Safety energy-saving hollow glass and coating film as well as preparation method

A glass and hollow technology, applied in the direction of parallel glass structure, window/door improvement, coating, etc., can solve the problems of poor heat insulation performance, no ability to purify indoor air, easy to break, etc., to achieve indoor air purification, Improve heat insulation performance, increase the effect of shock resistance and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

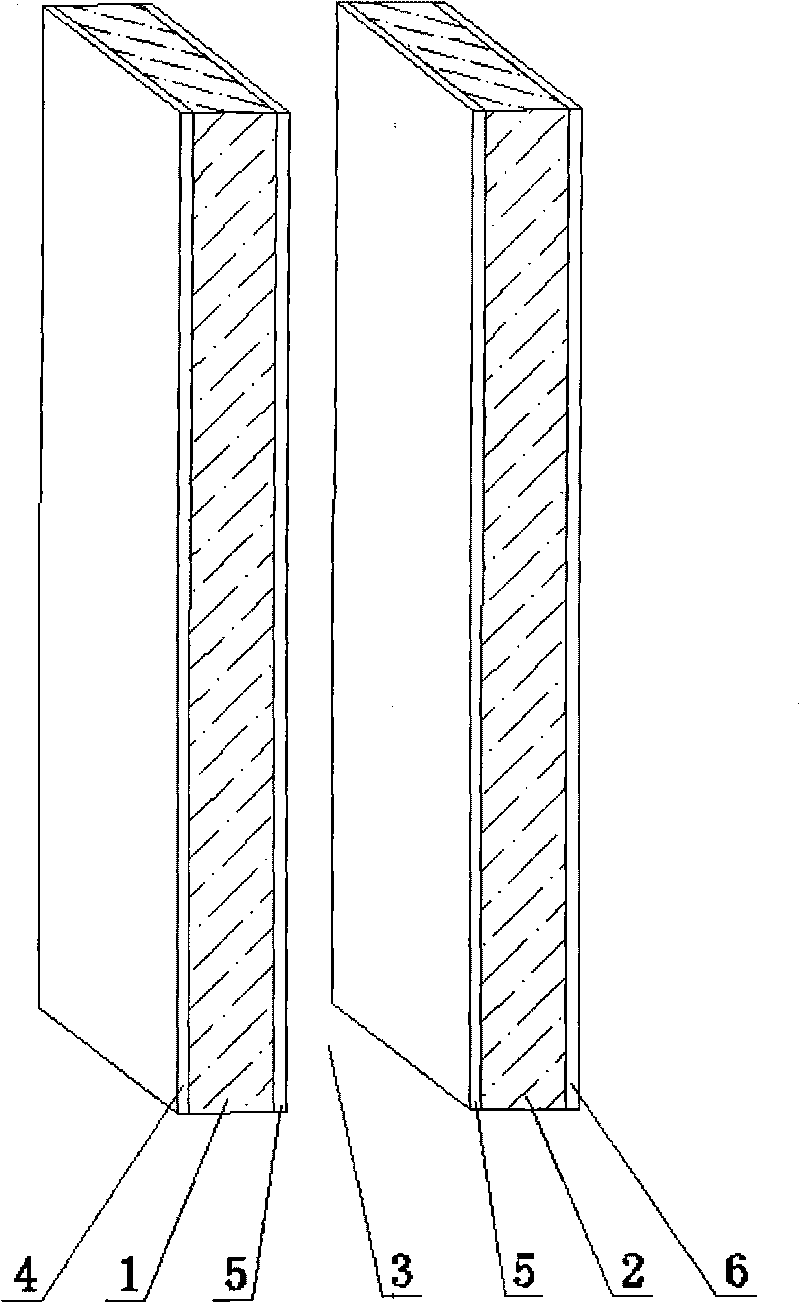

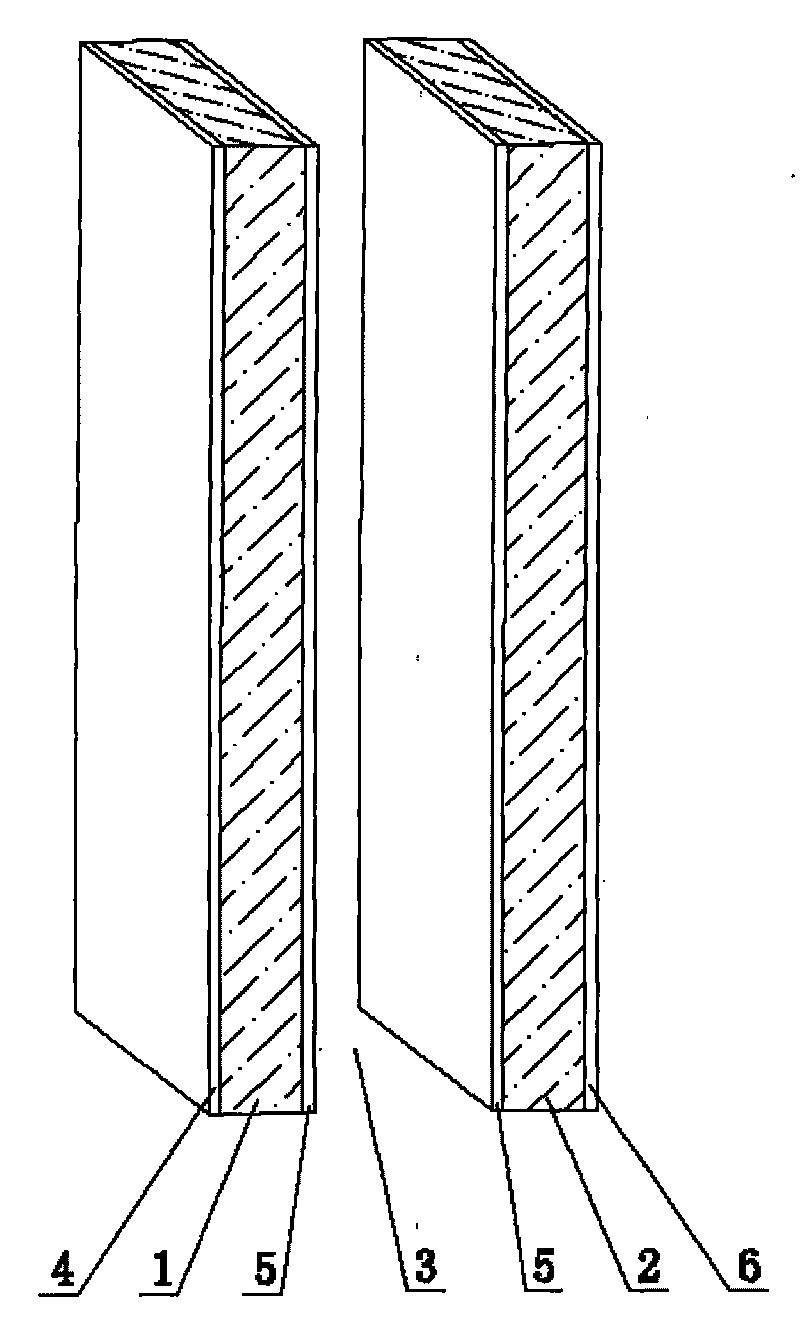

[0018] Embodiment 1: as figure 1 As shown, a safe and energy-saving hollow glass is composed of inner and outer layers of glass 1 and 2 with a cavity 3 in the middle. The outer layer of glass 1 is coated with heat insulation function 4, and the outer layer of glass The inside of 1 and the outside of the inner glass 2 are coatings 5 that enhance the strength of the glass, block sound waves and filter ultraviolet rays, and the inside of the inner glass 2 is a coating 6 that absorbs, purifies and decomposes radioactive and toxic gases in the room.

Embodiment 2

[0019] Embodiment 2: a kind of coating film with thermal insulation function, according to 10 parts of water-soluble modified amino resin solution, 0.8 part of colloidal silver, 1 part of indium tin, 0.6 part of rutile type titanium dioxide slurry, rare earth metal polymer (containing neodymium and Praseodymium) 2.5 parts, 28.2 parts of n-octyl acrylate, 1.8 parts of acrylic acid, 128 parts of dioxane, 5.2 parts of benzoyl peroxide, 17.2 parts of hexamethoxymethylmelamine, 0.3 parts of polymer transparent sunscreen, 10 parts of ammonia water The proportioning preparation of parts by weight.

Embodiment 3

[0020] Embodiment 3: The manufacture method of the coating film with heat insulation function, at first dioxane is added in the reaction pot, heated and refluxed on the oil bath, acrylic acid, n-octyl acrylate and benzene peroxide are slowly added dropwise within 3h Mixture of formyl; after dripping, react under reflux conditions for 6 hours to ensure complete reaction of the monomer, then vacuumize to remove about 82% of dioxane, cool to below 60°C, drop a small amount of ammonia water to neutralize, and then add Mix hexamethoxymethyl melamine; then mix the polymerized modified amino resin, colloidal silver, indium tin, rutile titanium dioxide slurry, rare earth metal polymer and other solvents with it, and stir at 50°C for 5~ 8 minutes, then filtered, precipitated, and then filtered to form a water-soluble modified milky transparent functional coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com