A carrier and its application, a catalyst, its preparation method and application, and a hydrocracking method

A technology of carrier and dealumination agent, applied in the field of hydrocarbon oil hydrocracking, can solve the problems of difficult elution of non-framework aluminum, destruction of zeolite crystal structure, reduction of zeolite pore patency, etc. Effect of non-framework aluminum content and enrichment of secondary pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

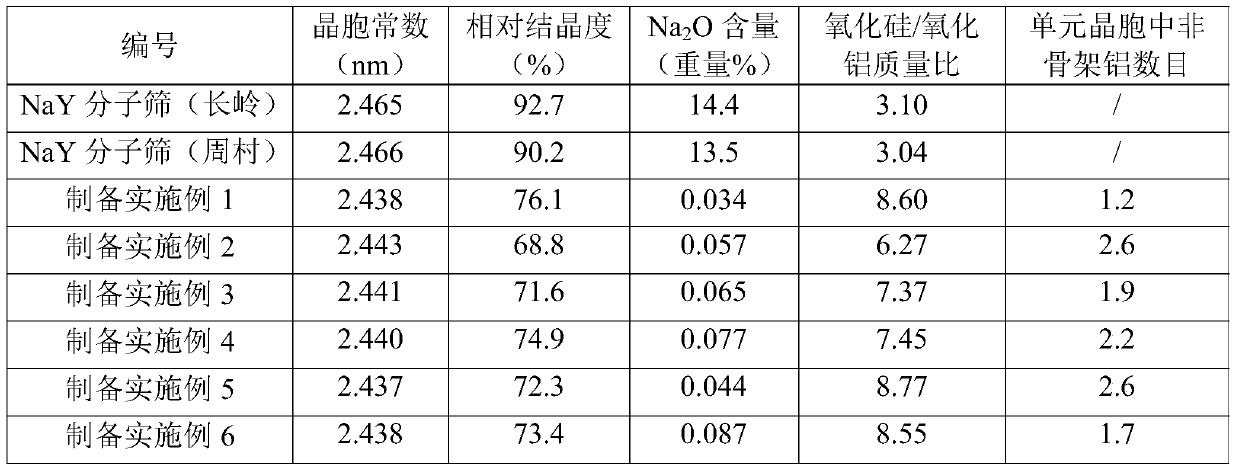

[0129] (1) Disperse 100g (dry basis) NaY molecular sieve (produced by Sinopec Catalyst Changling Branch, whose physical and chemical property parameters are listed in Table 2 and Table 3 respectively) in 1500mL water, with stirring, at ambient temperature (25 ° C, The same below) was added dropwise at a constant speed to 200 mL of an aqueous solution containing 50 g of ammonium sulfate (purchased from Beijing Yili Chemical Reagent Factory) (the dropping time was controlled to be 30 min). After the ammonium sulfate aqueous solution was added dropwise, the stirring was stopped and the mixed solution was filtered, and the solid phase was washed with deionized water for 3 times, and then dried in an air atmosphere at 105° C. under normal pressure (1 standard atmospheric pressure, the same below) for 3 hours to obtain The sodium ion content of the exchanged molecular sieves is listed in Table 4.

[0130] (2) Place the exchanged molecular sieve prepared in step (1) in a tube furnace...

preparation Embodiment 2

[0156] (1) Disperse 100g (dry basis) NaY molecular sieve (same as Preparation Example 1) in 1500mL of water, and with stirring, add 300mL containing 50g of ammonium nitrate (purchased from Lee Chemical Reagent Factory) aqueous solution (control drop time is 50min). After the ammonium nitrate aqueous solution is added dropwise, stop stirring and filter the mixed solution, wash the solid phase with deionized water for 3 times, and dry it in an air atmosphere at 120°C for 3 hours under normal pressure to obtain an exchanged molecular sieve with a sodium ion content of Listed in Table 4.

[0157] (2) Mix the exchanged molecular sieve prepared in step (1) with water to obtain a slurry containing molecular sieve (55% by weight on a dry basis). Fill the slurry containing molecular sieves in a crucible (the specifications of the crucible: the inner diameter is 40 mm, the height is 40 mm, the same below), seal the crucible and place it in a muffle furnace, raise the temperature to 550...

preparation Embodiment 3

[0166] (1) Disperse 100g (dry basis) NaY molecular sieve (produced by Sinopec Catalyst Zhoucun Branch, whose physical and chemical properties are listed in Table 2 and Table 3 respectively) in 1300mL of water, and add dropwise at a constant speed at 35°C with stirring 100mL contains 45g of ammonium nitrate (purchased from Beijing Yili Chemical Reagent Factory) aqueous solution (controlling the dropping time to 40min). After the dropwise addition of the aqueous solution is completed, the stirring is stopped and the mixed solution is filtered. After the solid phase is washed with deionized water for 3 times, it is dried in an air atmosphere at 110°C for 3.5 hours under normal pressure, thereby obtaining an exchanged molecular sieve with a sodium ion content of Listed in Table 4.

[0167] (2) Place 85g (dry basis) of the exchanged molecular sieve prepared in step (1) in a tube furnace, and continuously feed water vapor into the tube furnace (the rate of introduction of water vapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com