Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Low non-framework aluminum content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

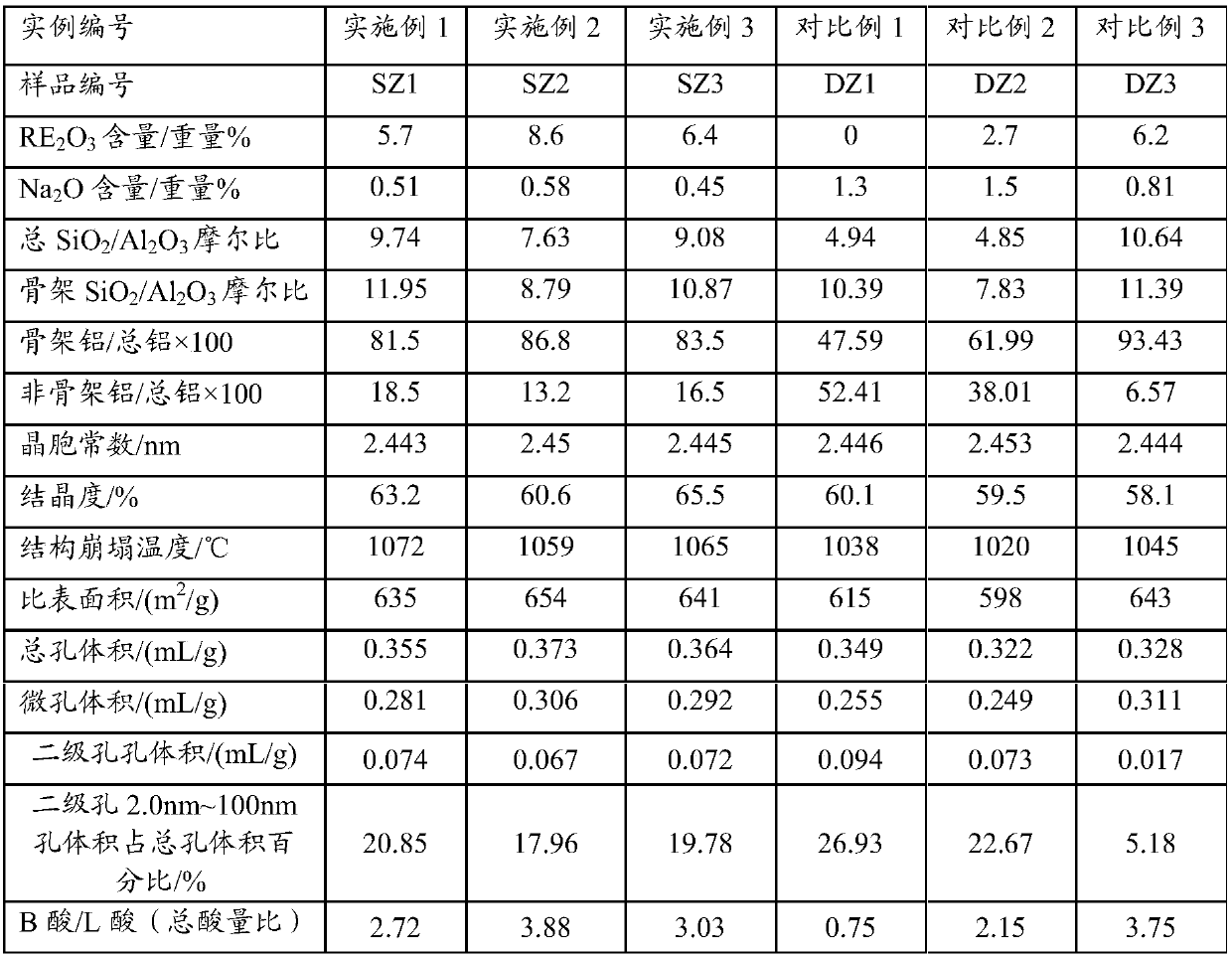

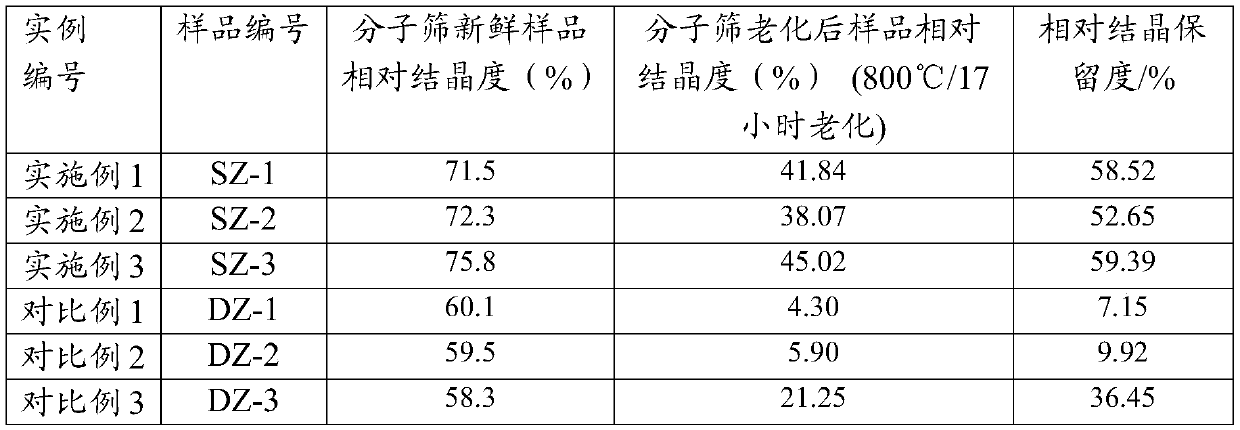

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

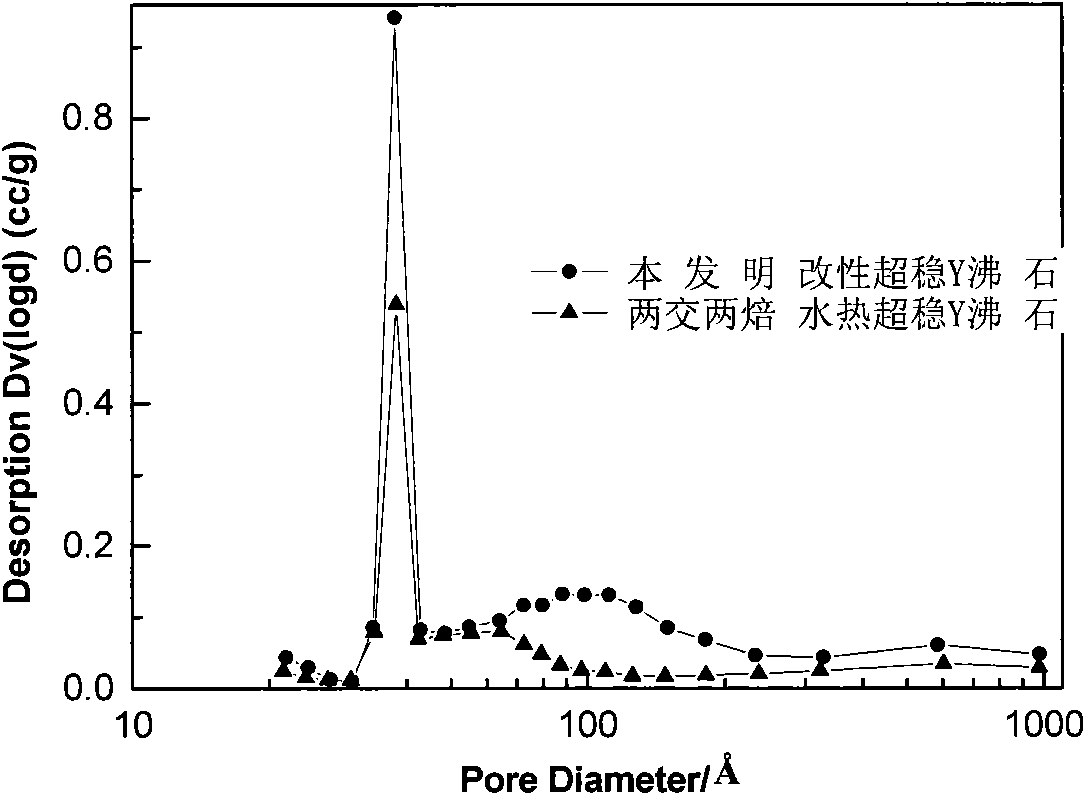

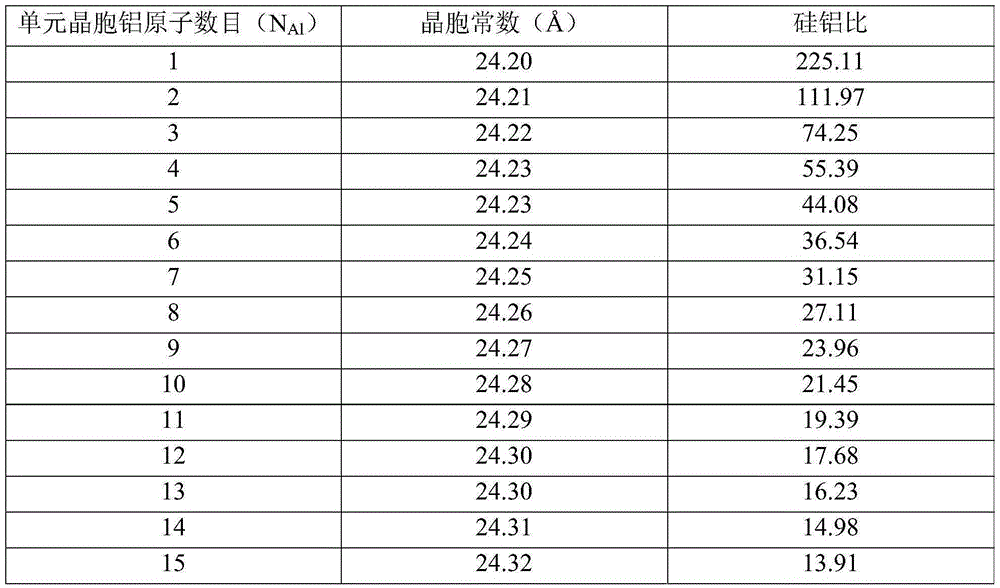

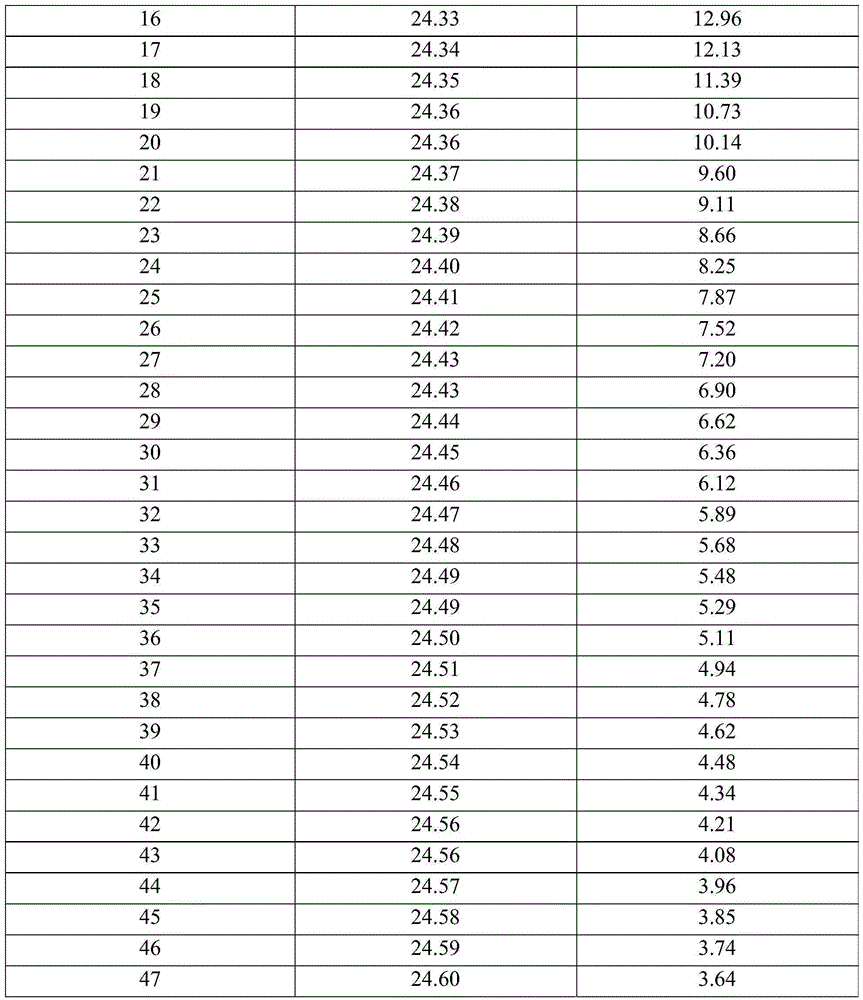

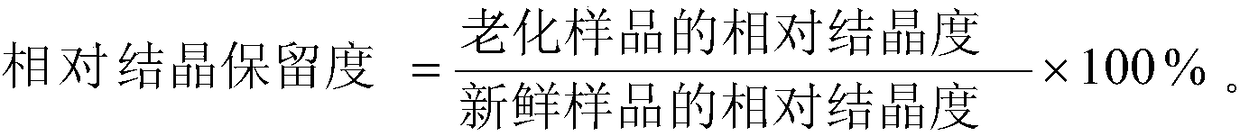

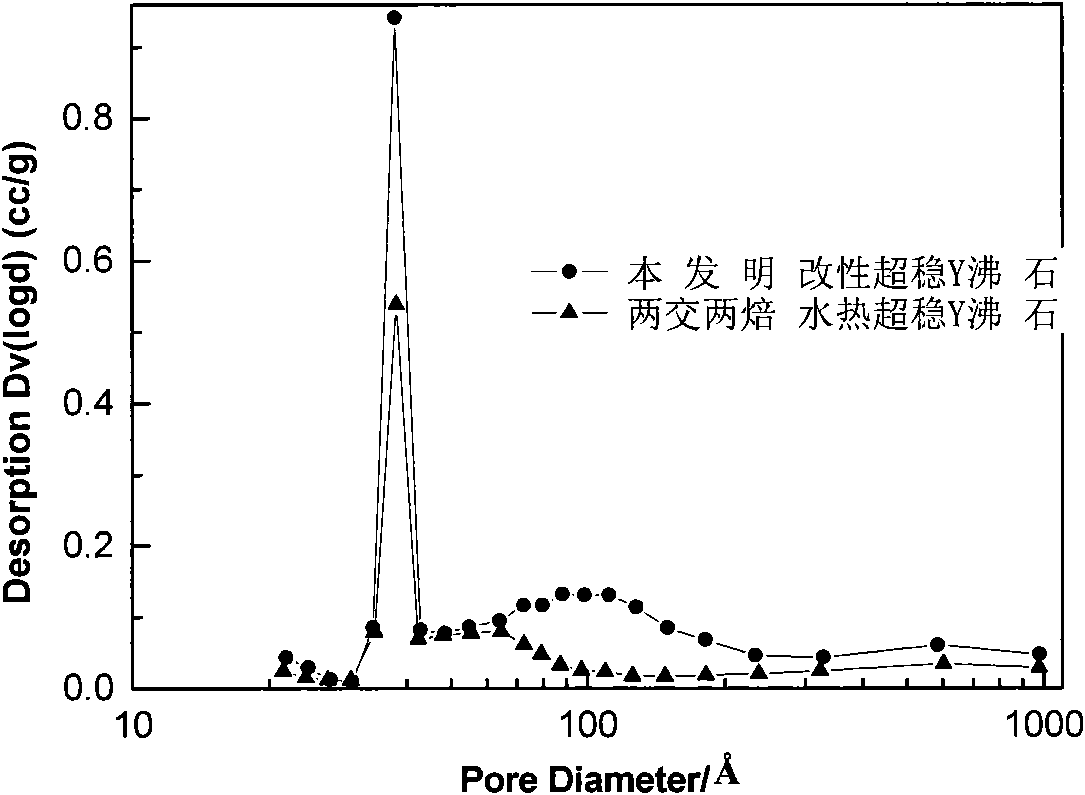

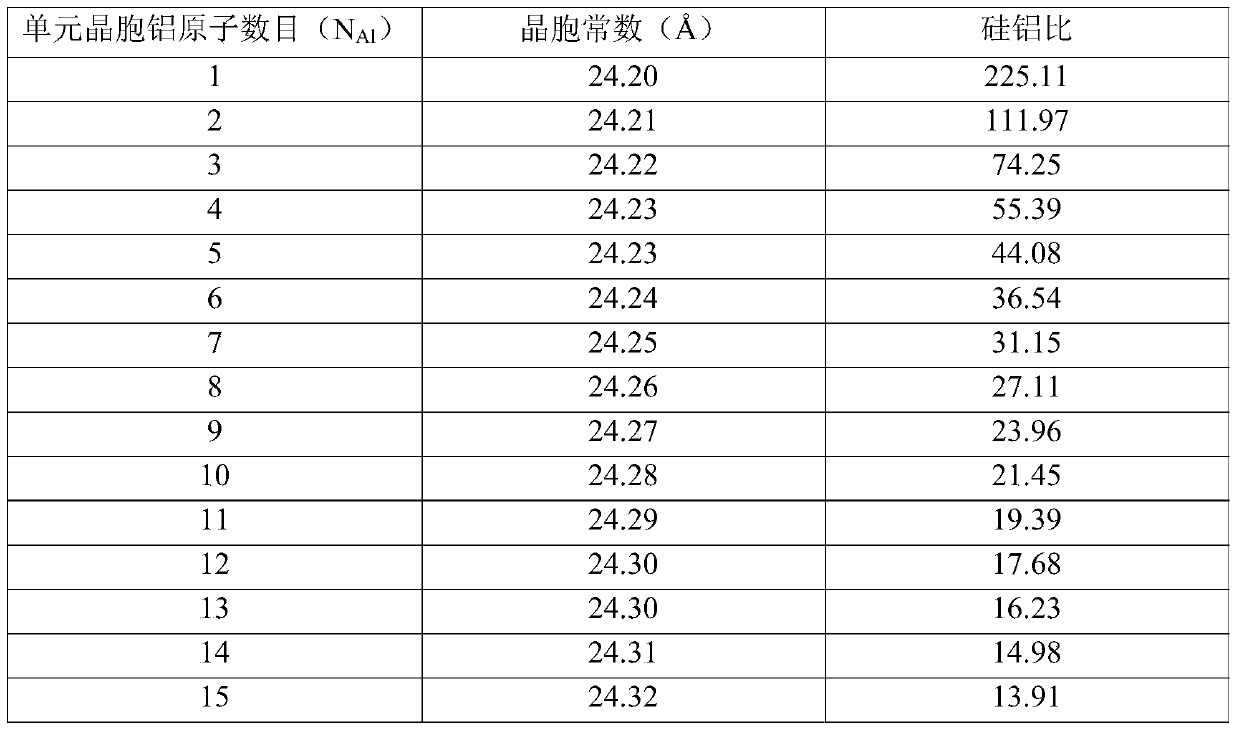

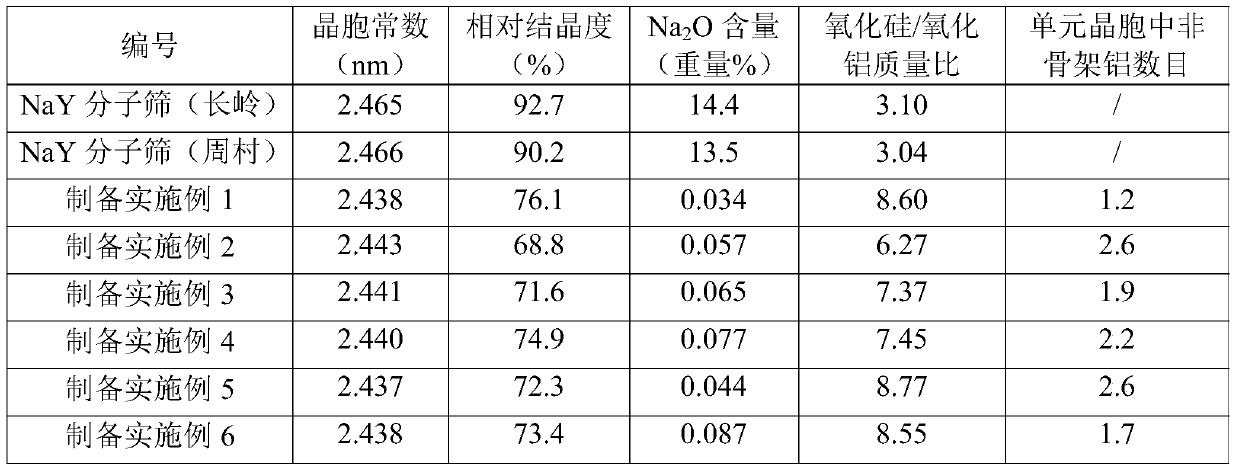

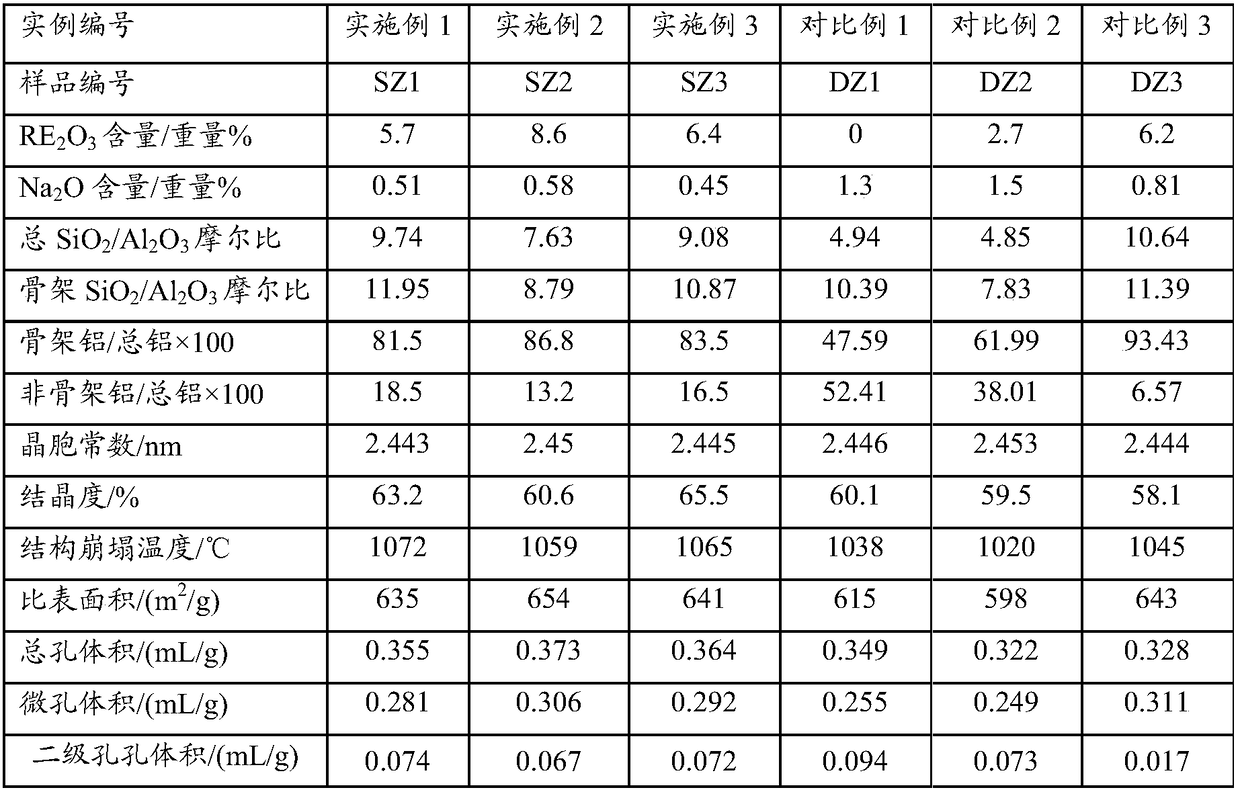

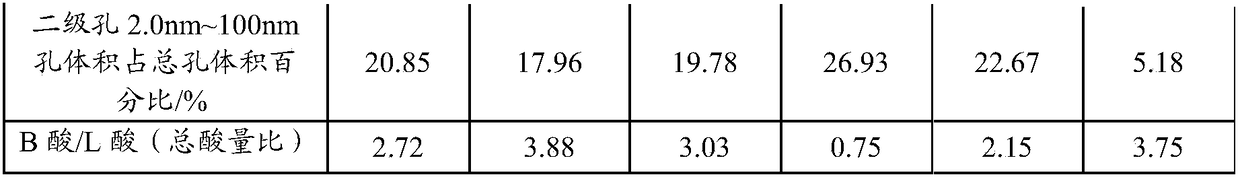

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

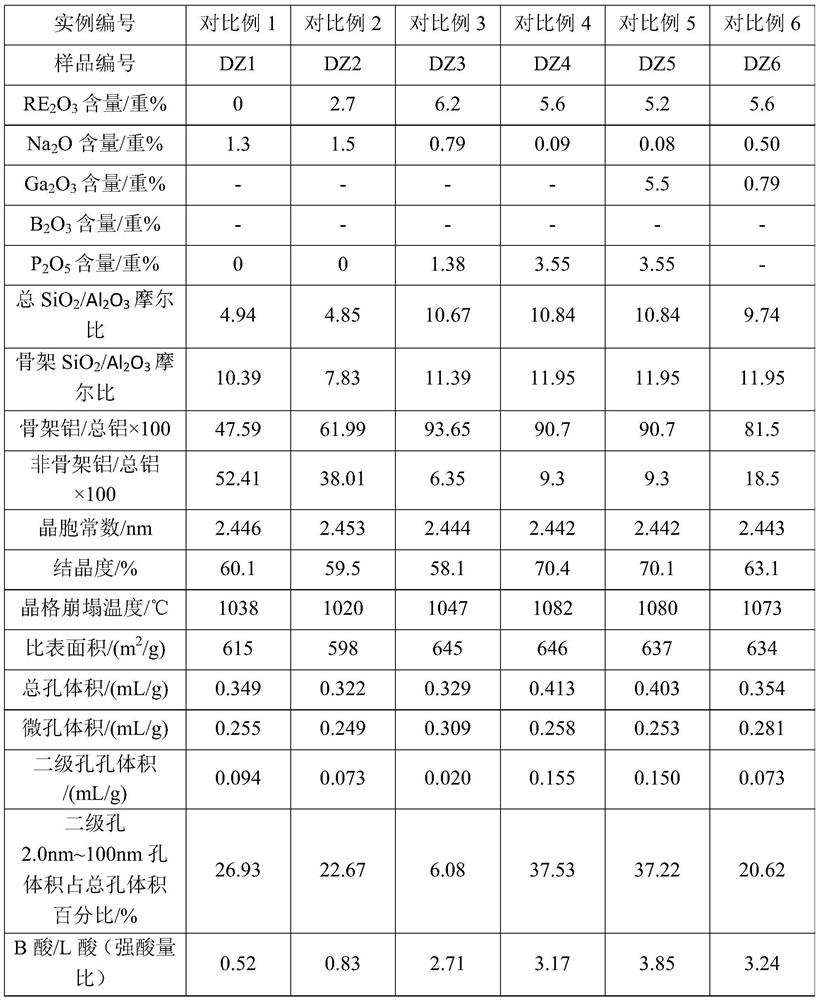

Catalytic cracking catalyst

ActiveCN108452833AReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

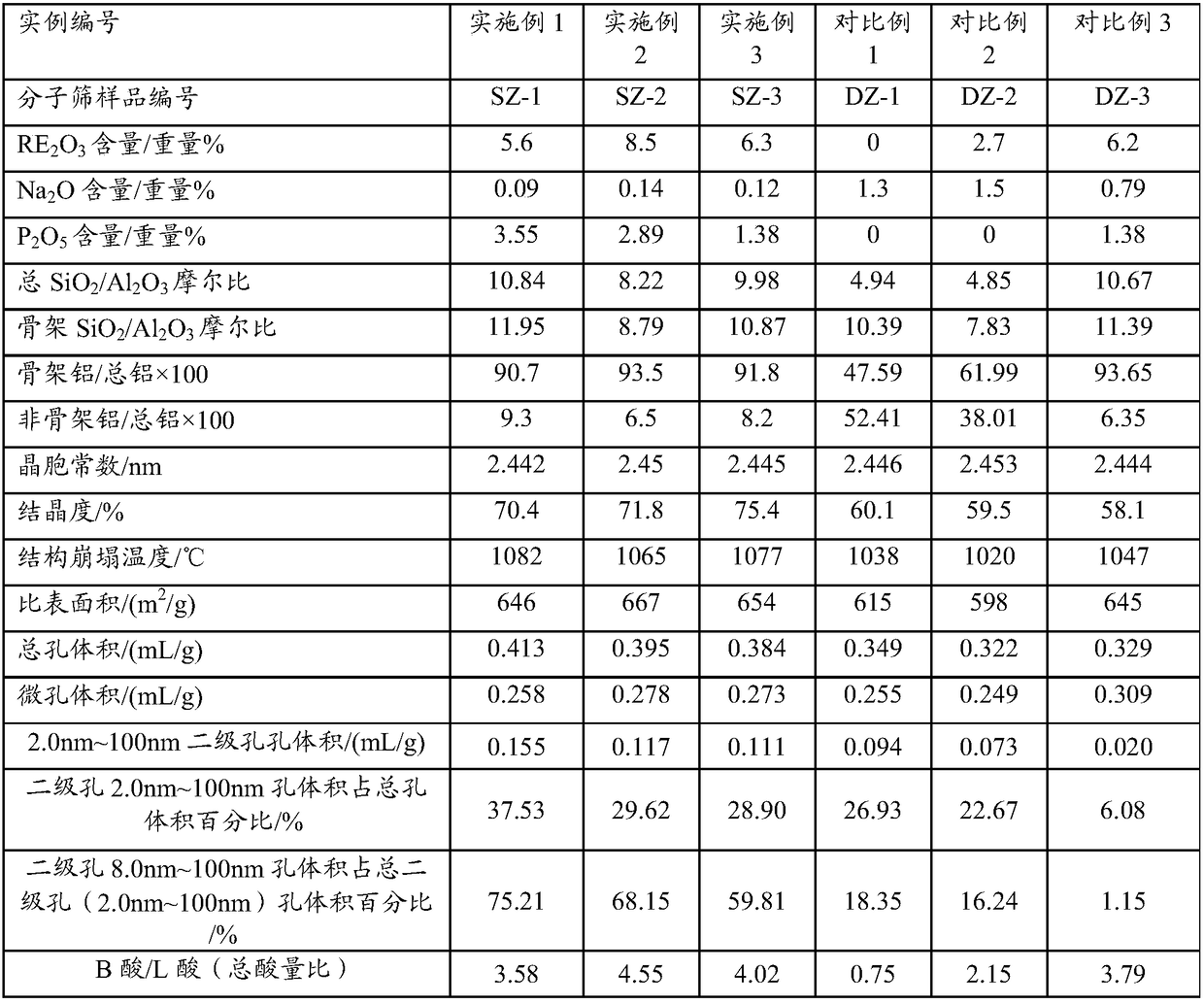

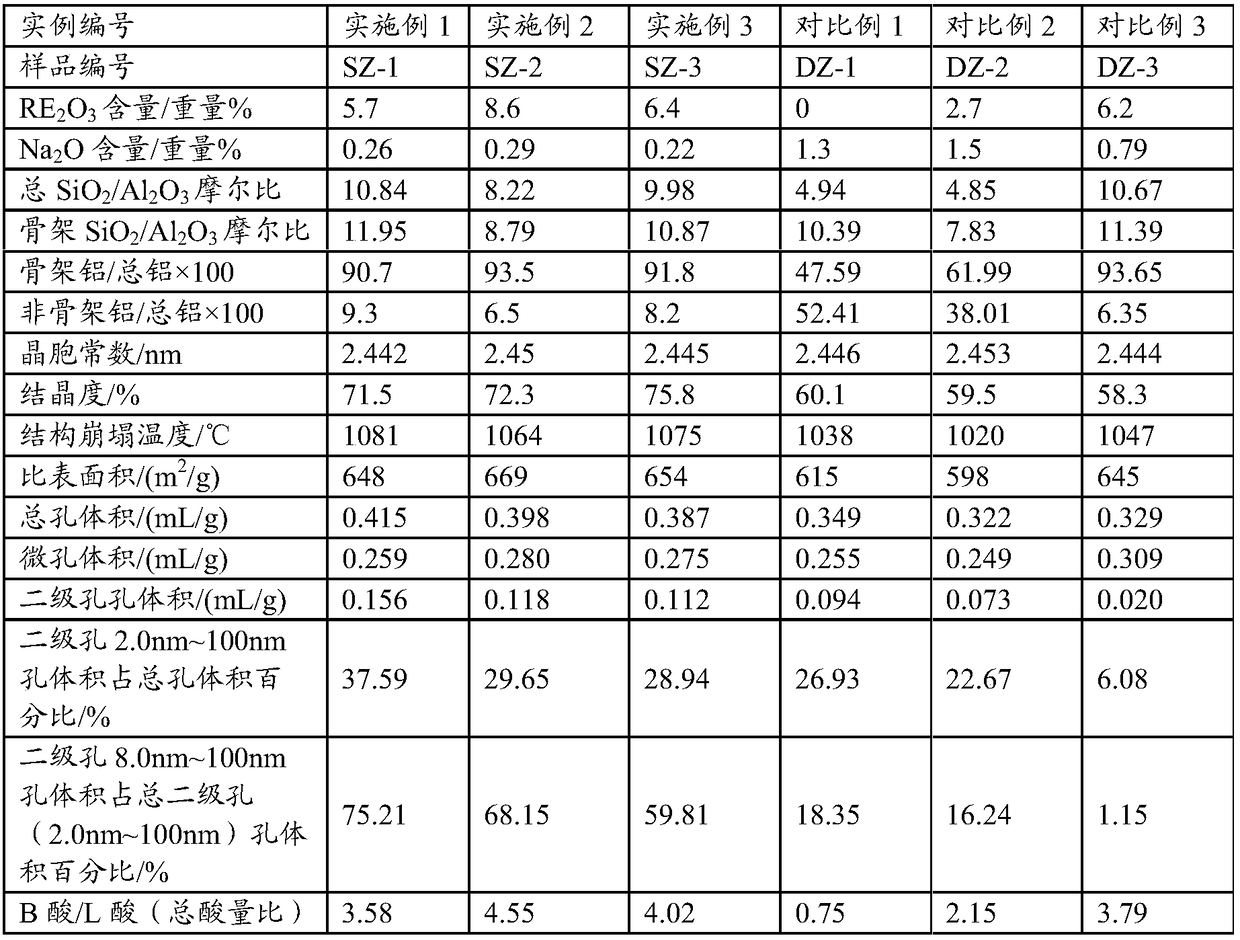

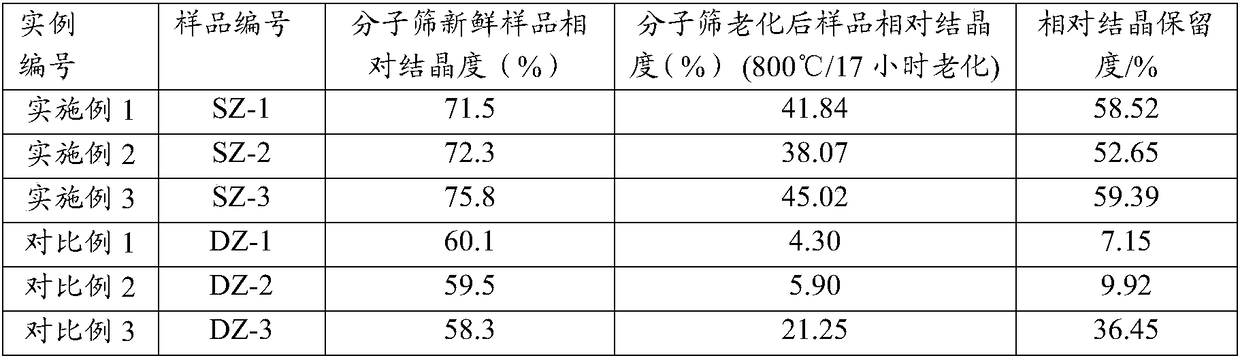

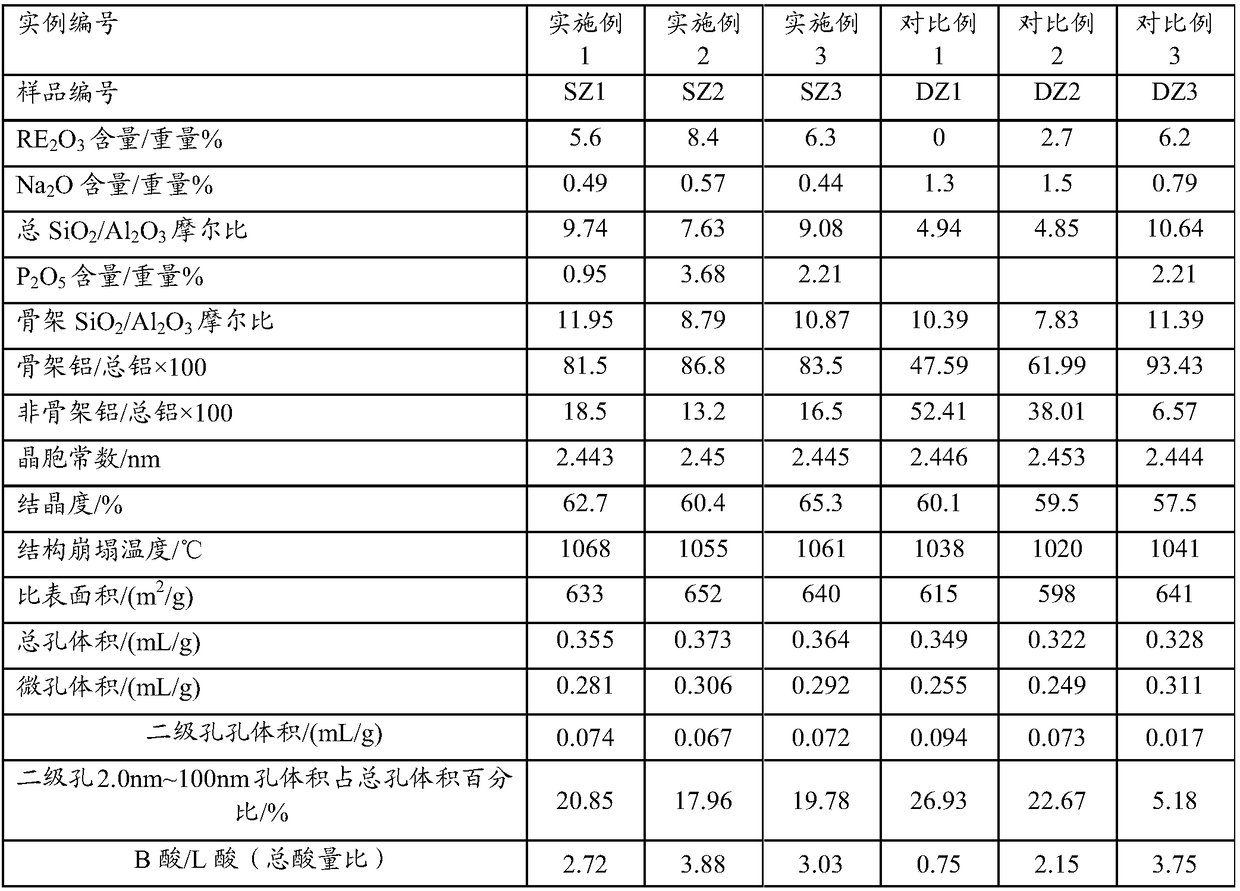

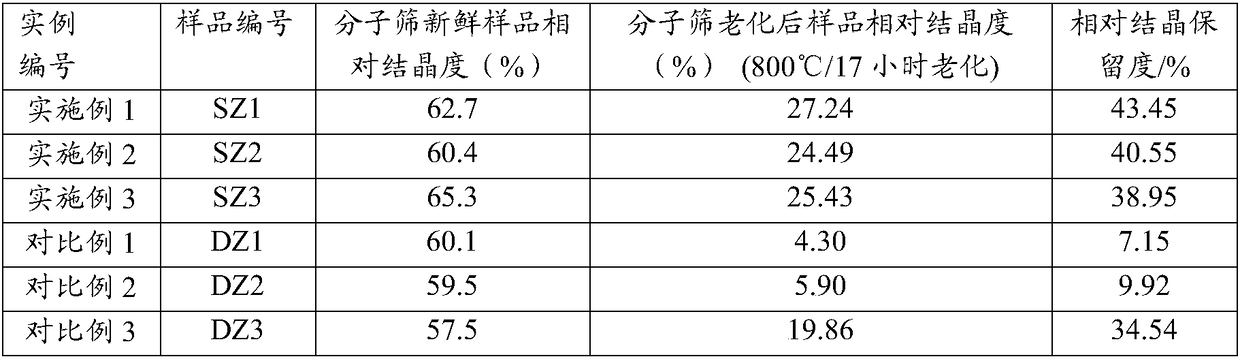

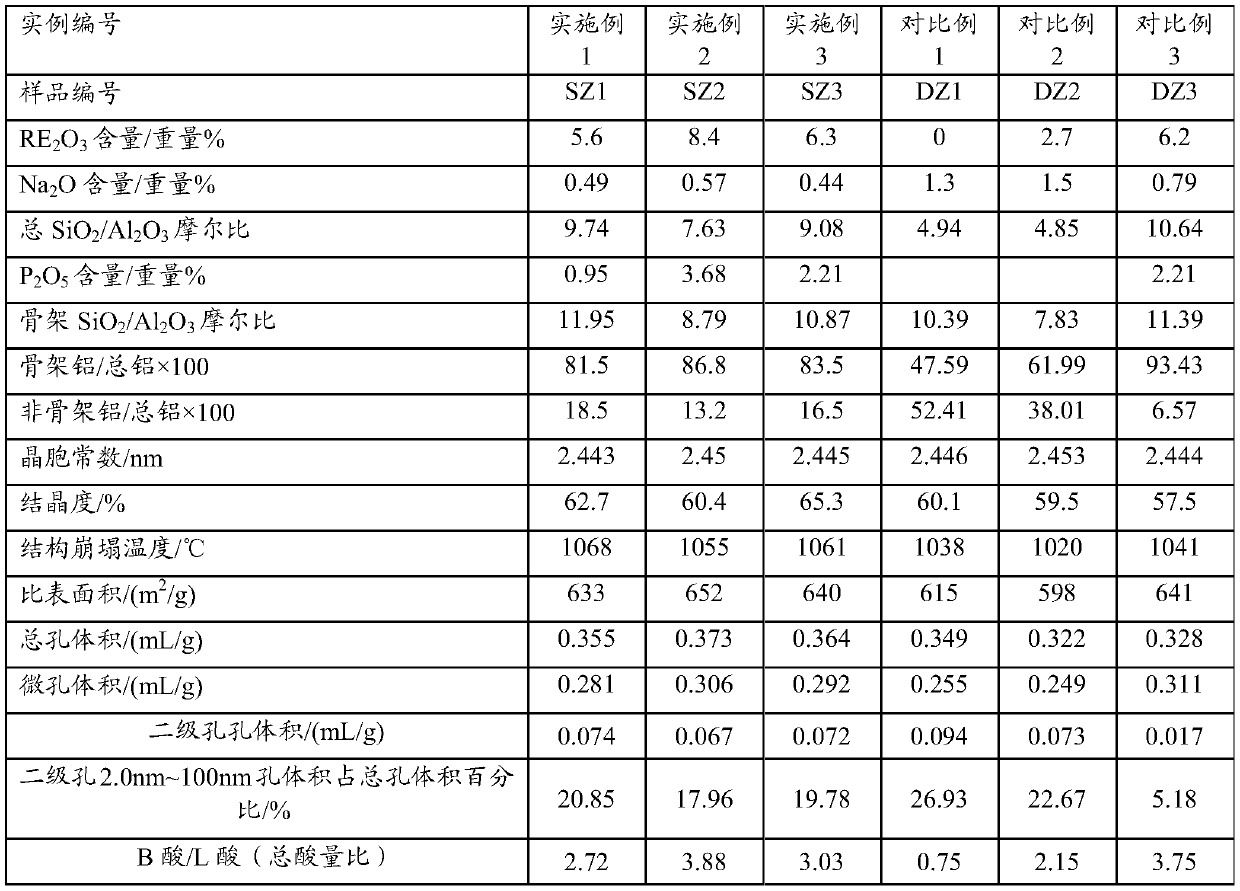

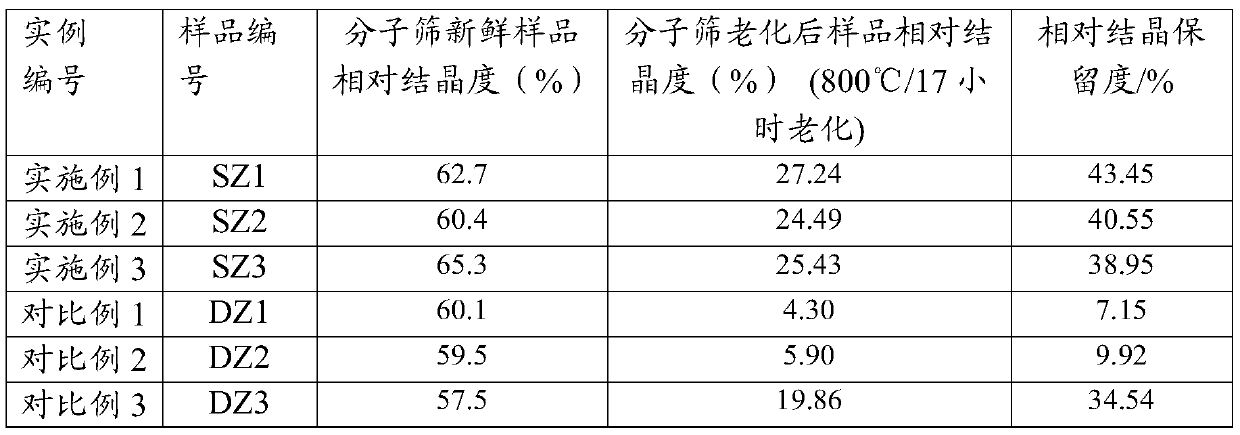

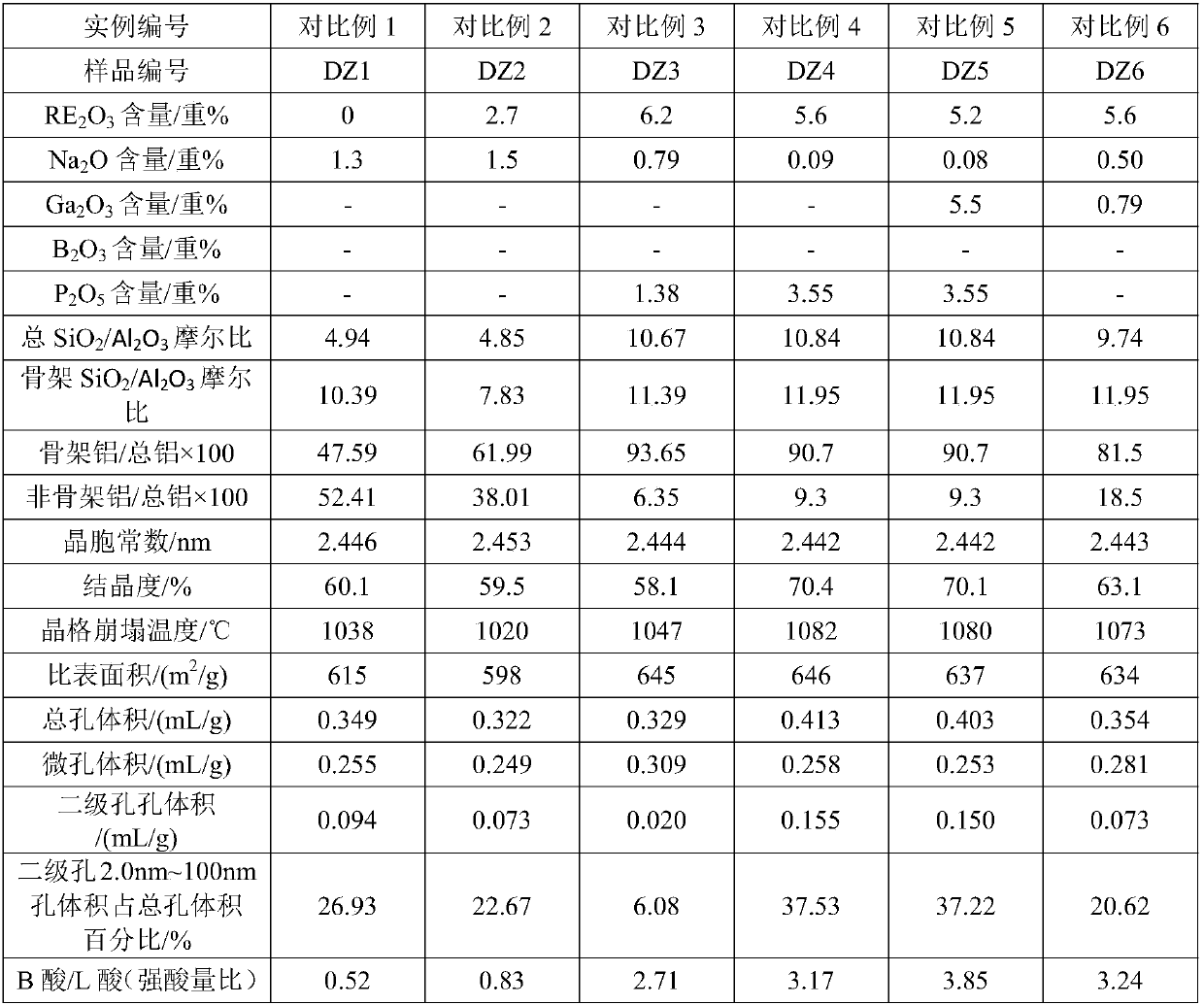

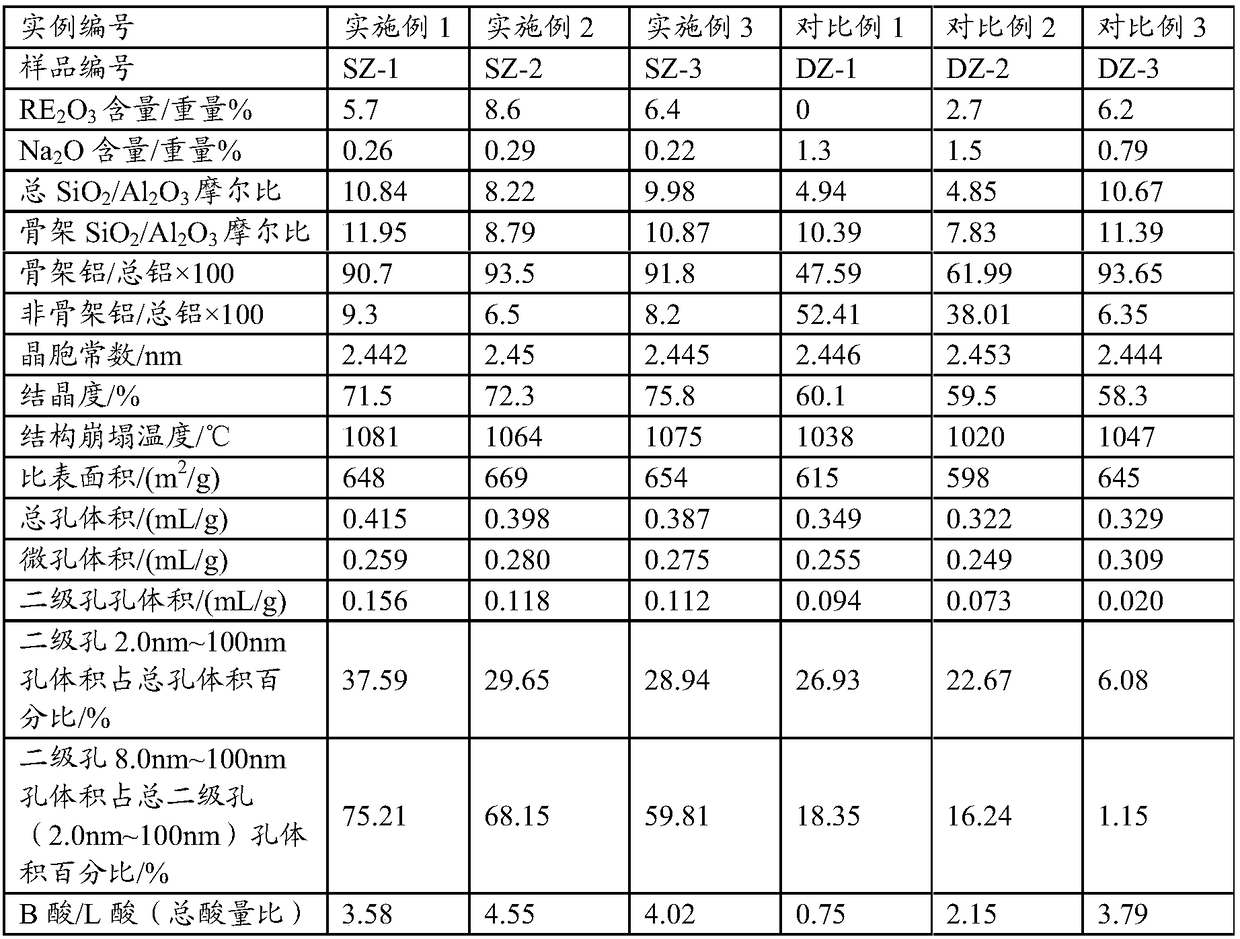

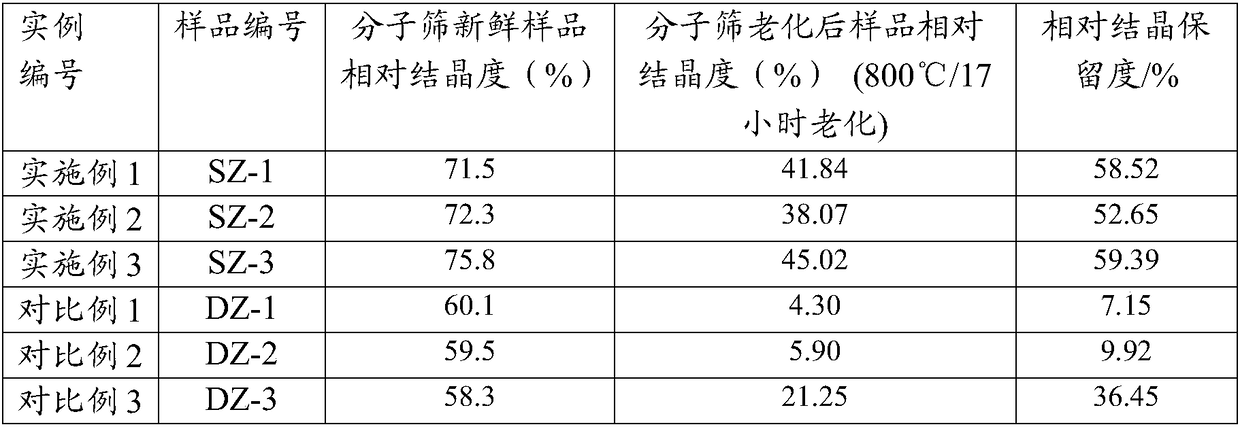

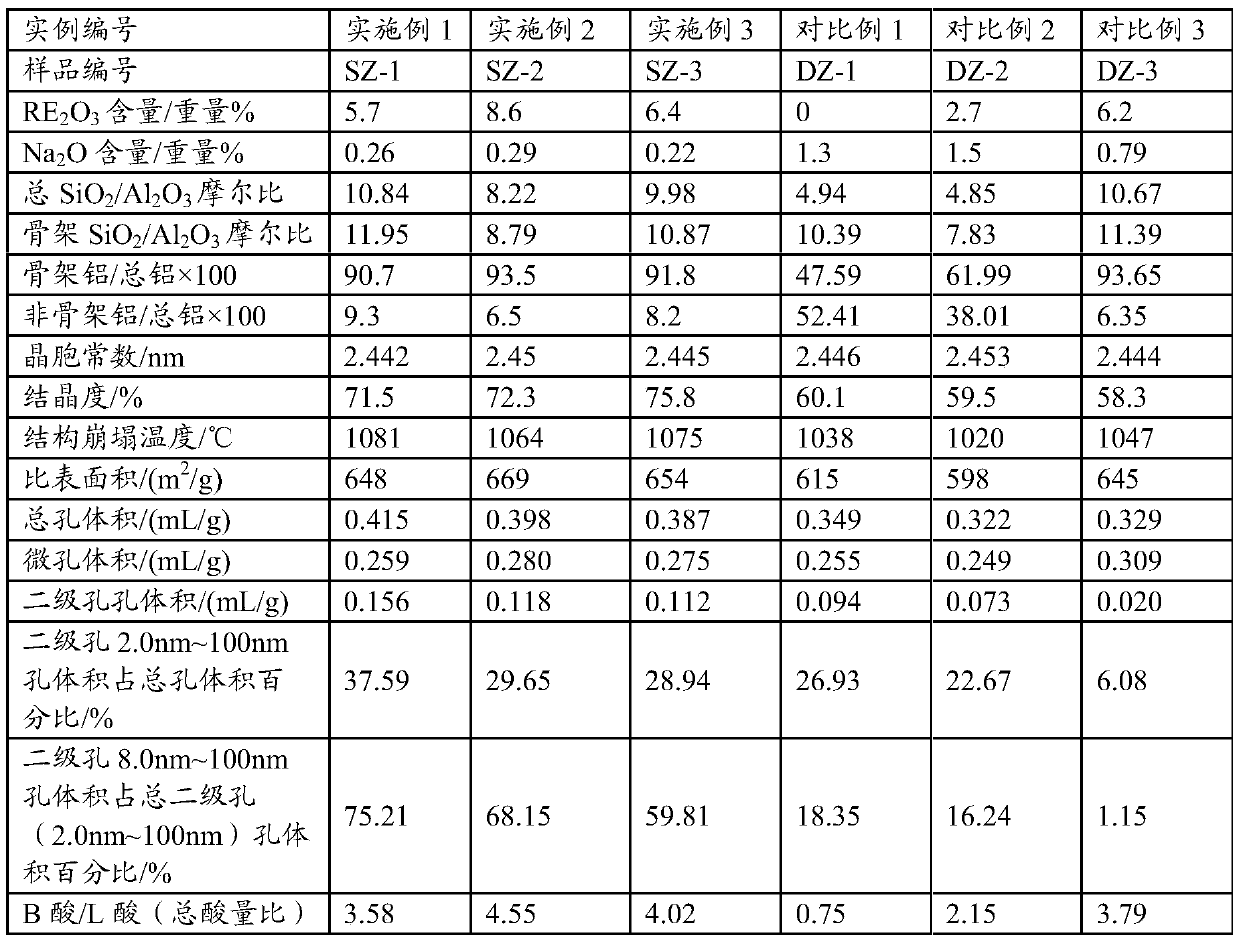

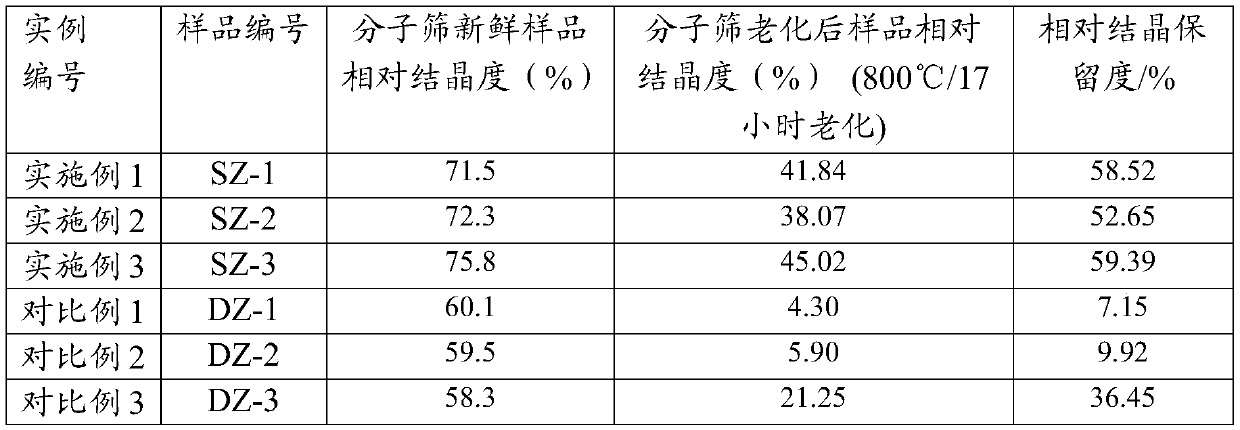

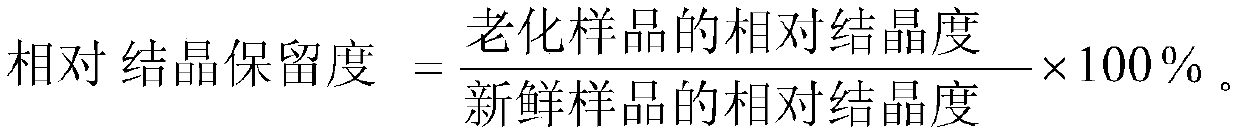

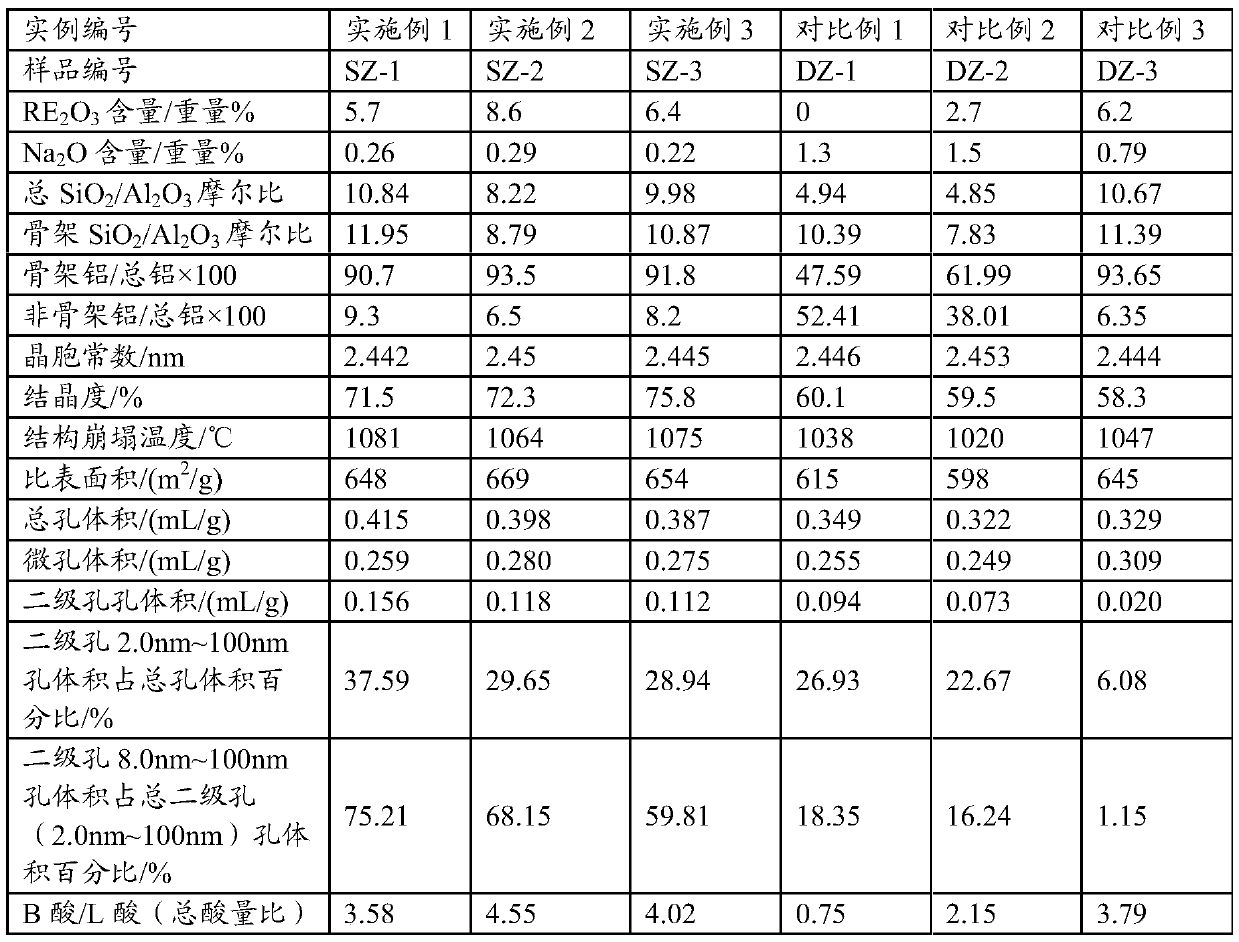

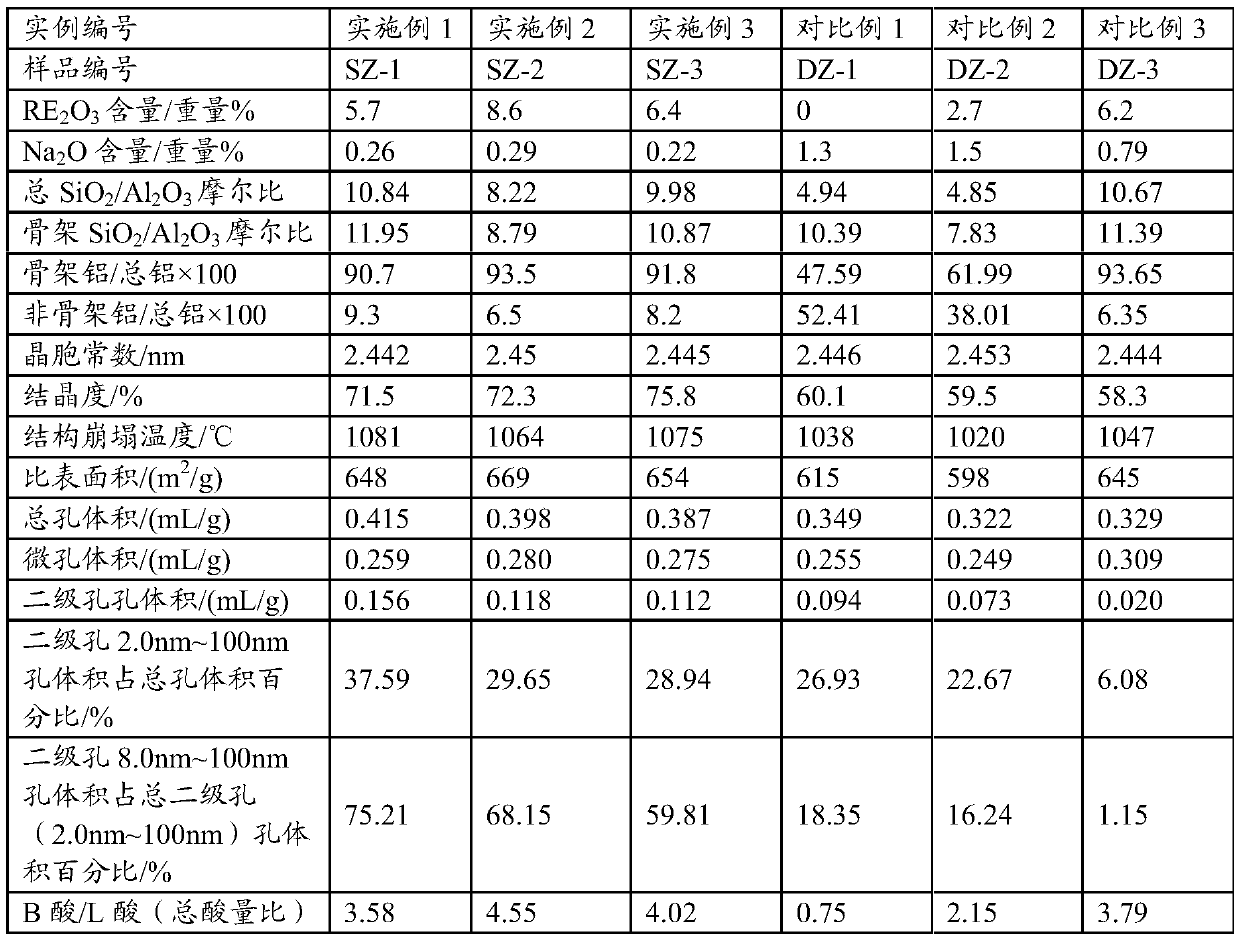

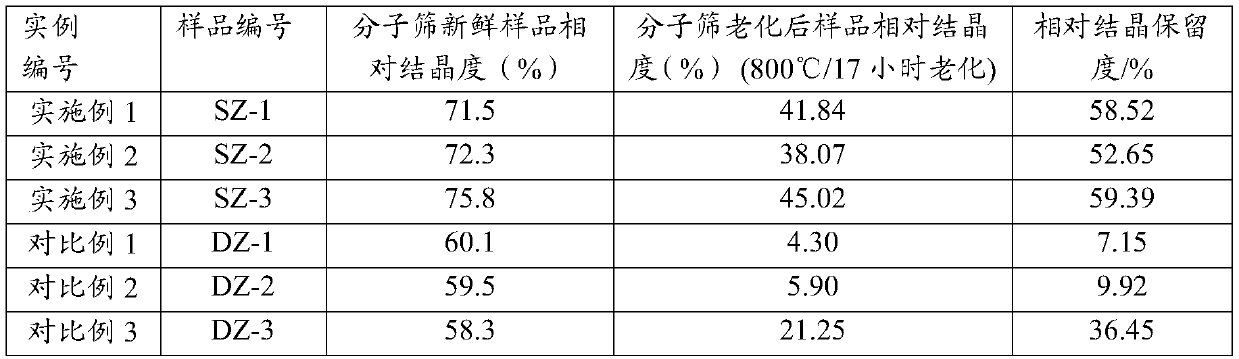

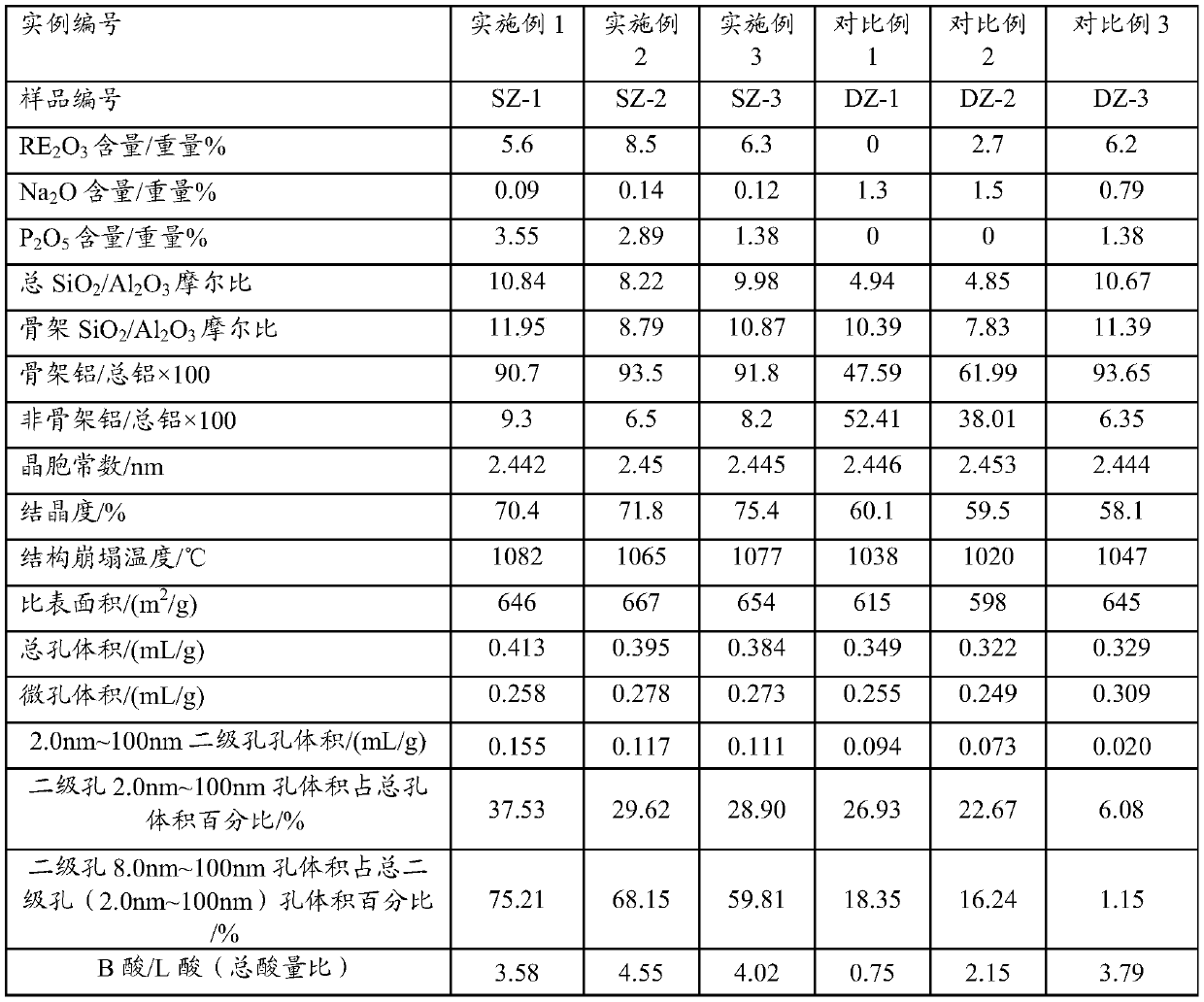

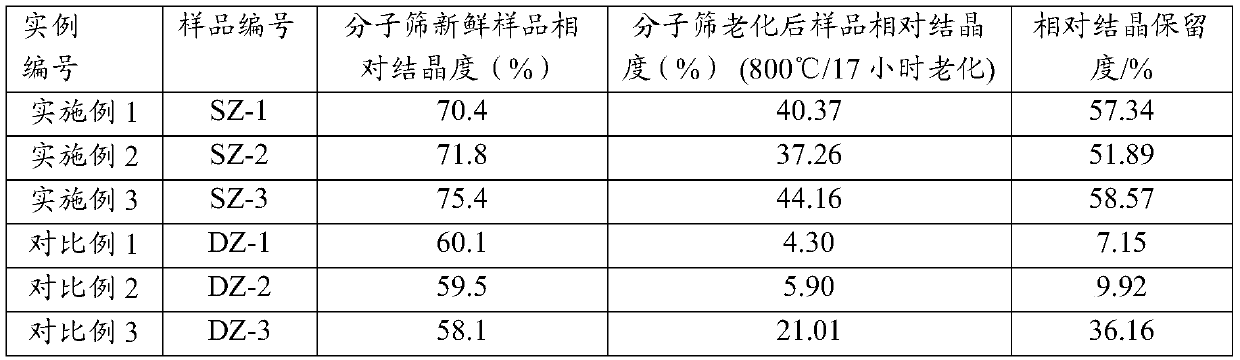

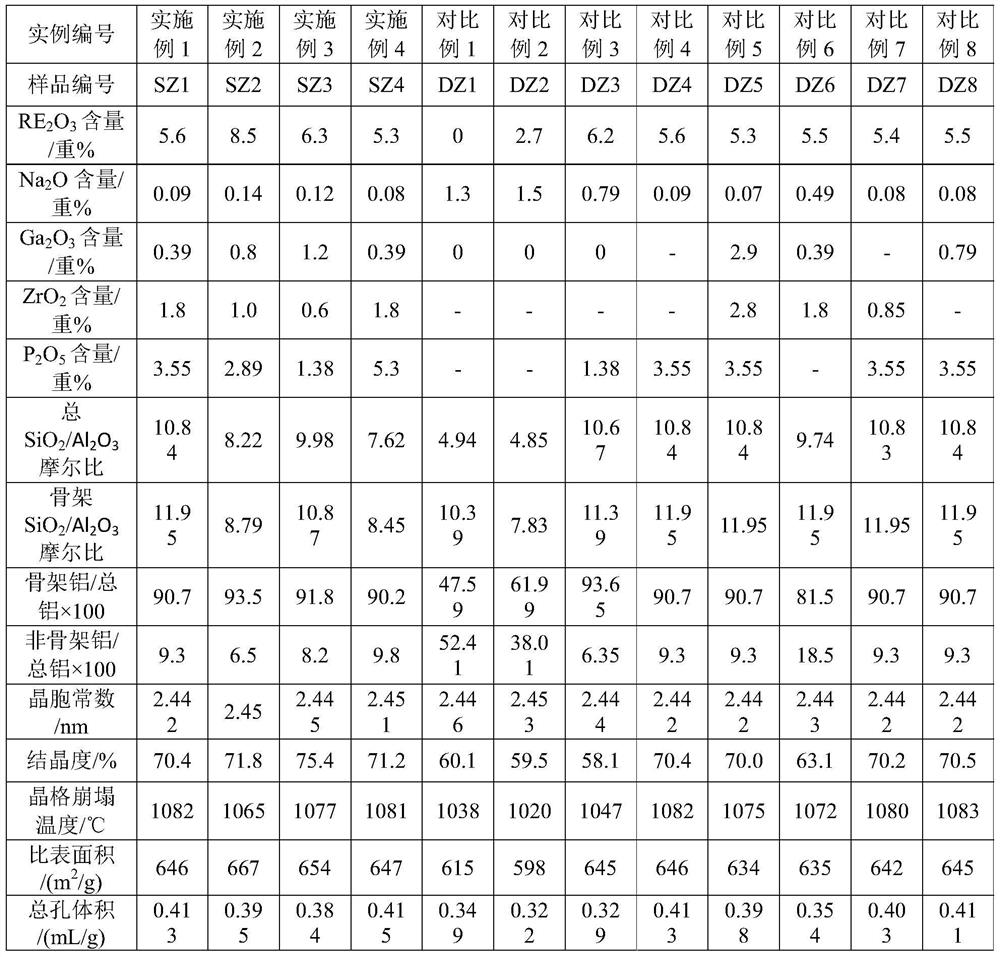

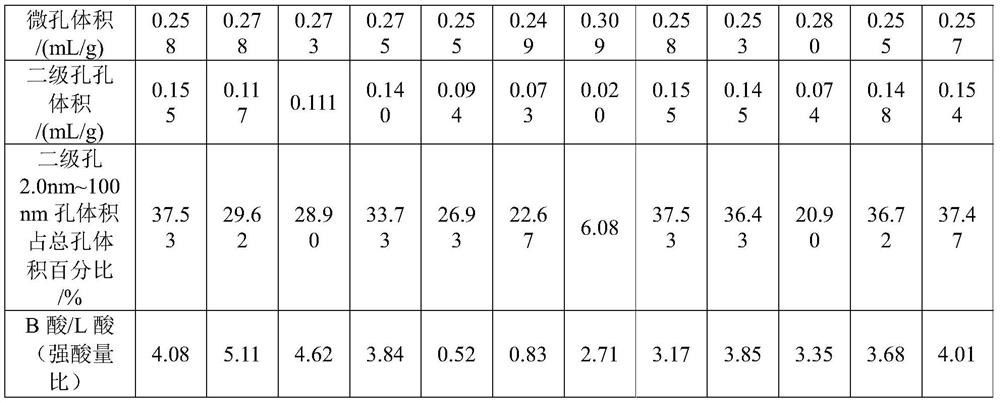

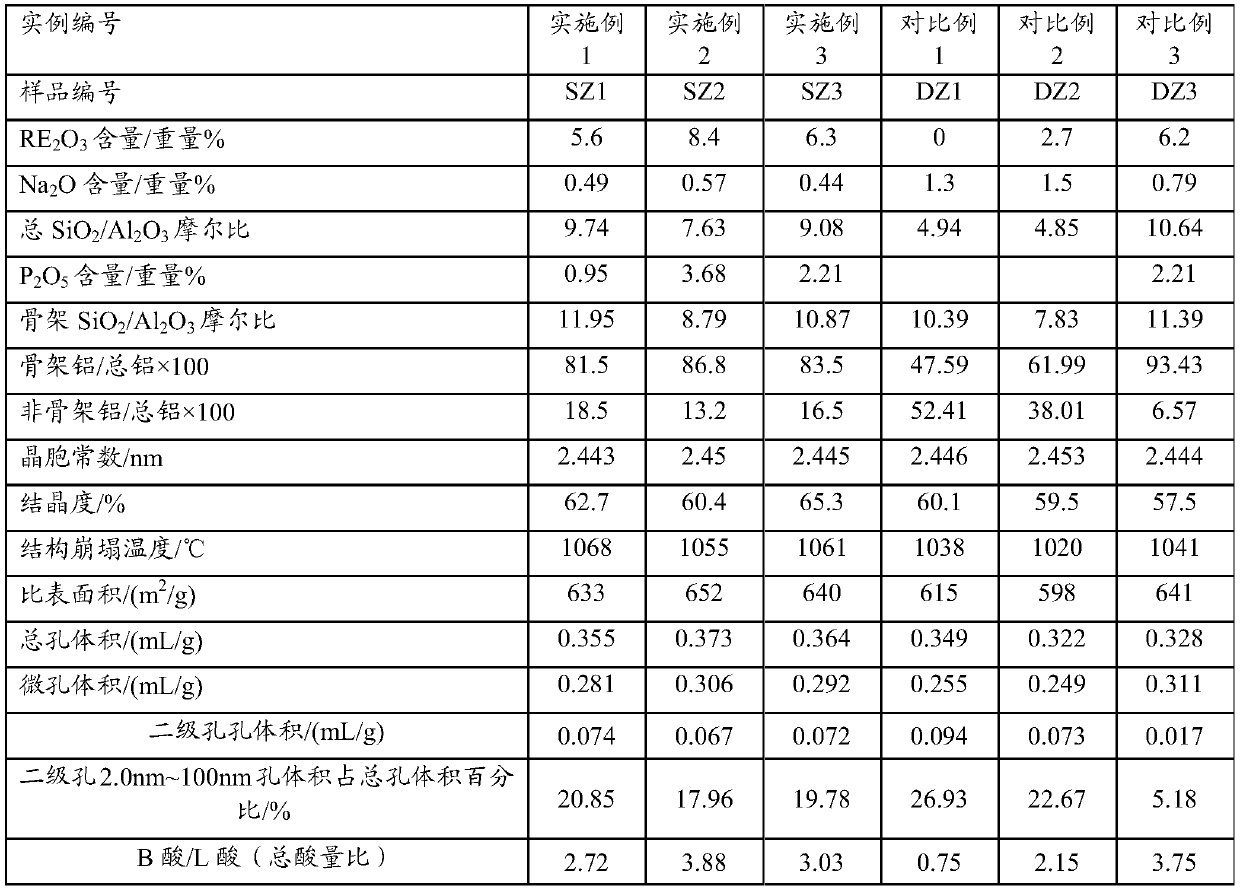

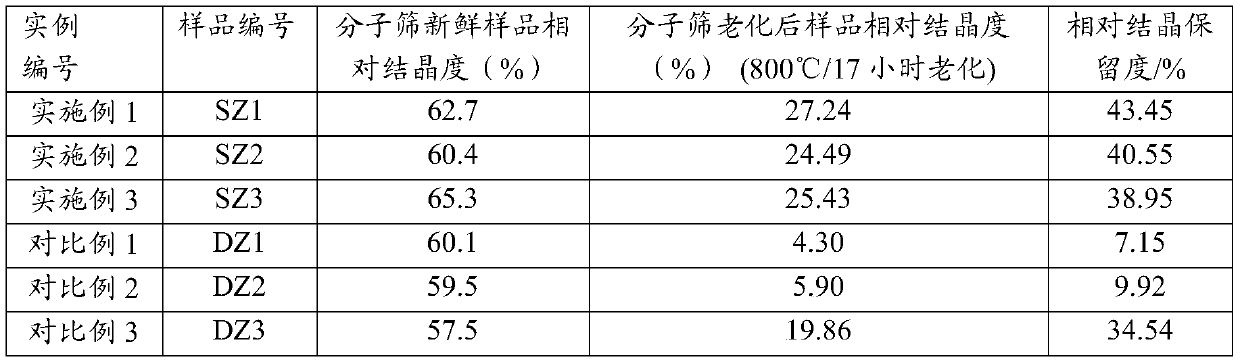

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains a modified Y type molecular sieve containing phosphorus and rare earth, an alumina binder containing an additive and clay. In the modified Y type molecular sieve containing phosphorus and rare earth, the content of rare earth oxide is 4 to 11 wt%; the content of phosphorus is 0.05 to 10 wt%; the contentof sodium oxide is no more than 0.5 wt%; a total pore volume is 0.4 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of the total pore volume; a lattice constant is 2.440 nm to2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is no less than 1060 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. The catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452838AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveFuel oil

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, alumina containing an additive and a modified Y type molecular sieve. The modified Y type molecularsieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of thetotal pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEGC; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7h; carrying out a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalytic cracking catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452835AReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

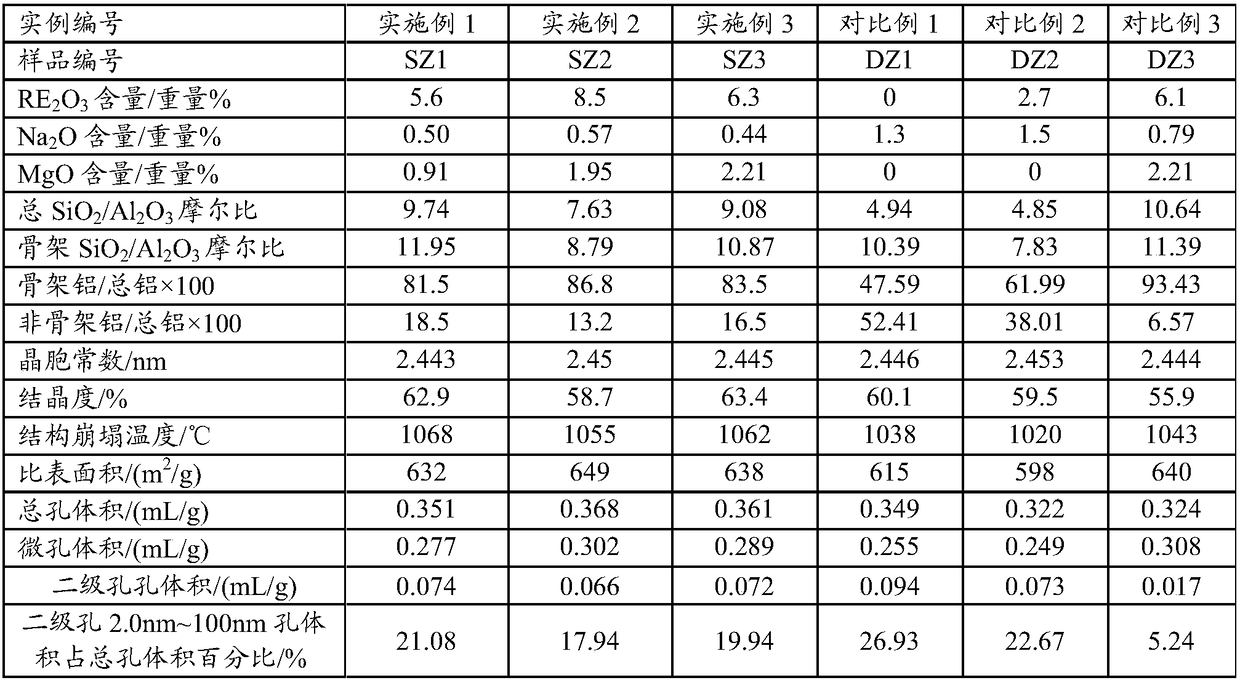

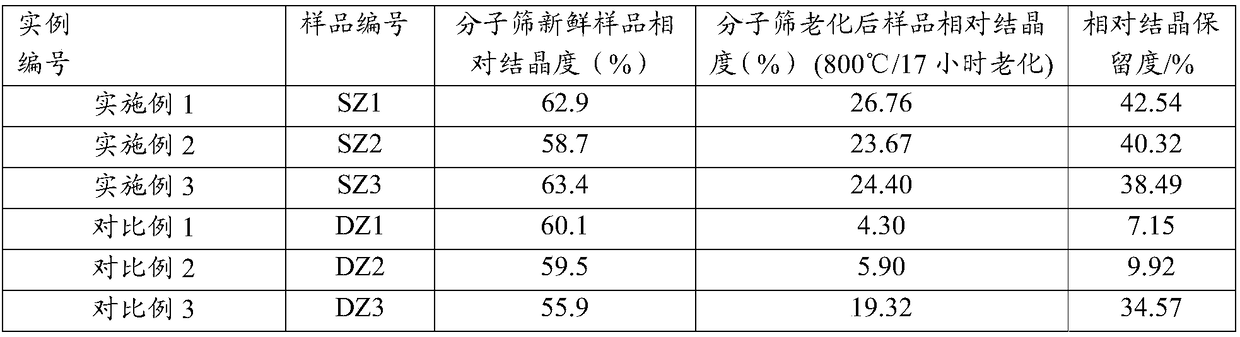

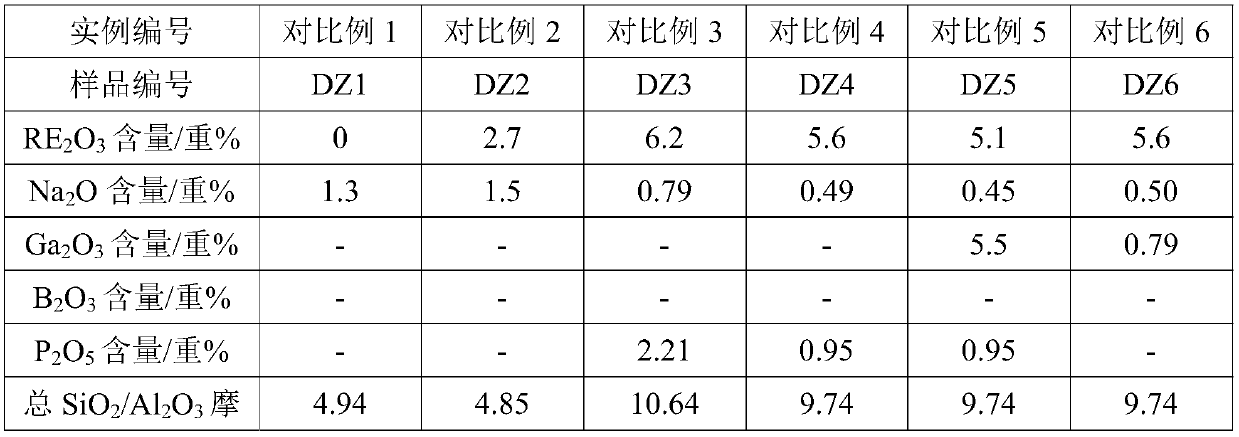

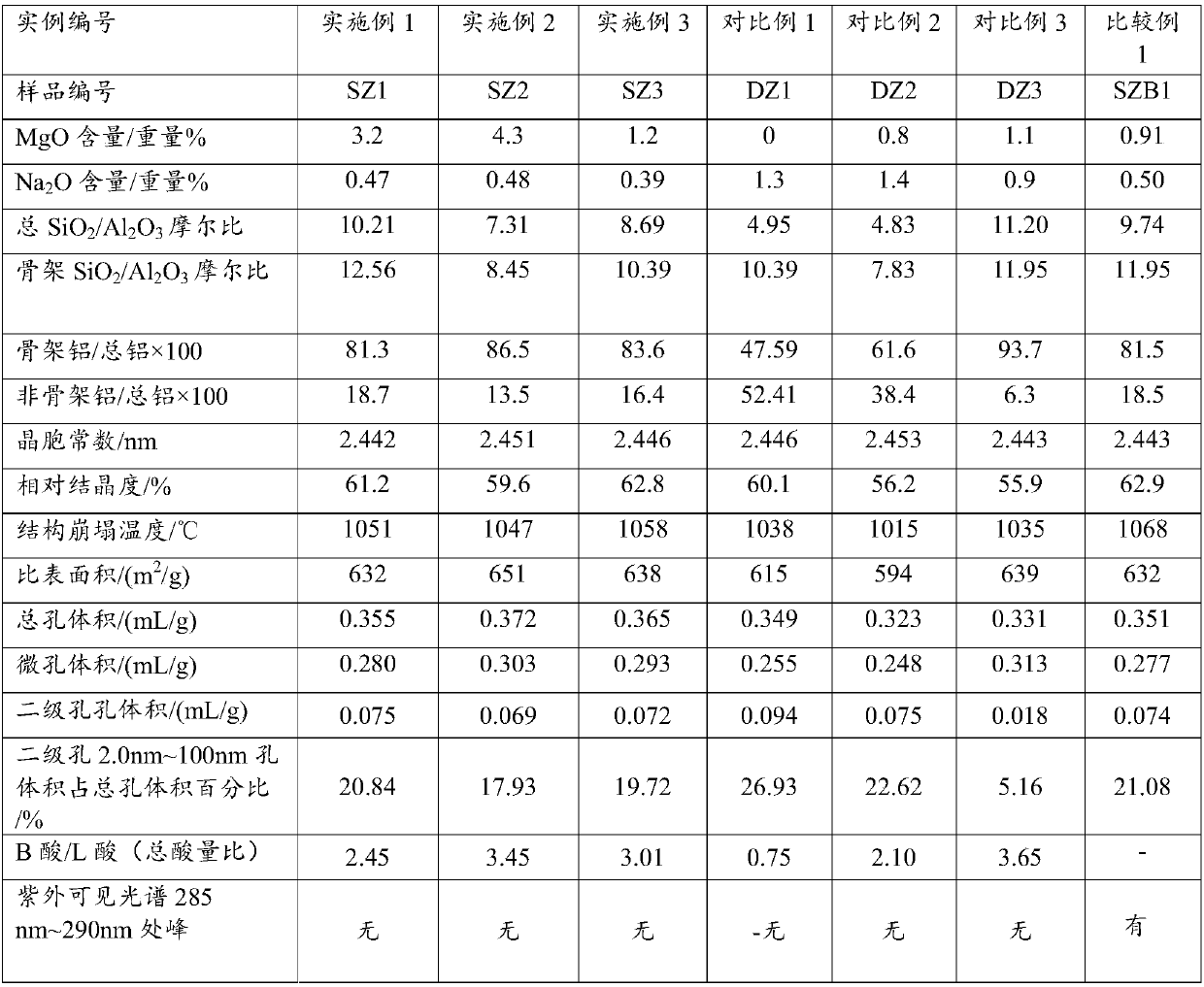

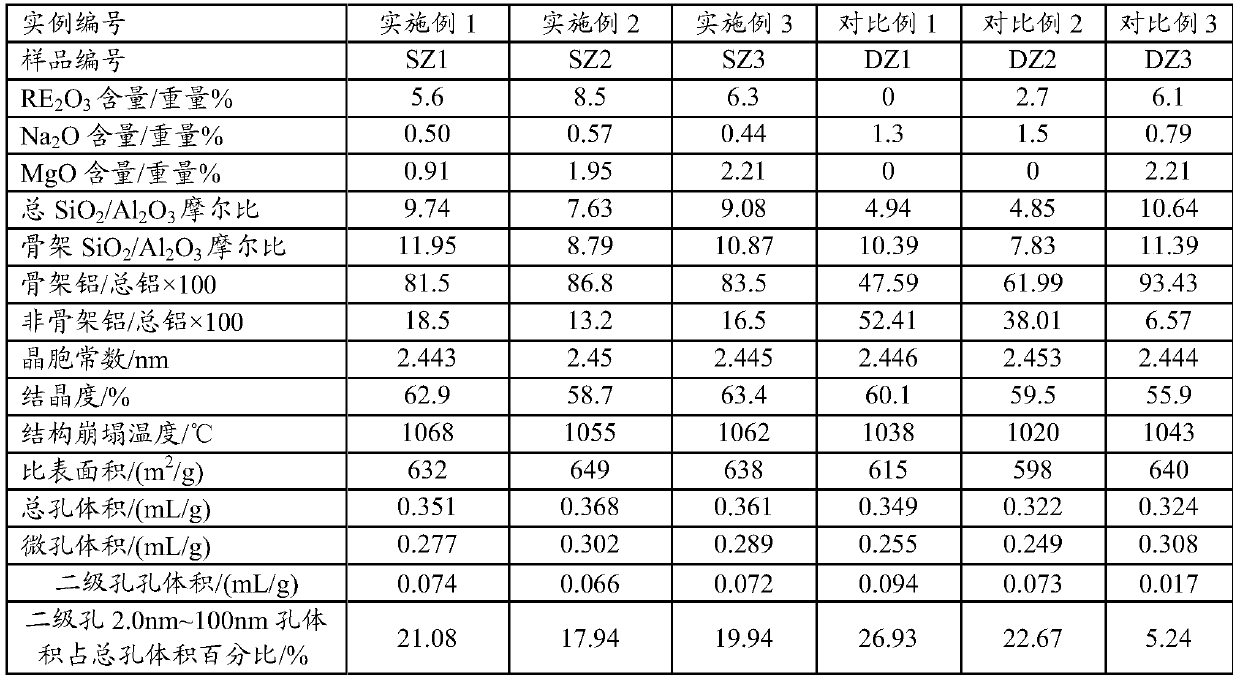

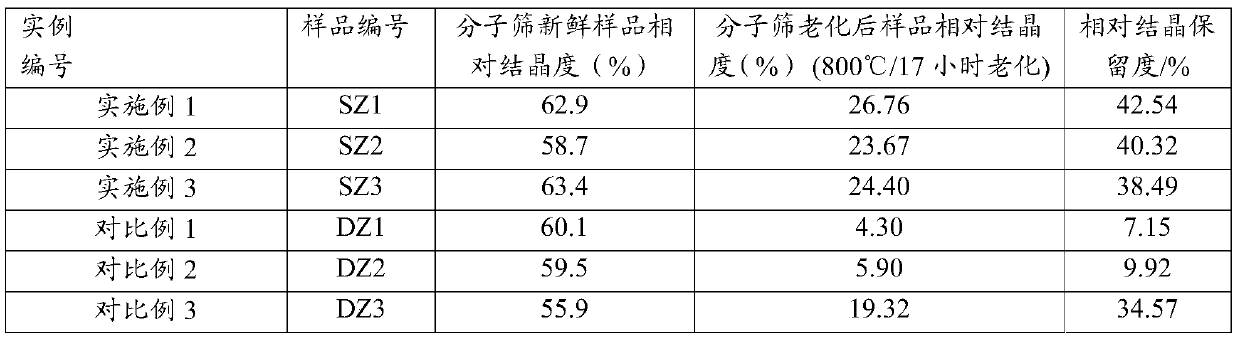

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains a modified Y type molecular sieve containing magnesium, alumina containing an additive and clay. In the modified Y type molecular sieve containing magnesium, the content of rare earth oxide is 4 to 10 wt%; the content of magnesium oxide is 0.1 to 4 wt%; the content of sodium oxide is 0.3 to 0.8 wt%; a total pore volume is 0.33 to 0.39 mL / g; the pore volume of secondary pores with pore diameters of 2 to 100 nm in the modified Y type molecular sieve accounts for 10 to 30% of the total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum in the modified Y type molecular sieve is no more than 20% of total aluminum content; and lattice collapse temperature isno less than 1045 DEG C. The modified Y type molecular sieve has higher heavy oil conversion activity, low coke selectivity, and higher diesel oil yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452829AHigh hydrothermal stabilityHigh conversion activity of heavy oilMolecular sieve catalystsMolecular sieveRare earth

The invention relates to a catalytic cracking catalyst, which contains a modified Y-type molecular sieve, an alumina binder and clay, wherein the modified Y-type molecular sieve contains 5-12 wt% of oxidized rare earth and 0.1-0.7 wt% of sodium oxide, and has the total pore volume of 0.33-0.39 mL / g, the pore volume of the secondary pores with the pore size of 2-100 nm in the modified Y-type molecular sieve accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the non-framework aluminum content in the modified Y-type molecular sieve is not more than 20% of thetotal aluminum content, the lattice collapse temperature is not below 1050 DEG C, and a ratio of the amount of B acid to the amount of L acid is not less than 2.50. According to the present invention,the catalytic cracking catalyst has advantages of high heavy oil conversion activity, low coke selectivity, high diesel yield, high liquefied gas yield, high light-oil yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carrier and catalyst and preparation method and application thereof and hydrocracking method

ActiveCN106622390AHigh crystallinitySecondary holeCatalyst carriersMolecular sieve catalystsMolecular sieveInorganic oxide

The invention discloses a carrier and an application thereof. The carrier contains an aluminum-removal Y-type molecular sieve and a heatproof inorganic oxide. The invention also discloses a catalyst by employing the carrier and a preparation method and an application thereof. The invention further discloses a hydrocracking method of the catalyst. According to the molecular sieve in the carrier, the molecular sieve has high crystallization degree and abundant secondary pores, and has lower non-framework aluminum content. The catalyst is prepared by VIII metallic element and VIB metallic element loaded on the carrier, the catalyst displays better catalysis performance in a hydrocracking reaction, and can obtain good balance among catalytic activity, middle distillate selectivity and tail oil BMCI value.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-stability modified Y-type molecular sieve and preparation method thereof

ActiveCN108455625AHigh thermal and hydrothermal stabilityImprove transformation activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveWater vapor

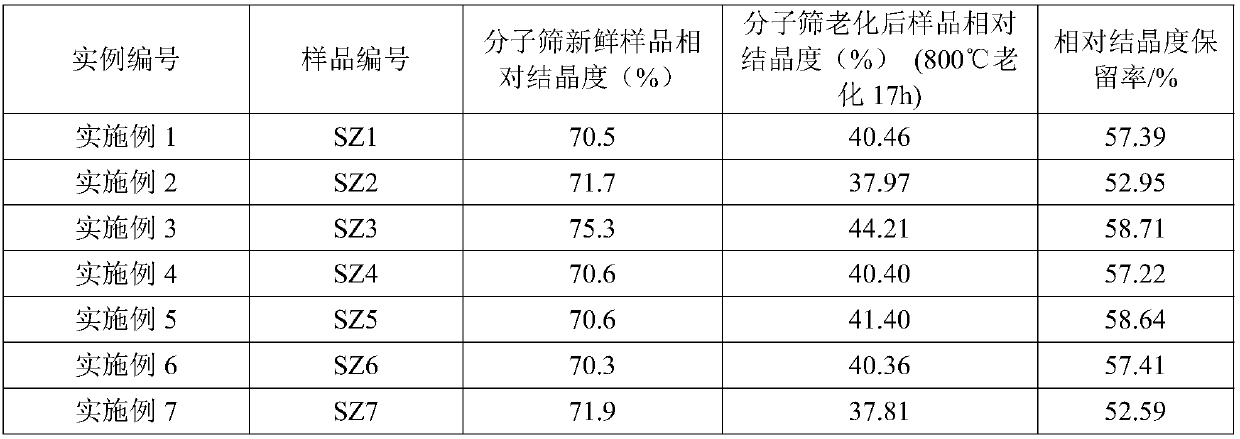

The invention relates to a high-stability modified Y-type molecular sieve and a preparation method thereof, wherein the modified Y-type molecular sieve contains 5-12 wt% of RE2O3 and 0.1-0.7 wt% of Na2O, and has the total pore volume of 0.33-0.39 mL / g, the pore volume of the secondary pores with the pore size of 2-100 nm accounts for 10-25% of the total pore volume, the unit cell constant is 2.440-2.455 nm, the non-framework aluminum content is not more than 20% of the total aluminum content, the lattice collapse temperature is not below 1050 DEG C, and the pyridine adsorption infrared methoddetermination results show that a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: ion exchange, modification treatment at a certain temperature under water vapor conditions, and reaction with silicon tetrachloride. According to the present invention, the modified Y-type molecular sieve has advantages of high heavy oil conversion activity, low coke selectivity, high diesel yield, high liquefied gas yield, high light-oil yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-stable Y-type molecular sieve containing phosphorus and rare earth, and preparation method thereof

ActiveCN108452828AHigh thermal and hydrothermal stabilityHigh heavy oil conversion activityCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium

The invention relates to a super-stable Y-type molecular sieve containing phosphorus and rare earth, wherein the Y-type molecular sieve contains 4-11 wt% of rare earth, 0.05-10 wt% of phosphorus and 0.1-0.7 wt% of sodium oxide, and has the pore volume of 0.33-0.39 mL / g, the pore volume of the pores with the pore size of 2-100 nm accounts for 15-30% of the total pore volume, the unit cell constantis 2.440-2.455 nm, the non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is more than 1050 DEG C, and a ratio of the amount of B acid to the amount of L acid is not less than 2.50. The preparation method comprises: preparing a rare earth-containing Y-type molecular sieve having a conventional unit cell size, calcining for 4.5-7 h at a temperature of 350-480 DEG C under 30-90% by volume of steam atmosphere, carrying out phosphorus modification treatment, and carrying out a contact reaction with silicon tetrachloride gas. According to the present invention, the Y-type molecular sieve has advantages of good hydrothermal stability, high heavy oil conversion activity, low coke selectivity, high heavy oil conversion diesel yield, high liquefied gas yield and high total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452834AReduce sodium oxide contentHigh crystallinity valueCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains a modified Y type molecular sieve containing phosphorus and rare earth, alumina containing an additive and clay. The modified Y type molecular sieve containing phosphorus and rare earth comprises 4 to 11 wt% of rare earth, 0.05 to 10 wt% of phosphorus and 0.1 to 0.7 wt% of sodium oxide, and has a pore volume is 0.33 to 0.39 mL / g; the volume of pores with pore diameters of 2 to 100 nm accounts for 15 to 30% of a total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 20% of total aluminum content; lattice collapse temperature is more than 1050 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 2.50. The catalyst has higher heavy oil cracking activity, good coke selectivity, and high gasoline yield, liquefied gas yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking catalyst and a preparing method thereof

ActiveCN104667958ALarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

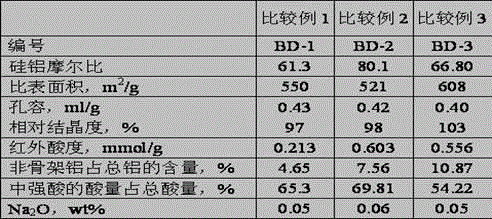

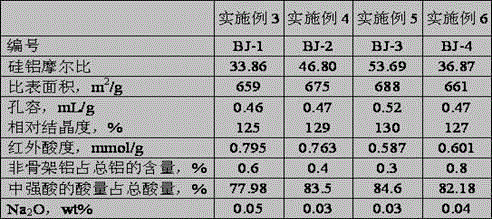

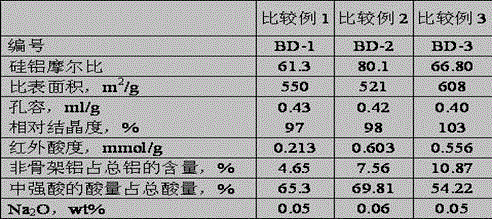

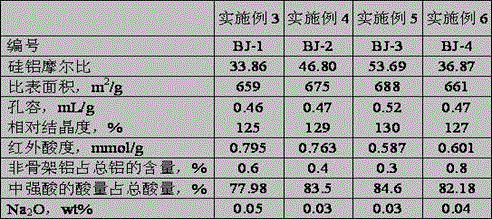

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289BIncrease the areaHigh crystallinityCatalytic crackingMolecular sieve catalystsOrganic acidNitrogen

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and its preparation method

ActiveCN104667958BLarge specific surface areaHigh crystallinityCatalyst carriersMolecular sieve catalystsMolecular sieveStrong acids

A hydrocracking catalyst and a preparing method thereof are disclosed. The catalyst comprises metal components with hydrogenation activity and a carrier comprising a beta molecular sieve, amorphous silicon aluminum and aluminum oxide, wherein properties of the beta molecular sieve are as follows: the specific surface area is 400-800 m2 / g, the total pore volume is 0.4-0.55 mL / g, the SiO2 / Al2O3 mole ratio is 30-60, the relative crystallinity is 120-140%, the infrared acid content is 0.55-1.0 mmol / g, the non-framework aluminum accounts for less than 1% of the total aluminum, the amount of medium-strong acids which is measured by a NH3-TPD method accounts for 70-85% of the total acid amount, and the percent of Na2O is not more than 0.15 wt%. The preparing method includes mixing the beta molecular sieve, the amorphous silicon aluminum and the aluminum oxide, kneading and forming to prepare the carrier; and loading the metal components with hydrogenation activity by a conventional method. The beta molecular sieve which is proper in silicon aluminum ratio, large in specific surface area, proper in acidity, reasonable in pore structure and low in content of non-framework aluminum, and the amorphous silicon aluminum are adopted as cracking components of the catalyst. The prepared catalyst is characterized by producing a clean diesel oil product with a low condensation point with the highest yield, improving properties of hydrogenation tail oil, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ultra-stable Y-type molecular sieve containing phosphorus and rare earth and preparation method thereof

ActiveCN108452828BHigh crystallinityHigh thermal and hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveHeat stability

An ultra-stable Y-type molecular sieve containing phosphorus and rare earth and a preparation method thereof. The Y-type molecular sieve contains 4 to 11 wt% rare earth, 0.05 to 10 wt% phosphorus, 0.1 to 0.7 wt% sodium oxide, and has a pore volume of 0.33 to 0.39 mL / g, the volume of 2-100nm pores accounts for 15-30% of the total pore volume, the unit cell constant is 2.440-2.455nm, non-framework aluminum accounts for less than 20% of the total aluminum, the lattice collapse temperature is greater than 1050°C, and the B acid content The ratio to the amount of L acid is not less than 2.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earth, roasting it for 4.5-7 hours in an atmosphere of 350-480°C and 30-90 volume % water vapor, phosphorus modification treatment and mixing with silicon tetrachloride gas. Contact reaction steps. The Y-type molecular sieve has good hydrothermal stability, high heavy oil cracking activity, good coke selectivity, and high yields of heavy oil converted into gasoline, liquefied gas and total liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

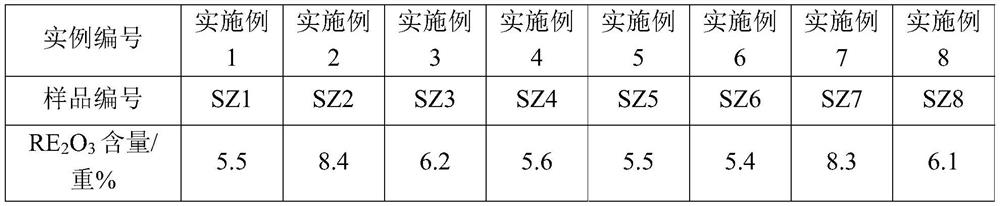

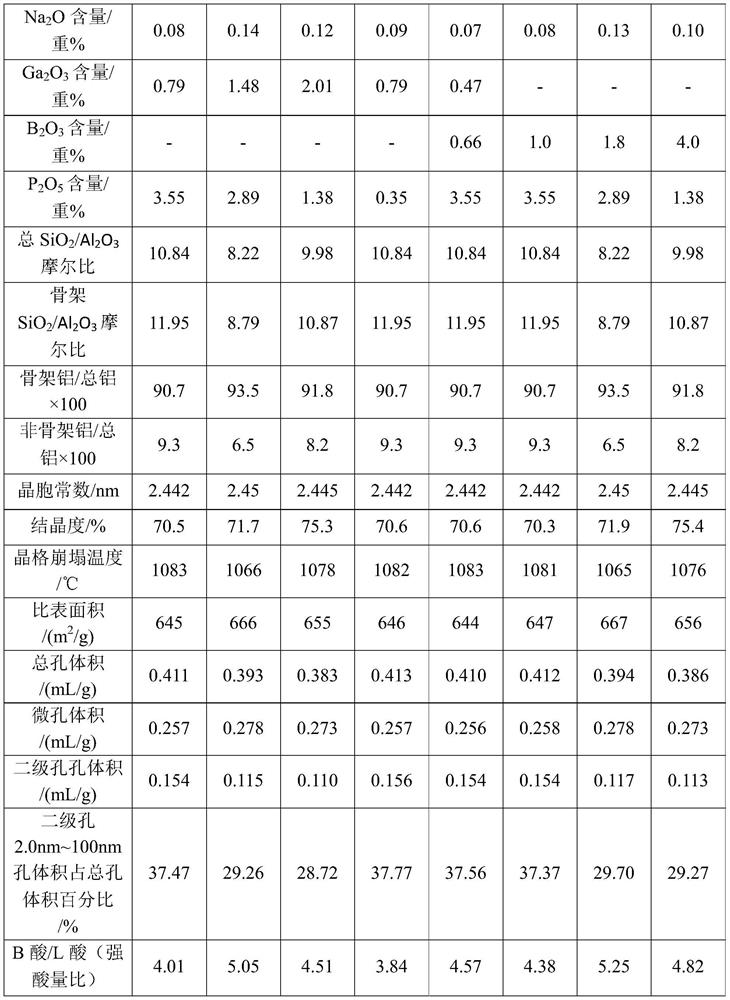

Catalytic cracking catalyst, preparation method and applications thereof

ActiveCN110833851AHigh crystallinityImprove thermal stabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

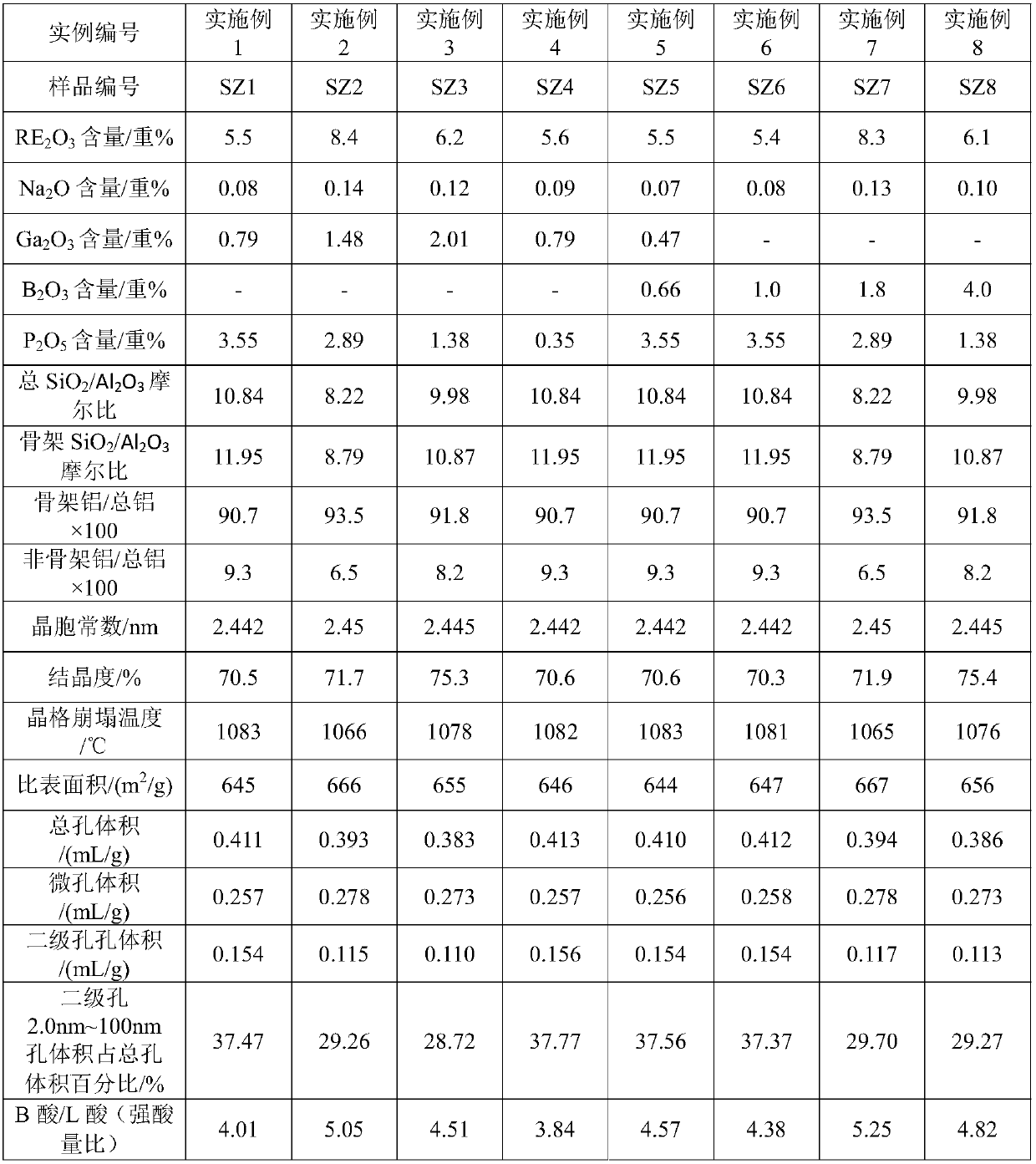

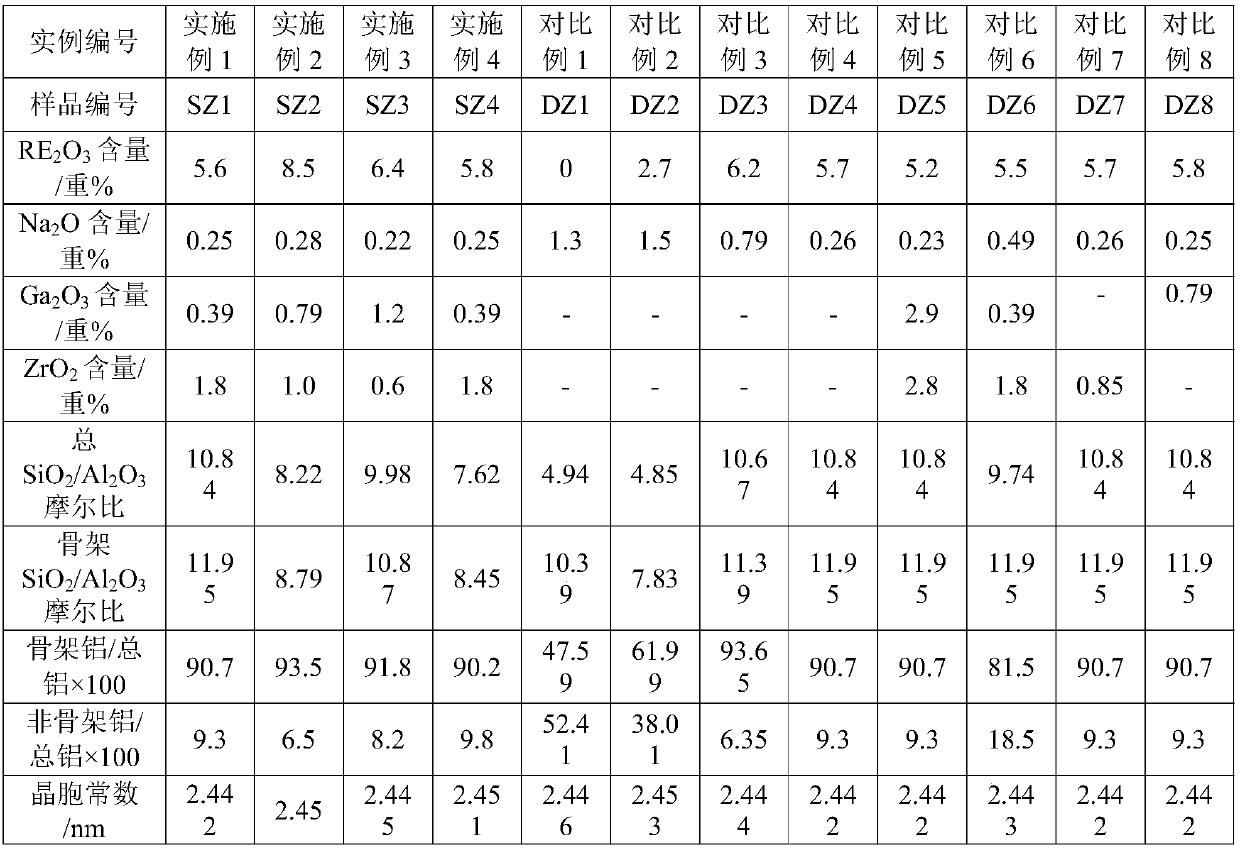

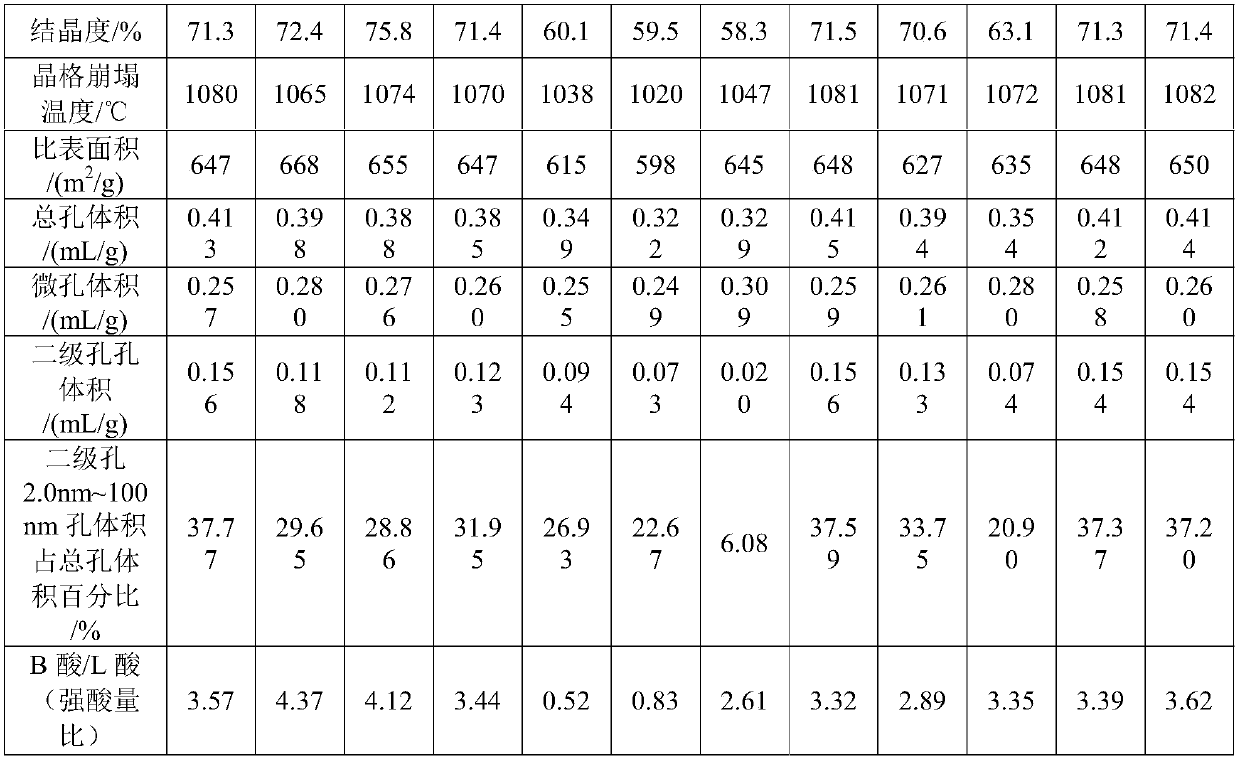

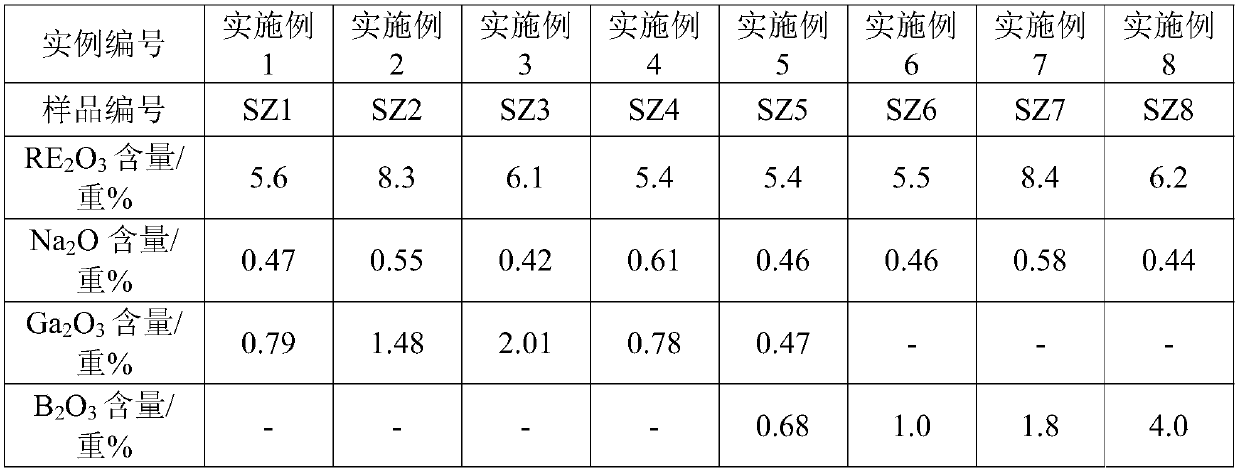

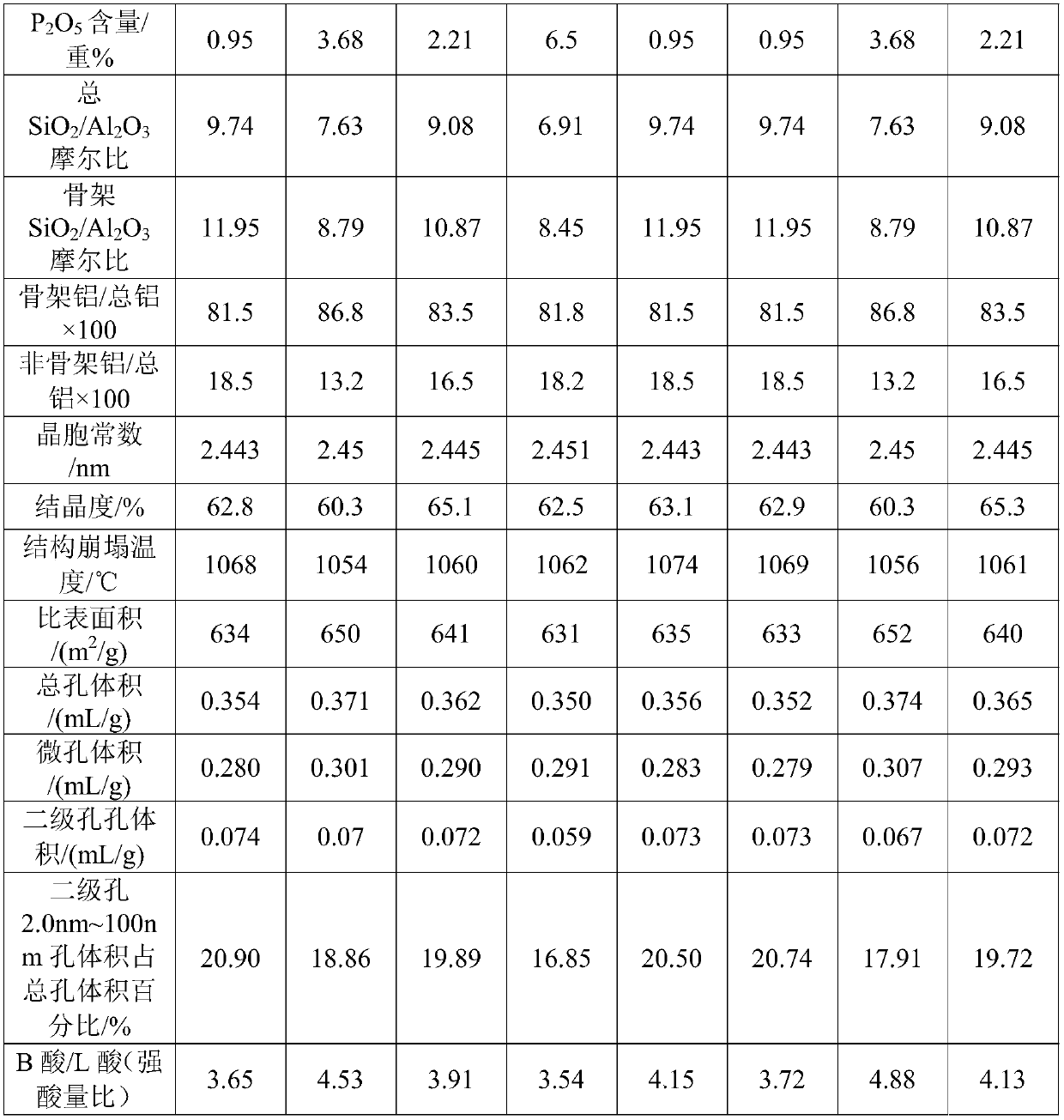

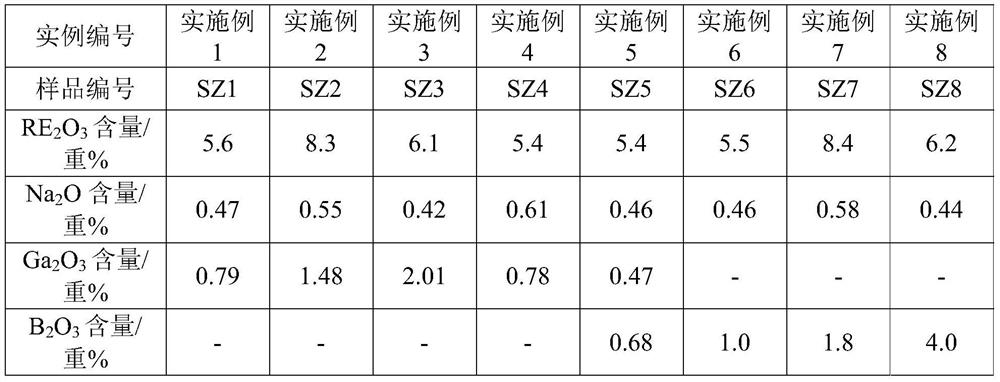

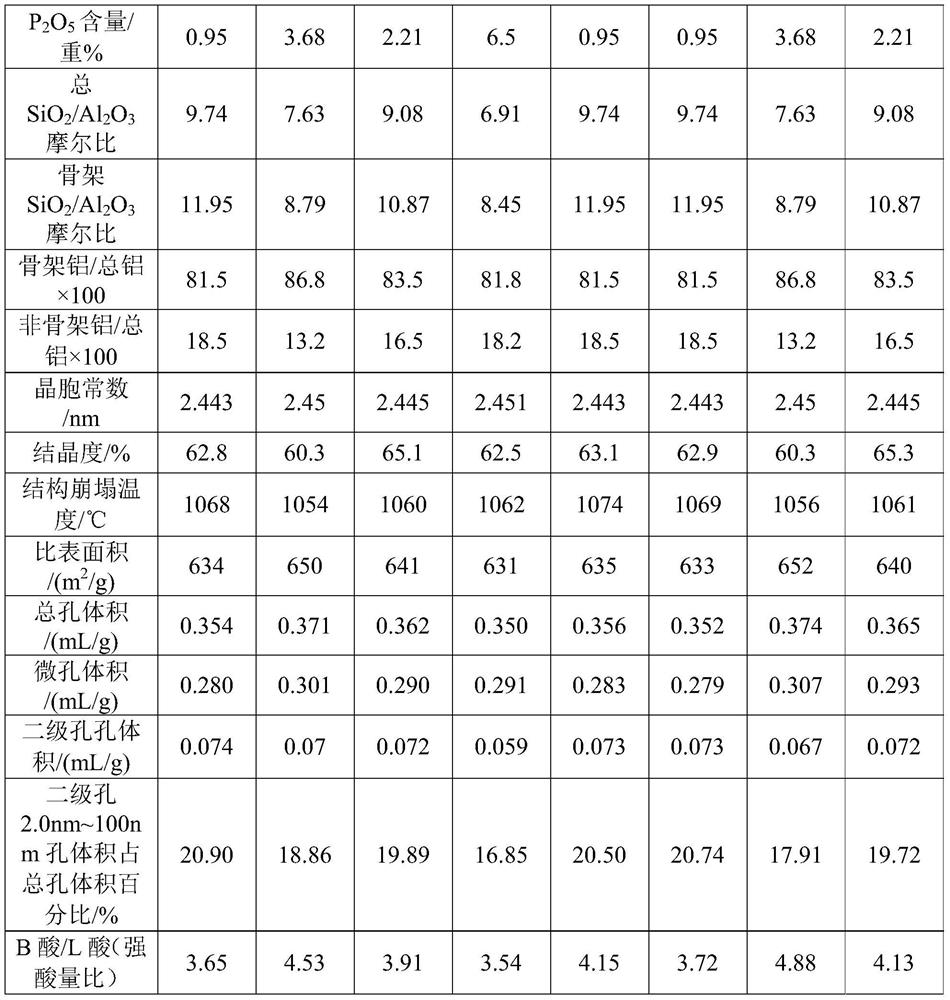

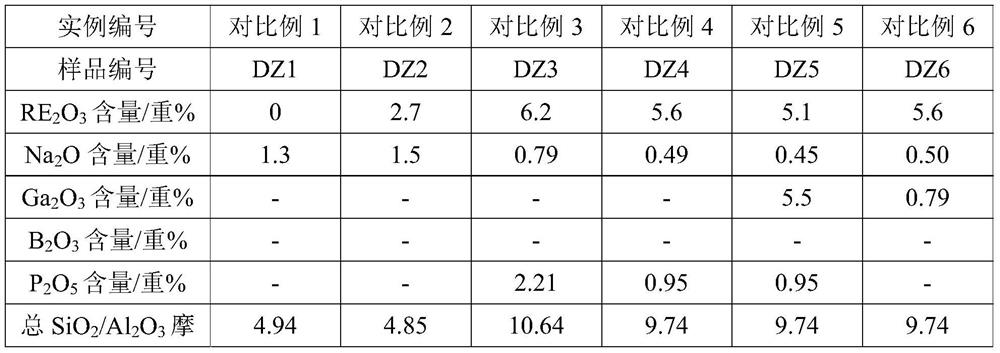

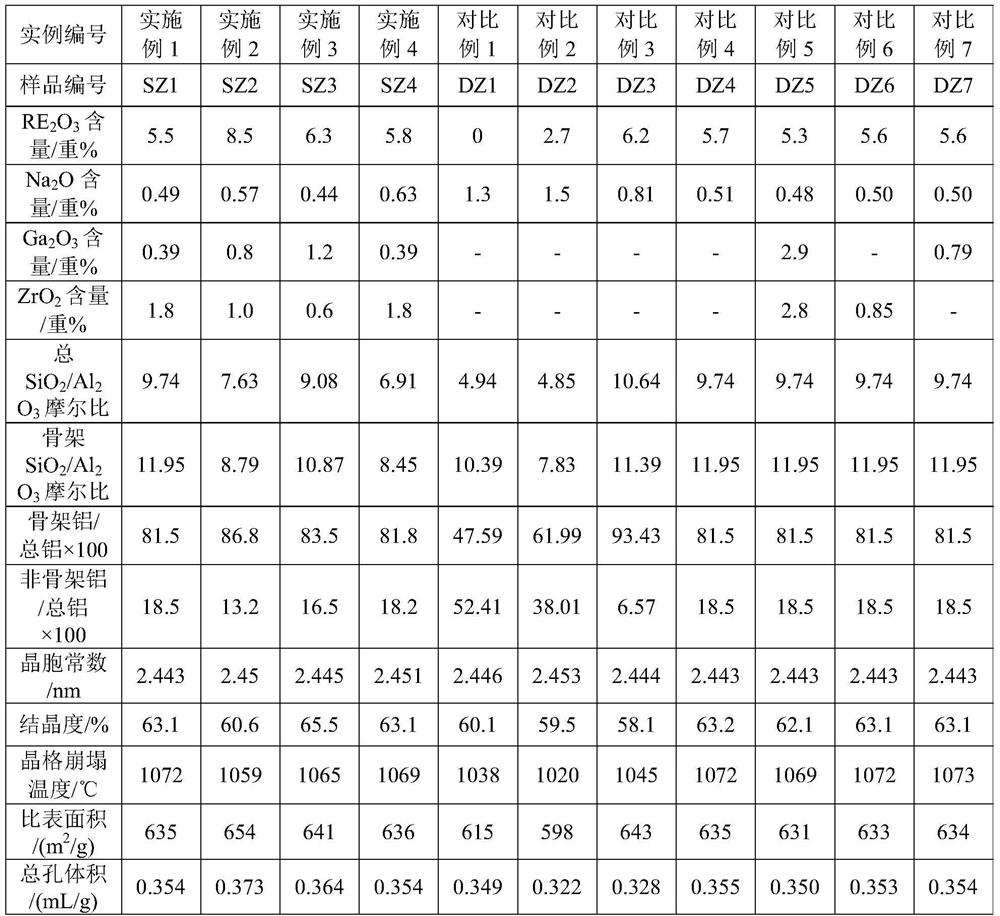

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises 4-11 wt% of rare earth elements (calculated as oxide), 0.05-10 wt% of phosphorus (calculated as P2O5), not more than 0.5 wt% of sodium oxide and 0.1-5 wt% of an active element oxide, the active element is gallium and / or boron, the total pore volume of the modified Y-type molecular sieve is 0.36-0.48 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 20-40% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1060 DEG C, the non-skeleton aluminum accounts for not more than 10% of the total aluminum content, and a ratio of the amount of the acid B to the amount of the acid L in the amount of the strong acid of the modified Y-type molecular sieve is not less than 3.5. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the catalyst has high LCO conversion efficiency, low coke selectivity and high yield of gasoline rich in aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst, preparation method and applications thereof

ActiveCN110833857AHigh crystallinityImprove thermal stabilityCatalytic crackingMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises (calculated as the weight of the dry base of the modified Y-type molecular sieve) 5-12 wt% of rare earth elements (calculated as oxide), not more than 0.5 wt% of sodium oxide, 0.1-2.5 wt% of gallium oxide, and 0.1-2.5 wt% of zirconium oxide, the total pore volume of the modified Y-type molecular sieve is 0.36-0.48 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 20-38% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1060 DEG C, the non-skeleton aluminum accounts for not more than 10% of the total aluminum content, and a ratio of the amount of the acid B to the amount of the acid L in the amount of the strong acid is not less than 3.0. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the LCO conversion efficiency is high, the coke selectivity is low, the yield of gasoline rich in BTX aromatic hydrocarbon and the yield of propylene are high, and the concentration of propylene in liquefied gasis high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and preparation method thereof

ActiveCN110833856AImprove conversion efficiencyEvenly distributedCatalytic crackingMolecular sieve catalystsRare-earth elementMolecular sieve

The invention relates to a modified Y-type molecular sieve and a preparation method thereof. The modified Y-type molecular sieve comprises (calculated as the weight of the dry base) 4-11 wt% of rare earth elements (calculated as oxide), 0.05-10 wt% of phosphorus (calculated as P2O5), 0.1-0.7 wt% of sodium oxide, and 0.1-5 wt% of an active element oxide, the active element is gallium and / or boron,the total pore volume of the modified Y-type molecular sieve is 0.33-0.39 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 15-30% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1050 DEG C, the non-skeleton aluminum of the modified Y-type molecular sieve accounts for not more than 20% of the total aluminum content, and a ratio of the amount of the acid B to the amount of the acid L in the amount of the strong acid is not less than 3.5. According to the invention, the modified Y-type molecular sieve has characteristics of high crystallinity, high thermal stability and hydrothermal stability and secondary pore structure; and with the application of the modified Y-type molecular sieve in processing hydrogenation of LCO, the LCO conversion efficiency is high, the coke selectivity is low, and the yield of gasoline rich in aromatic hydrocarbon is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation and application thereof

ActiveCN110653000AReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a catalytic cracking catalyst as well as preparation and application thereof. The catalyst contains a modified Y-type molecular sieve, an aluminum oxide binder and clay; according to the modified Y-type molecular sieve, the content of magnesium oxide in the modified Y-type molecular sieve is 0.5-4.5 wt%; the content of sodium oxide is 0.1 wt%-0.5 wt%; the total pore volumeis 0.33 mL / g to 0.39 mL / g; the pore volume of secondary pores with the pore diameter of 2nm-100nm of the modified Y-type molecular sieve accounts for 10%-25% of the total pore volume, the lattice constant is 2.440 to 2.455nm, the content of non-skeleton aluminum in the modified Y-type molecular sieve is not higher than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1040 DEG C, and the ratio of the amount of acid B to the amount of acid L in the total acid amount of the modified Y-type molecular sieve, which is measured by pyridine adsorption infrared method at 200 DEG C, is not lower than 2.30; when the molecular sieve is used for ultraviolet and visible light analysis, the ultraviolet and visible absorption spectrum is not absorbed at the wavelengthof 285-295 nm. The catalytic cracking catalyst is used for catalytic cracking of heavy oil, and has the advantages of low coke selectivity, high gasoline yield, high liquefied gas yield and high isohydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452837AHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsWater vaporRare earth

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains clay, an alumina binder and a modified Y type molecular sieve. The modified Y type molecular sieve comprises 5 to 12 wt% of rare earth and no more than 0.5 wt% of sodium oxide, and has a total pore volume of 0.36 to 0.48 mL / g; the pore volume of secondary pores accounts for 20 to 38% of the total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum is no more than 10% of total aluminum content; lattice collapse temperature is higher than 1060 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 3.50. A preparation method for the catalytic cracking catalyst comprises the following steps: preparing a rare earth-containing Y type molecular sieve with a conventional cell size; carrying out roasting in a water vapor atmosphere with a temperature of 350 to 520 DEG C and a volume percentage of 30 to 95% for 4.5 to 7 h; carryingout a contact reaction with silicon tetrachloride; and carrying out acid treatment. The catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking catalyst

ActiveCN108452837BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst contains clay, alumina binder and modified Y-type molecular sieve. The modified Y-type molecular sieve contains 5 to 12 wt% rare earth, no more than 0.5 wt% sodium oxide, and a total pore volume of 0.36 to 0.48 mL / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, non-framework aluminum accounts for less than 10% of the total aluminum, the lattice collapse temperature is higher than 1060℃, B acid content The ratio to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. . The catalytic cracking catalyst has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and its preparation method

ActiveCN108452831BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveWater vapor

A rare earth-containing modified Y-type molecular sieve rich in secondary pores and a preparation method thereof. The Y-type molecular sieve has a rare earth content of 5 to 12% by weight, a sodium content of no more than 0.5% by weight, and a total pore volume of 0.36 to 0.48 mL. / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, the non-framework aluminum content accounts for less than 10% of the total aluminum content, the lattice collapse temperature is higher than 1060°C, B acid The ratio of the amount to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. A step of. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and its preparation method and application

ActiveCN110833859BHigh crystallinityImprove thermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveRare-earth element

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking catalyst

ActiveCN108452838BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst containing clay, alumina containing additives and modified Y-type molecular sieve. The modified Y-type molecular sieve contains 5 to 12% by weight of rare earths, no more than 0.5% by weight of sodium oxide, and a total pore volume of 0.36 to 0.36% by weight. 0.48mL / g, the secondary pore volume accounts for 20~38% of the total pore volume, the unit cell constant is 2.440~2.455nm, non-framework aluminum accounts for less than 10% of the total aluminum, the lattice collapse temperature is higher than 1060℃, B acid The ratio of the amount to the amount of L acid is not less than 3.50. The preparation method includes: preparing a Y-type molecular sieve with a conventional unit cell size containing rare earths, roasting it for 4.5 to 7 hours in an atmosphere of 350 to 520°C and 30 to 95 volume % water vapor, contacting with silicon tetrachloride gas and treating with acid. . The catalytic cracking catalyst has higher heavy oil conversion activity and lower coke selectivity, and has higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking catalyst

ActiveCN108452835BReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst containing magnesium-containing modified Y-type molecular sieve, alumina containing additives and clay; the rare earth oxide content of the magnesium-containing modified high-silicon ultra-stable Y-type molecular sieve is 4% to 10% by weight, and the oxidation The magnesium content is 0.1 to 4 wt%, the sodium oxide content is 0.3 to 0.8 wt%, the total pore volume is 0.33mL / g to 0.39mL / g, and the modified Y-type molecular sieve has a secondary pore size of 2nm to 100nm. The pore volume accounts for 10% to 30% of the total pore volume, the unit cell constant is 2.440nm to 2.455nm, and the non-framework aluminum content in the modified Y-type molecular sieve accounts for no more than 20% of the total aluminum content. The lattice collapse temperature is not lower than 1045℃. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity, and has higher diesel yield, light oil yield and total liquid recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

A phosphorus-containing and rare earth modified Y-type molecular sieve rich in secondary pores and its preparation method

ActiveCN108452832BHigh thermal and hydrothermal stabilityHigh activityCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

A phosphorus- and rare earth-containing modified Y-type molecular sieve rich in secondary pores and a preparation method thereof. The modified Y-type molecular sieve has a rare earth oxide content of 4 to 11 wt%, a phosphorus content of 0.05 to 10 wt%, and a sodium oxide content. The content does not exceed 0.5% by weight, the total pore volume is 0.4~0.48mL / g, the pore volume of the secondary pores accounts for 20~38% of the total pore volume, the unit cell constant is 2.440nm~2.455nm, and the non-framework aluminum content accounts for the total The aluminum content is not higher than 10%, the lattice collapse temperature is not lower than 1060°C, and the ratio of B acid amount to L acid amount is not lower than 3.50. The preparation method of the molecular sieve includes the steps of exchanging rare earths, hydrothermal roasting, gas phase ultra-stable modification, acid treatment and introducing phosphorus. The modified Y-type molecular sieve has higher heavy oil conversion activity and lower coke selectivity. It has higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and its preparation method and application

ActiveCN110833849BHigh crystallinityImprove thermal stabilityMolecular sieve catalystsFaujasite aluminosilicate zeoliteHigh concentrationRare-earth element

The disclosure relates to a modified Y-type molecular sieve and a preparation method thereof. The content of rare earth elements in the modified Y-type molecular sieve is 4 to 11% by weight in terms of oxides, and the content of P 2 o 5 The content of phosphorus is 0.05-10% by weight, the content of sodium oxide is not more than 0.5% by weight, the content of gallium oxide is 0.1-2.5% by weight, and the content of zirconia is 0.1-2.5% by weight; the total amount of the modified Y-type molecular sieve The pore volume is 0.36-0.48mL / g, and the pore volume of secondary pores with a pore diameter of 2-100nm accounts for 20-40% of the total pore volume; the unit cell constant of the modified Y-type molecular sieve is 2.440-2.455nm , the lattice collapse temperature is not lower than 1060°C; the non-skeletal aluminum content of the modified Y-type molecular sieve accounts for no more than 10% of the total aluminum content, and the amount of B acid in the strong acid amount of the modified Y-type molecular sieve is equal to The ratio of L acid amount is not less than 3.5. The modified Y-type molecular sieve of the present disclosure is used for processing hydrogenated LCO while having high LCO conversion efficiency, low coke selectivity, higher gasoline yield and high propylene yield rich in BTX aromatics, The concentration of propylene in liquefied gas is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

A carrier and its application, a catalyst, its preparation method and application, and a hydrocracking method

ActiveCN106622390BHigh crystallinitySecondary holeCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a carrier and an application thereof. The carrier contains an aluminum-removal Y-type molecular sieve and a heatproof inorganic oxide. The invention also discloses a catalyst by employing the carrier and a preparation method and an application thereof. The invention further discloses a hydrocracking method of the catalyst. According to the molecular sieve in the carrier, the molecular sieve has high crystallization degree and abundant secondary pores, and has lower non-framework aluminum content. The catalyst is prepared by VIII metallic element and VIB metallic element loaded on the carrier, the catalyst displays better catalysis performance in a hydrocracking reaction, and can obtain good balance among catalytic activity, middle distillate selectivity and tail oil BMCI value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and preparation method thereof

ActiveCN110833856BImprove conversion efficiencyEvenly distributedCatalytic crackingMolecular sieve catalystsRare-earth elementMolecular sieve

The disclosure relates to a modified Y-type molecular sieve and a preparation method thereof. Based on the dry basis weight of the modified Y-type molecular sieve, the content of rare earth elements in the modified Y-type molecular sieve is 4-11% by weight in terms of oxides, and the content of P 2 o 5 The content of phosphorus is 0.05-10 wt%, the content of sodium oxide is 0.1-0.7 wt%, the content of active element oxide is 0.1-5 wt%, and the active element is gallium and / or boron; the modified Y-type molecular sieve The total pore volume is 0.33-0.39mL / g, and the pore volume of secondary pores with a pore diameter of 2-100nm accounts for 15-30% of the total pore volume; the unit cell constant of the modified Y-type molecular sieve is 2.440-2.455nm, The lattice collapse temperature is not lower than 1050°C; the non-skeletal aluminum content of the modified Y-type molecular sieve accounts for no more than 20% of the total aluminum content, and the ratio of the B acid content to the L acid content in the strong acid content of the modified Y-type molecular sieve Not less than 3.5. The molecular sieve has high crystallinity, thermal and hydrothermal stability, and has a secondary pore structure. When used for processing hydrogenated LCO, the LCO conversion efficiency is high, the coke selectivity is low, and the gasoline yield is higher and rich in aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and its preparation method and application

ActiveCN110833854BHigh crystallinityImprove thermal stabilityMolecular sieve catalystsCatalyst activation/preparationRare-earth elementMolecular sieve

The invention relates to a catalytic cracking catalyst, a preparation method and applications thereof, wherein the catalyst comprises 10-50 wt% of a modified Y-type molecular sieve, 10-40 wt% of an alumina binder (calculated as alumina), and 10-80 wt% of clay (calculated as dry base), wherein the modified Y-type molecular sieve comprises (calculated as the weight of the dry base of the modified Y-type molecular sieve) 5-12 wt% of rare earth elements (calculated as oxide), 0.1-0.7 wt% of sodium oxide, 0.1-2.5 wt% of gallium oxide, and 0.1-2.5 wt% of zirconium oxide, the total pore volume of themodified Y-type molecular sieve is 0.33-0.39 mL / g, the pore volume of the secondary pores with a pore size of 2-100 nm accounts for 10-25% of the total pore volume, the cell constant is 2.440-2.455 nm, the lattice collapse temperature is not lower than 1050 DEG C, the non-skeleton aluminum accounts for not more than 20% of the total aluminum content, and a ratio of the amount of the acid B to theamount of the acid L in the amount of the strong acid is not less than 3.0. According to the invention, with the application of the catalyst in processing hydrogenation of LCO, the LCO conversion efficiency is high, the coke selectivity is low, the yield of gasoline rich in aromatic hydrocarbon and the yield of propylene are high, and the concentration of propylene in liquefied gas is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalytic cracking catalyst

ActiveCN108452834BReduce sodium oxide contentHigh crystallinity valueCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

A catalytic cracking catalyst containing a modified Y-type molecular sieve containing phosphorus and rare earth, alumina and clay containing additives. The modified Y-type molecular sieve containing phosphorus and rare earth contains 4 to 11 wt% rare earth, 0.05 to 10 wt% % phosphorus, 0.1~0.7% by weight sodium oxide, pore volume is 0.33~0.39mL / g, the volume of 2~100nm pores accounts for 15~30% of the total pore volume, the unit cell constant is 2.440~2.455nm, non-framework aluminum accounts for the total Less than 20% of aluminum, the lattice collapse temperature is greater than 1050°C, and the ratio of B acid content to L acid content is not less than 2.50. The catalytic cracking catalyst has high heavy oil cracking activity, good coke selectivity, high gasoline yield, and high liquefied gas yield and total liquid collection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst

ActiveCN108452836AReduce sodium oxide contentLow non-framework aluminum contentCatalytic crackingMolecular sieve catalystsMolecular sieveAluminium

The invention provides a catalytic cracking catalyst. The catalytic cracking catalyst contains a modified Y type molecular sieve, alumina containing an additive and clay. In the modified Y type molecular sieve, the content of rare earth oxide is 5 to 12 wt%; the content of sodium oxide is 0.1 to 0.7 wt%; a total pore volume is 0.33 to 0.39 mL / g; the pore volume of secondary pores with a pore diameter of 2 to 100 nm in the modified Y type molecular sieve accounts for 10 to 25% of the total pore volume; a lattice constant is 2.440 nm to 2.455 nm; the content of non-framework aluminum in the modified Y type molecular sieve is no more than 20% of total aluminum content; lattice collapse temperature is no less than 1050 DEG C; and a ratio of the amount of acid B to the amount of acid L is no less than 2.50. The catalyst has higher heavy oil conversion activity, low coke selectivity, and higher gasoline yield, liquefied gas yield, light oil yield and total liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com