A hydrocracking method for producing high-octane gasoline

A hydrocracking and hydrofining reaction technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of not maximizing the utilization rate of aromatics and the loss of aromatics, and achieve less non-skeleton aluminum, high Effect of Octane Number, Excellent Selective Hydrogenation Activity and Selective Ring-Opening Cracking Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation process of the second hydrocracking catalyst C is as follows:

[0049] First, the Y molecular sieve in the second hydrocracking catalyst C is prepared by multiple dealumination and three water roasting:

[0050] (1) Using NaY zeolite as raw material to exchange with ammonium chloride solution, the processing conditions are: according to the ratio of NaY molecular sieve (dry basis): ammonium chloride: water = 1: 0.7: 10, exchange at 85 ° C for 1 hour, filter After washing with deionized water, it was dried at 120 °C for 4 h.

[0051] (2) The molecular sieve obtained in step (1) is subjected to the first hydrothermal calcination treatment, the calcination temperature is 600° C., and the calcination is carried out in a 100% water vapor atmosphere for 2 hours.

[0052] (3) The molecular sieve obtained in step (2) is in the ratio of molecular sieve (dry basis): citric acid: sulfuric acid: water = 1: 0.15: 0.05: 8, after first adding water to the molecular si...

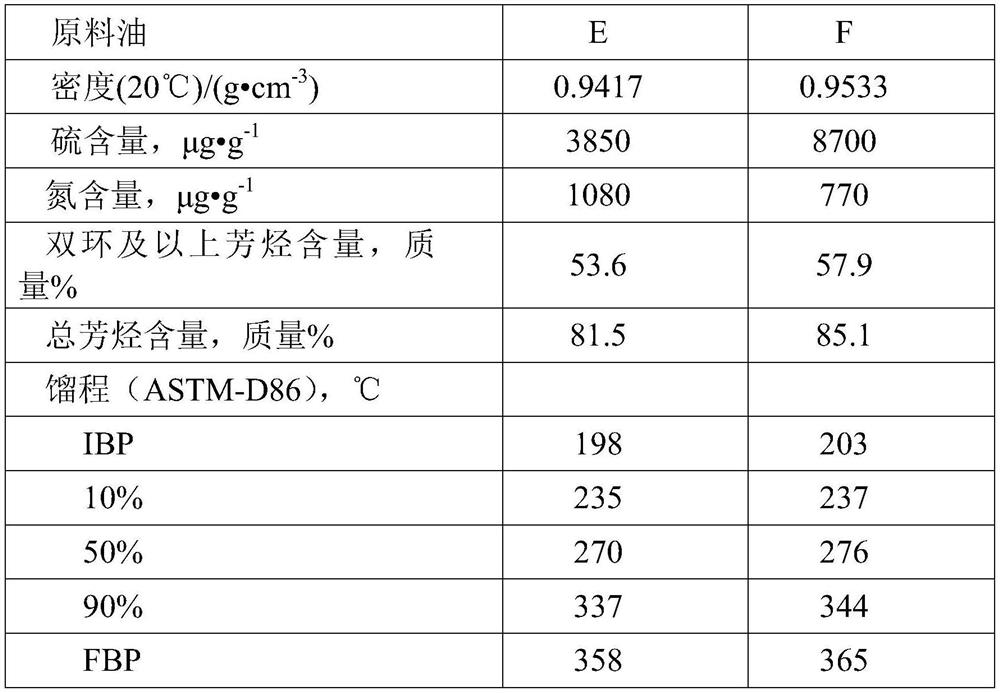

Embodiment 1

[0072] The raw material oil E enters the hydrotreating reaction zone together with hydrogen, and contacts and reacts with the hydrotreating catalyst A. The reaction effluent of the hydrotreating reaction zone enters the hydrocracking reaction zone I together with the middle distillate, and reacts with the first hydrocracking catalyst. B contact reaction. The reaction effluent of hydrocracking reaction zone 1 enters into separation facilities such as high-pressure separator 1, low-pressure separator, and fractionation tower successively, and obtains dry gas, liquefied gas, gasoline fraction, middle distillate and tail after cooling, gas-liquid separation, and fractionation. The cut point for oil fractions, middle distillates and tails fractions is 280°C. In the middle distillate, the aromatic hydrocarbon content is 78% by weight, and the content of alkylbenzenes and tetrahydronaphthalene monocyclic aromatic hydrocarbons is 68% by weight; wherein all the middle distillate is cir...

Embodiment 2

[0075] The feed oil E enters the hydrotreating reaction zone together with hydrogen, contacts and reacts with the hydrotreating catalyst A, and the reaction effluent and the middle distillate in the hydrotreating reaction zone enter the hydrocracking reaction zone I, and react with the first hydrotreating catalyst A. B contact reaction. The reaction effluent of hydrocracking reaction zone 1 enters into separation facilities such as high-pressure separator 1, low-pressure separator, and fractionation tower successively, and obtains dry gas, liquefied gas, gasoline fraction, middle distillate and tail after cooling, gas-liquid separation, and fractionation. The cut point of the oil fraction, middle distillate and tail oil fraction is 290°C, the content of aromatic hydrocarbons in the middle distillate is 76% by weight, and the content of monocyclic aromatic hydrocarbons of alkylbenzenes and tetralin is 68% by weight. Wherein all the middle distillate is recycled to the hydrocrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com