Mesoporous graphite phase carbon nitride and preparation method and application thereof

A graphite-phase carbon nitride and mesoporous technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as environmental hazards, rising production costs, and protracted production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

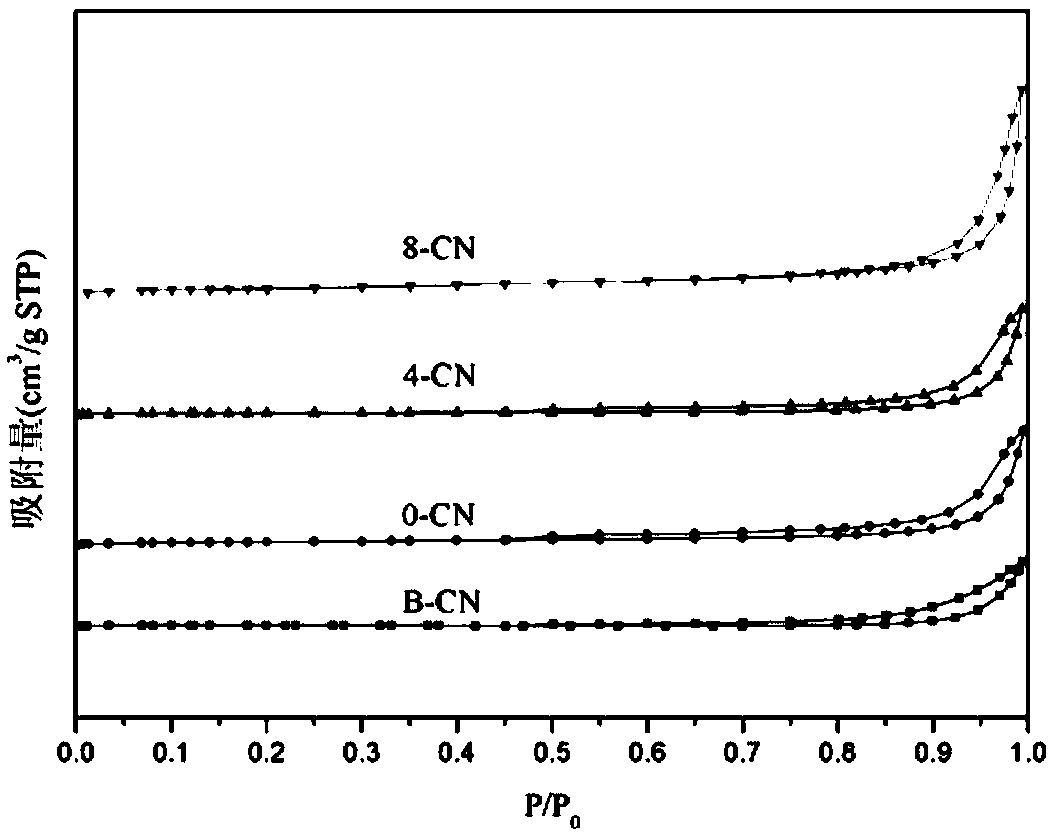

[0050] Dissolve a certain amount (0, 4, 8, 16 g) of ammonium chloride in 30 mL of water, add 4 g of melamine, and stir at room temperature for 30 min to obtain a white uniform solution. The white solution was transferred to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, subjected to hydrothermal reaction at 180°C for 12 hours, and suction filtered to obtain a white pasty solid. The white paste solid was dried in a vacuum oven at 80°C for 12 h, and then ground to obtain a powder; the powder was placed in a 100 mL corundum crucible with a lid, and the crucible was wrapped with aluminum foil, and baked in a muffle furnace. The temperature regime of the calcination is as follows: from room temperature to 550 °C at a rate of 5 °C / min, then kept at this temperature for 3 h, cooled naturally, and after lowering to room temperature, the sample was ground to obtain a light yellow powder. According to X-ray diffractometer (XRD) and ASAP 2020 specific surface ...

Embodiment 2

[0060] Dissolve a certain amount (0, 4, 8, 16 g) of ammonium nitrate in 30 mL of water, add 4 g of melamine, and stir at room temperature for 30 min to obtain a white uniform solution. Transfer the white solution to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, conduct a hydrothermal reaction at 180°C for 12 hours, filter with suction to obtain a white paste solid, wash the white paste solid with deionized water, and remove nitrate ion. Put the white paste solid in a vacuum drying oven and dry at 80°C for 12 hours, and grind to obtain a white powder; put the white powder in a 100mL corundum crucible with a lid, wrap the outer layer with aluminum foil, and bake in a muffle furnace , the temperature programming conditions are: from room temperature to 550 °C at a rate of 5 °C / min, and then maintained at this temperature for 3 hours, after cooling down to room temperature, the sample was ground to obtain a light yellow powder. The yellow powder is me...

Embodiment 3

[0063] Dissolve a certain amount (0, 4, 8, 16 g) of ammonium sulfate in 30 mL of water, add 4 g of melamine, and stir at room temperature for 30 min to obtain a white uniform solution. Transfer the white solution to a 100mL polytetrafluoroethylene-lined stainless steel hydrothermal kettle, conduct a hydrothermal reaction at 180°C for 12 hours, filter with suction to obtain a white paste solid, wash the white paste solid with deionized water, and remove sulfate radicals ion. Put the white paste solid in a vacuum drying oven and dry at 80°C for 12 hours, and grind to obtain a white powder; put the white powder in a 100mL corundum crucible with a lid, wrap the outer layer with aluminum foil, and bake in a muffle furnace , the temperature programming conditions are: from room temperature to 550 °C at a rate of 5 °C / min, and then maintained at this temperature for 3 hours, after cooling down to room temperature, the sample was ground to obtain a light yellow powder. The yellow pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com