Modified Y-type molecular sieve and its preparation method and application

A molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor accessibility of active centers, small unit cell constants, high silicon-aluminum ratio, and achieve low coke selection. The effect of low content of non-framework aluminum and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

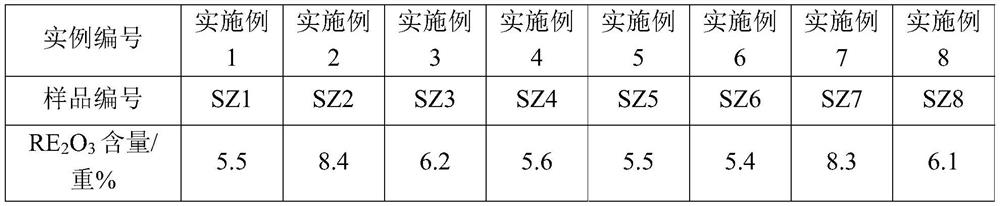

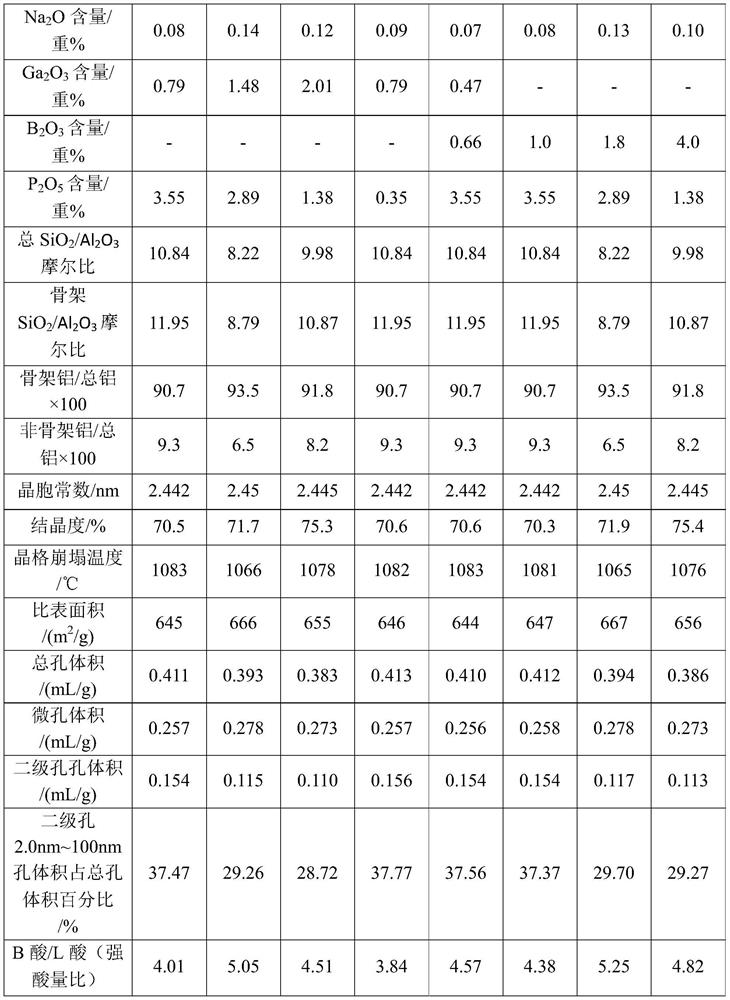

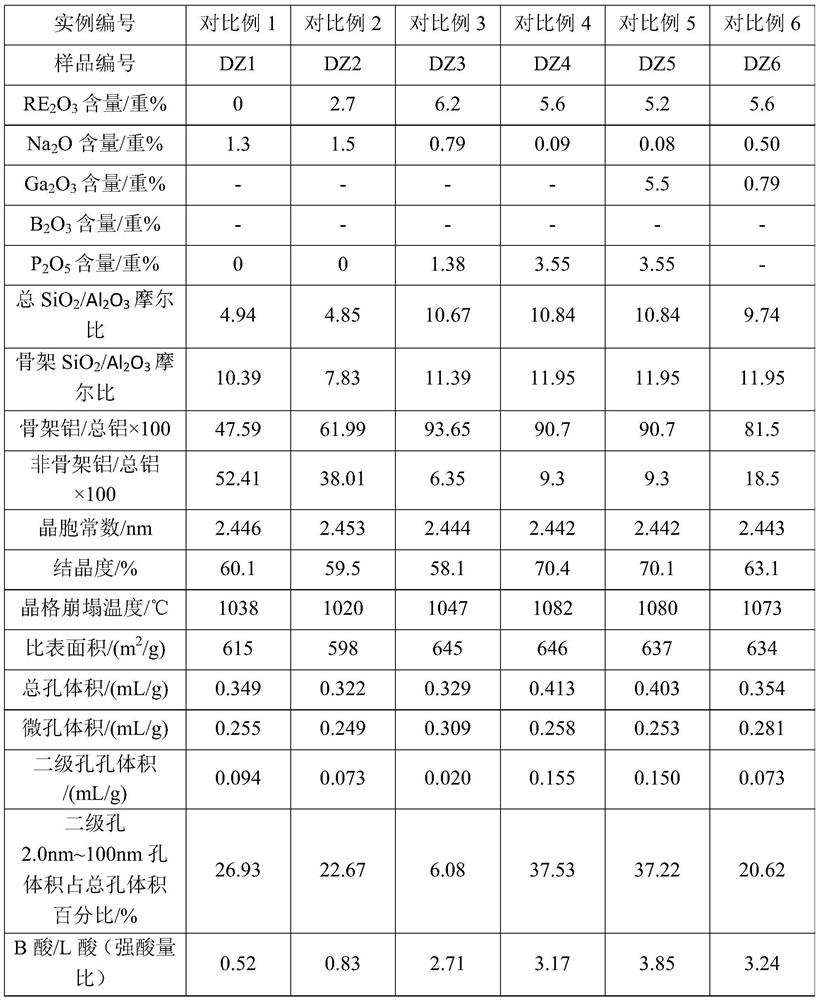

[0082] The preparation method of the present disclosure can prepare a high-silicon Y-type molecular sieve rich in secondary pores with high crystallinity, high thermal stability and high hydrothermal stability, and can make the molecular sieve have higher Crystallinity, the aluminum distribution in the prepared molecular sieve is uniform, the non-skeleton aluminum content is less, and the secondary pores are smooth. The modified Y-type molecular sieve is used for processing hydrogenation LCO and has high LCO conversion efficiency and low coke selection. performance, with higher and aromatic-rich gasoline yields.

[0083] In the preparation method of the modified Y-type molecular sieve provided by the present disclosure, in step (1), the NaY molecular sieve and the rare earth solution are subjected to an ion exchange reaction to obtain a Y-type molecular sieve with a conventional unit cell size containing rare earths with reduced sodium oxide content, and ion exchange The metho...

Embodiment approach

[0094] In one embodiment, the phosphorus modification treatment conditions are as follows: adding the acid-treated molecular sieve sample into the exchange solution containing phosphorus compounds, performing exchange reaction at 15-100°C for 10-100 minutes, filtering and washing Wherein, the weight ratio of the water in the exchange liquid and the molecular sieve is (2~5): 1, preferably (3~4): 1, phosphorus (in P 2 o 5 weight) to molecular sieve is (0.0005-0.10):1, preferably (0.001-0.06):1.

[0095] In the preparation method according to the present disclosure, the phosphorus-modified molecular sieve can be exchanged and / or impregnated by contacting the solution containing the active element to load the active element on the modified Y-type molecular sieve. And / or the effect of dipping treatment, the solution containing active elements is preferably an aqueous solution of gallium salt or boron compound or an aqueous solution containing gallium salt and boron compound, or a ...

specific Embodiment approach

[0116] In a third specific embodiment of the present disclosure, the method for preparing a modified Y-type molecular sieve comprises the following steps:

[0117] (1) Perform ion exchange reaction between NaY molecular sieve (also known as NaY zeolite) and rare earth solution, filter and wash to obtain ion exchanged molecular sieve, which has reduced sodium oxide content, contains rare earth elements and has conventional crystal cell size; the ion exchange is usually exchanged for 30 to 120 minutes under conditions of stirring and a temperature of 15 to 95° C., preferably 65 to 95° C.;

[0118] (2) Calcining the ion-exchanged molecular sieve at a temperature of 350 to 480°C in an atmosphere containing 30 to 90% by volume of water vapor for 4.5 to 7 hours, and drying to obtain a mild hydrothermal superstable product with a water content of less than 1% by weight. Modified molecular sieve; the unit cell constant of the mildly hydrothermally ultrastable modified molecular sieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com