Zirconium doped cerium vanadate denitration catalyst, preparation method and application

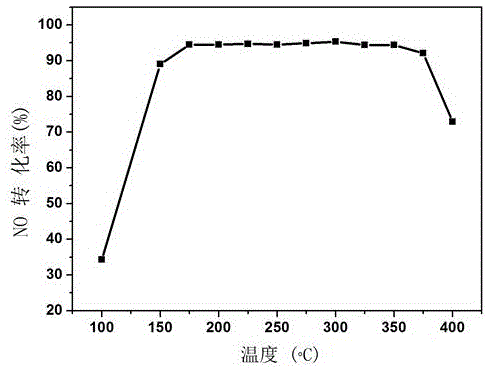

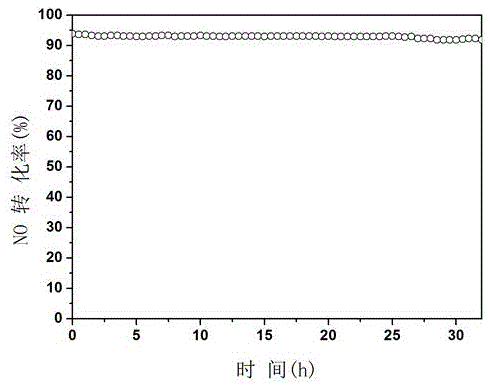

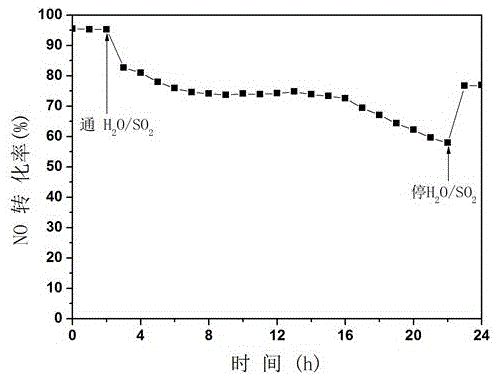

A technology of denitrification catalyst and cerium vanadate, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of strong selectivity, wide temperature window, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The catalyst has a rod-like structure, the length of the rod is 50-150nm, and the diameter is 5-100nm.

[0038] The preparation method of the above-mentioned zirconium-doped cerium vanadate denitration catalyst comprises the following steps:

[0039] (1) Prepare cerium nitrate solution and zirconium nitrate solution respectively, mix them evenly after stirring, the molar ratio of the metal cerium element in the cerium nitrate solution and the metal zirconium element in the zirconium nitrate solution is 0.85:0.15;

[0040] (2) Add fully dissolved ammonium metavanadate to the mixed solution obtained in step (1), and stir evenly, wherein the molar ratio of metal vanadium to metal cerium in ammonium metavanadate is 1:0.85;

[0041] (3) Adjust the mixed solution obtained in step (2) to pH=8.0 with NaOH;

[0042] (4) Transfer the turbid solution obtained in step (3) into a 100ml polytetrafluoroethylene kettle liner, and in an autoclave at 180 o After reacting for 12 hours a...

Embodiment 2

[0048] The catalyst has a rod-like structure, and the length and diameter of the rods are 10-100nm and 5-100nm.

[0049] The present invention provides a kind of preparation method of above-mentioned zirconium doped cerium vanadate denitration catalyst, it comprises the following steps:

[0050] (1) Prepare cerium nitrate solution and zirconium nitrate solution respectively, mix them evenly after stirring, the molar ratio of the metal cerium element in the cerium nitrate solution and the metal zirconium element in the zirconium nitrate solution is 0.90:0.10;

[0051] (2) Add fully dissolved ammonium metavanadate to the mixed solution obtained in step (1), and stir evenly, wherein the molar ratio of metal vanadium to metal cerium in ammonium metavanadate is 1:0.90;

[0052] (3) Adjust the mixed solution obtained in step (2) to pH=8.0 with NaOH;

[0053] (4) Transfer the turbid solution obtained in step (3) into a 100ml polytetrafluoroethylene kettle liner, and in an autoclave ...

Embodiment 3

[0058] The catalyst has a granular structure with a particle diameter of 5-100nm.

[0059] The present invention provides a kind of preparation method of above-mentioned zirconium doped cerium vanadate denitration catalyst, it comprises the following steps:

[0060] (1) Prepare cerium nitrate solution and zirconium nitrate solution respectively, mix them evenly after stirring, the molar ratio of the metal cerium element in the cerium nitrate solution and the metal zirconium element in the zirconium nitrate solution is 0.50:0.50;

[0061] (2) Add fully dissolved ammonium metavanadate to the mixed solution obtained in step (1), and stir evenly, wherein the molar ratio of metal vanadium to metal cerium in ammonium metavanadate is 1:0.50;

[0062] (3) Adjust the mixed solution obtained in step (2) to pH=8.0 with NaOH;

[0063] (4) Transfer the turbid solution obtained in step (3) into a 100ml polytetrafluoroethylene kettle liner, and in an autoclave at 180 o After reacting for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com