Industrial producing process for coal series needle coke

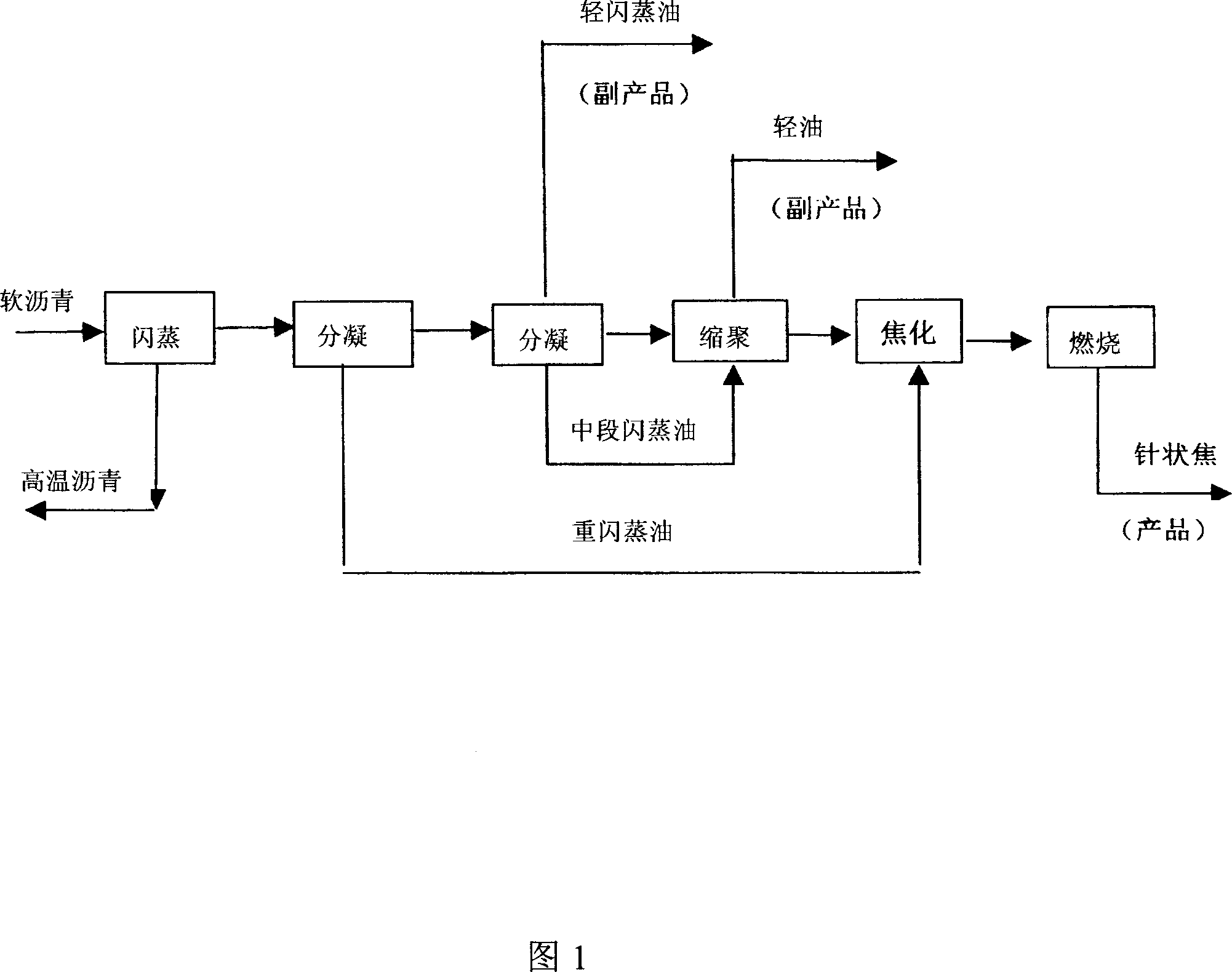

A production process and technology of needle coke, which is applied in the field of industrialized production process of coal-based needle coke, to prevent coking of heating furnace tubes, reduce the amount of steam injection, and prevent the formation of secondary quinoline insolubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] The raw material used is soft asphalt, its softening point: 30-40°C, distillation test: the distillate volume before 300°C is less than 10vol%, density (100°C): 1.16-1.20g / cm 3 , Kangxi carbon: 27 ~ 35wt%, viscosity (140 ℃): 10 ~ 40cP.

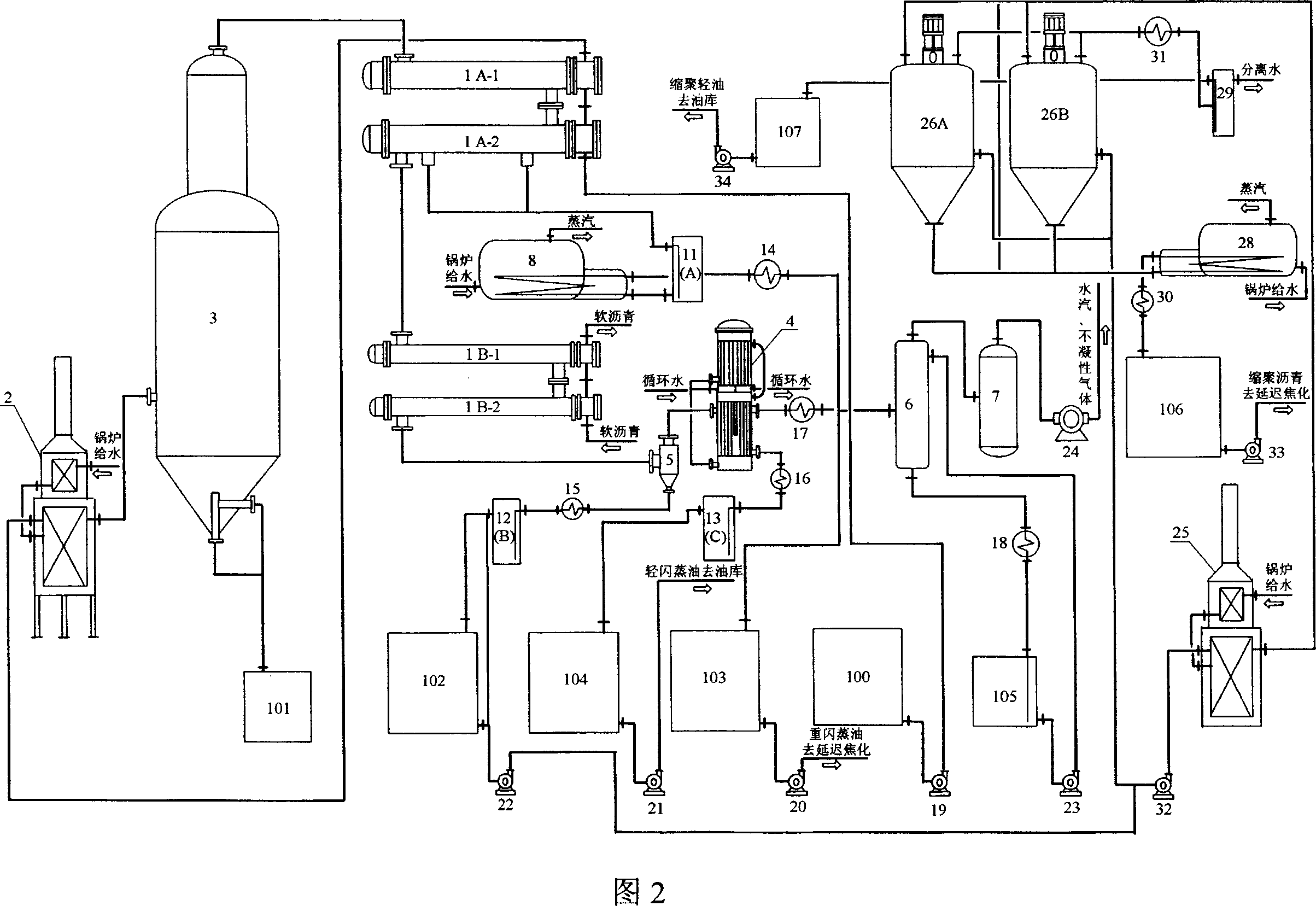

[0115]Fig. 2 is a schematic flow chart of the raw material pretreatment process of the present invention. In the flash system, the soft asphalt from the soft asphalt tank 100 of the oil depot is pressurized by the flash raw material pump 19, the flow rate is controlled by a flow regulator, and then sent to the partial condenser 1A-1, 1A-2, where it is combined with the vacuum flash The flash oil vapor coming out of the top of the steam tower 3 is heated by heat exchange; then it enters the flash heating furnace 2, and the temperature of the soft asphalt entering the flash heating furnace is 210-240°C. Here, it first enters the upper convection section furnace tube for heating , and then enter the furnace tube in the radiant section. At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com