Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high cost, high consumption, and environmental protection pressure, and achieve regular shape, complete crystal form, and high specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

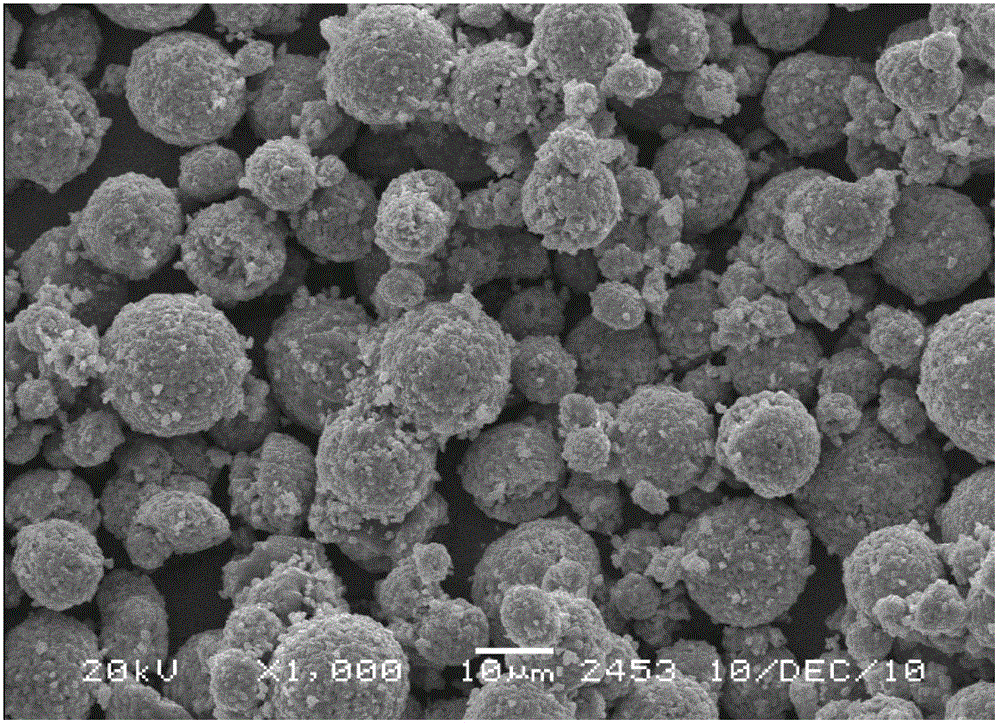

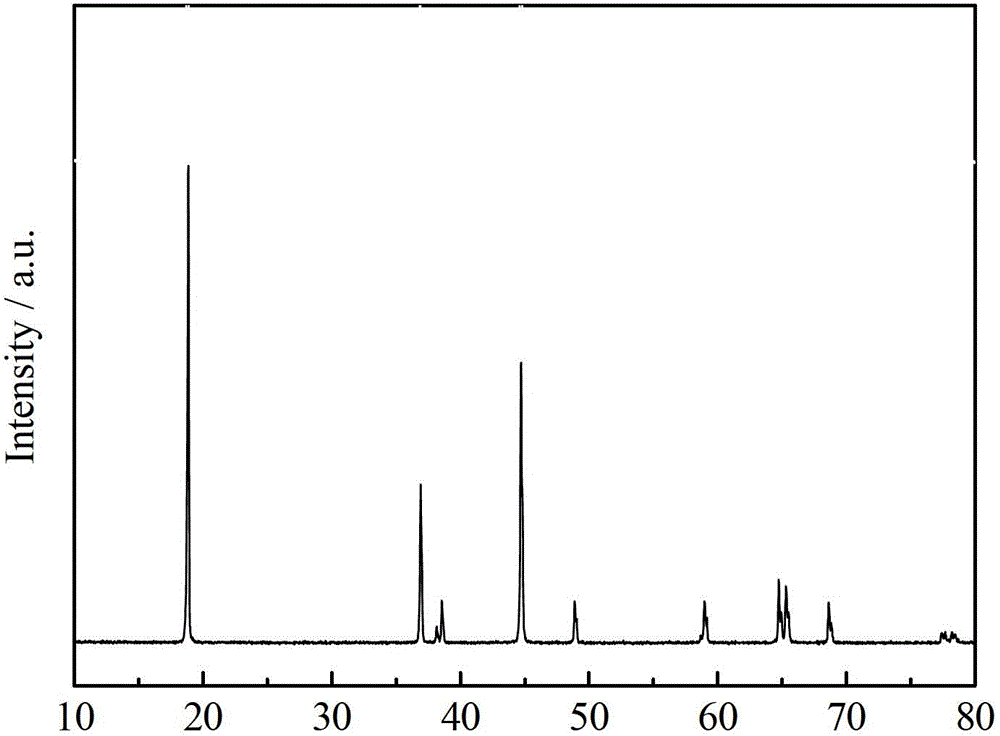

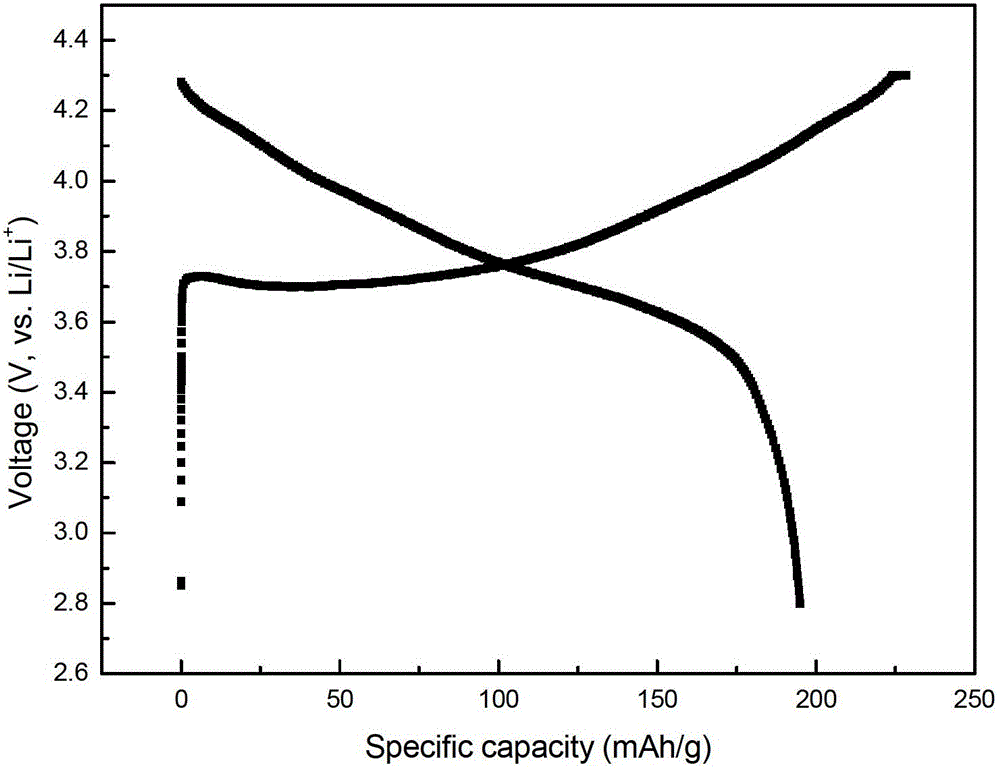

[0030] The nickel cobalt aluminum hydroxide precursor (Ni 0.8 co 0.15 Al 0.05 )(OH) 2 Pre-fired at 600°C for 5 hours in a pure oxygen atmosphere furnace with 2 atmospheric pressures, and obtained the oxidized precursor material after cooling; then mixed lithium hydroxide and the oxidized precursor evenly, and then placed in a flowing oxygen atmosphere furnace at 700°C Calcined for 15 hours, crushed and graded after cooling to obtain LiNi 0.8 co 0.15 Al 0.05 o 2 Material. Among them, nickel cobalt aluminum hydroxide precursor (Ni 0.8 co 0.15 Al 0.05 )(OH) 2 For commercial sale. The LiNi 0.8 co 0.15 Al 0.05 o 2 The tap density of the material is 2.22g / cm 3 , with an average particle size of 9.916 μm. Its scanning electron microscope picture is as figure 1 As shown, the morphology is spherical and spherical; its X-ray diffraction pattern is shown in figure 2 As shown, it is consistent with the JCPDS standard card 87-1562; assembled into an experimental half-ce...

Embodiment 2

[0032] The nickel-cobalt-aluminum carbonate precursor (Ni 0.8 co 0.15 Al 0.05 )CO 3 Place in an oxygen atmosphere furnace with 4 atmospheric pressure at 650°C for 10 hours, after cooling, mix lithium carbonate and oxidation precursor evenly, then place it in a flowing oxygen atmosphere furnace and bake at 750°C for 24 hours, after cooling, break and classify, get LiNi 0.8 co 0.15 Al 0.05 o 2 Material. Among them, nickel-cobalt-aluminum carbonate precursor (Ni 0.8 co 0.15 Al 0.05 )CO 3 For commercial sale.

[0033] After inspection, the LiNi 0.8 co 0.15 Al 0.05 o 2 The tap density of the material is 2.05g / cm 3 , with an average particle size of 9.481 μm; assembled into an experimental half-cell, charged and discharged at 0.2C between 2.8-4.3V, the initial capacity was 192.8mAh / g, the first charge-discharge efficiency was 83.8%, and the capacity retention rate after 300 cycles was 81.2%.

Embodiment 3

[0035] The nickel cobalt aluminum oxalate precursor (Ni 0.7 co 0.2 Al 0.1 )C 2 o 4 2H 2 O is pre-fired at 600°C for 12 hours in an oxygen atmosphere furnace with 8 atmospheric pressures. After cooling, mix lithium carbonate and the oxidation precursor evenly, and then place it in a flowing oxygen atmosphere furnace and bake at 650°C for 24 hours. After cooling, it is broken and classified , to get LiNi 0.8 co 0.15 Al 0.05 o 2 Material. Among them, nickel cobalt aluminum oxalate precursor (Ni 0.7 co 0.2 Al 0.1 )C 2 o 4 2H 2 O is commercially available.

[0036] After inspection, the LiNi 0.7 co 0.2 Al 0.1 o 2 The tap density of the material is 1.87g / cm 3 , the average particle size is 7.273μm; assembled into an experimental half-cell, charged and discharged at 0.2C between 2.8-4.3V, the initial capacity is 178.3mAh / g, the first charge-discharge efficiency is 85.2%, and the capacity retention rate after 100 cycles is 83.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com