Production method of high-purity lithium hydroxide

A lithium hydroxide, high-purity technology, applied in the field of salt chemical industry, can solve the problems of long and complex process routes, high cost of raw and auxiliary materials, and low yield of lithium ions, and achieve simple process routes, high comprehensive utilization of resources, lithium The effect of high ion yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

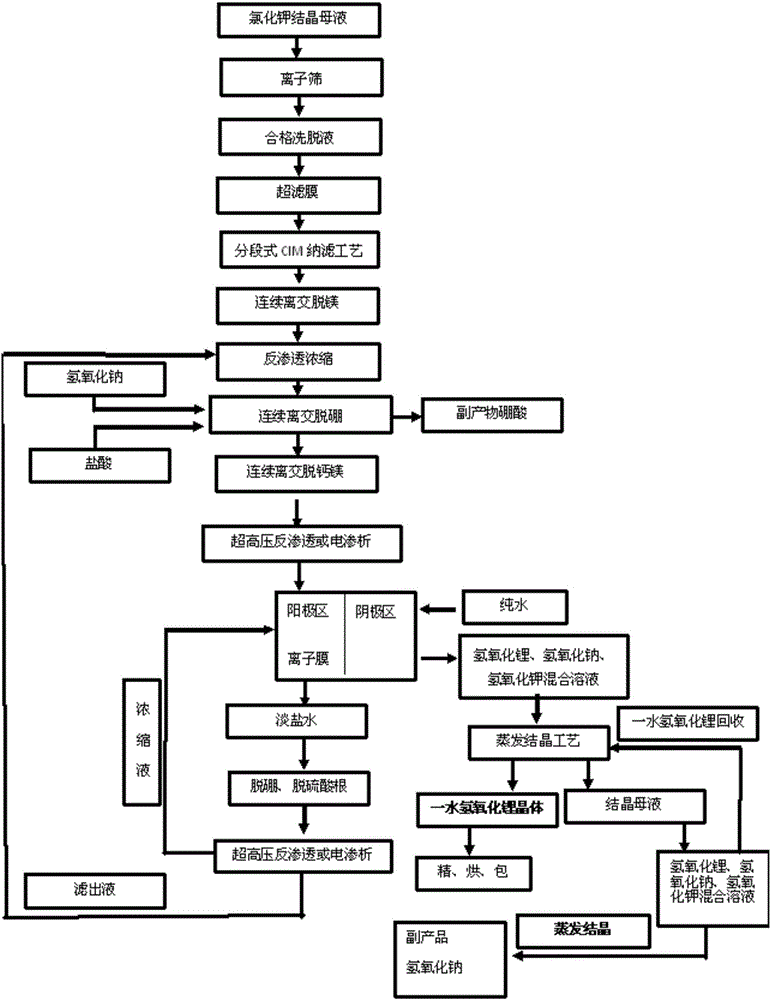

Image

Examples

Embodiment Construction

[0039] The best implementation mode of the present invention is described below through the preferred embodiment. The specific implementation mode here is to illustrate the present invention in detail, and should not be construed as a limitation of the present invention, without departing from the spirit and essential scope of the present invention , various variations and modifications can be made, all of which should be included within the protection scope of the present invention.

[0040] The preferred embodiment of the present invention provides a method for producing high-purity lithium hydroxide. The production method of this high-purity lithium hydroxide comprises the following steps:

[0041]a. Obtain the first concentrated solution concentrated by reverse osmosis, wherein the content of magnesium ions is ≤30ppm, the content of lithium ions is about 4-6g / L, the content of sodium ions is 3-5g / L, the content of calcium ions is ≤5ppm, potassium Ion ≤ 300ppm, sulfate ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com