Modified Y-type molecular sieve and preparation method thereof

A molecular sieve and modification technology, used in molecular sieve catalysts, chemical instruments and methods, petroleum industry, etc., can solve the problems of low catalyst cracking activity, poor thermal and hydrothermal stability, reduced zeolite selectivity, etc., and achieve high LCO conversion. Effects of efficiency, high hydrothermal stability, low coke selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

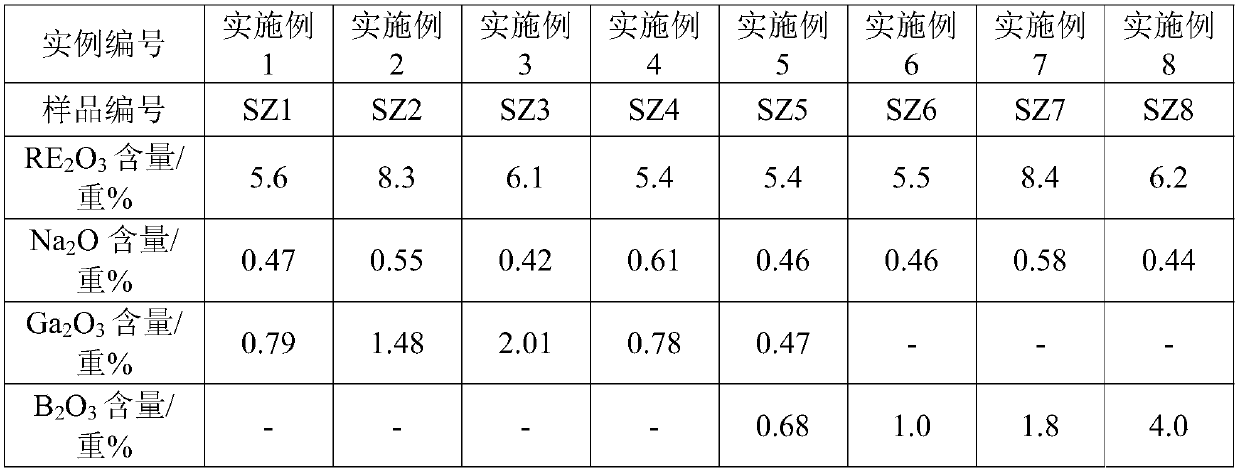

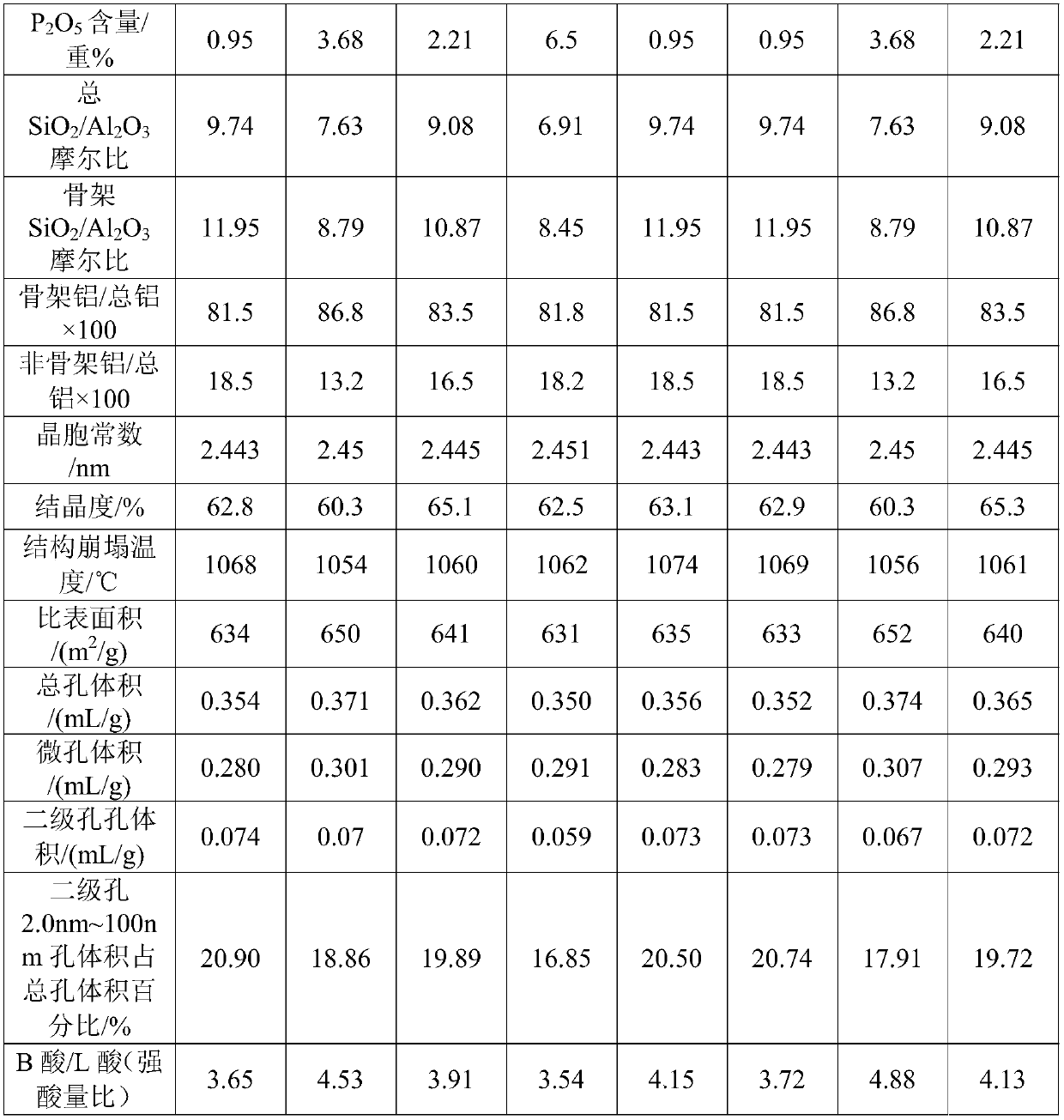

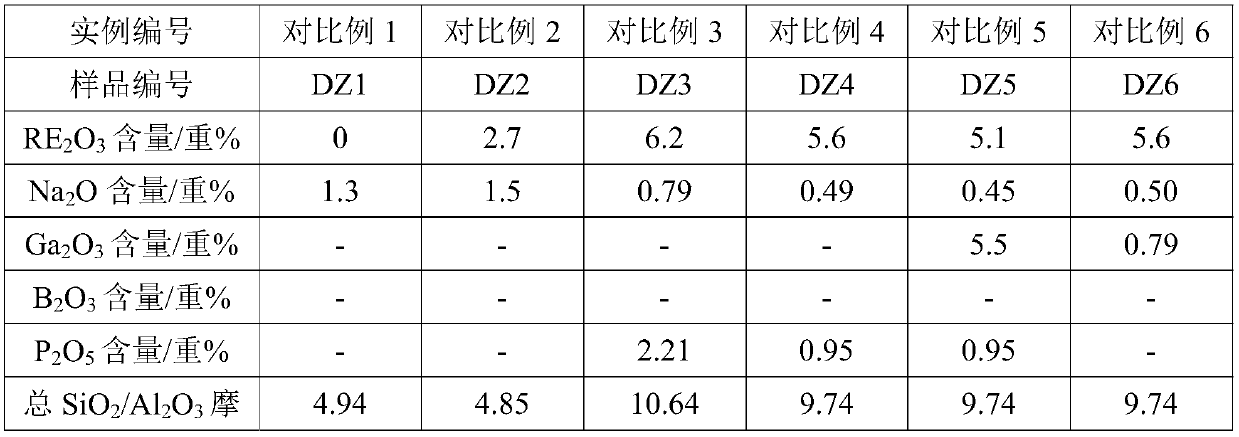

Examples

preparation example Construction

[0075] The preparation method of the present disclosure can prepare a high-silicon Y-type molecular sieve containing phosphorus, rare earth and gallium with a certain secondary pore structure with high crystallinity, high thermal stability and high hydrothermal stability. The aluminum in the molecular sieve is evenly distributed and has no skeleton With less aluminum content, the modified Y-type molecular sieve is used for processing hydrogenated LCO and has high LCO conversion efficiency, low coke selectivity, and higher aromatics-rich gasoline yield.

[0076] In the preparation method of the modified Y-type molecular sieve provided by the present disclosure, in step (1), the NaY molecular sieve and the rare earth solution are subjected to an ion exchange reaction to obtain a Y-type molecular sieve with a conventional unit cell size containing rare earths with reduced sodium oxide content, and ion exchange The method of reaction can be known to those skilled in the art, for ex...

Embodiment approach

[0084] In one embodiment, the phosphorus modification treatment conditions are as follows: adding the Y-type molecular sieve powder sample with reduced unit cell constant to the exchange solution containing phosphorus compounds, and performing exchange reaction at 15-100°C for 10-100 minutes , filter, wash; Wherein, the weight ratio of the water in the exchange liquid and the molecular sieve is (2~5): 1, preferably (3~4): 1, phosphorus (in P 2 o 5 weight) to molecular sieve is (0.0005-0.10):1, preferably (0.001-0.05):1.

[0085] Further, in order to ensure the effect of gas phase ultrastable modification, the molecular sieve can be dried before step (3), to reduce the water content in the molecular sieve, so that the 4 The moisture content of the contacted molecular sieves does not exceed 1% by weight. For example, in the embodiment where the phosphorus modification treatment is carried out before the gas phase ultrastable modification step, the phosphorus-containing moderat...

specific Embodiment approach

[0105] In a third specific embodiment of the present disclosure, the method for preparing a modified Y-type molecular sieve comprises the following steps:

[0106] (1) Perform ion exchange reaction between NaY molecular sieve (also known as NaY zeolite) and rare earth solution, filter and wash to obtain ion-exchanged molecular sieve, the molecular sieve after ion exchange has reduced sodium oxide content, contains rare earth elements and has a conventional unit cell Size; the ion exchange is usually exchanged for 30 to 120 minutes under the conditions of stirring and a temperature of 15 to 95 ° C, preferably 65 to 95 ° C;

[0107] (2) The Y-type molecular sieve with the rare earth-containing conventional unit cell size with reduced sodium oxide content is roasted for 4.5-7 hours at a temperature of 350-480°C in an atmosphere containing 30-90% by volume of water vapor, and dried to obtain a water content A mildly hydrothermally ultrastable modified molecular sieve as low as 1% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com