In-situ synthesis method and applications of CuFe-SAPO-34 catalyst

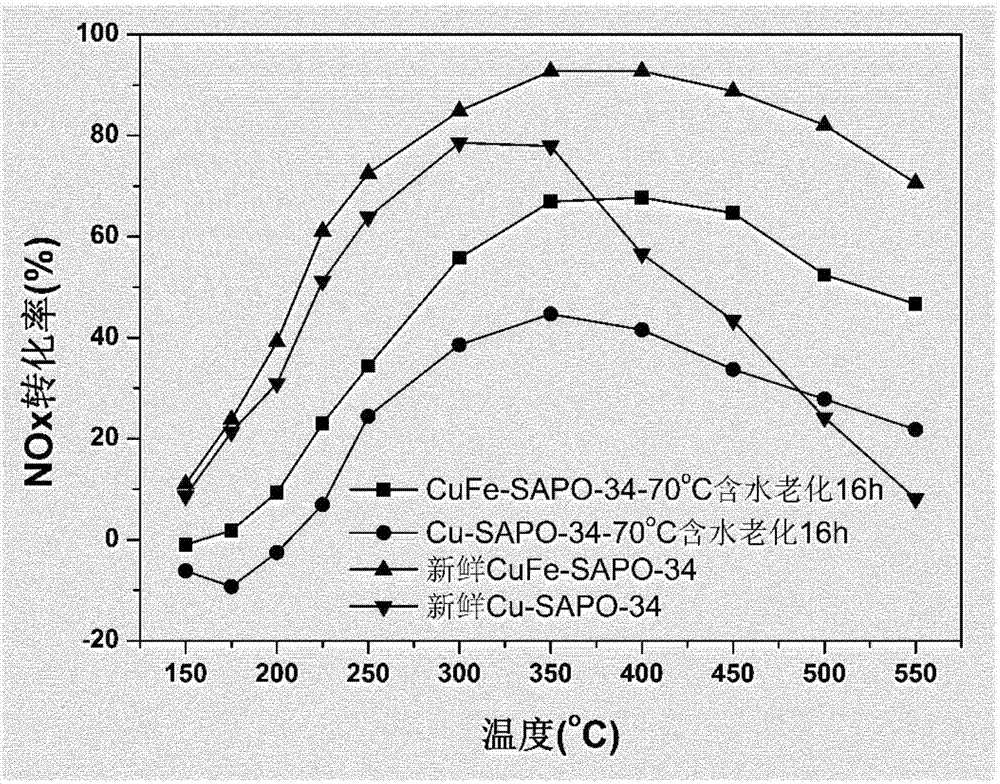

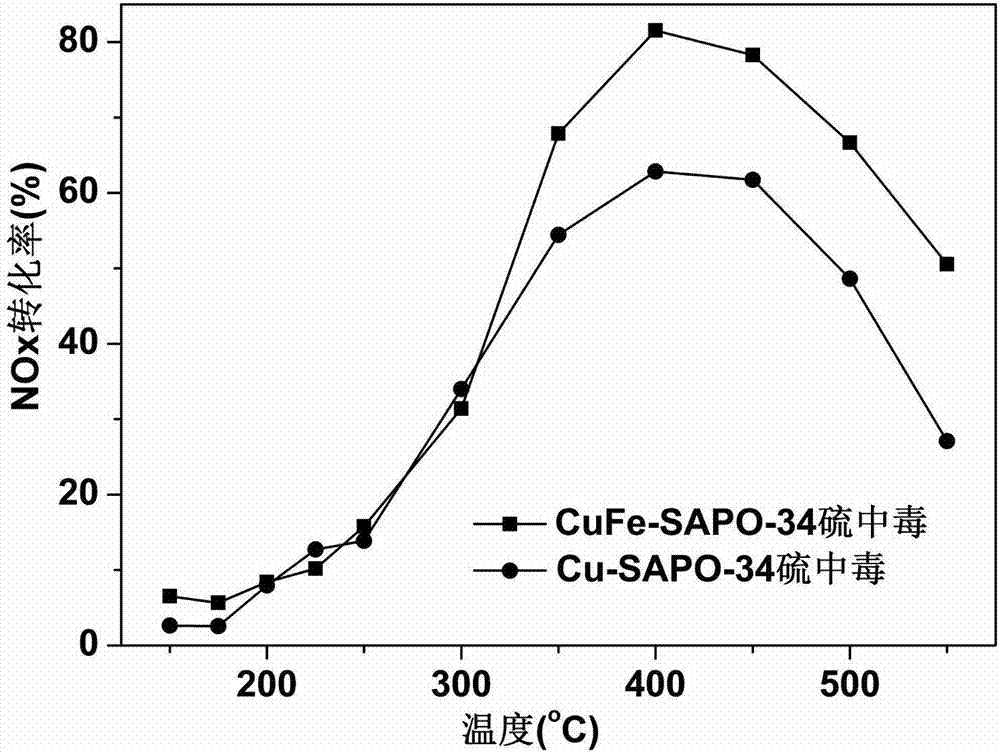

An in-situ synthesis, cufe-sapo-34 technology, applied in the field of catalysis, can solve the problems such as no relevant reports on the low-temperature water resistance and sulfur poisoning resistance of the catalyst, the metal loading is not easy to control, and the steps are cumbersome, so as to improve the sulfur resistance. Poisoning ability, improving low temperature water resistance, widening temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] With pseudoboehmite AlOOH as aluminum source, silica (SiO 2 ) is the source of silicon, phosphoric acid (H 3 PO 4 ) is the phosphorus source, Cu-TEPA is the Cu source, Fe(NO 3 ) 3 9H 2 O is iron source, each raw material is mixed, then add n-propylamine (C 3 h 9 N) is the template agent, stirred overnight until evenly stirred; then put the solution into the reaction kettle, and put the reaction kettle into an oven at 180°C for crystallization for 3 days; after the reaction kettle was fully cooled, stirred and stood still and filtered out impurities Suction filtration, put the filtered sample into an oven at 105°C for 3 hours to dry it; then put the dried sample into a muffle furnace, and heat up to 600°C for 6 hours at a rate of 1°C / min to obtain CuFe-SAPO-34 catalyst prepared by one-step synthesis method. Among them, control AlOOH, H 3 PO 4 , SiO 2 、H 2 The molar ratio of O, Cu salt, tetraethylenepentamine, Fe salt and n-propylamine is 1:1:0.57:77.17:0.12::0...

Embodiment 2

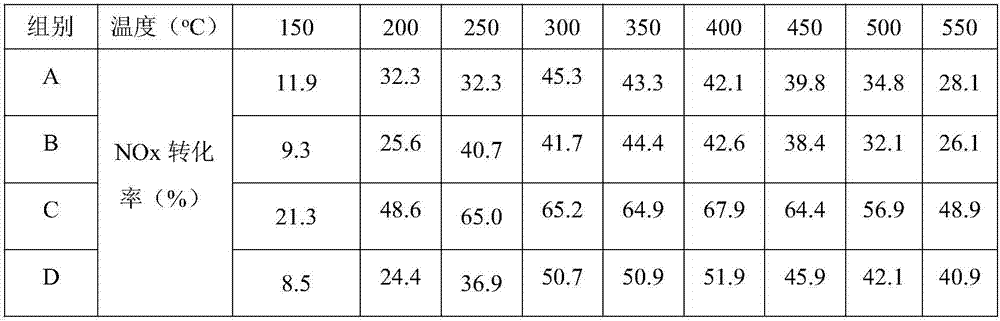

[0069] In this example, the performance of CuFe-SAPO-34 catalysts obtained under different Fe salt additions was investigated.

[0070] Catalyst preparation method: adjust the dosage of Fe, control AlOOH, H 3 PO 4 , SiO 2 、H 2 The molar ratios of O, Cu salt, tetraethylenepentamine, Fe salt and n-propylamine are A (1:1:0.57:77.17:0.12:0.12:0.0095:3.38), B (1:1:0.57:77.17:0.12: 0.12:0.019:3.38), C(1:1:0.57:77.17:0.12:0.12:0.029:3.38), D(1:1:0.57:77.17:0.12:0.12:0.043:3.38). All the other are identical with embodiment 1.

[0071] The catalytic properties of the prepared CuFe-SAPO-34 catalyst at different temperatures are shown in Table 1.

[0072] Catalytic properties of catalysts obtained under different Fe additions in table 1

[0073]

Embodiment 3

[0075] In this example, the properties of CuFe-SAPO-34 catalysts obtained at different crystallization temperatures were investigated.

[0076] Control AlOOH, H 3 PO 4 , SiO 2 、H 2 The molar ratio of O, Cu salt, tetraethylenepentamine, Fe salt and n-propylamine is 1:1:0.57:77.17:0.12::0.12:0.057:3.38, and the crystallization temperature is 150°C and 200°C respectively, and the rest are the same as in the examples 1 is the same. The properties of the prepared CuFe-SAPO-34 catalyst are shown in Table 2.

[0077] The catalytic performance of the catalyst obtained under the different crystallization temperature of table 2

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com