Composite packaging adhesive film for solar packaging material and preparation method of composite packaging adhesive film

A solar encapsulation and encapsulation film technology, applied in the direction of adhesives, adhesive additives, film/sheet adhesives, etc., can solve the problems of air bubbles and low gel content in the cured film, and achieve a uniform and perfect cross-linked network , to achieve the effect of cross-linking curing efficiency and expanding the activation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

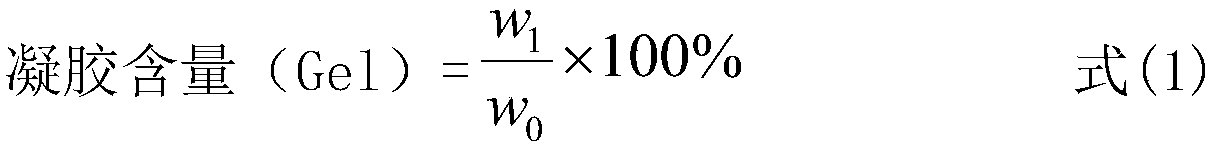

Method used

Image

Examples

preparation example Construction

[0043] A preparation method for a composite encapsulation adhesive film for solar encapsulation materials, comprising:

[0044] Melt extrusion steps of POE resin: Mix the POE resin, crosslinking agent, co-crosslinking agent, ultraviolet absorber, antioxidant, and tackifier in the formula to obtain a POE compound; then put the POE compound into the second A single-screw extruder melts and extrudes to obtain POE molten material;

[0045] The melt extrusion step of EVA resin: mix the EVA resin, composite cross-linking agent, auxiliary cross-linking agent, ultraviolet absorber, antioxidant and tackifier uniformly to obtain the EVA compound; then put the EVA compound into The second single-screw extruder melts and extrudes to obtain the EVA molten material;

[0046] Co-extrusion step: transport POE molten material and EVA molten material to the co-extrusion die, the distributor at the entrance of the die distributes the EVA molten material to the upper layer to form an EVA film la...

Embodiment 1

[0087] The cross-linking agent in the EVA mixture formula in comparative example 3 is replaced by a composite cross-linking agent, and the composite cross-linking agent is made of tert-butyl peroxycarbonate-2-ethylhexyl and N-methyldiallyl A mixture of base amines, the mass ratio of the two: tert-butyl peroxycarbonate-2-ethylhexyl:N-methyldiallylamine=5 / 1. Other components and consumption are identical with comparative example 3. According to the method and conditions described in Comparative Example 3, an EVA / POE cured film and a small component were prepared.

[0088] The laminated cured films and small components prepared in Comparative Example 1, Comparative Example 2, Comparative Example 3, Comparative Example 4 and Example 1 were analyzed and tested, and the results are shown in Table 4.

[0089] Table 4 comparative example 1, 2, 3, 4 and embodiment 1 make the performance of cured film and small assembly

[0090]

[0091]

[0092] Note: In comparative examples 3,...

Embodiment 2

[0095] The cross-linking agent in the EVA mixture formula in comparative example 3 is replaced by a composite cross-linking agent, and the composite cross-linking agent is made of tert-butyl peroxycarbonate-2-ethylhexyl and N-methyldiallyl A mixture of base amines, the mass ratio of the two is: tert-butyl peroxycarbonate-2-ethylhexyl:N-methyldiallylamine=5 / 1. The dosage (parts by weight) of the composite crosslinking agent is adjusted to: (1) 0.4 parts; (2) 0.5 parts; (3) 1 part; (4) 1.6 parts; (5) 1.7 parts. Other components and consumption are identical with comparative example 3. According to the method and conditions described in Comparative Example 3, an EVA / POE cured film and a small component were prepared.

[0096] The laminated cured film and small components prepared with different dosages of the composite crosslinking agent in Example 2 were tested, and the results are shown in Table 5.

[0097] Table 5 The performance of the cured film and small components made b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com