chemical process catalyst, gas treatment, dispersed particle filtration, etc., can solve the problems that are difficult to call perfect, highly toxic and poisonous vanadium-based materials, and achieve convenient use and expand work Temperature, effects of preventing clogging and abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

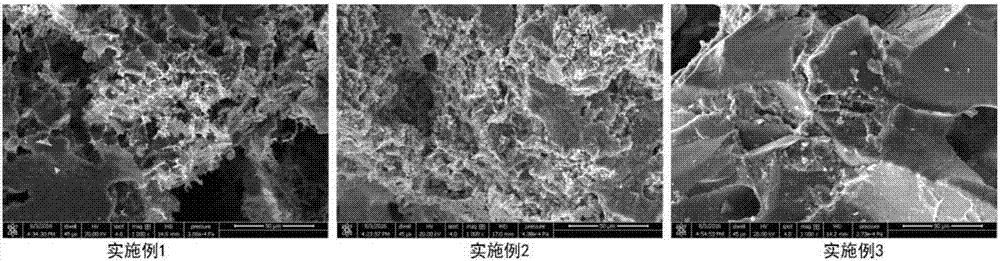

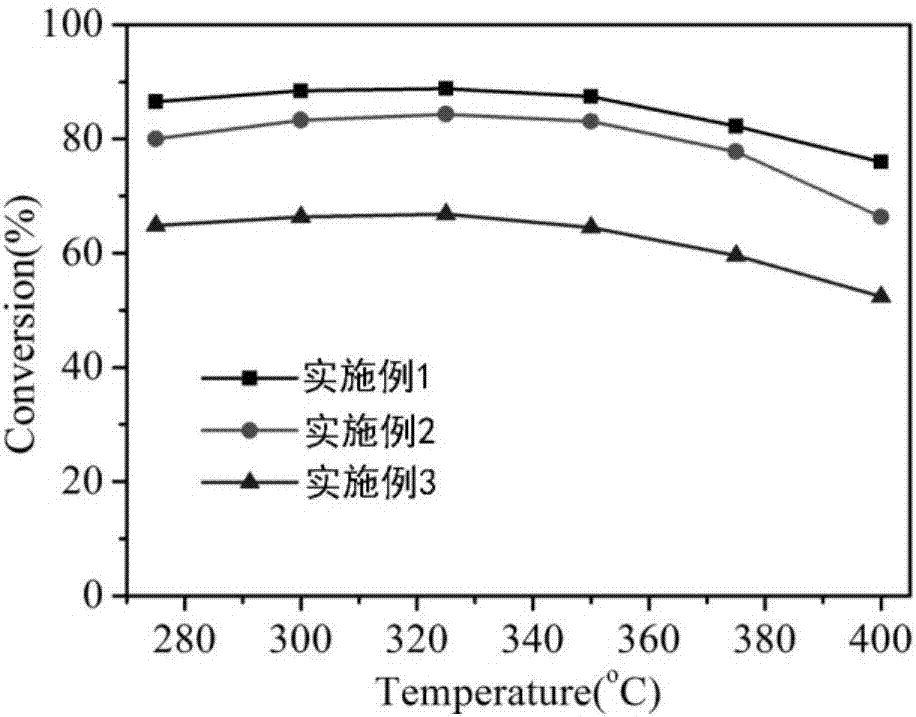

[0039] Example 1: Synchronous vacuum impregnation method is used to prepare a catalytic ceramic filter integrating flue gas dust removal and denitrification

[0040] 1) Under rapid stirring, dissolve tetrabutyl titanate in ethanol, then add hydrolysis inhibitor acetic acid to obtain liquid A, the volume ratio of tetrabutyl titanate:ethanol:acetic acid is 2:7:1;

[0041] 2) Under rapid stirring, dissolve copper nitrate, iron nitrate, cerium nitrate and manganese nitrate in ethanol to obtain liquid B, the mass ratio of copper nitrate: iron nitrate: cerium nitrate: manganese nitrate: ethanol is 1:2:2 :1:15;

[0042] 3) Pour liquid B into liquid A to obtain liquid C, stir quickly, the mass ratio of tetrabutyl titanate: copper nitrate: iron nitrate: cerium nitrate: manganese nitrate is 2:1:2:2:1;

[0043] 4) Submerge the tubular porous cordierite ceramics into liquid C, place in a vacuum impregnation device, the vacuum degree is 450Pa, the immersion time is 2h, the number of immer...

Embodiment 2

[0046] Example 2: Synchronous vacuum impregnation method is used to prepare a catalytic ceramic filter integrating flue gas dust removal and denitrification

[0047] 1) Under rapid stirring, dissolve tetrabutyl titanate in ethanol, then add hydrolysis inhibitor acetic acid to obtain liquid A, the volume ratio of tetrabutyl titanate:ethanol:acetic acid is 2:7:1;

[0048] 2) Under rapid stirring, dissolve copper nitrate, iron nitrate, cerium nitrate and manganese nitrate in ethanol to obtain liquid B, the mass ratio of copper nitrate: iron nitrate: cerium nitrate: manganese nitrate: ethanol is 1:2:2 :1:15;

[0049] 3) Pour liquid B into liquid A to obtain liquid C, stir quickly, the mass ratio of tetrabutyl titanate: copper nitrate: iron nitrate: cerium nitrate: manganese nitrate is 2:1:2:2:1;

[0050] 4) Immerse the tubular porous mullite ceramics into liquid C, place it in a vacuum impregnation device, the vacuum degree is 750Pa, the immersion time is 2h, and the number of im...

Embodiment 3

[0053] Example 3: Synchronous vacuum impregnation method is used to prepare a catalytic ceramic filter integrating flue gas dust removal and denitrification

[0054] 1) Under rapid stirring, dissolve tetrabutyl titanate in ethanol, then add hydrolysis inhibitor acetic acid to obtain liquid A, the volume ratio of tetrabutyl titanate:ethanol:acetic acid is 2:7:1;

[0055] 2) Under rapid stirring, dissolve copper nitrate, iron nitrate, cerium nitrate and manganese nitrate in ethanol to obtain liquid B, the mass ratio of copper nitrate: iron nitrate: cerium nitrate: manganese nitrate: ethanol is 1:2:2 :1:15;

[0056] 3) Pour liquid B into liquid A to obtain liquid C, stir quickly, the mass ratio of tetrabutyl titanate: copper nitrate: iron nitrate: cerium nitrate: manganese nitrate is 2:1:2:2:1;

[0057] 4) Immerse the tubular porous silicon carbide ceramics into liquid C, place it in a vacuum impregnation device, the vacuum degree is 1000Pa, the immersion time is 2h, and the num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com