Honeycomb-like cerium-zirconium-titanium-based denitration catalyst and preparation method thereof

A denitrification catalyst, cerium-zirconium-titanium technology, applied in the field of denitrification catalysts, can solve the problems of high catalyst toxicity, environmental secondary pollution, short service life of catalysts, etc., to increase stability and oxygen storage capacity, widen the temperature window, and improve activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

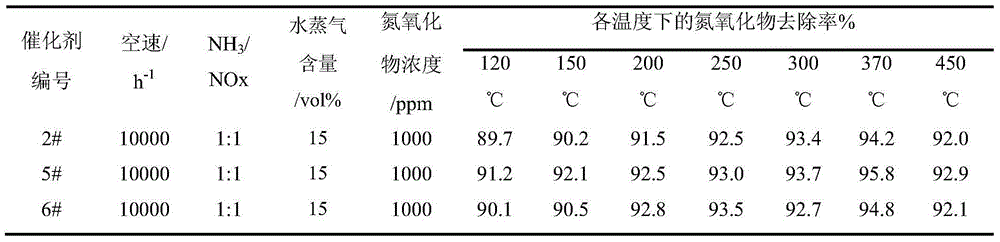

Embodiment 1

[0036] Weigh 50Kg of cerium nitrate and 30Kg of zirconium nitrate, add 100Kg of deionized water, and dissolve at 80°C to form an active component solution. Put 600Kg titanium dioxide, 2Kg wood pulp, 35.5Kg glass fiber, 6.5Kg turmeric powder, 4.2Kg stearic acid, 9.125Kg fumed silica, 350Kg deionized water into the mixer with the above-mentioned active component solution, Add ammonia water to the mud during the mixing process to adjust the pH of the mud to 9.2. Then, put the obtained mud into a filter for 12 hours of aging, and filter, and put the filtered mud into a pre-extrusion machine for pre-extrusion. The pre-extruded mud material was stale for 24 hours and then added to a vacuum extruder for extrusion molding. The vacuum degree of the vacuum extruder was 0.5 MPa, and the extrusion pressure was 3.5 MPa to obtain a honeycomb green body. After that, put the green body into the 2 In an air-permeable carton of ×24hr, drying was performed at a temperature of 50°C for 10 days,...

Embodiment example 2

[0039]Weigh 50Kg of cerium nitrate and 41.7Kg of zirconium nitrate, add 115Kg of deionized water, dissolve at 80°C and use as active component solution for later use. Put 600Kg titanium dioxide, 2Kg wood pulp, 35.5Kg glass fiber, 6.5Kg turmeric powder, 4.2Kg stearic acid, 9.125Kg fumed silica, 350Kg deionized water into the mixer with the above-mentioned active component solution, Add ammonia water to the mud during the mixing process to adjust the pH of the mud to 9.2. Then, put the obtained mud into a filter for 12 hours of aging, and filter, and put the filtered mud into a pre-extrusion machine for pre-extrusion. The pre-extruded mud material was stale for 24 hours and then added to a vacuum extruder for extrusion molding. The vacuum degree of the vacuum extruder was 0.5 MPa, and the extrusion pressure was 3.5 MPa to obtain a honeycomb green body. After that, put the green body into the 2 In an air-permeable carton of ×24hr, drying was performed at a temperature of 50°C f...

Embodiment example 3

[0042] Weigh 50Kg of cerium nitrate and 41.7Kg of zirconium nitrate, add 115Kg of deionized water, and dissolve at 80°C as the active component solution for later use. Put 600Kg titanium dioxide, 2Kg wood pulp, 35.5Kg glass fiber, 6.5Kg turmeric powder, 4.2Kg stearic acid, 9.125Kg fumed silica, 350Kg deionized water into the mixer with the above-mentioned active component solution, Add ammonia water to the mud during the mixing process to adjust the pH of the mud to 11. Then, put the obtained mud into a filter for 12 hours of aging, and filter, and put the filtered mud into a pre-extrusion machine for pre-extrusion. The pre-extruded mud material was stale for 24 hours and then added to a vacuum extruder for extrusion molding. The vacuum degree of the vacuum extruder was 0.5 MPa, and the extrusion pressure was 3.5 MPa to obtain a honeycomb green body. After that, put the green body into the 2 In an air-permeable carton of ×24hr, drying was performed at a temperature of 50°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com