Preparation method and use of active low molecular weight fucosan

A fucoidan, low molecular weight technology, applied in application, food science, food preservation, etc., can solve the problems of high molecular weight and lack of physiological activity of polysaccharides, and achieve the effects of uniform molecular weight, strong controllability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of fucoidan

[0033] 80-mesh kelp powder was added to deionized water at a ratio of 1:25 (w / v), extracted at 80 °C for 3 h, stirred continuously during the extraction process, the stirring speed was 2000 r / min, and centrifuged (3000 r / min, 10 min) , take the supernatant, add HCl (12 mol / L) to make the final concentration 0.1 mol / L; then centrifuge (3000 r / min, 5 min), remove the alginic acid precipitate, collect the supernatant, add absolute ethanol Make the final concentration 30% (v / v), overnight; centrifuge (5000 r / min, 10 min), take the supernatant, and add absolute ethanol to make the final concentration 60% (v / v), Overnight; centrifuge (3000 r / min, 5 min), take the precipitate, and dry it in vacuum to obtain dry fucoidan powder.

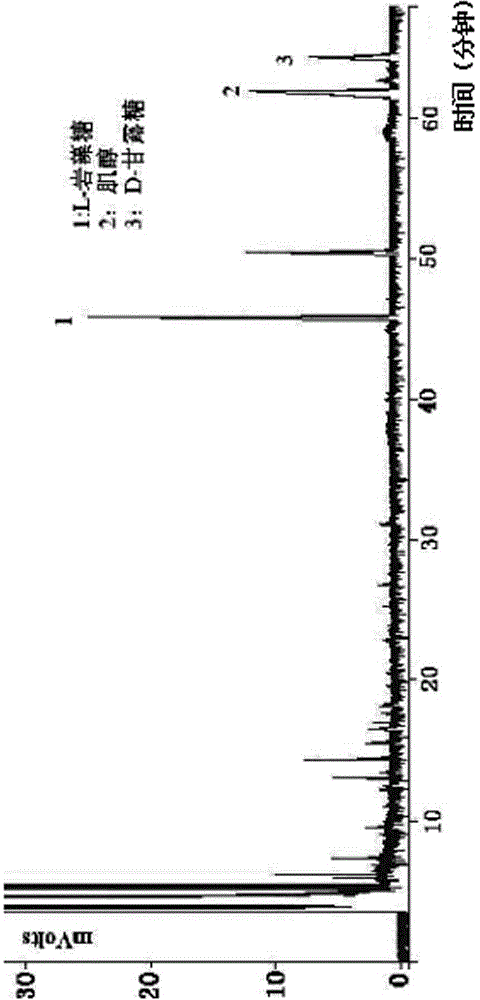

[0034] The obtained fucoidan is subjected to infrared spectroscopic analysis, and the results are shown in figure 1 with figure 2 , figure 1 Medium 846 cm -1 The absorption peak at shows that the p...

Embodiment 2

[0035] Embodiment 2: Preparation of low molecular weight fucoidan

[0036] Hydrolysis: Mix the fucoidan dry powder obtained in Example 1 with β-galactosidase (Shanghai Jiahe Biotechnology Co., Ltd., model: Amresco9031-11-2) and 30000 U / g enzyme activity respectively. g of β-glucosidase (Shanghai Hualan Chemical Technology Co., Ltd., model: 9001-22-3) was mixed evenly at a weight ratio of 1000:0.5:0.5, and deionized water was added to make 3% by weight (w / w) sugar solution, add 4.0 mol / L HCl to adjust the pH value to 5.0, hydrolyze at 37 °C for 5 h, then add 4 mol / L NaOH aqueous solution to adjust the pH value to neutral, heat to 80 °C and keep it warm for 5 min , thereby terminating the hydrolysis reaction, and obtaining low-molecular-weight fucoidan aqueous solutions of different molecular fragments.

[0037] Separation: 100 L of low-molecular-weight fucoidan aqueous solution containing different molecular fragments was separated by a medium-sized ultrafiltration membrane...

Embodiment 3

[0039] Embodiment 3: Antibacterial experiment of low-weight fucoidan

[0040] Staphylococcus aureus ( Staphyloccocus aureus ) strain (the strain number is ACCCNO.02863, and the preservation date is October 20, 2007) and Escherichia coli ( Escherichia coli ) strain (the strain number is ACCCNO.01623, and the preservation date is May 22, 2006) provided by the China Agricultural Microorganism Culture Collection Management Center.

[0041] 1. Experimental method

[0042] a. According to the method of Example 1, extract fucoidan from kelp; according to the method of Example 2, respectively prepare fucoidan with a molecular weight range of ≤5000 Da, 5000-100000 Da and ≥100000 Da, barium sulfate-suspended Nephelometric method detects that sulfate radical content is respectively 28.2 mass %, 26.9 mass % and 25.3 mass %;

[0043] b. Prepare a polysaccharide mother liquor with a concentration of 3.0% by weight of the low-molecular-weight fucoidan prepared in step a, filter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com