Resource utilization process for high pressure oxygen continuous leaching of arsenic sulfide slag

A technology of arsenic sulfide and high-pressure oxygen, applied in the direction of improving process efficiency, etc., can solve the problems of low production efficiency, poor working environment, difficult control, etc., and achieve the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

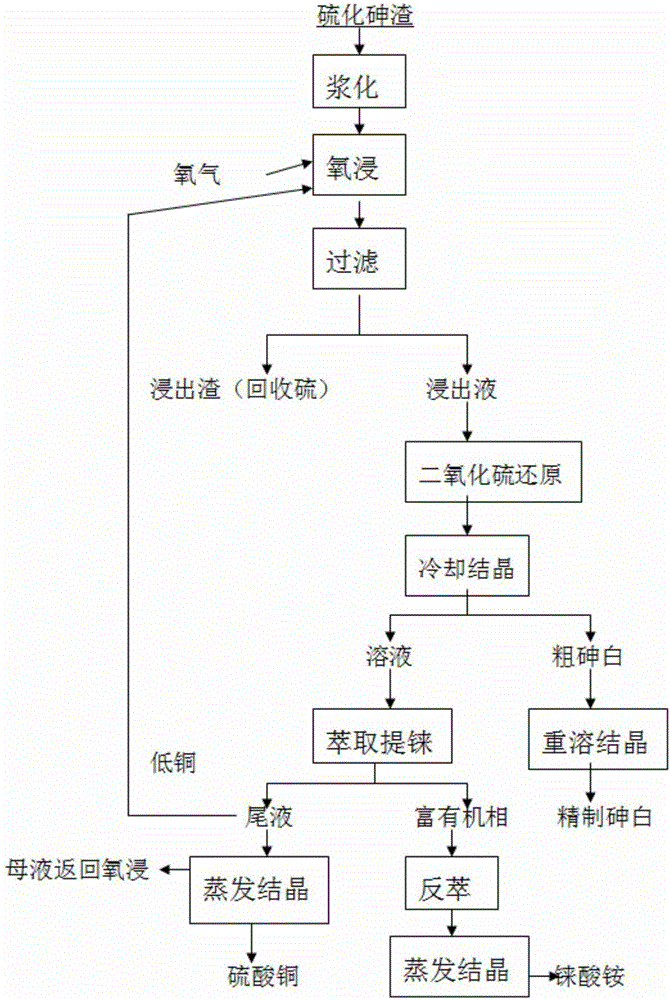

[0023] A high pressure oxygen continuous leaching process for resource utilization of arsenic sulfide slag, comprising the following steps:

[0024] A. Add the arsenic sulfide slag to the waste acid solution for slurrying, start the mixer, adjust the stirring speed to 95rpm, put in the specified amount of raw materials, stir for 1.2 hours, and pump it into the slurry storage tank after the raw materials are completely dispersed and slurried;

[0025] B. Use a hose pump to pump the slurry from the slurry storage tank to the high-pressure reactor, and at the same time use a hose pump to pump the waste acid liquid from the waste acid storage tank to the high-pressure reactor, and feed oxygen into the reactor for 2.2 hours. Generate precipitate as leaching residue;

[0026] C. Recover the leach slag after filtration to recover sulfur, and at the same time lead the leachate from the high-pressure reactor;

[0027] D, reducing the leaching solution with sulfur dioxide, cooling and ...

Embodiment 2

[0038] A high pressure oxygen continuous leaching process for resource utilization of arsenic sulfide slag, comprising the following steps:

[0039] A. Add the arsenic sulfide slag to the waste acid solution for slurrying, start the mixer, adjust the stirring speed to 100rpm, put in the specified amount of raw materials, stir for 1 hour, and pump it into the slurry storage tank after the raw materials are completely dispersed and slurryed;

[0040] B. Use a hose pump to pump the slurry from the slurry storage tank to the high-pressure reactor, and at the same time use a hose pump to pump the waste acid liquid from the waste acid storage tank to the high-pressure reactor, and feed oxygen into the reactor for 2.5 hours. Generate precipitate as leaching residue;

[0041] C. Recover the leach slag after filtration to recover sulfur, and at the same time lead the leachate from the high-pressure reactor;

[0042] D, reducing the leaching solution with sulfur dioxide, cooling and cr...

Embodiment 3

[0053] A high pressure oxygen continuous leaching process for resource utilization of arsenic sulfide slag, comprising the following steps:

[0054] A. Add the arsenic sulfide slag to the waste acid solution for slurrying, start the mixer, adjust the stirring speed to 80rpm, put in the specified amount of raw materials, stir for 1.5 hours, and pump it into the slurry storage tank after the raw materials are completely dispersed and slurried;

[0055] B. Use a hose pump to pump the ore slurry from the slurry storage tank to the high-pressure reactor, and at the same time use a hose pump to pump the waste acid liquid from the waste acid storage tank to the high-pressure reactor, and feed oxygen into the reactor for 2 hours. Generate precipitate as leaching residue;

[0056] C. Recover the leach slag after filtration to recover sulfur, and at the same time lead the leachate from the high-pressure reactor;

[0057] D, reducing the leaching solution with sulfur dioxide, cooling an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com