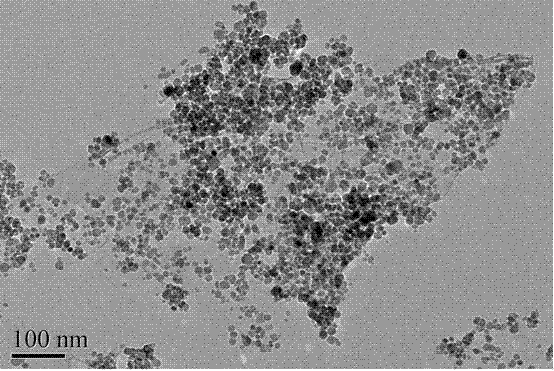

Method for preparing ferroferric oxide/graphene magnetic nano composite material by solvothermal one-step method

A ferric tetroxide, magnetic nanotechnology, applied in the direction of iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., to achieve the effects of mild reaction conditions, narrow particle size distribution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Assemble a 250mL reaction bottle in an ice-water bath, add 23mL of concentrated sulfuric acid, add 2g of natural flake graphite powder and 1g of sodium nitrate under stirring, control the temperature below 4°C for 2 hours, and then gradually add 6g of high manganese Potassium acid, control the reaction temperature not to exceed 20°C, stir the reaction for 1 hour, then raise the temperature to about 35°C and continue stirring for 30 minutes, then slowly add 60mL deionized water, continue stirring for 20 minutes, and add 25mL hydrogen peroxide (30Vol%) to react for 15 minutes. The solution turned bright yellow and was dissolved with 40mL HCl solution (10Vol%), centrifuged and washed with deionized water until the pH was close to neutral, and finally the filter cake was dried in a vacuum oven at 60°C for 8 hours to prepare graphite oxide.

[0021] (2) Add ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 4.0000g, dry graphite oxide 0.2000g, polyvinylpyrrolidone (PVP) 0.025...

Embodiment 2

[0027] (1) Prepare graphite oxide by the traditional Hummers method, assemble a 250mL reaction bottle in an ice-water bath, add 23mL of concentrated sulfuric acid, add 2g of natural flake graphite powder and 1g of sodium nitrate under stirring, and control the temperature below 4°C during the whole process React for 2 hours, then gradually add 6g of potassium permanganate, control the reaction temperature not to exceed 20°C, stir the reaction for 1h, then raise the temperature to about 35°C and continue stirring for 30 minutes, then slowly add 60mL of deionized water, continue stirring for 20 minutes, and add React 25mL hydrogen peroxide (30Vol%) for 15min to make the solution turn bright yellow, and dissolve it with 40mL HCl solution (10Vol%), centrifuge and wash with deionized water until the pH is close to neutral, and finally put the filter cake in a vacuum oven at 60°C Dry 8 hours and prepare graphite oxide;

[0028] (2) Add ferric chloride hexahydrate (FeCl 3 ·6H 2 O) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com